Table Of ContentE L E C T R O T E C H N I C A L I N S T I T U TE

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

M. PoŜaryskiego str. 28; 04-703 WARSZAWA tel. (+48 22) 812 23 38 fax. (+48 22) 812 04 07

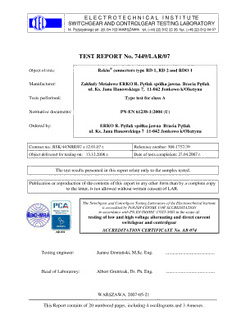

TEST REPORT No. 7449/LAR/07

Object of tests: Rekin® connectors type RD 1, RD 2 and RDO 1

Manufacturer: Zakłady Metalowe ERKO R. Pętlak spółka jawna Bracia Pętlak

ul. Ks. Jana Hanowskiego 7, 11-042 Jonkowo k/Olsztyna

Tests performed: Type test for class A

Normative documents: PN-EN 61238-1:2004 (U)

Ordered by: ERKO R. Pętlak spółka jawna Bracia Pętlak

ul. Ks. Jana Hanowskiego 7 11-042 Jonkowo k/Olsztyna

Contract no.: BSK/44/NBR/07 z 12.01.07 r. Reference number: 504-1757/39

Object delivered for testing on: 13.12.2006 r. Date of tests completion: 27.04.2007 r.

The test results presented in this report relate only to the samples tested.

Publication or reproduction of the contents of this report in any other form than by a complete copy

to the letter, is not allowed without written consent of LAR.

The Switchgear and Controlgear Testing Laboratory of the Electrotechnical Institute

is accredited by POLISH CENTRE FOR ACCREDITATION

in accordance with PN-EN ISO/IEC 17025:2001 in the scope of:

testing of low and high voltage alternating and direct current

switchgear and controlgear

ACCREDITATION CERTIFICATE No. AB 074

Testing engineer: Janusz Domański, M.Sc. Eng. ..........................................

Head of Laboratory: Albert Gmitrzak, Dr. Ph. Eng. ..........................................

WARSZAWA, 2007-05-21

This Report contains of 20 numbered pages, including 4 oscillograms and 3 Annexes.

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 2/20

Contents

Page

1. Location and time of tests...................................................................................................................3

2. Test object...........................................................................................................................................3

3. Scope of tests.......................................................................................................................................4

4. Reference documents related to tests...................................................................................................4

5. Test procedure and results of tests......................................................................................................5

5.1 Electrical tests ...............................................................................................................................5

5.1.1 Heat cycling tests...................................................................................................................5

5.1.2 Resistance to short-circuit currents........................................................................................6

5.1.3 Measurement of connectors resistance...................................................................................7

5.1.4 Evaluation of test results......................................................................................................11

5.2 Mechanical tests..........................................................................................................................11

6. Conclusion.........................................................................................................................................11

Figure 1 - Test circuit for heat cycle tests of Rekin connectors type RD 1, RD 2 and RDO1 ……..…12

Photography 1 - Test stand for measurement and control of temperature …………………………….13

Oscillogram 1444 - Short-circuit test of test loop no. 1 ……………………………………………….14

Oscillogram 1457 - Short-circuit test of test loop no. 2 ……………………………………………….15

Oscillogram 1488 - Short-circuit test of test loop no. 4 ……………………………………………….16

Oscillogram 1604 - Short-circuit test of test loop no. 3 ……………………………………………….17

Annex 1 - Drawing RD1–OO – WTO złączki REKIN RD1……………………………………………18

Annex 2 - Drawing RD2–OO – WTO złączki REKIN RD2………………………………………...….19

Annex 3 - Drawing RDO1–OO – WTO złączki REKIN RDO1………………………………………...20

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 3/20

1. Location and time of tests

The tests were performed at Switchgear and Controlgear Testing Laboratory of the Electrotechnical

Institute in Warsaw from 12th January 2007 until 27th April 2007.

2. Test object

The object of tests were the Rekin® connectors typ RD 1, RD 2, RDO 1 used for connecting copper

winding wires, both enameled and non-enameled. The Manufacturer provided for tests the sets of

Rekin® connectors, clamped on the copper profiled winding wires. The set of connectors with the

winding wires are called in this report the test loops.

The types of connectors and dimensions of wires delivered for tests are given in Table 1.

Table 1 – Type of Rekin® connectors and dimensions of connected wires

Type of Quantity Number Number Enameled, profiled

Cross-section of conductor

Item conne- of of of test copper wires

ctor pieces connectors loops Dimensions (B x H) [mm] mm2

1. 6 T1 - T6 1 4,5 x 5,5 24,75 Min.

RD 1

2. 6 T1 - T6 3 5,5 x 10,5 57,75 Max.

3. 6 T1 - T6 2 2 x 4,5 x 5,5 49,5 Min.

RD 2

4. 6 T1 - T6 4 2 x 4,5 x 7,0 63,0 Max.

5. 6 T7 - T12 1 4,5 x 5,5 24,75 Min.

6. 6 T7 - T12 2 2 x 4,5 x 5,5 49,5 -

RDO 1

7. 6 T7 - T12 3 5,5 x 10,5 57,75 -

8. 6 T7 - T12 4 2 x 4,5 x 7,0 63,0 Max.

For compression of Rekin® connectors type RD 1, RD 2 and RDO 1 the Manufacturer used the head

GRD1 and dies type SRD with the pressure of 140 kN and hydraulic aggregate AH 400/RD.

The Manufacturer delivered technical documentation and Technical Acceptance Specification (WTO):

• Drawing RD1–00 – WTO złączki REKIN RD1,

• Drawing RD2–00 – WTO złączki REKIN RD2,

• Drawing RDO1–00 – WTO złączki REKIN RDO1.

The drawings of type RD 1, type RD 2 and type RDO 1 connectors are given adequately in Annexes

no.1, no. 2 and no. 3.

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 4/20

3. Scope of tests

Type tests according to PN-EN 61238-1:2004 (U) for the class A connectors.

Program of tests:

1. Electrical tests

1.1. Heat cycle test

1.2. Short-circuit tests

1.3. Measurements of connectors resistance

2. Mechanical tests

The results of tests are given in table below.

Tests according to

Item Kind of test Result of tests

PN-EN 61238-1:2004 (U)

1 Electrical tests Clause. 6 Positive

1.1 Heat cycle test Sub-clause 6.3 Positive

1.2 Short-circuit tests Sub-clause 6.3.4 Positive

1.3 Measurements of connectors resistance Sub-clause 6.2.1 Positive

2 Mechanical tests See Test Report Positive

No. LE-503/07

4. Reference documents related to tests

The tests and results assessment were carried out according to the following documents:

PN-EN 61238-1:2004 (U) Zaciskowe i mechaniczne złącza kabli energetycznych na napięcie

znamionowe nie przekraczające 36 kV (U = 42 kV). Część 1:

m

Metody badania i wymagania

IDT

IEC 61238-1:2003 Compression and mechanical connectors for power cables for rated

voltages up to 36 kV (U = 42 kV). Part 1: Test methods and

m

requirements

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 5/20

5. Tests procedure and result of tests

5.1 Electrical tests

Each test loop as in Table 1 was tested according to PN-EN 61238-1:2004 (U), Clause 6. There were

made the following electrical tests:

1. 1000 heating-cooling cycles within the range of temperature from 35 °C to (123±3) °C

2. Six short-circuit after the 200th heat cycle.

3. Measurements of connectors resistance:

- before the first heat cycle,

- before short-circuit tests,

- after short-circuit tests,

- after 250th heat cycle,

- every 75±10 heat cycles, i.e. after 325, 400, 475, 550, 625, 700, 775, 850, 925 and 1000

cycles.

5.1.1 Heat cycling tests

The tests were made according to PN-EN 61238-1:2004 (U), Sub-clause 6.3. The test loops of the

connectors Rekin® with wires as in Table 1 and with a reference wire 1 m long in each loop, were laid

in a place without air draught, at a height of 60 cm above the floor. Each test loop was supplied from

an independent source with adjustable voltage. The heat tests were made with alternating current of

power frequency.

The current value was selected in the first heat cycle according to IEC 1238-1:1993 item. 6.3.1.b),

adequately to the type of the connector and to the cross section of the connected winding wire in such

a way that the temperature of the reference wire at the steady state conditions could reach (120±3) °C.

For control of heat cycling test and for temperature adjustment the electronic controllers were used,

which were controlled with a signal from the temperature measuring system in the half length of the

reference wire (lr). The value of the testing current was adjusted using the induction voltage regulator

on the primary winding of the transformer supplying the heating circuit.

The schematic diagram of the testing circuit for heat cycling tests is shown in Figure No. 1. Contactor

was used for making and breaking the heating current.

The values of the test currents, heating times, times of natural cooling to the temperature ≤ 35 °C and

total time of each cycle for every test loop are given in table 2. The heating and cooling times were

determined from records of digital recorder type 4181M, No. NMM-80110900.

The stand for measurement and control of temperature is given on Photo 1.

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 6/20

Table 2 – Parameters of heat cycle tests

Number Heating

Type of connectors / Duration of

of test current Heating time Cooling time

wires the cycle

loop [A]

1 RD 1/ 4,5 x 5,5 Cu 350 12 min 15 s 12 min 30 s 24 min 45 s

RDO 1/ 4,5 x 5,5 Cu

3 RD 1/ 5,5 x 10,5 Cu 700 12 min 15 s 14 min 26 min 15 s

RDO 1/ 5,5 x 10,5 Cu

2 RD 2/ 2 x 4,5 x 5,5 Cu 600 12 min 50 s 15 min 10 s 28 min

RDO 1/ 2 x 4,5 x 5,5 Cu

4 RD 2/ 2 x 4,5 x 7,0 Cu 800 12 min 20 s 15 min 30 s 27 min 50 s

RDO 1/ 2 x 4,5 x 7,0 Cu

5.1.2 Resistance to short-circuit currents

Verification was made after 200 heating-cooling cycles acc. to PN-EN 61238-1:2004 (U), Sub-clause.

6.3.4. On each testing section were made six short-circuits. The test currents of the testing sections

no. 1 and no. 2, determined acc. to PN-EN 61238-1:2004 (U), adequately 6,24 kA and 9,58 kA, caused

over-heat isolation of winding conductors. With agree on the manufacturer, further short-circuit tests

were made at short-circuit currents, which may really occurs in this application in service conditions.

The calculation and real values of short-circuit currents, registered during the tests and time of current

flow in each testing section, are given on Table 3.

In this Report is enclosed one exemplary oscillogram from each short-circuit test made on every test

loop. For registration of the short-circuit currents and test parameters the HIOKI 8842 recorder was

used. The temperature of connectors and temperature of reference wires were measured by using

digital recorder type 4181M and the thermocouples type K.

Table 3 – Parameters of the short-circuit test

Equivalent

Number Value of current Duration

Type of connectors / of 1 s Osc.

of test [kA] of short-

wires current Number

loop Calculation2) Real circuit [s] kA

1 RD 1/ 4,5 x 5,5 Cu

2,48 6,24 1) 1,02 6,3 1444

RDO 1/ 4,5 x 5,5 Cu

2 RD 2/ 2 x 4,5 x 5,5 Cu 9,58 1) 0,77 8,07 14563)

4,95

RDO 1/ 2 x 4,5 x 5,5 Cu 4,83 1,16 5,20 1457

3 RD 1/ 5,5 x 10,5 Cu

6,27 6,09 1,16 6,56 1604

RDO 1/ 5,5 x 10,5 Cu

4 RD2/ 2 x 4,5 x 7,0 Cu

6,3) 6,22 1,09 6,49 1588

RDO 1/ 2 x 4,5 x 7,0 Cu

1) The value of current was determined according to PN-EN 61238-1:2004 (U), Sub-clause 6.3.4.

2) The value of current was calculated an the basis of real short-circuit currents which may occurs in

service conditions. The given values were agreed between manufacturer and user of connectors.

For calculations the following values were used:

- density of current ≤ 4 A/mm2

- multiplication factor of short-circuit current 20-25

The test current was calculated with the formula: I = 4 x S x 25, where S – cross-section of the

conductor, in mm2.

3) Oscillogram not included to this Test Report.

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 7/20

5.1.3 Measurement of connectors resistance

Verification was made according to PN-EN 61238-1:2004 (U), Sub-clause 6.3.4. Resistance

measurements of connectors under tests were carried out with technical method by using the low

resistance ohmmeter type BIDLE no. 247101-41 series 48967 – list number NAR 801-19800

The values of resistance for each tested connector are given on Tables 4 to 11.

Table 4 – Resistance of connectors type RD 1 with Cu profiled wires

4,5 mm x 5,5 mm – test loop no. 1

Number of connector

Connectors type RD 1

T1 T2 T3 T4 T5 T6

Number of cycle Resistance [m Ω]

0 46 41 47 45 49 49

200 44 40 43 48 49 52

200 52 67 62 61 65 60

250 46 58 82 82 91 77

325 - - - - - -

400 48 62 84 80 90 66

475 51 66 89 76 90 63

550 54 68 89 77 89 68

625 58 70 90 78 87 80

700 59 70 89 78 88 81

775 56 72 88 80 91 74

850 54 74 87 83 94 72

925 55 74 88 83 90 76

1000 56 74 90 85 89 78

Table 5 – Resistance of connectors type RD 1 with Cu profiled wires

5,5 mm x 10,5 mm – test loop no. 3

Number of connector

Connectors type RD 1

T1 T2 T3 T4 T5 T6

Number of cycle Resistance [m Ω]

0 41 45 62 87 72 87

200 40 46 62 83 71 86

200 1) 62 61 62 95 108 102

250 59 58 28 28 36 34

325 58 54 28 28 34 32

400 56 62 29 28 34 33

475 66 57 28 26 35 33

550 68 59 29 28 38 30

625 54 58 27 26 30 29

700 - - - - - -

775 59 61 28 27 34 30

850 62 63 28 28 33 31

925 65 65 29 29 32 32

1000 69 66 29 29 32 30

1) At the test current of 6,09 kA (equivalent 1 s current = 6,56 kA - see Table 3),

determined to cross-section of wire acc. to PN-EN 61238-1:2004 (U) there was

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 8/20

over-heat connectors T3, T4, T5 and T6 and also isolation of winding conductors.

For farther tests Manufacturer has delivered new connectors T3, T4, T5 and T6

and new winding conductors.

Table 6 - Resistance of connectors type RD 2 with Cu profiled wires

2 x 4,5 mm x 5,5 mm – test loop no. 2

Number of connector

Connectors type RD 2

T1 T2 T3 T4 T5 T6

Number of cycle Resistance [m Ω]

0 39 44 41 39 45 37

200 39 41 40 38 44 40

200 44 51 41 45 50 45

250 42 48 40 46 51 41

325 43 49 42 45 50 40

400 43 50 43 44 51 40

475 46 55 48 45 52 41

550 45 55 44 44 53 42

625 44 56 41 43 56 45

700 46 56 47 46 57 44

775 45 54 45 46 60 45

850 46 53 39 45 63 48

925 48 60 42 45 62 48

1000 51 68 44 46 62 48

Table 7 - Resistance of connectors type RD 2 with Cu profiled wires

2 x 4,5 mm x 7,0 mm – test loop no. 4

Number of connector

Connectors type RD 2

T1 T2 T3 T4 T5 T6

Number of cycle Resistance [ m Ω]

0 40 39 42 41 41 41

200 44 39 38 38 43 38

200 43 42 42 41 43 49

250 42 42 44 43 43 48

325 41 41 49 45 44 50

400 44 43 51 46 41 51

475 45 46 49 45 42 50

550 46 67 45 46 45 51

625 47 48 43 46 47 52

700 48 48 42 46 47 52

775 47 44 45 45 49 51

850 46 42 47 47 51 50

925 47 44 46 46 50 49

1000 48 48 47 47 50 50

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 9/20

Table 8 - Resistance of connectors type RDO 1 with Cu profiled wires

4,5 mm x 5,5 mm – test loop no. 1

Connectors Number of connector

type RDO 1 T7 T8 T9 T10 T11 T12

Number of cycle Resistance [m Ω]

0 102 101 92 109 111 100

200 113 110 103 112 103 99

200 111 105 123 123 105 107

250 133 115 121 118 122 109

325 - - - - - -

400 131 114 124 119 110 112

475 137 112 126 115 123 117

550 135 114 121 118 122 120

625 135 116 119 121 124 125

700 138 120 119 119 125 123

775 140 122 123 121 120 121

850 141 125 126 122 115 122

925 142 124 128 122 122 121

1000 143 125 132 123 123 122

Table 9 - Resistance of connectors type RDO 1 with Cu profiled wires

5,5 mm x 10,5 mm – test loop no. 3

Connectors Number of connector

type RDO 1 T7 T8 T9 T10 T11 T12

Number of cycle Resistance [m Ω]

0 81 72 79 83 87 79

200 80 80 77 78 82 78

200 81 90 81 87 91 80

250 84 91 83 86 92 81

325 89 93 87 87 93 80

400 87 93 86 87 95 81

475 91 102 88 94 98 86

550 92 104 89 95 97 84

625 96 103 87 93 104 92

700 94 101 97 92 103 91

775 95 102 88 94 103 90

850 94 101 87 93 102 92

925 95 101 88 93 103 93

1000 96 103 89 94 106 95

TEST REPORT No.

ELECTROTECHNICAL INSTIUTE

7449/LAR/2007

SWITCHGEAR AND CONTROLGEAR TESTING LABORATORY

Page: 10/20

Table 10 - Resistance of connectors type RDO 1 with Cu profiled wires

2 x 4,5 mm x 5,5 mm – test loop no. 2

Connectors Number of connector

type RDO 1 T7 T8 T9 T10 T11 T12

Number of cycle Resistance [m Ω]

0 83 83 84 83 86 86

200 75 82 82 81 81 84

200 90 104 102 105 97 1) 86 1)

250 100 98 108 107 87 89

325 101 100 106 108 92 90

400 102 105 103 109 94 89

475 102 110 99 110 95 90

550 100 101 102 111 92 95

625 99 112 104 112 82 105

700 103 114 105 112 92 102

775 104 112 121 114 94 120

850 105 110 128 118 96 135

925 106 126 135 132 98 140

1000 107 158 150 165 99 152

1) After short-circuit tests (after 200 cycles) the connectors T5 and T6 have been

changed on new one by reason of their damage at short-circuit current of

9,58 kA, determined acc. to PN-EN 61238-1:2004 (U). The short-circuit tests

were repeated at the current of 4,83 kA (osc. No. 1457), calculated as in Table 3.

Table 11 - Resistance of connectors type RDO 1 with Cu profiled wires

2 x 4,5 mm x 7 mm – test loop no. 4

Connectors Number of connector

type RDO 1 T7 T8 T9 T10 T11 T12

Number of cycle Resistance [m Ω]

0 82 78 77 80 83 79

200 84 79 76 77 79 76

200 83 74 75 78 87 83

250 84 75 79 78 92 84

325 87 77 83 80 97 86

400 86 81 85 81 82 85

475 86 83 83 82 88 90

550 87 83 82 84 92 93

625 88 84 83 86 94 98

700 87 88 85 85 94 99

775 89 87 86 89 95 98

850 90 84 88 92 98 97

925 89 84 88 90 97 96

1000 90 84 88 88 94 98