Table Of ContentUS 20150018476A1

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2015/0018476 A1

Thomson et al. (43) Pub. Date: Jan. 15, 2015

(54) FLUORINATED ACRYLATE BLOCK Publication Classi?cation

COPOLYMERS WITH LOW DYNAMIC

SURFACE TENSION (51) Int. Cl.

C08L 53/00 (2006.01)

(71) Applicant: BASF SE, LudWigshafen (DE) C09D 7/06 (2006.01)

(52) US. Cl.

(72) Inventors: Mary Thomson, Mannheim (DE); Ralf

CPC .. C08L 53/00 (2013.01); C09D 7/06 (2013.01)

Knischka, Neustadt (DE); Clemens

Auschra, Freiburg (DE); Lothar USPC ....................................... .. 524/505; 525/92 C

Engelbrecht, Mannheim (DE)

(73) Assignee: BASF SE, LudWigshafen (DE) (57) ABSTRACT

(21) Appl. No.: 14/375,670

The present invention relates to a composition, comprising a

(22) PCT Filed: Feb. 22, 2013 binder resin, a block copolymer Which comprises at least a

blockA and a block B, Wherein the blockA comprises mono

(86) PCT N0.: PCT/EP2013/053567 mer units derived from a compound selected from (meth)

§371(CX1L acrylic acid, a (meth)acrylic acid ester, a (meth)acrylamide, a

(2) Date: Jul. 30, 2014 vinyl aromatic compound, or any mixture thereof, the block B

comprises monomer units derived from a compound selected

Related US. Application Data from a ?uorinated (meth)acrylic ester having the following

(60) Provisional application No. 61/602,096, ?led on Feb. formula (I): HZC:C(R1)(C(0)ORF_1), Wherein R1 is H or

methyl; and RF_ 1 is an organic residue containing a per?uori

23, 2012.

nated C4_6alkyl group, a ?uorinated alpha-ole?n having the

(30) Foreign Application Priority Data following formula (II): HZC:CH(RF_2) (11) wherein RP2 is

an organic residue containing a per?uorinated C4_6 alkyl

Feb. 23, 2012 (EP) ................................ .. 12156662.4 group, i.e. *(CF2)3_5%F3 or any mixture thereof.

Patent Application Publication Jan. 15, 2015 US 2015/0018476 A1

Figures

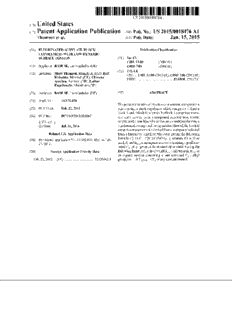

Dynamic suriaae tenaian of samp?es at G,25wt% additive

—5— blank

M w Eiéia 3506M

amass-r3012

w[Dtrmeyfnnmsaai/cmomeni ]c

m U1

{3,95 Q03 0,11 13.1? 112.25 {338 (3.57“ 8.8% 1.29 1.93 2,59 33:1 £5,511 £31?

Buléiile life time is;

Figure 1

US 2015/0018476 A1 Jan. 15,2015

FLUORINATED ACRYLATE BLOCK [0010] According to a ?rst aspect of the present invention,

COPOLYMERS WITH LOW DYNAMIC the object is solved by providing a composition, comprising

SURFACE TENSION [0011] a binder resin,

[0012] a block copolymer which comprises at least a

[0001] The present invention relates to a composition

block A and a block B, wherein

which comprises a block copolymer having ?uorinated

[0013] the block A comprises monomer units derived

monomer units and to the use of said block copolymer as from a compound selected from (meth)acrylic acid, a

substrate wetting, anti-cratering and/or leveling agent for

(meth)acrylic acid ester, a (meth)acrylamide, a vinyl

coating, ink and/ or adhesive compositions.

aromatic compound, or any mixture thereof,

[0002] Smooth and crater free surfaces are important for [0014] the block B comprises monomer units derived

almost all coating, ink and adhesive applications; they pro from a compound selected from a ?uorinated (meth)

vide not only a visually appealing ?lm but serve also as a acrylic ester having the following formula (I):

protective barrier for the substrate as well as homogenous

HZCICR1(C(O)ORF.1) (I)

bondstrength throughout the ?lm.

[0015] wherein

[0003] When e. g. the coating is not homogenous and some

[0016] R1 is H or methyl; and

parts of the surface are only thinly, or not all, coated it leads to

[0017] RPl is an organic residue containing a per

poor protection of the substrate. As a result, substrate wetting,

anti cratering and leveling agents are added to all sorts of

coatings. These dif?culties in application of coating resin, [0018] a ?uorinated alpha-ole?n having the following

particularly in liquid systems, occur particularly when the formula (II):

surface tension of the liquid system is high and the surface

tension of the substrate, or contaminants on the substrate, is

[0019] wherein RF2 is an organic residue contain

much lower. The addition of substrate wetting and anti cra

ing a per?uorinated C4_6 alkyl group, i.e. i(CF2)

tering additives reduces both the dynamic and static surface

3-5*CF3

tension of the liquid coating, leading to smoother ?lm forma

[0020] or any mixture thereof.

tion.

[0021] A per?uorinated C4_6 alkyl group is represented by

[0004] As long as the viscosity of the coating formulation is

the formula i(CF2)3_5iCF3.

low, su?icient substrate wetting and leveling can be achieved

[0022] Preferably, RPl and RF_2, which can be the same or

with commercially available additives. Large problems can

different, have the following formula (III):

be observed in the cases of high solids coatings, powdered

coatings and high speed coating processes. There is a strong

demand for substrate wetting and anti-cratering additives

[0023] wherein x is 0 or 1; and R2 is a divalent non

with a very low dynamic surface tension, which can provide ?uorinated C1_4 alkylene group, which can be substi

smooth and uniform ?lms in these highly demanding appli

tuted or unsubstituted.

cations. [0024] In a preferred embodiment, R2 in formula (III) is

[0005] The same reasoning applies also for inks and adhe i(CH2)1_ 4*; such as 4CH2i; iCHZiCHzi; 4CH2i

sives. CHziCHZi; or iCH2%H2%H2%H2i.

[0025] In a preferred embodiment, the ?uorinated (meth)

[0006] Long chain per?uoro chemicals, typically with per

acrylic ester compound of formula (I) is selected from 3,3,4,

?uorinated chains of length C8 and longer, are used as anti

4,5,5,6,6,7,7,8,8,8-trideca?uoroctyl acrylate, 3,3,4,4,5,5,6,6,

cratering and leveling agents for coating compositions but are

6-nona?uorhexyl-acrylate, or mixtures thereof.

known to form very environmentally persistent degradation

products, including per?uoro-octanoic acid (PFOA). Thus, [0026] Preferred ?uorinated alpha-ole?ns of formula (II)

there is a need for alternatives which do not form such envi include e.g. 3,3,4,4,5,5,6,6,7,7,8,8,8-trideca?uoro-l-octene,

ronmentally persistent degradation products. However, any 3,3,4,4,5,5,6,6,6-nona?uoro-l-hexene, or any mixture

improvement in degradation properties should not be thereof.

[0027] The block B may consist of monomer units derived

achieved at the expense of properties which are relevant for

from the ?uorinated (meth)acrylic ester compound of for

leveling agents such as low dynamic surface tension. In gen

mula (I) or from the ?uorinated alpha-ole?n of formula (II).

eral, the effect on dynamic surface tension reduction is

believed to decrease with the order of the per?uorinated unit. [0028] Alternatively, the block B may contain two or more

different monomer units.

[0007] WO 2005/059048 describes coating compositions

[0029] If the block copolymer contains two or more blocks

containing leveling agents prepared by nitroxide mediated

of type “B”, they may differ in block length (i.e. different

polymerization. Monomer units may be substituted by ?uoro

number of monomer units), but preferably have the same

or per?uoro.

arrangement or sequence of monomer units.

[0008] WO 2009/103613 describes the use of short per?u [0030] Preferably, the block B of the block copolymer has

orinated chains in copolymers prepared by nitroxide medi

an average number of monomer units which are derived from

ated polymerization for the use of leveling agents. the ?uorinated (meth)acrylic ester compound of formula (I)

[0009] It is an object of the present invention to provide a and/or from the ?uorinated alpha-ole?n of formula (II) of at

polymeric leveling and anti-cratering agent which does not least 0.25, more preferably at least 0.5, or at least 1.

form environmentally very persistent degradation products [0031] If the average number of monomer units of a speci?c

such as per?uoro-octanoic acid but still enables manufactur block is below 1, this means that, statistically, not every

ing of coating, ink or adhesive compositions having very low polymer chain contains monomer units of said block. How

dynamic surface tension. ever, when using the block copolymer of the present inven

US 2015/0018476 A1 Jan. 15,2015

tion, a reduced dynamic surface tension is still obtained at [0041] Preferably, the block copolymer has a polydisper

such low amount of ?uorinated monomer units. sity index PDI (i.e. Mw/Mn) of less than 1.90, more prefer

[0032] In a preferred embodiment, the block B of the block ably of less than 1.60, even more preferably of less than 1.40,

copolymer has an average number of monomer units which or even less than 1.30.

are derived from the ?uorinated (meth)acrylic ester com [0042] The polydispersity index PDI may depend on the

pound of formula (I) and/or from the ?uorinated alpha-ole?n number of blocks being present and their arrangement in the

of formula (II) of from 0.25 to 40, more preferably 0.5 to 30, block copolymer. If the block copolymer is linear with one

even more preferably 1 to 20. block of A and one block of B, PDI may preferably be less

than 1.40, more preferably less than 1.30. If the block copoly

[0033] Preferably, block A comprises monomer units

derived from a compound selected from Cl_18 (meth)acry mer is linear with one block of A and two blocks of B, or

alternatively with one block of B and two blocks of A, PDI

lates, more preferably C 1_ 1 O (meth)acrylates, especially meth

yl(meth)acrylate (MMA), ethyl(meth)acrylate, n-butyl may preferably be less than 1.60, more preferably less than

(meth)acrylate, iso-butyl(meth)acrylate, t-butyl(meth) 1.50.

acrylate, 2-ethylhexyl(meth)acrylate, isodecyl(meth) [0043] The block copolymer is preferably obtained by a

acrylate, hydroxyl-functional (meth)acrylates like controlled free radical polymerization (sometimes also

2-hydroxyethyl(meth)acrylate, hydroxypropyl(meth)acry referred to as “controlled radical polymerization”).

late, acid functional (meth)acrylic monomers like acrylic acid [0044] Methods of “controlled free radical polymeriza

or methacrylic acid, sulphonic acid containing monomers tion” are generally known to the skilled person.

like 2-acrylamido-2-methylpropane sulfonic acid (AMPS), [0045] In a preferred embodiment, the controlled free radi

amino functional (meth)acrylates like dimethylaminoethyl cal polymerization is selected from nitroxide-mediated con

methacrylate (DMAEMA), epoxy functional (meth)acrylates trolled polymerization (NMP), atom transfer radical poly

like glycidylmethacrylate (GMA), (meth)acrylates contain merization (ATRP), or from reversible addition

ing siloxane groups, vinyl aromatic compounds such as sty fragmentation chain transfer polymerization (RAFT). These

rene, or any mixture thereof. polymerization methods and variants thereof are generally

[0034] The block A may consist of monomer units derived known to the skilled person.

from a compound selected from (meth)acrylic acid, a (meth) [0046] The reversible addition-fragmentation chain trans

fer polymerisation RAFT using chain transfer agents which

acrylic acid ester, a (meth)acrylamide, or a vinyl aromatic

compound. react by reversible addition-fragmentation chain transfer is

described, for example, in WO-A-98/01478, WO-A-99/

[0035] Alternatively, the block A may contain two or more

05099, WO-A-99/31144, and WO 2009/103613.

different monomer units.

[0047] RAFT describes a method of polymer synthesis by

[0036] If the block copolymer contains two or more blocks

radical polymerization in the presence of a free radical source

of type “A”, they may differ in block length (i.e. different

and using chain transfer agents which react by reversible

number of monomer units), but preferably have the same

addition-fragmentation chain transfer. The chain transfer

arrangement or sequence of monomer units. agent is, for example,

[0037] Preferably, the block A of the block copolymer has [0048] 2-phenylprop-2-yl dithiobenzoate (Ph-C(CH3,

an average number of monomer units which are derived from CH3)iS4C(S)-Ph) or benzyl dithioacetate Ph-CHZi

a compound selected from (meth)acrylic acid, a (meth)

S4C(S)4CH3 as described in WO 98/01478,

acrylic acid ester, a (meth)acrylamide, or a vinyl aromatic

[0049] carbamates such as benzyl 1-pyrrolecarbodithio

compound, of at least 5, more preferably at least 10, even

ate, as described in WO99/31144;

more preferably at least 15. In a preferred embodiment, the [0050] alkylxanthates such as ethyl 0t(O-ethylxanthyl

block A of the block copolymer has an average number of

propionate), as described in W0 98/ 58974.

monomer units which are derived from a compound selected

[0051] WO 96/30421 discloses a controlled polymerisation

from (meth)acrylic acid, a (meth)acrylic acid ester, a (meth)

process of ethylenically unsaturated polymers, such as sty

acrylamide, or a vinyl aromatic compound, of from 5 to 1000,

rene or (meth)acrylates, by employing the Atomic Transfer

more preferably from 10 to 500, even more preferably from

Radical Polymerisation (ATRP) method. This method pro

15 to 300.

duces de?ned oligomeric homopolymers and copolymers,

[0038] Preferably, the block copolymer has a number aver including block copolymers. Initiators are employed, which

age molecular weight Mn of from 1000 to 100,000 g/mol,

generate radical atoms, such as .C1, in the presence of a redox

more preferably from 2,000 to 50,000 g/mol, even more pref system of transition metals of different oxidation states, e.g.

erably 3,000 to 25,000 g/mol. Other appropriate Mn ranges Cu(I) and Cu(II), providing “living” or controlled radical

that can be used in the present invention are e. g. from 3,000 to polymerisation.

100,000 g/mol, or from 4,000 to 100,000 g/mol, or from 6,000 [0052] Details about nitroxide-mediated controlled poly

to 50,000 g/mol.

merization are described e.g. in WO 2005/059048 and WO

[0039] Preferably, the block copolymer comprises the 2009/103613. The initiator compounds described therein can

monomer units derived from the ?uorinated (meth)acry1ic be used in the present invention as well.

ester of formula (I) and/ or from the ?uorinated alpha-ole?n of [0053] More preferably, the controlled radical polymeriza

formula (II) in an amount of from 0.1 wt % to 70 wt %, more tion is selected from nitroxide-mediated controlled polymer

preferably from 0.5 wt % to 50 wt %, even more preferably ization (NMP) and atom transfer radical polymerization

from 1 wt % to 25 wt %. (ATRP), even more preferably from NMP.

[0040] Preferably, the block copolymer has a ?uorine con [0054] In a preferred embodiment, the controlled radical

tent of from 0.05 wt % to 35 wt %, more preferably from 0.25 polymerization is a nitroxide-mediated controlled polymer

wt % to 25 wt %, even more preferably from 0.5 wt % to 17 ization, which preferably uses a polymerization regulator

wt %. system based on polymerization regulator compounds being

US 2015/0018476 A1 Jan. 15,2015

preferably selected from one of the following formulas (IV),

(V) and (VI) or based on the corresponding stable free

nitroxyl radicals in conjunction with a radical source:

(IV)

G1 G2 G5

X

\

O — N O — R

G3 G4 G5

[0064] wherein any of the alkyl groups can be unsubsti

tuted or substituted, e.g. by one or more functional

groups such as hydroxyl, amino, carboxylic acid, halide,

cyano, and/ or carbonyl.

(V) [0065] The above polymerization regulator compounds as

G1 G2 G5

well as their corresponding stable free nitroxl radicals and

X R101 their preparation are described in GB 2 335 190 and GB 2 361

\ |

O—N N—R102 235.

[0066] As known to the skilled person, controlled free radi

cal polymerization may involve using an initiator fragment

G3 G4 G5 IN for initiating the radical polymerization. The initiator frag

ment can be released from a polymerization regulator com

pound IN-E, e.g. from one of those described above. In for

mulas (IV) to (VI), radical X represents the initiator fragment

IN, whereas the nitroxide radical would represent the group

(V1)

E.

O

[0067] The block copolymer can be a diblock copolymer, a

G5 G5 triblock copolymer, or multiblock copolymer.

G1 G3 [0068] The block copolymer can be linear, or branched

(such as star-shaped, comb-shaped, etc.).

G2 N G4 [0069] In the present invention, the term “block copoly

mer” also includes a gradient and/or tapered block copoly

O

X / mer. This type of structured copolymer is also generally

known to the skilled person. In a gradient or tapered block

copolymer, there is a gradient compositional transition

wherein

between blocks A and B.

[0055] R is hydrogen, C l _ l 8alkyl which is uninterrupted

[0070] In a preferred embodiment, a block can also be

or interrupted by one or more oxygen atoms, cyanoethyl, de?ned as a region of the polymer chain that is richer in

benzoyl, glycidyl, a monovalent radical of an aliphatic

?uorinated monomer than another block.

carboxylic acid having 2 to 18 carbon atoms, of a

[0071] In the block copolymer of the present invention, two

cycloaliphatic carboxylic acid having 7 to 15 carbon

neighbouring blocks can be directly linked to each other.

atoms, or an 0t,[3-unsaturated carboxylic acid having 3 to

Alternatively, two neighbouring blocks can be linked to each

5 carbon atoms or of an aromatic carboxylic acid having

other via a linking group LG, e.g. -A-LG-B-; -B-LG-B-;

7 to 15 carbon atoms;

-A-LG-A

[0056] R101 is Cl_l2alkyl, C5_7cycloalkyl, C7_8aralkyl,

[0072] The linking group LG can be any divalent group

C2_18alkanoyl, C3_5alkenoyl or benzoyl;

which may form a covalent bond to blocks A and B. Appro

[0057] R102 is Cl_18alkyl, C5_7cycloalkyl, C2_8alkenyl, priate linking groups are known to the skilled person.

which can be unsubstituted or substituted by a cyano, [0073] In a preferred embodiment, the linking group LG

carbonyl or carbamide group, or is glycidyl, a group of has the following formula (VII):

the formula 4CH2CH(OH)iZ or of the formula

4COiZ or 4CONHiZ wherein Z is hydrogen, iINl'iY'iINji (V11)

methyl or phenyl;

[0074] wherein the INl' and IN2' groups, which can be

[0058] G6 is hydrogen, the same or different, are derived from the initiator frag

ments INl and IN2 of the controlled free radical poly

[0059] G5 is hydrogen or Cl_4alkyl,

merization, and Y' is a divalent group covalently linked

O " l a". 21'Ol'l .""l" r a .'a" 'll'.

[0061] G2 and G4 are ethyl or propyl, or G1 and G2 are (e.g. (x-bond or J's-bond) between the INl' and IN2'

methyl and G3 and G4 are ethyl or propyl; and groups.

[0062] X is selected from 4CH2-phenyl, CH3CH-phe [0075] Preferably, the initiator fragments INl and IN2 are

nyl, (CH3)2C-phenyl, (C5_6cycloalkyl)2CCN, (CH3) the same and, consequently, the INl' and IN2' groups are the

2CCN, same as well.

US 2015/0018476 A1 Jan. 15,2015

[0076] The divalent group Y' can be derived from a com solid at room temperature and do not include a liquid carrier,

pound Y having at least two functional groups which may e.g. thermosetting powder coatings or radiation curable pow

react with the initiator fragments INl and IN2. Appropriate der coatings like polyester/PRIMID, polyester/TGIC, epoxy

compounds having at least two functional groups are e.g. functional polyacrylates with acidic crosslinker components,

diisocyanate compounds (such as toluene diisocyanate), ali

etc.

phatic polyisocyanates or isocyanurate compounds.

[0087] The weight ratio the block copolymer to binder resin

[0077] The linking group LG of formula (VII) can be

obtained by using, in the controlled free radical polymeriza can be varied over a broad range. Preferably, the weight ratio

of block copolymer to binder resin is within the range of from

tion, an initiator fragment IN having at least one functional

group, such as hydroxyl, amino, carboxylic acid, halide, 0.001 to 0.5 more preferably from 0.005 to 0.3 even more

cyano, and/or carbonyl. After having initiated controlled free preferably from 0.01 to 0.1.

radical polymerization, the initiator fragment IN is covalently

[0088] Preferably, the composition is a coating composi

bonded to one end of the polymer chain. In the presence of a

tion, an ink composition or an adhesive composition.

compoundY having two functional groups, a chemical reac

tion between said compound Y and two IN groups of two [0089] Exemplary compositions include a solvent-based

different polymer chains may take place, thereby bonding coating composition, a water-based coating composition, a

high solids coating composition, a powder coating composi

these polymer chains to each other via a linking group of

formula (VII). tion, a solvent-bome ink composition, a water-borne ink com

[0078] The block copolymer of the present invention may position, a UV-curable ink composition, or a UV-curable

coating composition, or combinations thereof.

contain only one block A, or may contain two or more blocks

of A. The blocks may have the same number of monomer [0090] According to a further aspect, the present invention

units or may differ in block length (i.e. different number of is directed to the use of the block copolymer described above

monomer units). as an anti-cratering and/or leveling and/or substrate wetting

[0079] The block copolymer of the present invention may agent in coating compositions, ink compositions, or adhesive

compositions.

contain only one block B, or may contain two or more blocks

of B. The blocks may have the same number of monomer [0091] As the block copolymer of the present invention

units or may differ in block length (i.e. different number of provides a signi?cant reduction in dynamic surface tension, it

monomer units). is preferably used as an anti-cratering and/or leveling agent in

challenging coating systems, such as high solids coatings,

[0080] If the block copolymer contains at least two blocks

powder coatings, solvent-borne inks, water-borne inks, UV

of A and at least two blocks of B, the block copolymer may

inks, UV coatings and/or in high speed coating processes.

comprise the following structural element:

[0081] -B-A-LG-A-B- or -A-B-LG-B-A [0092] According to a further aspect, the present invention

wherein LG is the linking group described above, which is is directed to the use of the block copolymer described above

for reducing dynamic surface tension in a coating composi

preferably of formula (VII).

tion, ink composition or adhesive composition, such as high

[0082] Preferably, the amount of the block copolymer, rela solids coating compositions and powder coating composi

tive to the total composition, is from 0.05 wt % to 15 wt %, tions, ink compositions such as solvent-borne inks, water

more preferably from 0.075 wt % to 10 wt % and most borne inks, UV inks, UV coatings.

preferred from 0.1 wt % to 5 wt %.

[0093] Preferably, the term “reducing dynamic surface ten

[0083] The binder resin can be selected from those com

sion” means that dynamic surface tension is lower if com

monly used for coating compositions. Appropriate binder

pared to a random but otherwise identical copolymer.

resins are known to the skilled person.

[0084] The binder resin can be selected from solvent based

EXAMPLES

resins, water based resins, emulsion polymers, solution poly

mers, or any mixture thereof.

I. Measuring Methods

[0085] The binder resins comprise all kinds of crosslinking

mechanism and coating systems based on one-component

[0094] If not indicated otherwise, parameters de?ned in the

multi-component systems, e.g. thermosetting resins, room present application are measured by the measuring methods

temperature curable resins, radiation-curable resins. Also described below:

included are physically drying coating systems like thermo

[0095] Number Average Molecular Weight Mn, Polydis

plastic acrylic resins.

persity Index PDI

[0086] The resins comprise state of the art polymer chem

[0096] Mn and PDI are measured by gel permeation chro

istry used in coatings, inks and adhesives: e. g. saturated poly

matography (GPC) with polystyrene standards. The eluent is

esters, unsaturated polyesters, polyacrylates, styrene-acrylic

THE.

resins, polyurethanes, epoxy resins, nitrocellulose resins,

hybrid systems like polyester/polyurethanes, polyacrylate/ [0097] Amount of F (in Wt %) and Amount of Fluorine

poly-urethanes, alkyd/melamine, polyester/CAB/melamine, Containing Monomer Units (in Wt %) in the Block Copoly

polyacrylate/CAB/melamine, etc. Preferred binder resins mer

comprise powder coating resins, i.e. resin systems which are [0098] Determined by 1H NMR, 400 MHZ.

US 2015/0018476 A1 Jan. 15,2015

II. Preparation Examples are mixed together, purged With N2 and reacted for 3 h at 120°

C. Residual monomer and ethyl acetate is distilled off at 105°

Inventive Example 1 C. and 20 mbar.

[0109] Yield: 38.3%; GPC (THF, PS-Standard, Mn:3649

Synthesis of a linear A-B Block-copolymer of g/mol, PDI:1.44, viscous liquid)

n-Butyl Acrylate (nBA) and [0110] GK3023-387 (75 Units)

3,3,4,4,5,5,6,6,7,7,8,8,8-Trideca?uoroctyl Acrylate [0111] 1211.13 g of n-Butyl Acrylate (nBA, MW 128.7

(TFOA) g/mol) and 60.00 g of NOR 1 (317.48 g/mol) are mixed

together, purged With N2 and reacted for 1.5 h at 115° C. A

[0099] Synthesis ofA Block

feed of 2422.26 g of nBA is fed to the reactor over 3 hours. At

125° C., the reaction continues for a further 4.5 h. Residual

monomer is distilled off at 105° C. and 20 mbar.

[0112] Yield: 50.36%; GPC (THF, PS-Standard, Mn:9650

g/mol, PDI:1.21, viscous liquid)

[0113] Synthesis ofB Block

NOR 1 n-BA

MW:317.48 MW:128.17

C20H31NOZ C7H1202

O—N O

Y!

O

O

[0100] In a 5000 mL glass reactor With overhead mechani

cal stirrer, condenser, metering pumps, computerized tem TFOA

perature control and data acquisition, the following A-blocks MW I 418.15

are synthesized. C11H7F1302

[0101] GK3023-360 (10 Units nBA)

[0102] 1816.70 g of n-Butyl Acrylate (nBA, MW 128.7

g/mol), 150.00 g of the initiator compound NOR 1 (317.48

g/mol) and 271.38 g of ethyl acetate (EtAc, MW 88.11 g/mol)

are mixed together, purged With N2 and reacted for 3 h at 120°

C. Residual monomer and ethyl acetate is distilled off at 105°

C. and 20 mbar.

[0103] Yield: 33.3%; GPC (THF, PS-Standard, Mn:1706

g/mol, PDI:1.26, liquid)

[0104] GK3023-264 (20 Units)

[0105] 1211.13 g of n-Butyl Acrylate (nBA, MW 128.7

g/mol) and 60.00 g of the initiator compound NOR 1 (317.48

g/mol) are mixed together, purged With N2 and reacted for 3 .5

h at 115° C. Residual monomer is distilled off at 105° C. and

20 mbar.

[0106] Yield: 42.83%; GPC (THF, PS-Standard, Mn:2435

[0114] In a 5-necked 100 mL Sul?er ?ask With an overhead

g/mol, PDI:1.36, viscous liquid)

stirrer, thermometer, cooler and septum, A g of Poly-nBA (see

[0107] GK3023-335 (35 Units) table) and B g of 3,3,4,4,5,5,6,6,7,7,8,8,8-Trideca?uoroctyl

[0108] 1383.92 g of n-Butyl Acrylate (nBA, MW 128.7 Acrylate (TFOA, MW 418.15 g/mol) are mixed together,

g/mol), 40.00 g of the initiator compound NOR 1 (317.48 purged With N2 for 30 minutes and polymerized for 8 hours at

g/mol) and 206.70 g of ethyl acetate (EtAc, MW 88.1 1 g/mol) 128° C. Residual monomer is distilled off at 105° C. and 20

US 2015/0018476 A1 Jan. 15,2015

6

mbar. The polymer is characterized by GPC (THF and With

PS-Standards; note: the refractive index of TFOA is negative)

and lH-NMR (in CDC13).

Description

A—block Wt % F (units of

Poly— A B Yield Mn“ Wt.% in nBA:units

Product nBA (gofA block) (g TFOA) (%) (g/mol) PDI" TFOAZ’ polymerb ofTFOA)b

GK3479- GK3023- 10.00 13.94 82.59 2029 1.29 50.90 30.03 10:3.96

039 360

GK3479- GK3023- 15.00 12.54 88.56 2035 1.23 40.40 23.87 102.59

040 360

GK3479- GK3023- 20.00 5.58 89.12 1771 1.22 19.07 11.25 100.90

041 360

GK3479- GK3023- 27.00 3.00 87.93 2055 1.21 7.51 4.43 10:0.31

076 360

GK3479- GK3023- 27.90 2.10 88.40 2016 1.22 5.91 3.49 100.24

077 360

GK3479- GK3023- 20.00 13.94 95.01 3510 1.20 36.93 21.79 20:4.03

044 264

GK3479- GK3023- 20.00 8.36 92.01 3121 1.22 24.97 14.73 202.29

046 264

GK3494- GK3023- 30.00 4.18 92.44 3377 1.24 10.30 6.07 20:0.79

071 264

GK3494- GK3023- 30.00 20.91 94.96 4331 1.22 37.22 21.96 20:4.08

014 264

GK3479- GK3023- 45.00 5.00 93.31 2949 1.26 6.26 3.70 20:0.46

080 264

GK3479- GK3023- 46.50 3.50 93.57 3012 1.26 4.97 2.93 20:0.36

081 264

GK3479- GK3023- 30.00 7.84 94.09 4476 1.17 17.36 10.24 352.41

043 335

GK3494- GK3023- 30.00 13.07 91.04 5068 1.16 28.26 16.67 35:4.53

028 335

GK3479- GK3023- 30.00 2.61 96.33 5218 1.19 6.29 3.71 35:0.77

070 335

GK3479- GK3023- 27.00 3.00 96.90 4869 1.20 6.21 3.66 35:0.76

079 335

GK3494- GK3023- 50.00 10.59 94.47 8638 1.16 14.89 8.78 75:4.15

026 387

GK3494- GK3023- 50.00 20.91 91.77 9119 1.18 24.86 14.67 75:7.85

027 387

GK3479- GK3023- 50.00 6.27 98.86 8223 1.19 10.22 6.03 752.70

042 387

GK3479- GK3023- 50.00 2.09 98.93 8012 1.19 3.65 2.16 75:0.90

047 387

GK3479- GK3023- 45.00 5.00 97.24 9907 1.23 7.81 4.61 752.01

078 387

GK3479- GK3023- 40.00 14.65 83.99 7803 1.19 5.19 3.06 75:1.30

48‘ 387

GK3479- GK3023- 46.50 3.50 98.11 9476 1.22 5.80 3.42 75:1.46

082 387

'1 by GPC With polystyrene standards

b by H1 NMR

LPolymerization at 115° C. for 2 hours.

US 2015/0018476 A1 Jan. 15,2015

7

Comparative Example 2 -00ntinued

Synthesis of a linear, loW polydispersity, random

copolymer of n-Butyl Acrylate (nBA) and O

3,3,4,4,5,5,6,6,7,7,8,8,8-Trideca?uoroctyl Acrylate

(TFOA)

[0115] GK3479-027

\ 5 F

O F

O F F F

O—N o + —’

[0116] In a 5-necked 100 mL Sul?er ?ask With an overhead

stirrer, thermometer, cooler and septum, C 65 .70 g of n-Butyl

Acrylate (nBA, MW 128.7 g/mol), D 3.70 g of 3,3,4,4,5,5,6,

6,7,7,8,8,8-Trideca?uoroctyl Acrylate (TFOA, MW 418.15

NOR1 H_BA g/mol) and E 2.50 g of NOR 1 (317.48 g/mol) are mixed

MW : 31148 MW : 12817 together, purged With N2 for 30 minutes and polymerized for

CZOHMNOZ QHIZOZ 3-4 hours at 125° C. Residual monomer is distilled off at 95°

C. and 10 mbar. The polymer is characterized by GPC (THF

and With PS-Standards) and lH-NMR (in CDCl3).

Wt % F

C D E Yield Mn " Wt. % in

Product (g oanA) (g ofTFOA) (g NORl) (%) (g/rnol) PDI “ TFOA Z7 polymer Z7

GK3479- 65.70 3.70 2.50 60.14 3724 1.20 8.02 4.73

027

GK3479- 62.00 7.40 2.50 61.80 4031 1.23 14.27 8.42

026

GK3479- 58.00 11.40 2.50 60.71 3814 1.25 19.46 11.48

024

GK3479- 47.79 2.67 2.50 44.87 2217 1.30 12.55 7.41

022

GK3479- 45.06 5.40 2.50 47.76 2298 1.27 17.73 10.46

021

GK3479- 42.38 8.08 2.50 46.11 2296 1.28 21.53 12.70

020

a by GPC With polystyrene standards

b by H1 NMR

-continued Comparative Example 3

_ Synthesis of random copolymer of n-Butyl Acrylate

(nBA) and 3,3,4,4,5,5,6,6,7,7,8,8,8-Trideca?uoroctyl

O Acrylate (TFOA) by free radical polymerization

O

[0117] GK3365-133

5 —> [0118] In a 5-necked 200 mL Sul?er ?ask With an overhead

F stirrer, thermometer, cooler and septum, 50.00 g of sec-Bu

F tanol (MW 74.12 g/mol) is purged With N2 for 30 minutes and

heated to 100° C. A pre-mixed feed ofA 5.00 g of 3,3,4,4,5,

F 1: 1: 5,6,6,7,7,8,8,8-Trideca?uoroctyl Acrylate (TFOA, MW 418.

TFOA 15 g/mol), B 88.54 g of n-Butyl Acrylate (nBA, MW 128.7

MW : 41815 g/mol) and C 6.46 g of tert-butyl Peroxy-2-ethylhexanoate

Cl 1H7F1302 (thOEH, MW 216.32 g/mol) is fed to the reactor over 3

hours. A1ter the completlon 01 the 1eed, the reactlon continues

to react for a further 3 hours. The solvent is distilled off at

1000 C. and 10 mbar. The polymer is characterized by GPC

(THF and With PS-Standards) and lH-NMR (in CDCl3).

US 2015/0018476 A1 Jan. 15, 2015

8

Wt % F

B A C Mn " Wt. % in

Product (g oanA) (g ofTFOA) (g ofthOEH) (gmol) PDI " TFOA b polymer b

GK3365- 88.54 5.00 6.46 2065 1.56 5.35 2.95

133

GK3365- 83.54 10.00 6.46 2072 1.56 10.69 5.90

134

GK3365- 78.54 15.00 6.46 2043 1.50 16.04 8.85

135

GK3365- 88.54 5.00 3.00 2604 1.70 5.35 2.95

136

Inventive Example 4 [0120] In a 5000 mL glass reactor With overhead mechani

cal stirrer, condenser, metering pumps, computerized tem

Synthesis Of a linear B-A-B Block-copolymer 0f perature control and data acquisition, the following A-blocks

n-Butyl Acrylate (nBA, A-blOCk) and 3,3,4,4,5,5,6,6, precursors are synthesized

7,7,8,8,8-Tr1decaf]l;10brloocctlil)l Acrylate (TFOA, [0121] GK3023_389 (75 Units)

_ _ [0122] 2165.22 g of n-Butyl Acrylate (nBA, MW 128.7

[0119] SyntheSIS OfA (Interior) BIOCk g/mol) and 80.00 g of the initiator compound NOR 2 (342.48

g/mol) are mixed together, purged With N2 and reacted for 1 .5

h at 115° C. A feed of 1 624.54 g oanA was fed to the reactor

0 \ over 5 hours. At 125° C., the reaction continues for a further

0 2 h. Residual monomer is distilled off at 105° C. and 20 mbar.

[0123] Yield: 50.29%; GPC (THF, PS-Standard,

O Mn:10740 g/mol, PDI:1.19, viscous liquid)

N + —> _

O [0124] GK3023-287 (15 Units)

0 OH [0125] 2944.4 g of n-Butyl Acrylate (nBA, MW 128.7

N/\/ g/mol) and 180 g of NOR 2 (342.48 g/mol) are mixed

H together, purged With N2 and reacted for 3.5 h at 115° C.

Residual monomer is distilled off at 105° C. and 20 mbar.

NOR 2 n-BA _

MW : 34143 MW :123_17 [0126] Yleldi 28.84%; GPC (THF, PS-Standard, Mn:2172

CISH34NZO4 QHIZOZ g/mol, PDI:1.25, viscous liquid)

[0127] GK3023-010 (35 Units)

[0128] In a 2000 mL glass reactor With overhead mechani

O—N 0 cal anchor stirrer, condenser and metering pumps 561.36 g of

n n-Butyl Acrylate (nBA, MW 128.7 g/mol) and 50.00 g of

NOR 2 (342.48 g/mol) are mixed together, purged With N2

and reacted for 2 h at 115° C. A feed of748.48 g oanA is fed

O O O

NH to the reactor over 6 hours. At 120° C., the reaction continues

for a further 6 h. Residual monomer is distilled off at 105° C.

and 20 mbar.

[0129] Yield: 49.67%; GPC (THF, PS-Standard, Mn:7739

HO g/mol, PDI:1.14, viscous liquid)

[0130] Coupling to Synthesize Difunctional A-Blocks

Description:(TFO, MW 346.09 g/mol) and C g of toluene are mixed together, purged With N2 for 30 minutes and polymerized for. 6 hours at re?ux (106-1100 C.). Residual monomer and sol vent is distilled off at 1200 C. and 20 mbar to >99%. The polymer is characterized by a mass balance of the distillate. Wt % F.