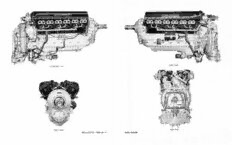

Table Of ContentPORT SIDE.

STARBOARD SIDE.

REAR END.

FRONT END.

ROLLS-ROYCE "MERLIN Jl". AERO ENGINE

HANDBOOK

FOR THE

INSTALLATION, RUNNING AND

MAINTENANCE

OF

ROLLS--ROYCE

"MERLIN" AERO ENGINES

SERIES II

(SUBJECT TO REVISION)

May, 1938

(Revi.<ed and Ret>rinted June, 1941)

Published by

ROLLS-ROYCE Llj\UTED

DERBY;

AND 14 & 15 CONDUIT STREET, LONDON

AMENDMEN1"'S

FOR THE

- PRINTED BY ---· ROLLS-ROYCE

BEMROSE & SONS LTD.

DERBY ANO LONDON

"MERLIN" AERO ENGINE HANDBOOK

Series II. May, 1938

CoNT.ENTS.

CONTENTS

PAGI!

LIST OF ILLUSTRATIONS ... vii

LEADING PARTICULARS OF ENGINE x

CHAPTER I.-GENERAL DESCRIPTION

Lubrication System '2

CHAPTER II.-UNPACKING AND INSTALLATION 4

Air Intakes 15

Auxiliary Systems 15

Controls ... 14

Cooling System ... II

Electric Generator 15

Electric Starting System 15

Engine Mounting 7

Exhaust System 15

Fuel System 7

Oil Filter in Installation Io

Oil System 8

Priming Arrangements 15

Re-setting Boost Pressure (Progressive Type Regulator) 14

Unpacking 4

CHAPTER III.-STARTING, RUNNING UP AND GENERAL SERVICE .NOTES 16

Coolant Pump Packing Gland and Grease in System 19

Correct Filling of Cooling System r6

Drain Taps and Glycol Loss ... 19

Ensuring Sound Coolant Joints 19

Ground Running Prior to Flight 18

Inspection and Test of Cooling Circulation 19

Running 18

Starting ... 17

CHAPTER IV.--FLYING ~I

CHAPTER V.-LUDRlCAN'fS, ETC., INSPECTION PERIODS AND FAULTS

Faults

Inspection Periods

CHAPTER VI.-DlSMANTLING THE ENGINE TO UNITS ... 30

v

CONTENTS. LIST OF ILLUSTRATIONS.

PAGE

CHAPTIZR V ll.- DESCRIPTION, DISMANTLING, INSPECTION AND ATTENTION OF

ASSEMBLIES

Air Compressor Drive (Rigbt-hand Cylinder Head)

Air Intakes 44

Airscrew Neduclion Gear r59 LIST OF ILLUSTRATIONS

Automatic Boost Regulator (Progressive Type) 67

.. \uxiliary Drive or Oil Pump Drive for· Retractable Undercarriage 177

PAGE

Camshaft anci Rocker Mechanism ll9 Front, Rear and Side Views of Engine Frontispiece

Camshaft Inclined Drives us Fig. I-Lubrication System .. . 2, 3

Carburetter antl Inciuction System 44 Flg. 2-Slinging the Engine .. . 4

Connecting Rods 132 Fig. 3- Side View for Checking List 5

Coolant Pump 83 Fig. 4-Side View for Checking List 6

Crankcase and Bearings 167 Fig. 5-Installation Drawing ... 6, 7

Crankshaft 133 Fig. 6- Diagram of Typical Fuel System 8

Cylinder Block .and Liners 136 Fig. 7-Diagram of Typical Oil System 9

Decarbouizing 152 Fig. 8-0il Filter IO

Drive for Engine Speed Indicator I24 Fig. 9-Engine Cooling System I2

Dynamo Drive and Couplings 92 Fig. 10-Diagrammatic Plan of Typical Cooling System 13

Electric !:itarting System 98 Fig. Ir-Control Positions and I3oost Gauge-Take-off 2I

Engine Controls 38 Fig. 12-Control Positions and Boost Gauge-Climbing 22

Engine Oil Pipes 167 Fig. 13-Control Positions and Boost Gatige- :'.\:laximum Cruising 22

Engine Oil Pumps (Pre5sure and Scavenge) I72 Fig. I4_-Control Positions and Boost Gauge-Economical Cruising 23

Exhaust :Manifolds t66 Fig. T 5- Lifting Reduction Gear 31

Fuel Pumps 87 Fig. I6-Extracting Dowels 31

Ignition Wiring and Magnetos 78 Fig. t7- Lifting Supercharger ... 32

Induction Manifolds 77 Fig. 18-Lifting Cylinder Block 34

Oil Relief Valves and Control for Two-pitch Airscrew 156 Fig. r9-Cylinder Rig ... 34

Pistons 127 Fig. 20-Extracting Main Bearing Caps 35

Priming and Volute Drain Pipes 76 Fig. 21-Lifting Crankshaft 36

Proprietary Units I82 Fig. 22-Engine Controls 39

Renewing a Cylinder Stud Tube 151 Fig. 23-Controls ... 42

Hemoval or Inspection of a Lesser Unit I82 Fig. 24-Diagram of Carburetter 44, 45

Servicing a Cylinder Block 137 Fig. 25- Carburetter 48

Starting Handle ll4 Fig. 26--Supercharger System 55

Supercharger 55 Fig. 27-Separating Supercharger Casings 58

Supercharger Drive Gears and Spring Drive 62 Fig. 28-Vice Block 59

Valves and Springs .. . 152 Fig. 29-Supercharger ... 60

\Vheelcase and Gears .. . 95 Fig. 30-Vice Blocks 62

Fig. 31-Locating Plate 63

Fig. 32~<iupercharger Gears 64

CHAPTER VIII.- RE-ASSEMBLING ENGINE FROM UNITS. 186 Fig. 33-Diagram of Boost Regulator 68

Adjusting Valve Tappet Clearances ... r92 Fig. 34-Boost Regula.tor 73

Magneto Timing 193 Fig. 35-Ignition Terminals 78

Valve Timing I9! Fig. 36-Diagram of Ignition Leads 79

Fig. 37-1\fagneto, with Parts Removed 8I

Fig. 38-Withdrawing Magneto Coupling Mange 82

Fig. 39-Coolant Pump 84

Fig. 40-Fuel Pumps 88

Fig. 4r-Tool for Removing Drive Gear 89

Fig. 42-Fuel Pumps 90

vi vii

LIST OF ILLUSTRATIONS. -.....- -·---- LIST OF ILLUSTRATIONS.

PACE PAGE

Fig. 43- Dyna.mo Drive Gears. .. 93 Fig. 93- Withdra'!"ing Dearings from Housing I62

Fig. 44- Vertical Drives 97 Fig. 9-1-Removing Rear Roller l.face r63

Fig. 45-Tlfagneto Drive 99 Fig. 95-Pil()t Drift 163

Fig. 46-Layout o[ Starter Systems ... IOO, 10! Fig. 96-Asserubling Rear Roller Raco i64

Fig. 47-Vicc Blocks 103 Fig. 97-Rcpladng Forv:nrd Bearings on Airscrew Shaft 164

Fig. 48-Removal Tools ... ro4 Fig. 98-Removing Oil Filters ... 171

Fig. 49- Tool for Magneto Drive 105 Fig. 99-Extracting Tool for Roller Race 172

Fig. 50--Tools £or Hand Starler Gear IO] Fig. 100-0il Puntp!I 174

Fig. 51-Tools for Starter Gear 107 Fig. 101-Withdrawing Drive Gear 175

Fig. 52-Tool for Starter Layshaft 108 Fig. xo2-0il Pump Drive J78

Fig. 53-Starter Gears ... 109 Fig. 103-Vice Block 180

Fig. 54-Vicc Blocks JI4 Fig. 104-Vice Block 180

Fig. 55- Testing Slip-loading of Clutch 115 Fig. 105-Withdrawing Tool ·Jso

Fig. 56-Cai:nshaft Inclinecl Drive aud Toors Il6 Fig. 106-Vice Rlock 181

Fig. 57-Testing Daeklash II8 Fig. 107-·-Vice Block 181

Fig. 58-!fool for Removing Gearslrn.It n8 Fig. ro8-Startcr Motor 183

Fig. 59-Removing Bevel \Vheel l:Zl Fig. ro9--Electric Generator 184

Fig. 60--Removing Rocker Shaft l:Z2 Fig. 110--TiltiDg Cylinder Block 188

Fig. 61-Carnshaft and Rocker Mechanism .. . 123 Fig. J 1 r-Slipping Spanner 189

Pig. 62-Drive for Engine Speed Indicator .. . u5 Fig. 112-Cylinder Nut Template 189

Fig. 63-Tool !or Holding Gear 125 f'ig. 113-Securing Rockers (Temporarily) 191

Fig. 64-Pislou and Connecting Rods 128 Fig. 114 -Valve Tappet Arljnstmcnt ... 193

Fig. 65-Crankshaft aud Bearings r34 Fig. 115-La.yont of Timing Gear 194

Fig. 66-Extracting a Cylinder Liner 139

Fig. 67-Blocks for Setting Up Cylinder 140

Fig. 68-Depth Gauge ... 141

Fig. 69-Record of Cyliuder joint Faces 141

Fig. 70-Facc Cntting Tool J42

Fig. 71-Record of Cylinder Joint F:aces 143

Fig. 72-Lapping Tool ... 143

Fig. 73- Record of Cylinder Joint Faces 143

Fig. 74-Record of Cylinder Joint Faces 144

Fig. 75- Gauge Ior joint Ring 144

Fig. 76-Cap Gange 145

Fig. 77- Lapping Tool ... 145

Fig. 78-Rccorcl of Cylinder Joint Faces 145

Fig. 79-Record of Cylinder Joint Fa.ces .146

Fig. So-Record of Cylinder Joint Faces 146

Fig. 81-Pilot Tool 146

Fig. 82-Test Rig 147

Fig. 83-Cylinder aud Valves ... 148

Fig. 84- Withdrawing a Cylinder Tubo 151

Fig. 85-Replacing a Cylinder Tube ... 151

Fig. 86- Removing Valve Springs 153

Fig. 87-Inlet Valve Grinding Tool 155

Fig. 88-Lappini; Tool and Blucing Gauge ... 155

Fig. 89- Blue Test Block J56

Fig ..9 o-Oil Relief Valves 157

Fig. 9r-·Airscrew Reduction Gear r6o

Fig. 92-Removiug Airscrew Shaft from Bearings ... 161

ix

viii

LEADING PARTICULARS OF ENGINE. LEADING PARTICUf.ARS OF ENGINE.

LUBRICATION.

Type oil :Hritish Air :vlinistry Specification-D.T.D. 109

(mineral).

Oil consumption at maximum cruising conditions Io-l8 pints per hour (5·6 to 10·2 litres/hour).

Oil pressure-main Normal-Go lbs./sq. inch (4·218 kgs./cm.2).

Leading Particulars of Engine Emergency minimum-45 lbs./sq. inch (3·16

kgs./cm.2).

Oil prP.ssure-auxiliary Normal---6 lbs./sq. inch (422 gr./cm.1).

Emergency minimum-2 lbs./sq. inch {i. .p

GENERAL. Inlet temperature for take-off (minimum) 15g°rc../ cm.2).

Inlet temperature for climbing and level flight (maximum) 90°c.

Type Supercharged, geared, glycol cooled, 60° Vee.

Inlet temperature maximum (5 minutes emergency) 95•c.

Cylinders: :N'umber and arrangement. .. i2 cylinders in ~vo lkcylinder monoblocks.

Bore· and stroke 5·4 ins. by 6 ins. (137·16 rn/m x 152·4 m/m). CARBURATION.

Compression ratio 6·0 : I. Type fuel British Air Ministry Specification-D.T.D. 230

(87 octane).

Airscrew reduction gear: Maximum fuel demand 90 gallons per hour (409 litres/hour).

Type Spur layshaft. Type of carburetters Duplex {Rolls-Royce S. U.).

DRiarteicot ions of rotation 0A•4ir7s7c re; wI .s haft, anti-clockwise; crankshaft, Fce<l pressure supply 2 to 2f lbs./sq. inch (140 to r93 gr./cm.2).

clockwise when · viewed from the engine

forward end. . IGNITION.

International power rating 990 B.H.P. at 2,600 R.P.1\L at r2,250 feet

Number and type of magnetos Two B.T.H. CIS/E/12-S.

(r,004 C.V., 2,600 R.P.M., 3,734 metres).

Maximum power rating I,030 B.H.P. at 3,000 R.P.M. at 16,250 feet Number and type of .sparking plugs (per cylinder) Two K.L.G. RV. r4/4, or

(1,044 C.V., 3,000 R.P.!\I., 4,953 metres). Lodge R.A.-14,14.

Maximum take-off power 890 B.li.P. at 2.850 R.P.!\'l. at sea level ~fagneto timing (fully advanced) 45° B.T.D.C.

(902 C.V., 2,850 R.P.M.). Contact ureaker gap ... 0·012 inches (-305 m/m).

Rated boost pressure ... +6! lbs:/sq. inch (439 gm./cm.2). Sparking plug gap 0·0J2 ins. to 0·015 ins. (-305 m /m to ·38 m/m).

Maximum take-off conditions ... +6l lbs./sq. inch boost and 2,850 R.P.M. Firing order IA, 6B, 4A, 3B, 2A, 5H, 6A, 1B, 3A, 4B,

Minimum take off R.P.M. at + 6l lbs. per sq. inch boost 2,0(8403.9 gm./cm.2). 5A, zB.

VALVE TIMING.

:Maximum climbing conditions +ot lbs./sq. inch boost and 2,600 R.P.M.

(439 gm./cm.2). Valve tappet clearance for timing a.n(I cold running 0·020 inch (·51 m/m).

Maximum level flight ... +6t lbs.jsq. inch boost and 3,000 R.P.M.·

Inlet valve opens 3i0 B.T.D.C.

(439 gm./cm.2).

Maximum continuous cruising conditions (normal rich mixtures) ... +d lbs./sq. inch boost and 2,600 R.P.M. Tnlet valve closes 52° A.R.D.C.

(316 gm./cm.2). Exhaust valve opens 72° B.B.D.C.

Maximum economical cn1ising conditions (weak mixtures) +2! lbs./sq. inch boost and 2,600 RP.M. Exhaust valve closes '12!0 A.T.D.C.

(158 gm./cm.2).

Maximum diving, R.P.M. 3,600 (see page 23).

PARTICULARS OF COOLING.

Weight of engine, nett dry, including ignition system, with bonding

and screening, carburetters and induction systems, engine-driven Coolant ... Ethylene Glycol.

fuel pump, water outlet collector pipes, hand turning gear, super·

Maximum temperature at outlet 95°C. when cruising, 120°C. on climb.

charger with necessary pipe work and drives for accessories

mcorporatcd in engine, but excluding airscrew hub, exhaust

manifolds or stub pipes, air intakes, co111Jexions from water

outlets and water pump to radiator, oil and coolant 1,335 lbs. STARTING.

Cylinder numbering Airscrew. Type Hand turning gear and i2-volt electric motor.

IB IA

2B 2A

3B 3A

4B 4A

5B 5A

6B 6A

x xi

CHAPTER !.-GENERAL DESCRIPTION. I

CHAPTER I

General Description

This handbook is divided into eight chapters, arranged and tabulated to facilitate easy reference

without the necessity for ari index.

The sub-headings given under each clmpter (pages v and vi) should therefore be referred to.

As a detailed illustrnted description of each section of the engine is contained in Chapter VH,

a general outline only is given below.

The lubrication system is also included and embodies a general section of the engine.

The Rolls-I{oyce "Merlin II" engine is a twelve cylinder, supercharged, liquid cooled type,

employing Ethylene Glycol as a cooling medium. It has two blocks of six cylinders, mom1ted at 60°

to one another, at inclined upper faces on the cn.nkcasc.

A spur reduction gear is airanged at the forward end, to drive an airscrcw shaft (mounted above

the engine centre line) at 0·477 times engine speed.

Means are incorporated whereby a two-position pitch airscrew can be operated, using ma.in

uy

pressure engine oil controlled the pilot to move a piston in the hub assembly, or alternative

means when it is required to incorporate a constant speed unit. A fixed pitch airscrew may be

used if required.

a

A superchargtr, co-axial with the crankshaft, and at the rear end, has speed multiplying gear

to drive an impeller, for the purpose of obtaining a positive induction pipe pressure when required,

and maintaining it up to a given rated altitude.

This boost pressure is regulated automatically, within limits, by an aneroid controlled relay, the

w1it being mom1ted above the supercharger.

Below the latter, a twin choke carburetter is attached, to draw from an air intake at the lower

face, aneroid controlled jets providing mixture adjustment for varying altitude and booi:;t pressure.

Four overhead valves, two inlet and two exhaust, operate in each combustion space, six of which

are. formed in the block casting. Steel liners are spigotcd at their upper erid to form both a liquid and

combustion joint, the lower end of the block skiit housing a floating gland around each liner. Eacl1

monoblock assembly is secured to the crankcase by long studs.

Inclined shafts from the whcclcasc drive one overhead camshaft for each head, to operate four

rockers for each cylinder, one per valve.

2 CHAPTER !.-GENERAL DESCRIPTION.

A six-throw, balanced crankshaft, carried in seven main bearings, engages the re<luction gear,

forwards, and rearwards drives all the auxiliaries by a thin spring steel shaft allowing torsional

flexibility.

Forked connecting rods of marine type are used having aluminium pistons. floating small end

bushes and gudgeon pins.

Ignition is by two magnetos, each firing one of the two plugs in all twelve cylinders, the high

tension leads being protected, earthed and suitably directed by metal conduits.

Two starting means are provided, narhely, by hand turning gear or an electric motor which

operates through a reduction gear train incorporated in the wheelcase.

A centrifugal pump, vertically mounted and driven from the wheelcase lower end, circulates the

coolant. A single inlet connects ·with ipstallation, two deliveries supplying, one each cylinder block.

In addition to those drives which are essentially part of the engine, auxiliary drives are provided

for the use o.f electric generator, engine speed indicator, generator p~mp for operating retractable

undercarriage, high pressure air compressor and generator pump for gun turret control.

Duplex fuel pumps fonn a unit driven from the wheelcase left hand side, each pump being of

sufficient capacity to supply the maximum demands of the engine. ·

Lubrication System. Lubrication is by a gear type pressure pump, the system being of a

"dry sump" type, and two other gear pumps being employed to drain

the crankcase front and rear end, independently. They are all incorporated with the lower half

crankcase.

The system is illustrated diagrammatically in Fig. I.

The first stage is regulated to approximately r50 lbs. per sq. inch (10·54 kg./cm.2) for the purpose

of operating the two-pitch airscrew. The second stage is regulated to 60 to 70 lbs. per sq. inch (4·21 to

4·92 kg./cm.2), and supplies the main high pressure oil to the engine. Drilled passages in the crank

case convey oil-to a main gallery pipe ~upplying each of the seven main bearings having two holes

in the lower half.

The six big-end bearings are fed via oil holes in the crank webs supplied by main bearings Nos. 2, .

3, 5, and 6, Nos. 2 and 6 having annul~r grooves, and Kos. 3 and 5 part annular grooves, registering

with holes in the crank journals and providing uniform oil distribution.

The fuel pump bushes and gland are also fed from the high pressure system, the flow being

restricted by a small hole in the pressure oil pump.

The third stage is regulated between 4 and 8 lbs. per sq. inch (281 to 562 gr./cm.2) and supplies

the various auxiliaries such as camshaft and rockers, reduction gear, electric generator and super

charger drive gears, and impeller bearings. The camshaft drives and timing gears are lubricated by oil

which drains back to the crankcase through the camshaft drive housings. Oil also drains back via

tubes through which pass the cylinder holding down studs.

Provision is made at the high pressure main supply on the relief valve casing for fitting a ther

mometer and pressure gauge.

l l

Insert Spread "• ExM MerlinII 0022" Insert Spread"• ExM Merlinil 0023"