Table Of ContentIssue Date: 2013-11-19 Page 1 of 20 Report Reference # E341350-A26-UL

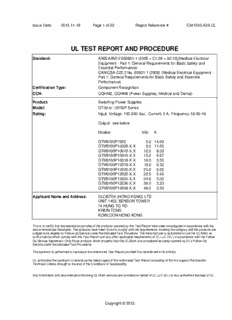

UL TEST REPORT AND PROCEDURE

Standard: ANSI/AAMI ES60601-1 (2005 + C1:09 + A2:10)(Medical Electrical

Equipment - Part 1: General Requirements for Basic Safety and

Essential Performance)

CAN/CSA-C22.2 No. 60601-1 (2008) (Medical Electrical Equipment -

Part 1: General Requirements for Basic Safety and Essential

Performance)

Certification Type: Component Recognition

CCN: QQHM2, QQHM8 (Power Supplies, Medical and Dental)

Product: Switching Power Supplies

Model: GT(M or -)9100P Series

Rating: Input: Voltage: 100-240 Vac, Current: 2 A, Frequency: 50-60 Hz

Output: see below

Models: Vdc A

GTM9100P7005 5.0 14.00

GTM9100P10009-X.X 9.0 11.00

GTM9100P10012-X.X 12.0 8.33

GTM9100P10015-X.X 15.0 6.67

GTM9100P10018-X.X 18.0 5.50

GTM9100P12019-X.X 19.0 6.32

GTM9100P12020-X.X 20.0 6.00

GTM9100P12022-X.X 22.0 5.45

GTM9100P12024-X.X 24.0 5.00

GTM9100P12036-X.X 36.0 3.33

GTM9100P12048-X.X 48.0 2.50

Applicant Name and Address: GLOBTEK (HONG KONG) LTD

UNIT 1402, BENSON TOWER

74 HUNG TO RD

KWUN TONG

KOWLOON HONG KONG

This is to certify that representative samples of the products covered by this Test Report have been investigated in accordance with the

above referenced Standards. The products have been found to comply with the requirements covering the category and the products are

judged to be eligible for Follow-Up Service under the indicated Test Procedure. The manufacturer is authorized to use the UL Mark on

such products which comply with this Test Report and any other applicable requirements of UL LLC ('UL') in accordance with the Follow-

Up Service Agreement. Only those products which properly bear the UL Mark are considered as being covered by UL's Follow-Up

Service under the indicated Test Procedure.

The applicant is authorized to reproduce the referenced Test Report provided it is reproduced in its entirety.

UL authorizes the applicant to reproduce the latest pages of the referenced Test Report consisting of the first page of the Specific

Technical Criteria through to the end of the Conditions of Acceptability.

Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL.

Copyright © 2013

Issue Date: 2013-11-19 Page 2 of 20 Report Reference # E341350-A26-UL

Prepared by: Bill Peng / Yena Zhuang Reviewed by: Calvin Tang

Copyright © 2013

Issue Date: 2013-11-19 Page 3 of 20 Report Reference # E341350-A26-UL

Supporting Documentation

The following documents located at the beginning of this Procedure supplement the requirements of this Test

Report:

A. Authorization - The Authorization page may include additional Factory Identification Code markings.

B. Generic Inspection Instructions -

i. Part AC details important information which may be applicable to products covered by this Procedure.

Products described in this Test Report must comply with any applicable items listed unless otherwise

stated in the body of this Test Report.

ii. Part AE details any requirements which may be applicable to all products covered by this Procedure.

Products described in this Test Report must comply with any applicable items listed unless otherwise

stated in the body of each Test Report.

iii. Part AF details the requirements for the UL Certification Mark which is not controlled by the technical

standard used to investigate these products. Products are permitted to bear only the Certification

Mark(s) corresponding to the countries for which it is certified, as indicated in each Test Report.

Issue Date: 2013-11-19 Page 4 of 20 Report Reference # E341350-A26-UL

Product Description

The products covered by this report are desktop switch-mode power supplies, intended to provide power to

and intended for use with Medical Electrical Equipment.

Model Differences

Differences within the GT(M or -)9100P family is limited to minor component changes to determine specific

output voltage and current parameters. The GT(M or -)9100 Series is the family model designation which is

represented by the following generic nomenclature: GT(M or -)9100PXXXYY-Z.Z-D

where: GT(M or -) designates GlobTek models with Medical safety approval

while: P designates the use of active power factor correction circuitry;

and XXX designates the rated output power as seen in the standard model list;

while YY designates the rated output voltage as seen in the standard model list;

and Z.Z designates the optional voltage deviation, which is subtracted from the standard output

voltage in 0.1 volt increments;

Standard Models: Vdc A

GTM9100P7005 5.0 14.00

GTM9100P10009-X.X 9.0 11.00

GTM9100P10012-X.X 12.0 8.33

GTM9100P10015-X.X 15.0 6.67

GTM9100P10018-X.X 18.0 5.50

GTM9100P12019-X.X 19.0 6.32

GTM9100P12020-X.X 20.0 6.00

GTM9100P12022-X.X 22.0 5.45

GTM9100P12024-X.X 24.0 5.00

GTM9100P12036-X.X 36.0 3.33

GTM9100P12048-X.X 48.0 2.50

Note - This nomenclature only covers models employing output ratings equivalent to or less than those listed

in Standard Models table.

Technical Considerations

Classification of installation and use : Recognized power adaptor, shall be determine in end use

application.

Device type (component/sub-assembly/ equipment/ system) : Component

Intended use (Including type of patient, application location) : None

Mode of operation : Continuous

Supply connection : Appliance coupler

Accessories and detachable parts included : None

Other options include : None

The product was investigated to the following additional standards:: ANSI/AAMI ES60601-1 (2005 +

C1:09 + A2:10) (Medical Electrical Equipment - Part 1: General Requirements for Basic Safety and

Essential Performance) (includes Deviations for United States), CAN/CSA-C22.2 No. 60601-1 (2008)

(Medical Electrical Equipment - Part 1: General Requirements for Basic Safety and Essential

Performance) (includes National Differences for Canada)

The product was not investigated to the following standards or clauses:: Biocompatibility (ISO 10993-

1), Clause 14, Programmable Electronic Systems, Electromagnetic Compatibility (IEC 60601-1-2), , ,

Issue Date: 2013-11-19 Page 5 of 20 Report Reference # E341350-A26-UL

The degree of protection against harmful ingress of water is:: Ordinary

The mode of operation is:: Continuous,

The product is suitable for use in the presence of a flammable anesthetics mixture with air or oxygen

or with nitrous oxide:: No

The product is classified only to the following hazards: Casualty, Fire, Shock.

Software is relied upon for meeting safety requirements related to mechanical, fire and shock: No

The GTM9100P Series is considered Class I (protectively earthed).

Engineering Conditions of Acceptability

For use only in or with complete equipment where the acceptability of the combination is determined by UL

LLC. When installed in an end-product, consideration must be given to the following:

This power supply has been judged on the basis of the required creepage and clearances in the

Standards for Medical Electrical Equipment, IEC 60601-1: 2005 + CORR.1 (2006) + CORR.2 (2007)

(Medical Electrical Equipment - Part 1: General Requirements for Basic Safety and Essential

Performance) - Edition 3 Sub clause 8.9, ANSI/AAMI ES60601-1 (2005 + C1:09 + A2:10) (Medical

Electrical Equipment - Part 1: General Requirements for Basic Safety and Essential Performance) -

Edition 1 - Revision Date 2012/01/01, Sub clause 8.9. And CAN/CSA-C22.2 No. 60601-1 (2008)

(Medical Electrical Equipment - Part 1: General Requirements for Basic Safety and Essential

Performance) Edition 2 - Revision Date 2011/06/01

The power supply was evaluated as 2 MOOP between Primary and Secondary.

The Unit provide primary transformer (T2), which was incorporates as Class B (130 degree C)

insulation system.

The reference voltage for Dielectric Voltage Test in End Product: 368Vrms, 704Vpk for T2.

The following Testings 1) Leakage Current Measurements, 2) Temperature Tests and 3) Dielectric

Voltage Withstand Tests should be evaluated in end product again.

End product to determine the acceptability of risk in conjunction to insulation to resistance to heat,

moisture, and dielectric strength.

End product to determine the acceptability of risk in conjunction to the movement of components and

conductors as part of the power supply.

End product to determine the acceptability of risk in conjunction to the routing of wires away from

moving parts and sharp edges as part of the power supply.

Temperature Test was conducted without Test Corner. End product to determine the acceptability of

risk in conjunction to temperature testing without test corner as part of the power supply.

End product to determine the acceptability of risk in conjunction to the Cleaning and Disinfection

Methods as part of the power supply.

End product to determine the acceptability of risk in conjunction to the Leakage of Liquids as part of

the power supply.

End product to determine the acceptability of risk in conjunction to the Arrangement of Indicators as

part of the power supply.

End product to determine the acceptability of risk in conjunction to the results of Mechanical Testing

conducted as part of the power supply.

End product to determine the acceptability of risk in conjunction to the selection of components as it

pertains to the intended use, essential performance, transport, storage conditions as part of the

power supply.

The end-product evaluation shall ensure that the requirements related to Accompanying Documents,

Issue Date: 2013-11-19 Page 6 of 20 Report Reference # E341350-A26-UL

Clause 7.9 are met.

The touch time for external enclosure isn’t determined by the client, end product shall consider it

according to client's definition.

Compliance with the requirements for EMC shall be evaluated for the end use product.

The end-use product shall ensure that the power supply is used within its ratings.

The Max. working temperature of this power supply is 40 degree C. Additional test may required if

the temperature is higher than 40 degree C.

Maximum ambient temperature of this power supply is 40 degree C at full load.

Clearance distance was evaluated for operating altitude up to 3000m.

This component power supply employs micro type fuses which do not comply with the end product

fuse requirement of Clause 8.11.5. The end product must provide acceptable fuses and be re-

evaluated to Clause 8.11.5. Overcurrent releases of adequate breaking capacity must be employed

in the end product.

Additional Information

Original:

1. This power supply has been complied with UL 60601-1, 1st Edition and CAN/CSA-C22.2 No. 601.1-M90,

2005 (Refer to E341350-A6 for details).

2. The risk management requirements of the standard were addressed.

Additional Standards

The product fulfills the requirements of: CAN/CSA-C22.2 No. 60601-1 (2008) (Medical Electrical Equipment -

Part 1: General Requirements for Basic Safety and Essential Performance) Edition 2 - Revision Date

2011/06/01 ANSI/AAMI ES60601-1 (2005 + C1:09 + A2:10) (Medical Electrical Equipment - Part 1: General

Requirements for Basic Safety and Essential Performance) - Edition 1 - Revision Date 2012/01/01

Markings and instructions

Clause Title Marking or Instruction Details

Company identification Classified or Recognized company's name, Trade name, Trademark or File

Model Model number

Supply Connection Voltage range, ac/dc, phases if more than single phase

Supply Frequency Rated frequency range in hertz

Alternating current

Power Input Amps, VA, or Watts

Output Rated output voltage, power, frequency.

Protective earth ground

Special Instructions to UL Representative

Issue Date: 2013-11-19 Page 7 of 20 Report Reference # E341350-A26-UL

For markings of output: only rated output voltage, current is applicable.

Production-Line Testing Requirements

Test Exemptions - The following models are exempt from the indicated test

Model Grounding Continuity Dielectric Voltage Patient Circuit Dielectric

Withstand Voltage Withstand

No Exemption Exempt No Exemption Exempt

Solid-State Component Test Exemptions - The following solid-state components may be disconnected

from the remainder of the circuitry during either Dielectric Voltage Withstand Test:

Component

N/A

Sample and Test Specifics for Follow-Up Tests at UL

The following tests shall be conducted in accordance with the Generic Inspection Instructions

Plastic Enclosure or Part Test Sample(s) Test Specifics

N/A

Issue Date: 2013-11-19 Page 8 of 20 Report Reference # E341350-A26-UL

TABLE: List of Critical Components

Object/part or Manufacturer/ type/model technical data CCN Marks of

Description trademark Conformity

Enclosure SABIC INNOVATIVE 940 V-0, 3.5 mm thick, 105 degree C. QMFZ2, 8 UL/CUL

PLASTICS B V See Enclosure 4-02 for details. (E45329)

AC Inlet TECX-UNIONS TU-301-SP Min. 250V, Min. 10A or better, C14 type, Max. 105 AXUT2 UL

TECHNOLOGY degree C. (E220004)

CORP

AC Inlet Alternate Various Various Min. 250V, Min. 10A or better; C14 type, Max. 105 AXUT2 UL

degree C.

Output Cable LU CHIANG XTW SPT-1 or SPT-2, 18 AWG, VW-1, 105 degree C. ZJCZ , 7 UL/CUL

ELECTRIC WIRE & (E55351)

CABLE

INDUSTRIAL CO

LTD

Output Cable Alternate Various Various SPT-1 or SPT-2, Min.22 AWG, VW-1, 105 degree ZJCZ , 7 UL/CUL

C.

Output Cable Alternate Various Various Min. 22 AWG, VW-1, Min. 80 degree C. AVLV2, 8 UL/CUL

Printed Wiring Board Various Various V-1 or better, 130 degree C. ZPMV2, 8 UL/CUL

Fuses, F1, F2 WALTER 2010 Micro Fuse, 3.15A, 250Vac. JDYX2, 8 UL/CUL

ELECTRONIC CO (E56092)

LTD

Fuses F1, F2 Alternate CONQUER MST Micro Fuse, 3.15A, 250Vac. JDYX2, 8 UL/CUL(E82

ELECTRONICS CO 636)

LTD

Fuses F1, F2 Alternate Various Various Micro Fuse, 3.15A, 250Vac. JDYX, 7 UL/CUL

Varistor, THINKING TVR07471-M Min.300 Vac. VZCA2, 8 UL/CUL

VAR1(Optional) ELECTRONIC (E314979)

INDUSTRIAL CO

LTD

Varistor, JOYIN CO LTD 7N471K Min.300 Vac. VZCA2, 8 UL/CUL

VAR1(Optional) (E325508)

Alternate

Issue Date: 2013-11-19 Page 9 of 20 Report Reference # E341350-A26-UL

Object/part or Manufacturer/ type/model technical data CCN Marks of

Description trademark Conformity

Varistor, VAR1(Optional) Various Various Min.300 Vac. VZCA2, 8 UL/CUL

Alternate

Thermistor, THINKING SCK-053 Min.2.5 ohm, 5 A min. XGPU2 UL

RT1(Optional) ELECTRONIC (E138827)

INDUSTRIAL CO

LTD

Thermistor, Various Various Min. 2.5 ohm, 5 A min. XGPU2 UL

RT1(Optional) Alternate

Photo coupler, IC6, SHARP CORP PC817 Distance > 0.4 mm, Min. 5000 Vac isolation. FPQU2 UL

IC7(IC7 is optional) ELECTRONIC (E64380)

COMPONENTS AND

DEVICES DIV

Photo coupler, IC6, IC7 VISHAY INFRARED TCET1107G Distance > 0.4 mm; Min. 5000 Vac isolation. FPQU2, 8 UL/CUL

(IC7 is optional) COMPONENTS INC (E52744)

Alternate

Photo coupler,(IC7 is LITE-ON LTV817 Distance > 0.4 mm, Min. 5000 Vac isolation. FPQU2, 8 UL/CUL

optional) IC6, IC7 TECHNOLOGY (E113898)

Alternate CORP

Photo coupler, IC6, Various Various Distance > 0.4 mm, Min. 5000 Vac isolation. FPQU2, 8 UL/CUL

IC7(IC7 is optional)

Alternate

MOSFET, Q1 FUJI ELECTRONIC 2SK3337-01 17 A / 600 V or better. -- --

MOSFET, Q1 - Alternate Various Various 17 A / 600 V or better. -- --

Line Choke, Various Various Rating 130 degree C. See enclosure 4-10 for -- --

LF1(Optional) details.

- Copper wire on LF1 Various Various Rating Min. 130 degree C. OBMW2 UL

Line Choke, Various Various Rating 130 degree C. See enclosure 4-11 for -- --

LF2(Optional) details.

- Copper wire on LF2 Various Various Rating Min. 130 degree C. OBMW2 UL

Bridge Diode, BD1 Various Various Min. 8 A, Min. 600 V -- --

Capacitor, C9 RUBYCON MXG Series Min. 420 V, Min. 47 uF, Min. 105 degree C. -- --

CORPORATION

Issue Date: 2013-11-19 Page 10 of 20 Report Reference # E341350-A26-UL

Object/part or Manufacturer/ type/model technical data CCN Marks of

Description trademark Conformity

Capacitor, C9 Various Various Min. 420 V, Min. 47 uF, Min. 105 degree C. -- --

Alternate

PFC Inductor Various Various Rating 130 degree C. See enclosure 4-12 for -- --

T1 details.

-Wire Various various Rating Min. 130 degree C. OBMW2 UL

- Bobbin used in T1 CHANG CHUN T373J, T375J, Phenolic, Rating Min. V-1, 150 degree C, Min. QMFZ2, 8 UL/CUL

PLASTICS CO LTD T375HF 0.43mm thick. Overall Dimension 31 mm by 29 (E59481)

mm by 21mm.

- Bobbin used in T1 SUMITOMO PM-9820 Phenolic, Rating V-0, 150 degree C, Min. 0.16mm QMFZ2, 8 UL/CUL

Alternate BAKELITE CO LTD thick. Overall Dimension 31 mm by 29 mm by (E41429)

21mm.

- Bobbin used in T1 HITACHI CHEMICAL CP-J-8800 Phenolic, Rating V-0, 150 degree C, Min. 0.16mm QMFZ2, 8 UL/CUL

Alternate CO LTD thick. Overall Dimension 31 mm by 29 mm by (E42956)

21mm.

- Bobbin used in T1 CHANG CHUN 4130(100%Virgin) Phenolic, Rating V-0, 140 degree C, Min. 0.74mm QMFZ2, 8 UL/CUL

Alternate PLASTICS CO LTD. (a)(b) thick. Overall Dimension 31 mm by 29 mm by (E59481)

21mm. Min. 0.74 mm thick.

Transformer, T2 YAO SHENG AM168B-T2-12V- (OBJY2) Class B(130 degree C) insulation OBJY2 UL

ELECTRONICS CO A (12 - 17V) system, designated (E173643)

LTD AM168B-T2-19V- M7AGHB, YCI-130.See enclosure 4-13, 4-14, 4-

A (17.1 - 21V) 15, 4-16, 4-17 for details.

AM168B-T2-23V-

A (21.1 -23.9V)

AM168B-T2-24V-

A (24 - 30V)

AM168B-T2-36V-

A (30.1 - 38 V)

AM168B-T2-48V-

A (38.1 - 48 V)

- Core Various Various Ferrite core, OD size 32 mm by 20mm by 22 mm. -- --

- Primary winding used Various Various Polyurethane with or without overcoat Polyamide, OBMW2 UL

in T2 Min. 130 degree C. MW -75 or MW28 Type.

- Secondary Winding GREAT LEOFLON TRW(F) Rating 130 degree C. Triple insulating wire. Only in OBJT2, 8 UL/CUL

Description:GTM9100P12024-X.X 24.0 5.00 . not investigated to the following standards or clauses:: Biocompatibility (ISO 10993 ISO 14971 was performed .