Table Of Content1967 HOW TO

TROUBLESHOOT &

,.

,

REPAIR ANY SMALL

PAUL DEMPSEY

'

HOW TO

TROUBLESHOOT &

REPAIR ANY SMALL

PAUL DEMPSEY

TAB

TAB BOOKS Inc .

....___,. Blue Ridge Summit, PA 17214

FIRST EDITION

FIRST PRINTING

Copyright © 1985 by TAB BOOKS Inc.

Printed in the United States of America

Reproduction or publication of the content in any manner, without express

permission of the publisher, is prohibited. No liability is assumed with respect to

the use of the information herein.

library of Congress Cataloging in Publication Data

Dempsey, Paul

How to troubleshoot and repair any small gas engine.

Includes index.

1. Internal combustion engines, Spark ignition

Maintenance and repair. I. Title.

T J790.D44 1985 621.43'4 85-14748

ISBN 0-8306-0967-9

ISBN 0-8306-1967-4 (pbk.)

Contents

Introduction vii

1 Engine Basics 1

Nomenclature-Operation-Dimensions and Measure

ments-Heat Lubrication-Maintenance

2 Ignition 23

Timing-Simple Alignment-Point Gap Adjustment-Point

To-Cam Adjustment-Insufficient Output-Conventional

Systems-Solid-State Systems

3 Carburetors and Fuel Systems 67

Operation-Types- Adjustments-Filters-Governors

Fuel Pumps-Mechanical Pumps

4 Rewind Starters 117

Side Pull-Service Procedures-Briggs & Stratton- Vertical

Pull

5 Electrical System 155

Starting Circuits-Charging Systems

6 Engine Mechanics 188

Diagnosis-Scope of Work-Cylinder Head-Valves

Pistons and Rings-Cylinder Bores-Connecting Rods

Assembly Crankshafts-Camshafts-Main Bearings

Seals- Governor Mechanisms-Oiling Systems

Index 259

Introduction

This book is written for the millions of owners of small engines

who want to be able to make their own repairs, and for mechanics

who are just getting into small-engine work. It combines some

engineering theory with detailed descriptions of repair procedures,

including troubleshooting and major engine work. Emphasis is on

four-cycle and two-cycle, American-made utility and industrial

engines. Briggs & Stratton, Kohler, Onan, Tecumseh and Clinton

receive special attention, but techniques described here apply to

most makes and models.

Major systems are discussed in detail; there are chapters on

ignition, carburetion, rewind starters, electrical systems, and engine

internals. In each case, some attention has been given to theory,

but one cannot repair a carburetor, a magneto, or a rewind starter

without understanding how it works. In retrospect, I think that

these short descriptions are the most important parts of this book.

Readers will remember this type of information and be able to ap

ply it for years to come and on engines not yet built.

Most small-engine repairs are fairly simple and can be accom

plished with no more than the usual collection of kitchen-drawer

tools supplimented by a 3/8-inch, square-drive socket set in U.S.

or metric sizes. Nevertheless, there are times when factory tools

are needed. These tools might not be readily obtainable. To simplify

matters, I have included part numbers and, whenever possible,

alternate sources of supply or instructions for home fabrication.

VII

'

Chapter 1

I

\

Engine Basics

This chapter covers elemental matters about the theory of engine

operation, and routine maintenance procedures. Because readers

might have little familiarity with the subject, I will begin with what

the Army used to call "naming of the parts."

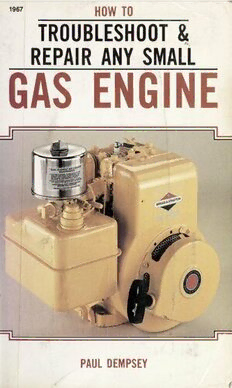

Figure 1-1 illustrates major external parts of a typical four

cycle, single-cylinder, side-valve, horizontal-crankshaft engine.

Most of the labeled parts, such as fuel tank, muffler, carburetor,

and air cleaner, are engine accessories, bolted to the basic package.

Each of these accessories, including some not highlighted in the

illustration, are described in various chapters of this book.

The engine proper consists of those parts inside the cavity

formed by the cylinder head and cylinder block, and that are not

visible until disassembly. Figure 1-2 shows the internal parts of a

four-cycle engine in exploded view. Note that the basic engine is

quite a simple affair; there are fewer than 20 parts and

subassemblies. These parts include:

• Cylinder head-caps the cylinder bore and mounts the spark

plug. Finned for cooling and almost always cast in aluminum.

• Piston- a moving plug that reciprocates in the cylinder bore.

Area between the top, or crown, of the piston and the inner face

of the cylinder head forms the combustion chamber where gasoline

and air are explosively combined to drive the piston.

• Piston rings-fitted on the piston to prevent gas leakage

1

I\)

..,..FILLER CAP (KEEP VENT OPEN)

~

FUEL TANK (OPTION)

I I I I '

TOP MOUNTED

11.--1-1/2 GAL. SHOWN

.........-rr

FUEL

CYLINDER ~ -==-.:::,--=====-"1

SHUT-OFF

HEAD -

~.=~~- VALVE

" J -

COOL ING

FINS

ORY TYPE

SHOULDER • v, AIR CLEANER

TYPE

DIPSTICK - •

- NAMEPLATE

}---"/ (,

~. I

~

AIR

BREAKER INTAKE

POINT COVER ·: SCREEN

9 1~

~

GASOLINE

CARBURETOR

OIL N--~ -- - ~-

ORA! ~ ~ BLOWER

-"--I ,._~

HOUSING

STOP BUTTON L-..------_.J \

PAN

FUEL PUMP OR COVER

Fig. 1-1. External views of a Kohler single-cylinder engine, with major accessories labeled.