Table Of ContentImplementation of the Rigid Ring Tyre

Model and Accompanying Soil Model in a

Complete Vehicle Simulation Tool for

Trucks

Master’s thesis in Applied Mechanics

ALBIN BRANTIN

´

OSCAR GRUNDEN

Department of Applied Mechanics

CHALMERS UNIVERSITY OF TECHNOLOGY

G¨oteborg, Sweden 2016

MASTER’S THESIS IN APPLIED MECHANICS

Implementation of the Rigid Ring Tyre Model and Accompanying Soil Model

in a Complete Vehicle Simulation Tool for Trucks

ALBIN BRANTIN

OSCAR GRUNDE´N

Department of Applied Mechanics

Vehicle Dynamics

CHALMERS UNIVERSITY OF TECHNOLOGY

G¨oteborg, Sweden 2016

Implementation of the Rigid Ring Tyre Model and Accompanying Soil Model in a Complete Vehicle

Simulation Tool for Trucks

ALBIN BRANTIN

OSCAR GRUNDE´N

(cid:13)c ALBIN BRANTIN, OSCAR GRUNDE´N, 2016

Master’s thesis 2016:58

ISSN 1652-8557

Department of Applied Mechanics

Vehicle Dynamics

Chalmers University of Technology

SE-412 96 G¨oteborg

Sweden

Telephone: +46 (0)31-772 1000

Examiner: Bengt Jacobson

Supervisors: Artem Kusachov, Fredrik ijer

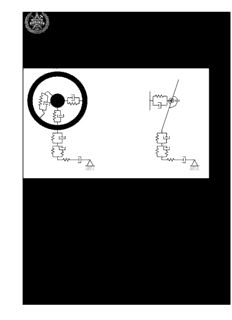

Cover:

A representation of the wheel plane and out of plane rigid ring model with soil model included.

Chalmers Reproservice

Go¨teborg, Sweden 2016

Implementation of the Rigid Ring Tyre Model and Accompanying Soil Model in a Complete Vehicle

Simulation Tool for Trucks

Master’s thesis in Applied Mechanics

ALBIN BRANTIN

OSCAR GRUNDE´N

Department of Applied Mechanics

Vehicle Dynamics

Chalmers University of Technology

Abstract

Volvo got a library of Virtual Transport Models of their trucks (VTM). These models cannot simulate

soft soil roads due to the currently implemented tyre model. A new tyre/soil model is being developed

in conjunction with the University of Ontario Institute of Technology, which is to be implemented to

work with the models in the VTM library.

The university model the tyre and soil using finite element method (FEM) and smoothed particle

hydrodynamics (SPH), which is too computationally demanding to implement in VTM. The model

that was to be implemented was instead a simplification comprising of springs, dampers and masses.

The parameters of these elements are estimated from different FE-simulations done by the university.

Once the tyre model is implemented it will be verified against the FE-model by comparing simulation

results. In addition, the model will be compared to the currently implemented model to ensure an

overall similarity between the models.

The overall results shows promise in the new tyre model. All of the single tyre simulations have given

satisfactory results after some of the parameters were corrected. The soil model is however not able

to completely capture the results of the FE-simulations but is considered acceptable. The full vehicle

model has given good results even though the vertical soil model and the rolling resistance in the soil

needs further investigation to capture an even more realistic dynamic response.

The rigid ring model on rigid ground is deemed to work properly and gives good results. The soil

model has given acceptable results but it does not capture the full soil behaviour. Additionally the

soil model has been non-physically altered to get good results. This warrants further studying of the

model and its parameters in order to further refine the model. The rolling resistance in the soil also

needs further investigation since the model is crude and uncertain. The implemented tyre model

requires the same order of magnitude in simulation time as the original magic formula rigid ground

model.

Keywords: Rigid Ring Tyre Model, Soft Soil Model, Tyre Modeling, Vehicle Dynamics

i

ii

Preface

This project acts as a continuation of an ongoing collaboration between Volvo Trucks, the University

of Ontario Institute of Technology and the Pennsylvania State University. Volvo wants to implement

a new tyre model into their full vehicle dynamic simulator, VTM. By adopting this tyre model into

VTM the same tyre model will be used as in their FEM tool. In addition a soil model compatible

with this model will be investigated and implemented.

Acknowledgements

We want to give a huge thank you to our supervisor, at Volvo GTT, Fredrik O¨ijer who has helped us

tremendously throughout the project. We would also like to thank Sachin Janardhanan and Inge

Johansson and all the other people at the Chassis Strategy and Vehicle Analysis department at Volvo

GTT who has been very helpful. Finally we would like to thank our examiner, Bengt Jacobson, and

our supervisor, at Chalmers, Artem Kusachov, for their help in this project.

iii

iv

Nomenclature

SI-units and radians are used.

C(v ) slope compensation factor [∼]

x

ca first slope compensation constant [1/(m/s)cb]

c second slope compensation constant [∼]

b

c third slope compensation constant [∼]

c

c lateral tyre stiffness [N/rad]

l

c longitudinal sidewall damping

bx

c lateral sidewall damping

by

c vertical sidewall damping

bz

c wheel plane rotational damping of the sidewall

bθ

c out of plane rotational damping of the sidewall

bγ

c vertical soil damping

soil

c(cid:48) equivalent vertical soil damping

soil

c(cid:48) approximate equivalent damping of the soil

soil,app

c total vertical damping of the tyre

tot

c vertical residual damping

vr

F bulldozing resistance force

B

F rolling resistance force

r

F rut rolling resistance force

R

F longitudinal slip force

sx

F lateral slip force

sy

F longitudinal force acting on tyre belt

wx

F lateral force acting on tyre belt

wy

F longitudinal force acting on wheel rim

x

F longitudinal slip force saturation for rigid ground

x,max

F longitudinal slip force saturation for soft soil ground

x,max,soil

F lateral force acting on wheel rim

y

F lateral slip force saturation for rigid ground

y,max

F vertical force acting on wheel rim

z

F static load

z0

I wheel plane rotational inertia of wheel rim, with or without inertia of wheel axle

1y

I out of plane rotational inertia of tyre belt

2x

I wheel plane rotational inertia of tyre belt

2y

k lateral tyre tread stiffness

l

k longitudinal sidewall stiffness

bx

k lateral sidewall stiffness

by

k vertical sidewall stiffness

bz

k out of plane rotational stiffness of the sidewall

bγ

k wheel plane rotational stiffness of the sidewall

bθ

k longitudinal tyre tread stiffness

cx

k cornering stiffness

f

k longitudinal tyre stiffness

k

v

k vertical soil stiffness

soil

k(cid:48) equivalent vertical component of soil stiffness

soil

k additional vertical soil stiffness

soil,2

k total vertical stiffness of the tyre

tot

k vertical residual stiffness

vr

M driving moment

in

M reaction moment acting on wheel rim

y,r

M reaction moment acting on tyre belt

y,b

M moment used as output from the model

y,out

m tyre rim mass, with or without wheel axle mass

1

m tyre belt mass

2

m fictive mass of the soil

soil

m fictive mass of soil + mass of tyre

tot,soil

R undeformed tyre radius

0

R effective radius

e

rrc rolling resistance coefficient [∼]

r first rolling resistance constant [∼]

a

r second rolling resistance constant [∼]

b

r third rolling resistance constant [∼]

c

u tyre tread deformation

x

u˙ tyre tread deformation speed

x

V velocity at the contact point

c

v longitudinal velocity of wheel rim

x

v lateral velocity of wheel rim

y

v vertical velocity of wheel rim

z

x longitudinal position of wheel rim

1

x longitudinal position of where the sidewall meets the tyre tread

2

y lateral position of wheel rim

1

y lateral position of where the sidewall meets the tyre tread

2

z vertical position of wheel rim

1

z vertical position of where the sidewall meets the tyre tread

2

z vertical position of tyre/soil interaction point

3

z vertical position of the road

r

α longitudinal slip [∼]

x

α lateral slip [rad]

y

β average local slope angle

β(cid:48) equivalent local slope angle

γ out of plane angle of tyre belt

2

δ logarithmic decrement of oscillations [∼]

ζ dimensionless damping constant [∼]

θ wheel plane angle of wheel rim

1

θ wheel plane angle of tyre belt

2

σ relaxation length of tyre

ϕ lateral road slope

x

ϕ longitudinal road slope

y

ω tyre frequency, soil frequency

ω nominal frequency

0

vi

Description:The university model the tyre and soil using finite element method (FEM) and smoothed particle requires the same order of magnitude in simulation time as the original magic formula rigid ground model. outputs are red. 8