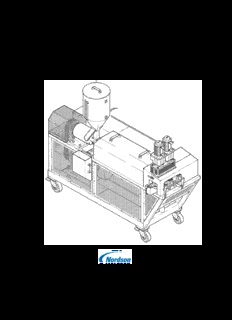

Hot--melt adhesive extruder EX 30--9 PDF

Preview Hot--melt adhesive extruder EX 30--9

Hot--melt adhesive extruder EX 30--9--2xGP 06 M2 Manual 190126759/001 -- English -- NordsonDeutschlandGmbH(cid:1)Buchholz--Mendt(cid:1)GERMANY Note Thismanualappliestotheentireseries. Ordernumber 7552415 Notice ThisisaNordsonCorporationpublicationwhichisprotectedbycopyright. Originalcopyrightdate2008. Nopartofthisdocumentmaybephotocopied,reproduced,ortranslatedtoanotherlanguagewithoutthepriorwritten consentofNordsonCorporation. Theinformationcontainedinthispublicationissubjecttochangewithoutnotice. 2011Allrightsreserved. Trademarks AccuJet,AeroCharge,AquaGuard,Asymtek,Automove,Autotech,Baitgun,BlueBox,CanWorks,Century,CF,CleanCoat,CleanSleeve,CleanSpray,ControlCoat, CoolWave, Cross-Cut, Cyclo-Kinetic, Dispensejet, DispenseMate, Durafiber, Durasystem, Easy Coat, Easymove Plus, Econo-Coat, EFD, ETI, Excel 2000, FlexiCoat,Flexi-Spray,Flex-O-Coat,FlowSentry,Fluidmove,FoamMelt,FoamMix,Heli-flow,Helix,Horizon,HotShot,Isocoil,Isocore,Iso-Flo,JR,KB30,Kinetix, LittleSquirt,Magnastatic,MEG,Meltex,Microcoat,Micromark,MicroSet,Millenium,MiniSquirt,Moist-Cure,Mountaingate,MultiScan,Nordson,OmniScan,OptiMix, Package of Values, Patternview, PermaFlo, Plasmod, PluraFoam, Porous Coat, PowderGrid, Powderware, Prism, ProBlue, Pro-Flo, ProLink, Pro-Meter, Pro-Stream,RBX,Rhino,Saturn,SC5,S.designstylized,SealSentry,SelectCharge,SelectCoat,SelectCure,Slautterback,Smart-Coat,SolderPlus,Spectrum, Speed-Coat,Spraymelt,SpraySquirt,SuperSquirt,SureCoat,Tela-Therm,TrackingPlus,Trends,Tribomatic,Ultrasaver,UniScan,UpTime,Veritec,VersaBlue, Versa-Coat,Versa-Screen,Versa-Spray,Walcom,Watermark,Whenyouexpectmore.areregisteredtrademarks----ofNordsonCorporation. AeroDeck,AeroWash,Apogee,ATS,Auto-Flo,AutoScan,BetterBook,CanNeck,Chameleon,CheckMate,ColorMax,ControlledFiberization,ControlWeave,CPX, DryCure,DuraBlue,Dura-Coat,DuraPail,Dura-Screen,EasyClean,Eclipse,EcoDry,e.DOT,E-Nordson,Equi=Bead,ESP,eStylized,Fillmaster,FillSentry,Gluie, HDLV,iControl,iFlow,Ink-Dot,iON,Iso-Flex,iTrend,KVLP,LacquerCure,March,Maxima,MicroFin,MicroMax,Minimeter,Multifil,OptiStroke,Origin,PatternPro, PluraMix,PowderPilot,Powercure,Primarc,Printplus,ProcessSentry,PulseSpray,PurTech,ReadyCoat,Scoreguard,SelectSeries,Sensomatic,Shaftshield, SheetAire,Spectral,Spectronic, Speedking,SprayWorks,Summit,SureBead,SureBrand,SureClean,Sure-Max,SwirlCoat,Tempus,ThruWave,TradePlus, Trak,Ultrasmart,Universal,Vantage,Viper, Vista,WebCure,2Rings(Design)aretrademarks--(cid:2)--ofNordsonCorporation. Designationsandtrademarksstatedinthisdocumentmaybebrandsthat,whenusedbythirdpartiesfortheirownpurposes, couldleadtoviolationoftheowners’rights. Ordernumber7552415 EX30--9 2011NordsonDeutschlandGmbH TableofContents I Table of Contents SafetyInstruction ....................................... 1-1 GeneralDescription ...................................... 1-1 SafetyInformation ..................................... 1-1 UsingHotmelt ........................................... 1-2 Temperature .......................................... 1-2 GlueTank ............................................ 1-2 SafetyInstructions ....................................... 1-3 GeneralInstructions ................................... 1-3 Introduction ............................................ 2-1 Introduction ............................................. 2-1 IntendedUse ............................................ 2-2 AreaofUse(EMC) .................................... 2-2 OperatingRestrictions ............................... 2-2 UnintendedUse -- Examples -- .......................... 2-2 ResidualRisks .......................................... 2-3 NoteonManual.......................................... 2-3 SeriesOverview ......................................... 2-4 ExplanationofTypeDesignation ......................... 2-4 ID--Plate.............................................. 2-4 SoftwareNotice ......................................... 2-5 NoticeonElectricalEngineering ......................... 2-5 Health--EndangeringMedia ............................. 2-5 DangerousPointsandSafetyDevices ...................... 2-6 DangerousPointsontheHotmeltAdhesiveExtruder ....... 2-6 DangerPointsintheVicinityoftheExtruder ............... 2-7 Protectivecovers ...................................... 2-7 Covers ............................................... 2-7 ProtectiveGridinsidetheHopper ........................ 2-7 Safetyequipmentontheextruder ........................ 2-8 Importantsafetynotice: .............................. 2-8 Lockablemainswitch .................................. 2-8 BlackMainSwitch(SpecialModel) .................... 2-8 EmergencyStopButton (OptionalforStand--AloneOperation) .................. 2-9 DoorLock .......................................... 2-9 TemperatureSetbac ................................... 2-9 Temperaturecontrol ................................... 2-9 UndertemperatureInterlock ........................... 2-10 Under--temperatureIndication......................... 2-10 OvertemperatureIndication/Shutdown ................ 2-10 ElectricalSafetyValve ................................. 2-11 SwitchCabinetLightTower(optional) ................... 2-11 ControlSystem........................................ 2-12 ElectricalCabinetVentilation ............................ 2-12 HoseconnectionX1(aswiringdiagram) .................. 2-12 InterfaceX8/X9/X10/X100 ........................ 2-12 GeneralDescription ...................................... 2-13 (cid:1)2011 NordsonDeutschlandGmbH ExtruderEX30--9 P/N7552415 II TableofContents FunctionalDiagram ...................................... 2-16 DescriptionofFunctionalElements ......................... 2-17 Drive................................................. 2-17 Back--pressurebearing ................................. 2-17 BasicFrame .......................................... 2-17 FillingArea ........................................... 2-17 Covers ............................................... 2-17 Screw ................................................ 2-18 ScrewCylinder ........................................ 2-19 CylinderFeedCoolinginScrewCylinders withInnerResinCladding (dependingonorder) ........... 2-20 Cylinderfeedcooling ................................... 2-21 BasicFunctionalityofHot--MeltProcessingExtruders ...... 2-22 ModeofOperation .................................. 2-23 Cooling ............................................ 2-23 Heating ............................................ 2-23 Screw ............................................. 2-23 PressureRegulation ................................... 2-24 PressureMonitoring ................................... 2-24 LevelMonitoringofHopper ............................. 2-25 TemperatureMonitoring ................................ 2-25 Pumpstation ............................................ 2-26 MotorandGearPump ................................. 2-26 Manometricswitch ..................................... 2-26 Pressuresensor ....................................... 2-26 Pressuresensor ....................................... 2-27 CalibrationofPressureSensor .......................... 2-27 Adjustmentat80%ofnominalpressurerangeasfixedvalue: 2-27 Installation ............................................. 3-1 Unpacking .............................................. 3-1 Transportation ........................................... 3-1 AttachingLightTower(optional) ......................... 3-1 InstallationandAlignment .............................. 3-2 Setup .............................................. 3-2 Lifting(UnpackedUnit) ................................. 3-2 Removal ............................................. 3-2 Storage .............................................. 3-2 Disposal.............................................. 3-2 ExhaustingHotMeltAdhesiveVapours ................... 3-3 Operatingconditions ..................................... 3-3 Installation: ........................................... 3-3 Airhumidity: .......................................... 3-3 Airtemperature: ....................................... 3-3 ElectricalConnections .................................... 3-4 Noticeontheuseofgroundfaultcircuitinterrupters ........ 3-4 LayingCable .......................................... 3-4 LineVoltage .......................................... 3-4 Externalcontrolandsignalcircuits ....................... 3-4 PilotVoltage/TachGenerator ........................... 3-5 Tachometeradaptationcard .......................... 3-5 Electricalinstallation ................................... 3-6 Assignmentoftemperaturecontrollers totemperaturesensors ................................. 3-6 ConnectingHeatedHoses ................................ 3-7 SecondOpen-jawedWrench ......................... 3-7 Connecting ........................................... 3-7 Disconnecting ......................................... 3-7 P/N7552415 ExtruderEX30--9 (cid:1)2011 NordsonDeutschlandGmbH TableofContents III RelievingPressure .................................. 3-7 ConnectorAllocation ..................................... 3-8 Installation ............................................ 3-9 Assignment: .......................................... 3-9 InterfaceX10/X100 .................................. 3-10 Procedure ............................................ 3-10 Specifications ........................................... 3-10 Waterspecifications ................................... 3-10 Waterinstallation ........................................ 3-11 Operation .............................................. 4-1 Start--up ................................................ 4-1 Preparationforstart--up ................................ 4-1 Turningthemachineon ................................ 4-2 Pre--condition: ...................................... 4-2 Userinterface MP277 .................................. 5-1 OperatingMode ......................................... 5-1 Manual/AutomaticOperation ........................... 5-1 GeneralNote! ...................................... 5-1 OperatingStatus ”Manual” ............................. 5-2 OperatingStatus”Automatic” ........................... 5-2 Temperaturesettings................................... 5-3 Settingofpump/nozzleinautomaticmode ............... 5-3 Overviewscreen .................................... 5-3 SettingValuesandParameters -- Notes -- ................... 5-3 Temperatures ......................................... 5-3 Passwordlevel ........................................ 5-4 Passwordlevel ........................................ 5-5 UserinterfaceMP277B .................................. 5-6 Service............................................... 5-6 Service --weeklytimer-- ................................. 5-7 Conectorforcustomer ................................. 5-8 Manualmode ......................................... 5-9 Automaticmode ....................................... 5-13 SwitchingSystemON/OFF ................................ 5-16 DailyStart--up ......................................... 5-16 DailySwitch--off ....................................... 5-16 SwitchingOffinanEmergency .......................... 5-16 Maintenance ........................................... 6-1 Dangerofburns ......................................... 6-1 RelievingPressure ....................................... 6-1 Decommissioning ........................................ 6-2 CleaningtheScrew .................................... 6-2 CleaningtheScrew .................................... 6-3 Settingintooperation .................................. 6-3 RegularMaintenance ..................................... 6-4 Maintenancegearpump(optional) ....................... 6-4 Retighteningoffasteningscrew ......................... 6-5 InspectionforExternalDamage ......................... 6-5 ExternalCleaning...................................... 6-5 MaintenanceofHeatingCartridges ...................... 6-6 MeasuringHeatingCartridges: .......................... 6-6 ExchangeofHeatingCartridge .......................... 6-6 Over--temperatureThermostat .......................... 6-6 (cid:1)2011 NordsonDeutschlandGmbH ExtruderEX30--9 P/N7552415 IV TableofContents ChangingTypeofAdhesive ............................... 6-7 PurgingwithCleaningAgent............................... 6-7 ElectricalCabinetVentilationMaintenance .................. 6-7 ReplacementandCleaningofFilterMat ................ 6-7 GeneralChecks ....................................... 6-8 ContinuousChecks .................................... 6-8 LubricantRecommendationsforThreadedConnectors ..... 6-9 FaultRectification ..................................... 6-9 Forheatingelementswithceramicinsulation: ............. 6-10 Forheatingelementswithmicaniteinsulation: ............. 6-10 MotorLubrication ...................................... 6-10 RetighteningandexchangeofV--belts .................... 6-11 Motor/Gear ............................................ 6-12 CommissioningandOperation ........................ 6-12 DuringOperation .................................... 6-12 MaintenanceIntervals ............................... 6-12 Shaftsealings: ...................................... 6-12 ServiceandMaintenance ............................... 6-13 Troubleshooting ........................................ 7-1 Troubleshooting/FailureCorrectiveAction ................. 7-1 SomeTips .............................................. 7-2 TroubleshootingwithControlSystem ....................... 7-2 Signallampsandswitchcabinetlighttower ............... 7-2 Automatik .......................................... 7-2 Handbetrieb ........................................ 7-2 Troubleshootingtables.................................... 7-3 RedSignalLampFlashing .............................. 7-3 Devicemalfunctioning .................................. 7-3 Noadhesive(nomotorrotation) ......................... 7-4 Motorsuperheated .................................... 7-4 Nomasterreferencevoltage ............................ 7-4 Noadhesive(withmotorrotation) ........................ 7-5 Incorrectmotorspeedcharacteristicsinautomaticmode .... 7-5 Insufficientadhesive ................................... 7-5 Onechannel(heatingzone)doesnotheat ................ 7-5 Removing .............................................. 8-1 Generalremarks ...................................... 8-1 RemovingandInsertingtheScrew ......................... 8-1 ImportantNote: ..................................... 8-1 Removal ............................................. 8-2 Insertion ................................................ 8-4 P/N7552415 ExtruderEX30--9 (cid:1)2011 NordsonDeutschlandGmbH TableofContents V SpareParts ............................................ 9-1 Introduction ............................................. 9-1 UsingtheIllustratedPartsList .......................... 9-1 Example ............................................. 9-1 Frameforattachingparts ............................... 9-2 Extruderunit .......................................... 9-4 Back--pressurebearing P/N7055832 ................... 9-6 Fillinghopper ......................................... 9-8 Pumpstation.......................................... 9-10 Pressurereliefvalve ................................... 9-13 ControlmoduleSDØ5x83 P/N7537391 ................ 9-14 Gearpump GP12M2 P/N7528130 .................... 9-16 Safety kit P/N7052127 ................................ 9-17 ExtruderCovers ....................................... 9-18 CoversPumpStation .................................. 9-20 Coversbasicframe .................................... 9-23 Pneumaticunit ........................................ 9-24 Waterconnection ...................................... 9-26 Waterchiller .......................................... 9-28 TechnicalData.......................................... 10-1 Description .............................................. 10-1 Connection,Start--up: .................................. 10-1 GeneralData ............................................ 10-1 ElectricalData ........................................... 10-2 Temperatures ........................................... 10-2 TechnicalData ........................................ 10-2 Dimension ............................................ 10-3 (cid:1)2011 NordsonDeutschlandGmbH ExtruderEX30--9 P/N7552415 VI TableofContents P/N7552415 ExtruderEX30--9 (cid:1)2011 NordsonDeutschlandGmbH SafetyInstruction 1-1 Chapter 1 Safety Instruction General Description Safety Information Theequipmentdescribed isintendedforuseinindustrialelectricaldrive systems. Thisequipmentcanendangerlifethroughrotatingmachineryandhigh voltages,thereforeitisessentialthatguardsforbothelectricaland mechanicalpartsarenotremoved. Thefollowingpointsshouldbeobservedforthesafetyofthepersonnel: (cid:2) Onlyqualifiedpersonnelfamiliarwiththeequipmentarepermittedto install,operateandmaintainthedevices. (cid:2) Systemdocumentationmustbeavailableandobservedatalltimes. (cid:2) Allnon -- qualifiedpersonnelarekeptatasafedistancefromthe equipment. (cid:2) Thesystemmustbeinstalledinaccordancewithlocalregulations. Aqualifiedpersonisapersonwhoisfamiliarwithallsafetynotesand establishedsafetypractices,withtheinstallation,operationand maintenanceofthisequipmentandthehazardsinvolved.Formoredetailed definitionsseeIEC364. Itisrecommendedthatanyonewhooperatesormaintainselectricalor mechanicalequipmentshouldhaveabasicknowledgeofFirstAid. Asaminimum,theyshouldknowwheretheFirstAidequipmentiskeptand theidentityoftheofficialFirstAiders. Thesesafetynotesdonotrepresentacompletelistofthestepsnecessary toensuresafeoperationoftheequipment.Ifyouwishfurtherinformation, pleasecontactyournearestrepresentative. (cid:1)2011 NordsonDeutschlandGmbH ExtruderEX30--9 P/N7552415 1-2 SafetyInstruction Using Hotmelt Temperature Thetemperaturemustnotexceedorfallbelowthespecifiedtemperature ranges;continuoustemperaturemonitoringisappropriate.Excessivelyhigh temperaturesmaygiverisetoodoursandimpairthequalityofthehotmelt. Excessivelylowtemperaturesalsohavenegativeeffects.Should satisfactoryresultsbeachievedonlyatatemperatureotherthanthe specifiedapplicationtemperature,pleasebesuretocontactus. Glue Tank Donotleavethegluetankinheatedstateforaprolongedperiodwithout removingtheadhesive(thermaldamagetothehotmelt). Whenthemachineistoremainoutofoperationforaprolongedperiod,the heatingshouldbeshutdownorthetemperaturelowered.Gluetanksmust becovered,inordertopreventcontaminationwithpaperdust,moistureand dirt. Werecommendregularcleaningofthemeltingandapplication systems. Shouldyouhaveanydoubtsorexperienceanydifficultieswhenusingthe hotmelt,pleasecallus:Wewanttohelpbeforeanydamageoccurs. Caution -- DangerofInjury Protecttheoperatingpersonnelagainstburnswhenhandlinghotmeltsinhot state.Unfortunately,injuriesoccurwhenprecautionarymeasuresare ignored.Protectiveglovesaretobeworn. Medicaladvicewhenhotmeltinhotstatehascomeintocontactwith theskin: (cid:2) Coolburnimmediatelywithcleanandcoldwater. (cid:2) Donotremovehotmeltresiduesfromtheskin. (cid:2) Coverburnwithcleanandmoistcompressesandconsultadoctor immediately. Hotmeltadhesivesalsogiveofffumesatthespecifiedapplication temperature.Thisoftengivesrisetounpleasantsmells. Incaseoftemperaturessubstantiallybelowthespecifiedapplication temperatures,thereisadangerthatharmfuldecompositionproductsmay form. Measurestoremovethefumesviaappropriateextractionare imperative. P/N7552415 ExtruderEX30--9 (cid:1)2011 NordsonDeutschlandGmbH

Description:The list of books you might like

The 5 Second Rule: Transform your Life, Work, and Confidence with Everyday Courage

Better Than the Movies

Haunting Adeline

Atomic Habits James Clear

Greek Government Gazette: Part 2, 2006 no. 1761

Greek Government Gazette: Part 2, 2006 no. 1943

analisis laporan keuangan

Identified particle transverse momentum spectra in p+p and d+Au collisions at sqrt{s_NN} = 200 GeV

Theocritus by CS Calverley

BAB IV ANALISIS DATA A. Analisis Struktural Novel Mengejar Matahari

ST Forum 1993 3

bölüm 1

Virus Bulletin 2006-01

Calendar of Bristol Apprentice Book, 1532-1565

Calendar Addendum to 2016 Catalog

erasmusinpraiseo00erasiala

enqphilosophical00burkrich_bw

ERIC ED370563: Multimedia and Hypermedia: An Invitation for Discussion.