Table Of ContentPrevious Page

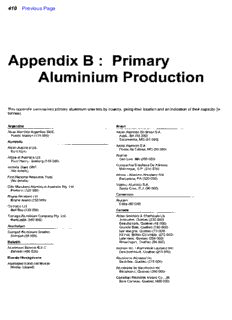

Appendix B : Primary

Aluminium Production

This appendix summarises primary aluminium smelters by country, giving their location and an indication of their capacity (in

tonnes).

Argentina Brazil

Aluar Aluminio Argentine SAIC Alcan Aluminio Do Brasil S.A.

Puerto Madryn (175 000) Aratu, BA (58 000)

Saramenha, MG (51 000)

Australia

Alcoa Aluminio S.A.

Alcan Australia Ltd.

Pocos de Caldas, MG (90 000)

Kurri Kurri

Alumar

Alcoa of Australia Ltd.

Sao Luis, MA (330 000)

Point Henry, Geelong (185 000)

Companhia Brasileira De Aliminio

Victoria State GMT

Mairinique, S. P. (215000)

(No details)

Albras - Aluminio Brasiliero S/A

First National Resource Trust

Barcarena, PA (320 000)

(No details)

Valesul Aluminio S.A.

Citic Marubeni Aluminium Australia Pty. Ltd.

Santa Cruz, RJ. (90 000)

Portland (320 000)

Cameroon

Boyne Smelters Ltd.

Boyne Island (230 000) Alucam

Edea (80 000)

Comalco Ltd.

Bell Bay (120 000) Canada

Tomago Aluminium Company Pty. Ltd. Alcan Smelters & Chemicals Ltd:

Newcastle (380 000) Jonquiere, Quebec (232 000)

Beauharnois, Quebec (48 000)

Azerbaijan Grande Baie Quebec (180 000)

T

Sumgait Aluminium Smelter Isle Maligne, Quebec (73 000)

Sumgait (58 000) Kitimat, British Columbia. (272 000)

Laterriere, Quebec (204 000)

Bahrein Shawinigan, Quebec (84 000)

Aluminium Bahrein B.S.C. Alumax Inc. / Aluminerie Lauralco Inc.

Bahrein (460 000) Deschambault, Quebec (215 000)

Bosnia-Herzegovena Aluminerie Alouette Inc.

Sept-lies, Quebec (21 5 000)

Aluminjski Kombinat Mostar

Mostar (closed) Aluminerie de Becancour Inc.

Becancour, Quebec (360 000)

Canadian Reynolds Metals Co. Ltd.

Baie Comeau, Quebec (400 000)

China (PRC) Ghana

China National NonFerrous Metals Industry Corp: Volta Aluminium Co. Ltd.

Bailianhe Aluminium Plant (5 000) Tema (200 000)

Baiyin Aluminium Plant (50 000)

Greece

Baoding Aluminium Factory (2 500)

Baotou Aluminium Smelter (70 000) Aluminium de Grece

Changsha Aluminium Factory (14 000) Distomon (150000)

Chongqing Aluminium Factory (11 000)

Hungary

Fushun Aluminium Plant (100 000)

Gansu Provincial Aluminium Co. (25 000) Hungalu-Hungarian Aluminium Corp.

Guangxi Desheng Aluminium Plant (7 000) lnota (35 000)

Guizhou Aluminium Plant (160 000)

Iceland

Hanzhong Aluminium Plant (5 000)

Hebei Matuo Aluminium Plant (12 000) Icelandic Aluminium Co. Ltd.

Hefei Aluminium Smelter (10 000) Straumsvik

Hejin Longmen Electrolytic (12 000)

India

Hubei Aluminium Plant (15 000)

Hunjiang Aluminium Plant (15 000) Bahrat Aluminium Co. Ltd.

Jiaozuo Aluminium Plant (15 000) Korba(IOOOOO)

Jiamusi Aluminium Factory (5 000)

Hindalco Industries Ltd.

Kunming Aluminium Plant (30 000)

Renukoot(150000)

Lanzhou Aluminium Plant (25 000)

Liancheng Aluminium Plant (85 000) Indian Aluminium Co. Ltd.

Longxi Aluminium Plant (10 000) Alupuram (20 000)

Nanping Aluminium Works (24 000) Hirakud (24 000)

Panshi Aluminium Factory (15 000) Belgaum (73 000)

PingguoAluminium Industry Co. (100 000)

Pingyang Aluminium Plant (15 000) National Aluminium Co. Ltd.

Qinghai Aluminium Smelter (100 000) Angul(218000)

Qingtongxia Aluminium Plant (82 000)

Indonesia

Quzhou Chemical Corp. (13 000)

Sanmanxia Aluminium Plant (30 000) PT. Indonesia Asahan Aluminium

Shandong Aluminium Industry Co. (35 000) Kuala Tanjung (225 000)

Shijiazhuang Aluminium Plant (15 000)

Iran

Taiyuan Aluminium Plant (15 000)

Tongchuan Aluminium Plant (15 000) IRALCO - Iranian Aluminium Company

Tongren Aluminium Factory (5 000) Arak(120000)

Tongshun Aluminium Plant (10 000)

Italy

Wulumiqi Aluminium Smelter (22 000)

Xiangxiang Aluminium Plant (14 000) Alumix Spa

Xiezhou Aluminium Plant (15 000) Fusina(13000)

Xuzhou Aluminium Works (13 000) Porto Vesme( 130 000)

Yongcheng Aluminium Plant (3 000)

Japan

Zhejiang Aluminium Co. (25 000)

Zhengzhou Aluminium Plant (32 000) Nippon Light Metal Co. Ltd.

Zibo Aluminium Plant (9 000) Kambara (20 000)

Zunyi Aluminium Plant (14 000)

Mexico

Croatia

Aluminio y Derivados de Veracruz S.A. de C.V.

TLM Sibenik Veracruz (66 000)

Sibenik (closed)

Netherlands

Egypt Aluminium Delfzijl

Delfzijl (97 000)

The Aluminium Company of Egypt

NagHammadi(180000) Pechiney Nederland N.V.

Vlissingen(170000)

France

New Zealand

Pechiney

Auzat (44 000) New Zealand Aluminium Smelters Ltd.

Dunkerque(215000) Bluff (259 000)

St. Jean de Maurienne (120 000)

Nigeria

Lannemezan (44 000)

Venthon (31 000) Aluminium Smelter Co. of Nigeria

lkotAbasi(90000)

Germany

Norway

Hamburger Aluminium - Werk GMBH

Hamburg (115 000) Hydro Aluminium A.S.

Ardal (265 000)

Hoogovens Aluminium Huttenwerk Voerde GMBH Sunndalsora (140000)

Voerde (80 000) Hoyanger (65 000)

Karmoy (220 000)

Aluminium Essen GMBH

Essen (135 000) Elkem Aluminium ANS

Lista (80 000)

VAW Aluminium AG

Mosjoen(115000)

Norf(210000)

Stade (68 000) SOR - Norge Aluminium A/S

Tbging (85 000) Husnes (78 000)

Poland Tadjikistan

Konin Aluminium Works Tadjik Aluminium Smelter - TAZ

Maliniec Smelter (55 000) Regar(517000)

Romania Turkey

Slatina Aluminium Working Enterprise Etibank Alumunyum Co. Ltd.

Slatina (265 000) Muessesesi Mudurlugu Seydisehir (60 000)

Russian Federation Ukraine

AO Bogoslovsk Aluminium Smelter - BAZ Dnieper Aluminium Smelter - DAZ

Bogoslovsk(158000) Zaporozhye (108000)

AO Bratsk Aluminium Plant - BrAZ United Arab Emirates

Bratsk (809 000)

Dubai Aluminium Co. Ltd.

AO Irkutsk Aluminium Plant - IrkAZ Jebel AIi (240 000)

Irkutsk (255 000)

United Kingdom

AO Uralsk Aluminium Smelter - UAZ

Anglesey Aluminium Ltd.

Ural (67 000)

Holyhead (124000)

AO Kandalaksha Aluminium Smelter

British Alcan Aluminium PIc.

Kandalaksha (63 000)

Kinlochleven(11 000)

AO Krasnoyarsk Aluminium Plant - KrZA Lochaber (38 000)

Krasnoyarsk (749 000) Lynemouth(135000)

AO Nadvoytsy Aluminium Smelter United States of America

Nadvoytsy (73 000)

Alcan Aluminum Corporation

AO Novokuznetsk Aluminium Smelter - NkAZ Sebree, Kentucky (163 000)

Novokuznetsk (284 000)

Alumax Inc.:

AO Volgograd Aluminium Smelter- VgAZ Bellingham, Washington (270 000)

Volgograd (141 000) Frederick, Maryland (175 000)

Mount Holly, South Carolina (181 000)

AO Volkhov Aluminium Smelter - VAZ

Volkhov (20 000) ALCOA - Aluminum Company of America

Alcoa, Tennessee (200 000)

AO Sayansk Aluminium Smelter - SaAZ Badin, North Carolina (115 000)

Sayansk (274 000) Evansville, Indiana (270 000)

Massena, New York (127 000)

Serbia & Montenegro

Rockdale, Texas (315 000)

DP Kombinat Aluminijuma Wentchee, Washington (265 000)

Podgorica (120000)

Columbia Aluminum Corporation

Slovak Republic Goldendale, Washington (168 000)

ZSNP Ziar Nad Hronom Columbia Falls Aluminum Company

Ziar nad Hronom (65 000) Columbia Falls, Montana (168 000)

Slovenia Kaiser Aluminum & Chemical Corp.

Mead, Washington (200 000)

Unial Tovarna Glinice in Aluminija

Tacoma, Washington (73 000)

Kidrecevo (75 000)

NSA (Division of Southwire)

South Africa

Hawesville, Kentucky (186 000)

Alusaf Ltd.:

Noranda Aluminum Inc.

Richards Bay (172 000)

New Madrid, Missouri (204 000)

Hillside (began 1995)

Northwest Aluminum Company

Spain

The Dalles, Oregon (82 000)

Aluminio Espanol S.A.

Ormet Corporation

San Ciprian (190000)

Hannibal, Ohio (245 000)

lndustria Espanola Del Aluminio S.A.

Ravenswood Aluminum Corp.

Aviles (40 000)

Ravenswood, West Virginia (166 000)

La Coruna (78 000)

Reynolds Metals Company

Surinam

Longview, Washington (204 000)

Suriname Aluminium Company Massena, New York (123 000)

Paranam (30 000) Troutdale, Oregon (121 000)

Sweden Vanalco Inc.

Vancouver, Washington (110 000)

GA Metall AB

Sundsvall(IOOOOO) Venezuela

Switzerland Aluminio Del Caroni S.A.

Puerto Ordaz (220 000)

Alusuisse Aluminium Ltd.

Steg (24 000) lndustria Venezolana De Aluminio C.A.

Puerto Ordaz (441 000)

Appendix C : Glossary

This appendix is a compilation of terms commonly used in the light metal industry. They are a mixture of those used to

describe the materials themselves (metallurgical) and their processing, production and characteristics.

A Bend Test - Application of a force to the central region of a

test bar that is supported on each end to determine the

Age Hardening - A special dispersion-strengthening heat resistance of the material to a static or slowly applied load.

treatment. By solution treatment, quenching, and Typically used for brittle materials. May be 3- or 4-point

ageing, a coherent precipitate can be formed that bend. In 4-point bending a pair of rollers is used to apply

provides a substantial strengthening effect. Also force to the central section - with the advantage that the

known as precipitation hardening. resulting stress in the test sample is uniform between

them.

Alloy - Combination of metals and other elements giving

improved properties over the pure metal. Bolt Stock - Round bar or wire suitable for manufacturing

bolts by cold heading.

Annealing - A heat treatment used to eliminate part or all

of the effects of cold working. Used to soften alloys

that have been hardened by cold work or by C

heat-treatment; often used to enable a metal to be cold

worked. To avoid excessive grain growth the metal Castability - The ease with which a metal flows into a mould

should be heated to the annealing temperature as to make a casting without producing defects or requiring

rapidly as possible, and held at temperature only as unusual or expensive techniques to prevent casting

long as necessary. Excessive grain growth reduces problems.

the mechanical properties of the metal and may give a

Cavity Shrinkage - A large void within a casting caused by

rough 'orange-peel' effect on the surface when the

the volume contraction that occurs during solidification.

material is subsequently worked. Annealing

Chill Zone - A region of small, randomly oriented grains that

temperatures depend on the particular alloy type, i.e.

those which age-harden at room temperature may forms rapidly at the surface of a casting as a result of

require a more complicated annealing schedule. Local heterogeneous nucleation.

annealing can be done by, for example, a blow-torch Circumscribing Circle - In extrusion - that circle which

on work-hardened, non-heatreatable alloys. For heat- defines the largest possible cross-section for the extruded

treated alloys, it impares the heat-treated properties. product (maximum die dimensions).

Artificial Ageing - Reheating a solution-treated and Coefficient of Thermal Expansion (linear) - Describes the

quenched alloy to a temperature below the solvus in amount by which a unit length of a material changes when

order to provide the thermal energy required for a its temperature changes by one degree Celsius (may vary

precipitate to form. For heat-treatable alloys that slowly with temperature range).

harden at normal temperatures, the rate can be Coherent Precipitate - A precipitate whose crystal structure

increased by heating the solution heat-treated alloy in and atomic arrangement are continuous with the matrix

the range 100-20O0C for a shorter period. The time at from which the precipitate formed. In effect a small region

the specified temperature depends on the alloy, but of enrichment by alloying elements, producing local strain

may be typically 2 to 30 hours. Maximum strength is (distortion) of the crystal lattice. This hinders the

generally attained by prolonged ageing at low movement of dislocations and provides excellent

temperature rather than by rapid ageing at high

strengthening.

temperature.

Cold Rolled Plate - A cold rolled product of rectangular

section over 6mm thick, supplied flat in a variety of

B conditions, with better surface finish, and normally to

closer tolerances, than hot rolled plate.

Bar - A round, rectangular or polygonal solid section

supplied in straight lengths. The term is generally

applied to materials of not less than 6mm diameter (or

minor dimensions).

Cold Working - Deformation of a metal below the Eutectoid - A three-phase reaction in which one solid phase

recrystallisation temperature. During cold working, transforms to two different solid phases.

dislocations increase in number and become

Extruded Round Tube - A circular hollow extrusion of

entangled (pinned), strengthening the metal. Solution

uniform wall thickness.

Heat-Treated Alloys: that age naturally at room

Extrusion - A deformation processing technique by which a

temperature should be worked within 2 hours of

material is pushed through an opening in a die.

quenching (30 mins for severe forming operations), i.e.

before age-hardening reaches any significant level.

Alloys can be re-solution heat-treated in order to F

complete the forming operation. But: repeated solution

treating can reduce the mechanical properties attained Fatigue Life - The number of stress cycles before a material

by natural or artificial ageing. fails by fatigue.

Columnar Zone - A region of elongated grains having a Fatigue Limit (Endurance limit) - The stress below which a

preferred orientation. These form as a result of material will not fail in a fatigue test.

competitive growth during the solidification of a

Fatigue strength - The stress required to cause failure by

casting, generally growing in at right-angles to the

fatigue in a given number of cycles; normally several

surface of the casting.

hundred million cycles.

Composites - A group of materials formed from mixtures

Fatigue Test - Measures the resistance of a material to failure

of metals, ceramics, or polymers, combined in such a

when a cyclic stress below the yield strength is applied.

manner that unusual combinations of properties are

obtained. These properties can be deliberately highly Fibre Metal Laminate (FML) - A proprietory sheet material

directional, i.e. anisotropic. consisting of thin metal sheets bonded with an adhesive

layer which contains a continuous fibre reinforcement.

Coring - Microsegregation within a grain.

Fibre Texture - A preferred orientation of grains obtained

Creep Rate - The rate at which a material deforms when

during the drawing process. Grains are elongated along

a constant stress is applied at a high temperature.

the drawing direction, causing anisotropic behaviour.

Creep Test - Measures the resistance of a material to

Flexural Modulus - The modulus of elasticity resulting from a

deformation and failure when subjected to a static load

bend test, the slope of the stress-strain curve.

below the yield strength at an elevated temperature.

Flexural Strength - The stress required to fracture a

Crystal Structure - The lattice arrangement of the atoms

specimen in a bend test. Also called the modulus of

in a material.

rupture (MOR).

Fluidity - The ability of liquid metal to fill a mould cavity

D

without premature solidification.

Foil - A cold rolled product of rectangular section and

Dendrite - The structure formed by a solid growing along

thickness not greater than 0.2 mm.

crystallographic directions when an undercooled liquid

nucleates. Forging Stock - Cast, extruded or rolled starting material for

the production of forgings.

Density - Mass per unit volume of a material, often

expressed in units of kg.m3 or g.cm3. Fracture Mechanics - The study of a material's ability to

withstand stress in the presence of a defect.

Dispersion Strengthening - Increasing the strength of a

Fracture Toughnesss - The resistance of a material to failure

material by incorporating finely divided particles (often

oxides or carbides). By proper control of the size, in the presence of a defect.

shape, amount, and individual properties of the Freezing Range - The temperature difference between the

phases, excellent combinations of properties can be liquidus and solidus temperatures.

obtained. Fusion Welding - Joining processes in which a portion of the

Drawing - A deformation processing technique by which a materials must melt in order to achieve good bonding.

material is reduced in cross-section by being pulled Fusion Zone - The portion of a weld heated to produce all

through an opening in a die.

liquid during the welding process. Solidification of the

Drawn Tube - A hollow product of uniform wall thickness fusion zone provides joining.

produced by cold drawing from tube bloom.

Ductility - The ability of a material to be permanently G

deformed without fracture when a force is applied.

Gas Porosity - Gas bubbles trapped within a casting during

E solidification. Occurs because of the lower solubility of gas

in the solid compared with that in the liquid.

Elastic Deformation - Deformation of the material that is Grain Refinement - The multiplication and equalisation of

recovered when the applied load is removed. grains in a cast microstructure.

Elongation (percentage) - The total percentage increase

in the length of a specimen during a tensile test. H

Epitaxial growth - Growth of a liquid onto an existing

solid material without the need for nucleation. Hall-Heroult Process - An electrolytic process used for

Eutectic - A three-phase reaction in which one liquid extraction of aluminium from the ore.

phase solidifies to produce two solid phases.

Eutectic microconstituent - A characteristic mixture of

two phases formed as a result of the eutectic reaction.

Hardness Test - Measures the resistance of a material to lntermetallic Compound - A chemical compound formed by

penetration by an object. Common hardness tests for two or more metals, having a particular composition and

light-alloys are Brinell (HB), Rockwell (R + scale letter) structure. Nonstoichiometric: A variable ratio of the

and Vickers (VPN). components present in the compound. Stoichiometric: A

Heat Treatment - A light alloy is generally said to be in a fixed ratio of the components present in the compound.

heat-treated condition when it has been subjected to Also called an intermediate solid solution.

one or both of the following: (a) Heating for a

prescribed period at a prescribed temperature, then L

cooling rapidly from this temperature, usually by

quenching (solution heat-treatment); (b) Ageing, either

Limited Solubility - When there is a limit to the amount of a

spontaneously at ordinary temperatures (natural

solute material which can be dissolved in the solvent

ageing) or by heating for a prescribed period at a

material.

prescribed low temperature (artificial ageing). The

Liquidus - The temperature at which the first solid begins to

application of both solution heat-treatment and artificial

form within a cooling liquid.

ageing is often termed 'fully heat treated'. This

situation may be more complex for some multi-phase

titanium alloy compositions. M

Heat-affected Zone (HAZ) - The area adjacent to a weld

that is heated above some critical temperature during Macrosegregation - Variations in composition of a material

the welding process. This results in changes in the over large distances caused by nonequilibrium

structure, such as grain growth or recrystallisation, and solidification.

alteration in properties. Macrostructure - Obvious features of a material's structure

Hollow Section - An extruded shape other than round, (visible without the aid of a microscope).

the cross-section of which completely encloses a void Matrix - The continuous solid phase in a complex

or voids. microstructure. Alloys: precipitates can form within the

Homogenisation - A heat treatment used to reduce the matrix. Composites: the phase in which the reinforcement

microsegregation caused during non equilibrium is embedded.

solidification. Mechanical Properties - Measurable characteristics of a

Hooke's Law - The relationship between stress and strain material that describe the resistance to applied forces,

in the elastic portion of the stress-strain curve. e.g. tensile, compressive, impact , fatigue, etc.

Hot Rolled Plate - A hot rolled product of rectangular Metal matrix Composite - A material which consists of a

section, > 6mm thick, supplied flat in a variety of reinforcement phase embedded in a metal alloy. The

conditions but generally with less control of surface reinforcements can be particles or fibres.

finish and tolerance than applies to sheet. Microsegregation - Compositional differences in a material

Hot Shortness - Melting of a lower melting point non over short distances caused by non equilibrium

equilibrium phase that forms by segregation, even solidification.

though the temperature is below the equilibrium Modification - Addition of alloying elements which change the

solidus temperature. microstructure of the eutectic microconstituent, e.g. Na or

Hot Working - Deformation of a metal above the Sr in AI-Si alloys.

recrystallisation temperature. During hot working, only Modulus of Elasticity (Young's modulus) - The slope of the

the shape of the metal changes; the strength remains stress-strain curve in the elastic region.

relatively unchanged because no strain hardening

Modulus of Resilience - The maximum elastic energy

occurs.

absorbed by a material when a load is applied.

Hypereutectic Alloys - Alloys above the eutectic

composition but containing at least some eutectic

N

microconstituent.

Hypoeutectic Alloys - Alloys below the eutectic

Natural ageing - Strengthening mechanism where a

composition but containing at least some eutectic

coherent precipitate forms from a solution-treated and

microconstituent.

quenched, age-hardenable alloy when held at room

temperature.

I

Non Ferrous alloy - An alloy based on some metal other than

iron.

Impact Energy - The energy required to fracture a

Notch sensitivity - Measures the deleterious effect of a

standard specimen when the load is applied rapidly.

notch, scratch, or other imperfection on a material's

Impact Test - Measures the ability of a material to absorb properties, such as toughness or fatigue resistance.

a rapidly applied load. Common tests are Charpy and

Izod.

P

Ingot Structure - The macrostructure, including the chill

zone, columnar zone, and equiaxed zone.

Phase - A material having the same composition, structure,

Inoculation - The addition of heterogeneous nuclei in a and properties everywhere under equilibrium conditions. A

controlled manner to increase the number of grains in distinctive part of a microstructure.

a casting.

Phase Diagram - Diagrams of temperature and Recrystallisation - A medium-temperature annealing heat

composition showing the phases and their boundaries. treatment designed to eliminate all of the effects of the

Unary: one component. Binary: with two components; strain hardening produced during cold working. The grain

Ternary: 3D plot of three components; lsomorphous: structure is altered as the temperature is sufficient for new

displays unlimited solid solubility. Isothermal plot: grains to nucleate and grow..

horizontal section through a ternary phase diagram.

Reduction in Area (RoA) - Total decrease in the

Physical Properties - Describe characteristics such as cross-sectional area of a specimen during the tensile test,

colour, elasticity, electrical or thermal conductivity, expressed as a percentage.

magnetism, and optical behaviour which are generally

Refrigeration - Used to delay the onset of age-hardening of

not influenced by forces acting on a material. solution heat-treated material; usually between -6 to -1O0C.

Pipe Shrinkage - A large conical-shaped void at the A work piece may be refrigerated for production control

surface of a casting caused by the volume contraction purposes. Avoids the start of natural age hardening.

that occurs during solidification.

Re-Heat Treatment - Alloys which have been incorrectly

Plastic Deformation - The permanent deformation of a heat-treated can be re-solution treated and precipitation

material when a load is applied and then removed. treated to restore properties. If solution treatment has been

Poisson's Ratio - The ratio between the lateral and carried out at too high a temperature, the condition cannot

longitudinal strains during elastic deformation. be remedied by reheat treatment. Note: Clad material

should not be re-heat-treated.

Pouring Temperature - The temperature of the metal

when it is poured into a mould during casting. Residual Stresses - Stresses in a material produced during

processing which, rather than causing deformation of the

Precipitate - A solid phase that forms from the original

material, remain stored in the structure. Internal stresses

matrix phase when the solubility limit is exceeded.

can arise from quenching or in castings by solidification in

Control of the formation of precipitates produces

the mould. Castings have stresses set up by different

optimum dispersion strengthening.

cooling rates, consequently different shrinkage rates. They

Proof Strength - The yield strength (obtained graphically) are more significant in large castings and those with

which is the stress corresponding to a small specified adjacent thick and thin sections. When a metal has

amount of plastic deformation. Proof stresses are solidified, these stresses are in a state of equilibrium, so

commonly quoted as 0.2%PS, or occasionally that the dimensions of a casting will not alter under normal

0.1%PS. conditions. Machining or use at high temperature can

disturb the equilibrium state and cause distortion;

particularly undesirable for close tolerance items.

Q

Rivet Stock - Round bar or wire suitable for the manufacture

Quenching - Means of reducing the temperature after of rivets.

heat-treatment and retaining the required material Rupture Time - The time required for a specimen to fail by

structure. The quench media may be water (hot or creep at a particular temperature and stress.

cold), water-jet/spray, oil, forced-air, polymer solutions.

Wrought: Care is required that shaped components

S

(long and thin) and sheet materials do not distort

unacceptably. Castings & Forgings: Care may be

Screw Stock - Round bar or wire suitable for the manufacture

necessary owing to stresses occurring from different

rates of cooling in sections of different thickness. of screws by cold heading.

Normally hot-water quenched. Note: oil quench cannot Segregation - Composition differences in a material, often

be used where the alloy has been heated in a caused by insufficient time for diffusion during

salt-bath. There is fire risk when hot nitrate comes into solidification.

contact with oil. Shape-memory Effect - The ability of certain materials to

develop microstructures that, after being deformed, can

R return the material to its initial shape when heated.

Shate - Rolled material, normally between 4-6mm thickness.

Rapid Solidification Processing (RSP) - Methods used Intermediate between sheet and plate.

to produce unique material compositions and Sheet - A cold rolled product of rectangular section, over 0.2

structures by using unusually high cooling rates during mm, but not exceeding 6 mm thick; supplied flat in all

solidification. Powders produced by RSP (of which available conditions. It may be produced as strip and then

there are several techniques) can have alloying flattened and cut to length.

element levels higher than that possible by

Sheet Texture - Preferred orientation of grains obtained

conventional metallurgy (segregation effects in ingot).

during the rolling process.

They may also contain dispersed phases of very fine

ceramic particles (oxide dispersion strengthened Shot Peening - Introducing compressive residual stresses

'ODS' alloys), or combined with particulate into the surface of a part by bombarding the surface with

reinforcements for metal matrix composites. balls to produce localised plastic deformation. Residual

compressive stresses may improve the fatigue resistance.

Recovery - A low-temperature annealing heat treatment

designed to eliminate residual stresses introduced Solid Solution - A solid phase of uniform composition

during deformation without reducing the strength of the containing a more than one element.

cold-worked material. Solidus - The temperature below which all liquid has

completely solidified.

Solubility - The amount of one material that will completely

dissolve in a second without becoming a second phase.

Solution Heat-treatment - The first step in the Temper Designation - A shorthand notation using letters and

age-hardening heat treatment. The alloy is heated numbers to describe the processing of an alloy. H tempers

above the solvus temperature to dissolve any second refer to cold-worked alloys; T tempers refer to

phases and to produce a homogeneous single-phase age-hardening treatments. The numbers following the

structure. (1) initially increases the ductility of alloys letter denote the precise steps in achieving the temper.

and enables a certain amount of cold work to be

Tensile Strength - Stress that corresponds to the maximum

applied before natural ageing starts to harden the

load in a tensile test.

metal. (2) increases strength but not to the level

Tensile Test - Measures the response of a material to a

achieved by subsequent artificial ageing. Temperature:

slowly applied uniaxial tensile force. Provides values for

Maximum property improvement is attained when the

yield strength (YS); proof stress (PS) for a given

solution heat-treatment is within the specified

permanent plastic deformation offset, e.g. 0.2 or 0.1%;

temperature range: too low, mechanical properties will

tensile strength (UTS); modulus of elasticity (E); ductility

be below requirements; too high there is a risk of

cracking due to overheating. Time: Varies with loading (El%).

and spacing of the workload. Care is needed with Clad Thermal Conductivity - Measures the rate at which heat is

materials because the alloying constituents tend to transferred through a material.

diffuse from the core into the cladding, so affecting Thermal Shock - Failure of a material caused by stresses

corrosion resistance. In general, cast aluminium alloys introduced by rapid changes in temperature.

need to be solution heat-treated for longer periods

Thermal Stresses - Stresses introduced into a material by

than wrought aluminium alloys.

differences in the amount of expansion or contraction that

Specific Strength - The ratio of strength to density. Also occur because of the temperature change.

called strength-to-weight ratio.

Thixocasting (Rheocasting) - A process by which a material

Stabilising - The relief of residual internal stresses by is stirred during solidification. Produces a semi-solid (partly

heating to a predetermined temperature, then cooling liquid, partly solid) structure that behaves as a solid when

slowly. Stabilising is more widely applied to castings no external force is applied but flows as a liquid under

than wrought products. Temperature: depends on the pressure. Used to produce billet materials for subsequent

history of the metal and its intended service use. [See processing, e.g. die-casting.

also: Residual stresses].

Total Solidification Time - The time required for a casting to

Stiffness - A qualitative measure of the elastic solidify completely after it has been poured.

deformation produced in a material, e.g. a stiff material

Toughness - A qualitative measure of the impact resistance

has a high modulus of elasticity.

of a material; high resistance = tough.

Strain Hardening - Strengthening of a material by

increasing the number of dislocations with

U

deformation, or cold working. Also known as work

hardening.

Undercooling - The temperature to which the liquid metal

Strain Rate - The rate at which a material is deformed. A

must cool below the equilibrium freezing temperature

material may behave much differently if it is slowly

before nucleation occurs.

pressed into a shape rather than formed rapidly into a

shape by an impact, [See also: Superplasticity].

Strain-hardening Coefficient - The effect that strain has W

on the resulting strength of the material. A material

with a high strain-hardening coefficient obtains high Widmanstatten Structure - Precipitation of a second phase

strength with only small amounts of deformation or from the matrix when there is a fixed crystallographic

strain. relationship between the precipitate and matrix crystal

structures. Often needlelike or platelike structures. A

Strength-to-weight Ratio - The strength of a material

microstructural feature of some titanium alloys.

divided by its density; materials with a high strength-to-

weight ratio are strong but lightweight. Wire - A round, square or regular polygonal solid section of

not more than 10 mm diameter or width across flats

Stress Relief Anneal - The recovery stage of the

produced by drawing; usually supplied in coil.

annealing heat treatment, during which residual

stresses are relieved without reducing the mechanical Work Hardening - Strain hardening or cold working.

properties of the material. Wrought Alloys - Alloys that are shaped by a deformation

Strip - A cold rolled product of rectangular section process, e.g. extrusion, rolling, drawing, etc.

supplied in coil, over 0.2 mm thick, but not exceeding 3

mm thick.

Y

Superplasticity - The ability of a material to deform

uniformly by an exceptionally large amount without Yield Strength - The stress applied to a material that just

fracture (often several hundred percent). Careful causes permanent plastic deformation.

control of temperature, grain size, and strain rate are

required for a material to behave in a superplastic

manner. Some light-alloys are specifically denoted as

superplastic forming (SPF) grades.

T

Temper- describes the condition of a material, i.e. its

history of thermal or cold working. The temper has a

strong influence on the alloy characteristics.

Appendix D :

Multilingual Vocabulary

English French German Italian Spanish

Adhesion Adherance Haftvermogen Aderenza Adherencia

lncrudimento per deformazione

Age hardening Durcissement structural Aushartung Endurecimiento estructural

a freddo

Air quenching Trempe a I'air Luftabschrecken Tempra aH'aria Temple al aire

All-over marking Marquage continu Rollstempelung Marchiatura in continue Marcado continue

Alloy Alliage Legierung Lega Aleacion

Alloying element Element d'addition Legierungselement Effetto di pressa Elemento de adicion

Aluminium Aluminium Aluminium Alluminio Aluminio

Aluminium alloy Alliage d'aluminium Aluminiumlegierung Lega di alluminio Aleacion de aluminio

Aluminium refined Aluminium raffine Reinstaluminium Alluminio raffinato Aluminio refinado

Anisotropy Anisotropie Anisotropie Anisotropia Anisotropia

Annealing Recuit Gluhung Ricotto Recocido

Anodising Anodisation Anodisation Anodizzazione Anodizacion

Artificial ageing Revenu Warmauslagerung Rinvenimento Revenido

Artificially aged Etat revenu Warmausgehartet State rinvenuto Estado revenido

As-quenched condition Brut de trempe Abgeschreckt Grezzo di tempra Bruto de temple

As-quenched condition Trempe fraiche Frische Abschreckhartung Tempra fresca Temple al agua

As-quenched temper Etat trempe Abgeschreckter Zustand Stato temprato Estado templado

Bar, Rod Barre Stab, Stange Barra Barra

Bend radius Rayon de pliage Biegeradius Raggio di piegatura Radio de plegado

Bend test Essai de pliage Biegeversuch Prova di piegatura Ensayo de plegado

Bending Cintrage Biegen Curvatura Doblado

Bevel welding bead Chanfrein (de soudure) Abschragung Smusso (di saldatura) Chaflan de soldadura

Blackening Noircissement Schwarzung, Triibung Annerimento Ennegrecimiento

Blank Flan Zuschnitt Flangia Pieza en bruto

Blankholder Serre flan Niederhalter Premilamiera Pisador

Blanking Decoupage sous presse Stanzen Tag Ib Corte a Ia prensa

Blister Soufflure Blase Soffiatura Burbuja

Bonding Collage Kleben lncollatura Pegado

Bow Fleche longitudinaie Langsdurchbiegung Freccia longitudinaie Flecha longitudinal

Brazing Brasage fort Hartloten Brasatura Soldadura fuerte

Brazing sheet ToIe pour brasure Lotblech Lastro per brasatura Chapa para soldar

Brittleness Fragilite Sprodigke Fragilita Fragilidad

Broken edge Bord irregulier Kantenrisse Bordo irregolare Canto irregular

Brushing Brassage Biirsten Spazzolatura Cepillado

Buckling Flambement Knicken lngobbamento Flameado

Buffing Polissage au disque Schwabbeln Pulitura con disco Pulido al disco

Burr Bavure Grat Bava Rebabas

Can stock ToIe pour boitage Dosenblech Lastra per lattine Chapa para latas de bebida

Cast Coulee Abgufi Lavorato Colada

Cast number Numero de coulee GuBnummer Numero di colata Numero de colada

Casting Moulage GuB Colata in stampo Fundicion

Casting alloy Alliage de moulage Gufilegierung Lega per colata Aleacion para moldeo

Chemical brightening Briilantage chimique Chemisches Glanzen Brillantatura chimica Abrillantado quimico

Chemical conversion Conversion chimique Chemische Kon version Conversione chimica Conversion quimica

Chemical polishing^ Polissage chimique Chemisches Polieren Pulitura chimica Pulido quimico

Circle Disque Ronde Dilatozione Disco

English French German Italian Spanish

Clad alloy Alliage plaque Plattierte Legierung Prodotto placcata Producto plaqueado

Clad sheet ToIe plaquee Plattiertes Blech Lastra placcata Chapa placada

Cladding Placage Plattierung Placcatura Plaqueado

Cladding blister Soufflure de placage Plattierblase Soffiatura di placcatura Burbuja de plaqueado

Clinching Clinchage Clinchen Aggroffatura Clisado

Clipping Ebarbage Entgratung Durezza Desbarbado

Coating Revetement Beschichten Rivestimento Revestimiento

Coil Bande Band Nastro Banda

Coil coating Revetement en bande Bandbeschichtung Rivestimento con nastro Revestimiento en banda

Coil crown effect Bombe d une bande Bandwolbung Tegolatura Abombado de un lado

Cold compression Compression a froid Koltstauchen Compressione a freddo Compresion en frio

Cold working Deformation a froid Kaltumformung De ormazione a caldo Deformacion en frio

Endurecinento por

Cold working, Strain hardening Ecrouissage Kaltverfestigung Campione

conformacion

Cold-drawn rod/bar Barre etiree a froid Kaltgezogene Stange Barra trafilata Barra estrada en frio

Continuous casting Coulee continue Stranggufi Colata Colada continua

Controlled atmosphere Atmosphere controlee Kontrollierte Atmosphare Atmosfera controllata Atmosfera controlada

Controlled stretching Traction controlee Kontrolliertes Recken Trozione controllata Traccion controlado

Convexity Convexite Konvexitat Convessita Convexidad

Cooling Refroidissement Abkuhlung Raffreddamento Enfriamiento

Corrosion Corrosion Korrosion Corrosione Corrosion

Crack Fissure RiG Cricca Fisura

Creep Fluage Plostisches Fliefien Scorrimento Flujo

Crevice corrosion Corrosion caverneuse Spaltkorrosion Corrosione interstiziale Corrosion cavemosa

Crevice corrosion Corrosion sous depot Belagkorrosion Corrosione da sollecitozione Corrosion por almacenmiento

Kritische

Critical quenching rate Vitesse critique de trempe Velocita critica di tempra Velocidad critica de temple

Abschreckgeschwindigkeit

Critical strain Ecrouissoge critique Kritischer Verformungsgrad lncrudimento Endurecinento critico

Cropping Eboutage Schopfen Sbavatura Despuntado

Crown Bombe Bombierung Bombato Abombado

Cutting Decoupage Schneiden Tomitura Cortado

Defect Defaut Qualitatsmangel Tranciatura Defecto

Degreasing Degraissage Entfettung Deformazione permanente Desengrasado

Dent Bosse, creux Einbeulung Ammaccatura Relieve, hueco

Desensitisation Desensibilisation Desensibilisierungsgluhung Semilavorato Desensibilizacion

Destructive test Essai destructif Zerstorungsprijfung Prova distruttiva Ensayo destructive

Diameter Diametre Durchmesser Detensionamento Diametro

Die Matrice Matrize Stampo Matriz

Die forging Matrigage Gesenkschmieden Stampaggio Matrizado

Die scores Rayure de filiere PreRriefen Striatura di filiera Rayado de hilera

Diffusion Diffusion Diffusion Diametro Difusion

Dilatation Dilatation Warmedehnung Diffusione Dilatacion

Direct extrusion Filage direct, Direktes Strangpressen Estrusione diretta Extrusion directa

Dissolution potential Potentiel de dissolution Auflosungspotential Potenziale di dissoluzione Potencial de disolucion

Draw bench Bancd'etirage Ziehbank Banco di trafila Banco de estirado

Drawing Emboutissage Tiefziehen lmballaggio lmbutitura Embuticion

Drawing Etirage Ziehen Trafilatura Estirado

Drawn tube Tube etire Kaltgezogenes Rohr Tubo trafilato Tubo estirado

Drawn wire Filtrefile Gezogener Draht FiIo trafilato HiIo trefilado

Ductility Ductilite Duktilitat Raddrizzatura Ductilidad

Duplex ageing Double revenu Stufenaushartung Disco Doble revenido

Dye penetrant test Essai de ressuage RiReindringprufung Prova di trasudamento Ensayo de resudacion

Dye penetrant test Ressuage Penetrationstest Prova liquidi penetranti Resudacion

Earing Comes d'emboutissage Zipfel Anisotropia Orejas de embuticion

Eccentricity Excentricite Exzentrizitat Eccentricita Excentricidad

Eddy current test Essai par courants de Foucault Wirbelstromprufverfahren Prova a correnti parassite Ensayo corriente de Foucault

Edge trimming Ebavurage Abgraten Entgraten Sbozzato carta Desbardado

Edge wave Bord long Randwelligkeit Bordo lungo Borde longitudinal

Electrical conductivity Conductivity electrique Elektrische Leitfahigkeit Conduttivita elettrica Conductividad electrica

Spezifischer elektrischer

Electrical resistivity Resistivite electrique Resistivita elettrica Resistidad electrica

Widerstand

Electrochemical brightening Brillantage electrochimique Eiektrochemisches Glanzen Brillantatura elettrochimica Abrillantado electroquimico

Elongation Allongement Dehnung Allungamento Alargamiento

Etching Attaque chimique Atzen Attacco chimico Ataque quimico

Etching Gravure (chimique) Chemische Gravierung lncisione (chimica) Grovado quimico

Corrosion exfoliante, Corrosion

Exfoliation corrosion Schichtkorrosion Corrosione a strati Corrosion exfoliante/escamosa

feuilletante

Expansion test Essai d'evasement Aufweitversuch (Rohr) Prova di svasatura Ensayo de abocardoniento

Extrudability Filabilite Verprelibarkeit lndoneita all'estrusione Extrusionabilidad

Extruded rod/bar Barre filee Stranggepreflte Stange Barra estrusa Barra extruida

Extruded section Profile file Vollprofil Protilo estruso Perfil

Extruded tube Tube file Stranggeprefltes Rohr Tubo estruso Tubo extruida

Extrusion Filage Strangpressen Estrusione Extrusion

Extrusion billet Billette de filage Preftbolzen Billetta estrusa Lingote de extrusion