Table Of ContentM/s. Narsingh Ispat Ltd.

Form -I

APPENDIX I

(See Paragraph-6)

FORM 1

Note: If space provided against any parameter is inadequate, kindly upload supporting document

under 'Additional Attachments if any' at the last part of the Form1. Please note that all such

Annexures must be part of single pdf document.

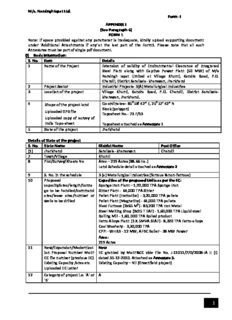

(I) Basic Information:

S. No. Item Details

1 Name of the Project Extension of validity of Environmental Clearance of Integrated

Steel Plant along with Captive Power Plant (50 MW) of M/s

Narsingh Ispat Limited at Village Khunti, Kandra Road, P.O.

Chandil, District Saraikela- kharswan, Jharkhand

2 Project Sector Industrial Projects- 3(A) Metallurgical Industries

3 Location of the project Village Khunti, Kandra Road, P.O. Chandil, District Saraikela-

kharswan, Jharkhand,

4 Shape of the project land Co-ordinates:- 850 58’ 42” E, 250 57’ 42” N

Block (polygon)

Uploaded GPS file

Toposheet No.- 73 F/13

Uploaded copy of survey of

India Topo-sheet Toposheet attached as Annexure 1

5 State of the project Jharkhand

Details of State of the project

S. No. State Name District Name Post Office

(1) Jharkhand Saraikela- kharsawan Chandil

7 Town/Village Khunti

8 Plot/Survey/Khasra No Area – 219 Acres (88.66 Ha.)

Land Schedule detail attached as Annexure 2

9 S. No. in the schedule 3 (a) Metallurgical Industries (ferrous & non-ferrous)

10 Proposed Capacities of the proposed Units as per the EC:

capacity/area/length/tonna Sponge Iron Plant – 1,92,000 TPA Sponge Iron

ge to be handled/command Sinter Plant - 64,000 TPA Sinter

area/lease area/number or Pellet Plant (Hematite) - 3,20,000 TPA pallets

wells to be drilled Pellet Plant (Magnetite) - 64,000 TPA pallets

Blast Furnace (2x65 M3) - 83,200 TPA Hot Metal

Steel Melting Shop (2x25 T EAF) - 1,60,000 TPA Liquid steel

Rolling Mill - 1,60, 000 TPA Rolled product

Ferro Alloys Plant (1 X 5MVA SEAF) - 8,320 TPA Ferro-alloys

Coal Washery - 3,30,000 TPA

CPP: - WHRB - 12 MW, AFBC Boiler - 38 MW Power

Area:

219 Acres

11 New/Expansion/Modernizat New

ion Proposal Number MoEF EC granted by MoEF&CC vide File No. J-11011/770/2008-IA II (I)

CC file number (previous EC) dated 31-12-2010. Attached as Annexure 3.

Existing Capacity /area etc Existing Capacity – Nil (Greenfield project)

Uploaded EC Letter

12 Category of project i.e. 'A' or A

'B'

1

M/s. Narsingh Ispat Ltd.

Form -I

13 Does it attract the general No

condition? If yes, please

specify

15 Does it attract the specific No

condition?

16 Is there any litigation No.

pending against the project?

17 Nearest railway station Chandil junction Railway Station – 10.2 Km

along with distance in kms

18 Nearest airport along with Ranchi – 79 km

distance in kms

19 Nearest Town/City/District Chandil Town, approx 8.5 km in west direction from the project

Headquarters along with site.

distance in kms Saraikela district head quarter, approx 27 km in South direction

from the project site.

20 Details of alternative sites Not applicable

examined shown on a topo-

sheet

21 Whether part of interlinked No

projects?

22 Whether the proposal No

involves approval/clearance

under the Forest

(Conservation) Act, 1980?

23 Whether the proposal No

involves approval/clearance

under the wildlife

(Protection) Act, 1972?

24 Whether the proposal No

involves approval/clearance

under the C.R.Z

notification,2011?

25 Whether there is any No

Government Order/Policy

relevant/relating to the site?

26 Whether there is any No.

litigation pending against

the project and/or land in

which the project is

proposed to be set up?

27 Project Cost (in lacs) Rs. 76443 Lacs

2

M/s. Narsingh Ispat Ltd.

Form -I

(II) Activity

1. Construction, operation or decommissioning of the Project involving actions, which will cause

physical changes in the locality (topography, land use, changes in water bodies, etc.)

S. No. Information/Checklist Yes / Details thereof (with approximate quantities /rates,

confirmation No wherever possible) with source of information data

1.1 Permanent or temporary change No The land use will be changed to barren land owned by

in land use, land cover or the company to the industrial land.

topography including increase in

intensity of land use (with

respect to local land use plan)

1.2 Clearance of existing land, No No clearing of existing land, vegetation and buildings is

vegetation and buildings? proposed.

1.3 Creation of new land uses? Yes Land use for acquired land has been converted from

barren land to industrial land.

1.4 Pre-construction investigations No Construction has been commenced after pre

e.g. bore houses, soil testing? construction investigations.

1.5 Construction works? Yes Construction of the units proposed under the existing

EC is going on.

1.6 Demolition works? No No demolition work is required. It is greenfield project

on barren land

1.7 Temporary sites used for Yes Workers required are mostly from nearby places.

construction works or housing of Temporary housing is required for management staff /

construction workers? officials during construction activities.

1.8 Above ground buildings, Yes Above ground construction include buildings, sheds,

structures or earthworks roads, temporary sheds etc. cutting, excavation and

including linear structures, cut filling of soil was carried out /being carried out for the

and fill or excavations and fill or equipment installed / being installed. .

excavations

1.9 Underground works including No No mining / tunnelling is involved.

mining or tunneling?

1.10 Reclamation works? No Not required

1.11 Dredging? No Not required

1.12 Offshore structures? No Not required

1.13 Production and manufacturing Yes Production and Manufacturing process:

processes? • Production of Sponge Iron using Coal based DRI Kilns.

• Production of Hot Metal / Pig through Blast Furnaces.

• Production of Liquid steel through Electric Arc

Furnace and Billets in Billet Caster

• Rolling of Billets into TMT Bar & Wire Rod in Rolling

Mills.

• Production of Sinter in Sinter Plant to be used in Blast

Furnace

• Production of Pallets in Pallet Plant for use in Sponge

Iron Plant & Blast Furnace

• Production of Ferro-alloys through 1x5 MVA

Submerged Electric Arc Furnace

1.14 Facilities for storage of goods or Yes Adequate storage facilities for raw material and finished

materials? product are being provided within the proposed project

site.

3

M/s. Narsingh Ispat Ltd.

Form -I

S. No. Information/Checklist Yes / Details thereof (with approximate quantities /rates,

confirmation No wherever possible) with source of information data

1.15 Facilities for treatment or Yes Solid Wastes:

disposal of solid waste or liquid Facilities for treatment and disposal of Solid Wastes:

effluents? 1. Blast Furnace slag shall be granulated and sold to the

Cement Plants

2. Dust from Bag Filters and iron ore fines from Sponge

Iron Plant shall be used in Sinter Plant.

3. Pallet plant and Sinter plant dust shall be recycled

4. Fly-ash shall be given to the Cement Plant

Plant has MoU with Burdwan Super Cement Pvt. Ltd. for

sale of BF granulated slag & fly-ash

Liquid Effluent

No liquid effluent shall be discharged from the plant.

Liquid effluent generated will undergo treatment

before use.

Effluent from DM Plant shall be treated in

Neutralisation Pit. Cooling Tower blowdown water and

Neutralisation pit treated water shall be used for slag

cooling and dust suppression.

1.16 Facilities for long term housing of No No residential facility is envisaged.

operational workers?

1.17 New road, rail or sea traffic No The site is well connected by road. No additional

during construction or construction of road network required except internal

operation? roads.

1.18 New road, rail, air water borne or No Existing facilities are being / shall be utilised.

other transport infrastructure

including new or altered routes

and stations, ports, airports etc.?

1.19 Closure or diversion of existing No There is no proposal for diversion or change in

transport routes or infrastructure transportation routes.

leading to changes in traffic

movements?

1.20 New or diverted transmission No Not envisaged.

lines or pipelines?

1.21 Impoundment, damming, No Not envisaged.

culverting, realignment or other

changes to the hydrology of

watercourses or aquifers?

1.22 Stream crossings? No Not envisaged.

1.23 Abstraction or transfers of water Yes Total make up water required for the project is 5900

from ground or surface waters? KLD.

Source of water: Swarnrekha River (permission for

drawl of 2.75 MCM per annum from Chandil Dam on

Swarnrekha River has been obtained from Water

Resources Department, Govt. of Jharkhand vide letter

No.-2/PMC-164/2007 (Part VI)-443 dated 30.05.2013).

1.24 Changes in water bodies or the No No effluent discharge from the plant

land surface affecting drainage or

run-off?

4

M/s. Narsingh Ispat Ltd.

Form -I

S. No. Information/Checklist Yes / Details thereof (with approximate quantities /rates,

confirmation No wherever possible) with source of information data

1.25 Transport of personnel or Yes The raw materials will be sourced from local market.

materials for construction, They will be transported to the site by road.

operation or decommissioning?

1.26 Long-term dismantling or No No dismantling or decommissioning or restoration

decommissioning or restoration works are involved.

works?

1.27 Ongoing activity during No No decommissioning involve.

decommissioning which could

have an impact on the

environment?

1.28 Influx of people to an area in Yes Presently 500 persons are involved for construction

either temporarily or work. About 1800 persons shall be involved during full

permanently? construction work. During full operational phase about

2000 persons shall be employed.

1.29 Introduction of alien species? No Only native species of flora will be planted wherever

required.

1.30 Loss of native species or genetic No No clearing required.

diversity?

1.31 Any other actions? No Not envisaged

5. Use of Natural resources for construction or operation of the Project (such as land, water,

materials or energy, especially any resources which are non-renewable or in short supply):

S. Information/Checklist Yes/No Details thereof (with approximate quantities /rates,

No. confirmation wherever possible) with source of information data

2.1 Land especially undeveloped yes The land required for the project is 219 Acres. The land use

or agricultural land (ha) land use will be changed to industrial from barren land.

2.2 Water (expected source & Yes Total make up water required for the project is 5900 KLD.

competing users) unit: KLD Source of water: Swarnrekha River (permission obtained

from Water Resources Department, Govt. of Jharkhand

vide letter No.-2/PMC-164/2007 (Part VI)-443 dated

30.05.2013). No competing users.

2.3 Minerals (MT) Yes Minerals in raw materials only. Raw materials (final stage):

Iron Ore - 24960 TPA

Iron Ore fines – 442880 TPA

Coke - 63680 TPA

Coke Breeze – 12800 TPA

Lime Stone – 20480 TPA

Dolomite – 16000 TPA

Quartzite – 1280 TPA

Bentonite – 5760 TPA

Mn Ore – 12480 TPA

Mn Slag – 8320 TPA

Carbon Paste – 208 TPA

Quartz – 2080 TPA

Coal - 640000 TPA

2.4 Construction material – Yes Blast Furnace (Hot Metal), Sinter Plant & BFG based

stone, aggregates, sand /soil Captive Power Plant are installed.

(expected source – MT) Construction material for remaining unit will be sourced

from local manufacturers and suppliers.

5

M/s. Narsingh Ispat Ltd.

Form -I

S. Information/Checklist Yes/No Details thereof (with approximate quantities /rates,

No. confirmation wherever possible) with source of information data

2.5 Forests and timber (source – No Not envisaged.

MT)

2.6 Energy including electricity Yes Power requirement: 57 MW

and fuels (source, Source:

competing users) Unit: fuel Captive Generation - 50 MW

(MT),energy (MW) Jharkhand State Electricity Board – 7 MW

DG Set (2×600 + 2x750) KVA.

Fuel: LDO will be used as fuel for start-up of Kilns, BF Stove

preheating and in DG Set.

2.7 Any other natural resources No Not envisaged.

(use appropriate standard

units)

6. Use, storage, transport, handling or production of substances or materials, which could be

harmful to human health or the environment or raise concerns about actual or perceived risks

to human health

S. No. Information/Checklist Yes/No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

3.1 Use of substances or materials, No No hazardous substances shall be used in the

which are hazardous (as per proposed Integrated Steel Plant.

MSIHC rules) to human health or

the environment (flora, fauna,

and water supplies

3.2 Changes in occurrence of disease No Project activities are not likely to cause changes in

or affect disease vectors (e.g. occurrence of disease or affect disease vectors

insect or water borne diseases)

3.3 Affect the welfare of people e.g. Yes Additional employment opportunity due to

by changing living conditions? operation of the proposed plant. This will be

benefited by direct and indirect employment which

shall improve the living conditions of the people and

also due to socio economic measures taken up by

the proponent.

3.4 Vulnerable groups of people who No Not envisaged.

could be affected by the project

e.g. hospital patients, children,

the elderly etc.

3.5 Any other causes No No other causes.

7. Production of solid wastes during construction or operation or decommissioning (MT/month)

S. No. Information/Checklist Yes/No Details thereof (with approximate quantities /rates,

confirmation wherever possible) with source of information data

4.1 Spoil, overburden or mine No No mine or separation activity.

wastes

4.2 Municipal waste (domestic and Yes Domestic waste shall be treated in Oxidation Pond

or commercial wastes)

4.3 Hazardous wastes (as per Yes No generation of hazardous waste, other than Used

Hazardous Waste Management Oil which will be sold to the authorized recyclers.

Rules)

6

M/s. Narsingh Ispat Ltd.

Form -I

S. No. Information/Checklist Yes/No Details thereof (with approximate quantities /rates,

confirmation wherever possible) with source of information data

4.4 Other industrial process wastes Yes S.N. Type of Waste Quantity Mode of Disposal

in TPA

1 FROM BLAST

FURNACE

• Slag 38,270 Granulated and

sold to cement

units.

• APC Dust 8,320 used in Sinter Plant

2 FROM DRI &

APC SYSTEM

• Dolo Char 57,600 This will be used for

Power Plant.

• Fly Ash 34,560 This will be used for

Bricks / Cement

manufacturing

• APC Dust 69,120 Used in sinter &

pellet plant

3 From Steel

Melting

Section 10,080 This will reused in

• Slag & APC process

Dust

4 Fine Dust from 2,88,00 This will reused in

Pellet Plant process

5 Fine Dust from 1,28,00 This will reused in

Sinter Plant process

6 FROM FERRO

ALLOYS PLANT

• Slag 4,493 Used For Land

Filling

• APC Dust 2,080 reused in process

7 FROM POWER

PLANT & APC

SYSTEM

• Bottom Ash 44,800 Given to brick

manufacturer to be

used as fuel

• Fly Ash 1,07,200 for bricks

Manufacturing &

cement Plant

8 FROM COAL

WASHERY

• Middling 2,39,360 Used in power

plant

• Reject 48,640 sale to Briquette

Manufacturers

9 FROM ROLLING

MILL PLANT

Mill Scale 3,200 Will be used in

Sinter Plant

4.5 Surplus product Yes Pig Iron – 44800 TPA

Sponge Iron – 57600 TPA

Ferro-alloys – 8320 TPA

7

M/s. Narsingh Ispat Ltd.

Form -I

S. No. Information/Checklist Yes/No Details thereof (with approximate quantities /rates,

confirmation wherever possible) with source of information data

4.6 Sewage sludge or other sludge No Shall be treated in ‘Oxidation Pond’

from effluent treatment

4.7 Construction or demolition Yes Construction waste like soil, brick bats, etc. is being

wastes utilized for levelling of land and construction of roads.

4.8 Redundant machinery or No There is no any redundant machinery or equipment.

equipment

4.9 Contaminated soils or other No There is no contamination of soil or any other

materials material

4.10 Agricultural wastes No No agricultural wastes are generated.

4.11 Other solid wastes No There is no other solid waste except the above

mentioned.

8. Release of pollutants or any hazardous, toxic or noxious substances to air(Kg/hr)

S. No Information/Checklist Yes/No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

5.1 Emissions from combustion of Yes Burning of coal in rotary kiln, CPP and coke in blast

fossil fuels from stationary or furnace, Sinter plant, submerged arc furnace etc. will

mobile sources generate emissions.

Emissions levels can be predicted after specifications

from plant suppliers or manufacturers are received.

Other mobile sources are - Raw Material & Product

Trucks, Vehicles used by Visitors and project

personnel

5.2 Emissions from production Yes All the production processes will generate emissions.

processes Iron & steel making with CPP will generate emissions

from burning of coal/coke in the process.

Sintering & Pelletising unit will also generate

emissions from the process.

Coal crushing for coal washery will be a source of

emission.

However with stack heights as per CPCB guidelines

to disperse SO & NOx with an adequately designed

2

APCS will be installed in appropriate sections.

5.3 Emissions from materials Yes Water sprinklers are provided / shall be provided for

handling including storage or suppression of dust at the raw material and

transport production handling points.

5.4 Emissions from construction Yes Working of construction equipment aided with fossil

activities including plant and fuel (diesel) and transportation of construction

equipment material is likely to increase emission of Particulate

Matters, SO and NO

2 x

5.5 Dust or odours from handling of Yes Dust generation as mentioned above. No odour

materials including construction problems.

materials, sewage and waste

5.6 Emissions from incineration of No Not envisaged

waste

5.7 Emissions from burning of waste No Not envisaged

in open air (e.g. slash materials,

construction debris)

5.8 Emissions from any other sources No Not envisaged

8

M/s. Narsingh Ispat Ltd.

Form -I

9. Generation of Noise and Vibration and Emissions of Light and Heat:

S. No Information/Checklist Yes/No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

6.1 From operation of equipment e.g. Yes Noise levels from operation of equipment like TG

engines, ventilation plant, Set shall be kept below 85 dB(A) by proper

crushers abatement measures. In high noise areas like Power

plant & Blast Furnace workers are provided with

personal protective equipments viz. Ear plugs/Ear

muffs etc. for further protection.

6.2 From industrial or similar Yes Noise from industrial process shall be kept below

processes the limit prescribed by CPCB. Noise abatement

measures shall be taken and persons working near

to high noise areas shall be provided with personal

protective equipment viz. Ear plugs/Ear muffs etc.

for further protection.

6.3 From construction or demolition No No construction or demolition activity generating

considerable noise or vibration. Construction

workers are being given personal protective

equipment

6.4 From blasting or piling No Not envisaged.

6.5 From construction or operational Yes The noise generated from construction or

traffic operational traffic shall also be kept within the

prescribed standards by taking necessary measures

like maintenance of vehicles etc.

6.6 From lighting or cooling systems No No noise generation from lighting or cooling system

is envisaged.

6.7 From any other sources No No other source.

7. Risks of contamination of land or water from releases of pollutants into the ground or into

sewers, surface waters, groundwater, coastal waters or the sea:

S. No. Information/Checklist Yes/ No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

7.1 From handling, storage, use or Yes Hazardous wastes (Used Oil) will be suitably

spillage of hazardous materials disposed-off through registered recyclers, as per

Hazardous and Other Wastes (Management &

Transboundary Movement) Rules, 2016 and

subsequent amendments

7.2 From discharge of sewage or No Sewage discharge and domestic discharge shall be

other effluents to water or the treated in Oxidation Pond.

land (expected mode and place of

discharge)

7.3 By deposition of pollutants No All the de dusting units are/will be well connected to

emitted to air into the land or stack of adequate heights. Good engineering

into water practices with adequate pollution control equipment

shall keep emission to minimal. ESP and bag filters

are installed / proposed to keep the emissions within

the prescribed norms. Hence there is not any risk of

contamination of land or water from release of

pollutants.

9

M/s. Narsingh Ispat Ltd.

Form -I

S. No. Information/Checklist Yes/ No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

7.4 From any other sources No Not envisaged

7.5 Is there a risk of long term build- No Not envisaged.

up of pollutants in the

environment from these sources?

8. Risk of accidents during construction or operation of the Project, which could affect human

health or the environment

S. No. Information/Checklist Yes/ No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

8.1 From explosions, spillages, fires No All safety rules as laid down by concerned

etc. from storage, handling, use Authorities are been complied. No hazardous

or production of hazardous substances is generated or used in the process.

substances From any other

causes

8.2 From any other causes No Not envisaged.

8.3 Could the project be affected by No No such event is known to have occurred in the

natural disasters causing area. Area falls under Seismic Zone II.

environmental damage (e.g.

floods, earthquakes, landslides,

cloudburst etc)?

9. Factors which should be considered (such as consequential development) which could lead to

environmental effects or the potential for cumulative impacts with other existing or planned

activities in the locality

S. No. Information/Checklist Yes/ No Details thereof (with approximate quantities

confirmation /rates, wherever possible) with source of

information data

9.1 Lead to development of Yes Supporting facilities like roads are available near to

supporting facilities, ancillary the project site. Approach roads and roads inside the

development or development plant shall be developed. Facilities for power supply,

stimulated by the project which waste water treatment etc. shall be developed

could have impact on the No housing facility considered in the project

environment e.g.: Extractive and supply industries will be developed,

• Supporting infrastructure hence the project will have a positive effect and shall

(roads, power supply, waste enhanced the growth of the region.

or waste water treatment,

etc.)

• housing development

• extractive industries

• supply industries

• Other

9.2 Lead to after-use of the site, No The plant will be installed, properly managed and

which could have an impact on proper green belt which has a beneficial impact on

the environment the environment.

9.3 Set a precedent for later Yes As new technology will be installed, the technology

developments enables energy efficiency and process optimisation

10

Description:Narsingh Ispat Limited at Village Khunti, Kandra Road, P.O.. Chandil, District Saraikela- kharswan, Jharkhand. 2. Project Sector. Industrial Projects-