Preview Chemical Engineering Kinetics

CONTRIBUTORS Numbersinparenthesesindicatethepagesonwhichtheauthors’contributionbegin. V. ARUTYUNOV, Laboratory of Hydrocarbon Oxidation, Semenov Institute of Chemical Physics, Moscow, Russia (167) G. BOZZANO, Dipartimento di Chimica Materiali e ingegneria Chimica, Politecnico di Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) M. DENTE, Dipartimento di Chimica Materiali e ingegneria Chimica, Politecnico di Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) T. FARAVELLI, Dipartimento di Chimica Materiali e ingegneria Chimica, Politecnico di Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) P. GALTIER, Institut Franc-ais du Pe´trole, IFP-Lyon, BP.3, F-69390 Vernaison, France (259) W.H.GREEN,JR.,DepartmentofChemicalEngineering,MassachusettsInstitute of Technology, Cambridge, MA 02139, USA (1) A. MARONGIU, Dipartimento di Chimica Materiali e ingegneria Chimica, Politecnico di Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) S.PIERUCCI,DipartimentodiChimicaMaterialieingegneriaChimica,Politecnico di Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) E.RANZI,DipartimentodiChimicaMaterialieingegneriaChimica,Politecnicodi Milano, Piazza L. da Vinci 32, 20133 Milano, Italy (51) A. ROMANETS, Russian Research Center Kurchatov Institute, Moscow, Russia (167) M.SINEV,LaboratoryofHeterogeneousCatalysis,SemenovInstituteofChemical Physics, Moscow, Russia (167) ix PREFACE Understanding and modeling the kinetics of chemical reactions certainly is crucial to any research and development effort aimed at process optimization and innovation. This issue provides four complementary points of view. It reflects the state-of-the-art as well as views on the way to proceed by reporting on the efforts of a, I hope representative, sample of research and development groups. I was in particular happy to find a group having close commercial ties with the process industry willing to communicate some of their results and methods. In order to stress as much as possible the generic nature of the mes- sages that are conveyed, the focus is not on catalytic processes. Theblessingofthelatter,i.e.thepossibilitytosuppressspecificundesiredside reactions,rendersanykineticmodelstronglycatalystdependentwhichisacurse to the modeler. Accounting in a clever way for so-called catalyst descriptors deserves a separate issue. A first contribution by W. H. Green Jr. from Massachusetts Institute of Technology sets the scene. The author advocates a paradigm shift in chemical kinetics from ‘‘postdictive’’ to predictive models. The latter would provide a sound basis for process and product design and, hence, not only accelerate the pace of innovation but also allow an a priori assessment of the societal, e.g. environmental, impact of new technologies. Predictive modeling requires further progress at three different levels. The construction of the models, the numerical solution of the conservation equations accounting also for the appropriate transport phenomena and finally the validation of the models are discussed. A‘‘datamodel’’,i.e.astandardwayofexpressinginformationdifferentfrom the classical lists-of-reactions is proposed. The core of it is constituted by the concept of functional groups well known from organic synthesis. The latter is implementedin‘‘hierarchicalfunctionalgrouptreestructure(s)whichcaneasily incorporate new chemistry information’’ because ‘‘it will be many decades beforethefunctionalgrouptreeswillbeatallcomplete’’.Focusingonfunctional groups rather than elementary reactions allows to calculate rate coefficients based on ‘‘an extension of the thermochemical group-additivity to transition states’’. The elementary reactions are generated automatically by computer codes in which ‘‘reaction recipes’’ based on the reactivity of the functional groups are formalized. Criteria and computational techniques which allow to have the size of a reaction network large enough to account for the important features of a process but not larger than that are discussed. The importance of accountingforuncertaintyisstressedthroughoutthepaper.Thepropagationof uncertainties in both the reaction network and the rate coefficients via the solution of the model equations is presented in a very systematic way. This xi xii PREFACE allows togive a statistically justifiedanswerto thequestion ofvalidation: ‘‘Are model predictions consistent with experimental data?’’ At each of the levels addressed the author refers to available software and databases, which makes this chapter visionary as well as practical. The contribution from the Politecnico di Milano reports on the tremendous experience accumulated over the years by the team of Mario Dente and Eliseo Ranzi in the field of steam cracking, one of the largest scale production proc- esses of the petrochemical industry. The authors have been pioneering the sub- stitution of global power law rates by what today is often called microkinetics, i.e. by kinetics accounting fully for the elementary reactions and the radicalar reaction intermediates. An overview is given of the challenges that have to be overcome in order to describe the kinetics of complex mixtures. The contribu- tion is not limited to clearly explaining the developed methodology. It also explicitly indicates the introduction of simplifications. The latter are required notonlytomaintainthecomputationaleffortswithinreasonablelimitsbutalso, and more fundamentally, because of the uncertainties concerning feed compo- sition. It is fascinating to see how the introduced simplifications are based on insight in the reaction mechanism. Nevertheless, the authors illustrate the generic nature of their methodology by applying it to other free radicalar processes such as polyaromatic, i.e. coke or soot, formation and thermal degradation of polymers. The Russian school of chemical kinetics is represented by a chapter on oxidation of alkanes by Mikhail Sinev and coworkers from Moscow. Their contribution addresses more ‘‘philosophical’’ issues. What should modeling be aimedat?Accordingtotheauthors,obtaininginsightsintheimportantreaction paths rather than a ‘‘perfect’’ description of experimental data should be pur- sued. The latter are considered to be too often affected by phenomena such as transport limitations, certainly during the oxidation of alkanes. Most of the examples relate to the oxidation of methane to methanol/formaldehyde, to synthesis gas or, by oxidative coupling, to ethene. The importance of the interaction between homogeneous gas phase reactions and heterogeneously catalyzed steps is stressed. For the homogeneous reactions the use of kinetic parameters obtained from quantum chemical calculations is advocated. Although some examples are given, it is realized that this is much less within reach for the elementary reactions involving the catalytic active sites. The possible optimization of either the process conditions or the catalyst formula- tionforoxidativecouplingofmethanebasedontheinsightsprovidedbykinetic modeling is illustrated. Thelastchaptergivesanindicationaboutthestate-of-the-artinanindustrial environment.TheauthorPierreGaltierreportsontheactivitiesattheIndustrial Studies and Development Center of the French Petroleum Institute (IFP) by a ‘‘Kinetics and modeling’’ group of several researchers performed over a period of more than 10 years. The aim of the research work is to develop basic knowledge on the kinetics of the main reactions involved in refining and PREFACE xiii petrochemical processes. This methodological research is designed to reduce development costs by constructing detailed and predictive kinetic models. The results of kinetic studies conducted at laboratory and pilot scale allow to improve the economics of industrial processes and to minimize the risks inherent to industrialization of new processes. Galtier focuses on the so-called ‘‘single-event’’methodologyasappliedtoabifunctionally,i.e.involvingbotha (de)hydrogenating and a carbon skeleton conversion function, catalyzed proc- ess:thehydrocrackingofheavycrudeoil cuts.Thesecondfunctionisprovided byacidsites,whichleadtoreactivecarbeniumionintermediates.Ascarbenium chemistryiswellknown,itsformalizationinreactionrecipesisstraightforward. It turns out that the number of elementary reaction families to be considered and, hence, the number of kinetic parameters is relatively small. Still, the number of elementary reactions becomes huge for heavy crude oil cuts. The author shows how the single-event methodology can be extrapolated to heavy cuts without generating the corresponding reaction network. Finally, let me point your attention to volume 28 of Advances in Chemical Engineering on ‘‘Molecular Modeling and Theory in Chemical Engineering’’ published five years ago. Several chapters elaborate on the use of quantum chemical calculations to obtain thermochemical and kinetic data. This is the onlyreasonwhyIoptednottoincludesimilarmaterialinthisvolume.Clearly, abinitiocomputationaltechniques,oratleasttheresultsofthelatter,shouldbe part of the toolkit to obtain chemical engineering kinetics. Guy B. Marin Ghent, Belgium September 2006 PREDICTIVE KINETICS: A NEW APPROACH FOR THE 21ST CENTURY (cid:1) William H. Green, Jr. DepartmentofChemicalEngineering,MassachusettsInstituteofTechnology,Cambridge, MA02139,USA I.Introduction 2 A. TheHistoricalApplicationsofKineticModeling 2 B. TheGoalofChemicalKineticModeling 5 II.ConstructionofPredictiveChemicalKineticModels 7 A. TheChallengeofDocumentingLargeSimulations 8 B. DataModelsforChemicalKinetics 9 C. AutomatedConstructionofLists-of-Reactions 11 D. A New Data Model for Chemical Reactions and Properties 13 E. TheReactionMechanismGenerator(RMG) 26 F. ApplicationsofRMG 27 III.EfficientlyandAccuratelySolvingLargeKinetic Simulations 29 A. FastSolutionofLargeSystemsofChemistry EquationsUsingSparsity 31 B. Using Reduced Chemistry Models in Multidimen- sionalSimulationswithoutIntroducingError 32 C. Constructing Reduced Chemistry Models Satisfying ErrorBoundsOverRanges 34 IV. Are Model Predictions Consistent with Experimental Data? 38 A. HowtoProveInconsistencyEvenifSomeParameters AreHighlyUncertain 39 B. How Standard Operating Practice Must Change in 21stCentury 41 C. EstimatingErrorBarsonModelPredictions 42 V. SummaryandOutlook 46 Acknowledgments 47 Nomenclature 47 References 48 (cid:1) Correspondingauthor.E-mail:balkwill@MIT.EDU 1 AdvancesinChemicalEngineering,vol.32 Copyrightr2007byElsevierInc. ISSN0065-2377 Allrightsreserved. DOI10.1016/S0065-2377(07)32001-2 2 WILLIAMH.GREEN,JR. Abstract The capability to reliably predict the behavior of reactive chemical systems would allow rational a priori design of chemical reaction sys- tems. Recent progress toward overcoming several technical obstacles to predictive kinetics for homogeneous gas-phase systems is reviewed. Thefocusison(1)updatestothefundamentaldatamodelusedinkinetic modeling, (2) methods for solving large kinetic simulations efficiently without relying on uncontrolled approximations, and (3) methods for determining whether or not the model predictions are consistent with experimental data. Appropriate handling and archiving of experimental data from different sources, and of the many uncertainties in the data embeddedthroughoutthekineticmodels,isamajorchallengefacingthe kinetics community as kinetics becomes a predictive science. I. Introduction Chemicalkineticmodelinghasbeenoneofthepillarsofchemicalengineering since the field was founded. In many respects, it is the aspect that distinguishes chemical engineering from other fields of engineering. However, despite a huge amountofworkbythousandsofresearchers,westillhaveaverylimitedability to predict what will happen in a newly proposed reactive system, even in well- characterized gas-phase systems with simple fluid mechanics. A number of technical problems significantly impeded progress in kinetics during the 20th century. Here we briefly review the history and the goals of chemical kinetic modeling,and highlight a few of thetechnical areas where significantadvances have been made in the first years of the 21st century. A. THE HISTORICAL APPLICATIONS OF KINETIC MODELING 1. Predictive vs. Postdictive Models Chemicalkineticmodelsplaymultipleroles.Inthe20thcentury,thesemodels weremostoftenusedtoassistintheinterpretationofexperimentaldata,andfor theinterpolationsusedinprocessoptimizationandcontrol.Kineticmodelsalso played an essential role in the process of generalizing new chemical knowledge from experimental results. In both of these applications, a large amount of experimental data were measured first and then kinetic models were used to rationalize or interpolate between these experimental data. It would not be too unfairtocharacterizemostofthisworkas‘‘postdictive’’,i.e.themodelerswere PREDICTIVEKINETICS 3 not able to say anything interesting until after a considerable amount of experimental work had been completed. Of course, chemical kinetic models would be even more useful if they could accurately predict the behavior of reacting systems under conditions signi- ficantly different from those that have already been measured. If these extra- polative predictions were accurate enough, chemical kinetic models could becomevaluabletoolsinprocessandproductdesign,andbyreducingtheneed todosomanyexperimentsinordertogainasmallamountofinformation,the models could accelerate the pace of innovation. Reliable predictive kinetic models would be particularly helpful in situations where it is impractical to do theexperiments,e.g.inthepublicpolicyarena,whereafailedexperimentcould be prohibitively costly, or in situations where the experiment is impossible (e.g. predicting what happens in very slow or very fast processes). Inrecentyears,ithasbecomepossibletoextrapolateaccuratelyusingdetailed chemical kinetic models to predict quantitatively the behavior of some rather complicatedchemicalsystems.Themostfamousexamplesofthissuccessarethe detailedatmosphericchemistrymodelswhosepredictionsunderlietheMontreal Protocol on ozone-depleting chemicals. However, these atmospheric chemistry modelsweredevelopedthroughahugeinternationaleffortoverseveraldecades, based heavily on a large number of laboratory experiments. Much more rapid and efficient methods of model development are required for detailed predic- tive chemical kinetics to become a practical everyday design tool for chemical engineering. 2. Technical Hurdles in the 20th Century Several technical issues significantly hampered progress in chemical kinetic modeling in the 20th century; among these were serious difficulties solving kinetic simulations numerically, difficulties constructing and checking (and peer-reviewing)largesimulations,problemswithestimatingreactionrateswhen thermochemistry and experimental data were missing, and problems checking whether model predictions were consistent with experimental data. First, significant numerical problems plagued the kinetic models. Almost all chemical kinetic systems are intrinsically ‘‘stiff’’, with a large separation of timescales between the most reactive and least reactive species in a mixture. Although a number of clever approximations were used to circumvent this problem, the situation was highly unsatisfactory (e.g. it was very difficult to provethattheapproximationswerevalid)untilWilliam Gearinventedthefirst algorithm capable of numerically solving stiff systems of differential equations with error control in the 1970s (Gear, 1971). Also, most chemical kinetic systems of interest to engineers involve a relatively large number of species, whichmadethemhardtohandleuntilcomputerswithsignificantcorememory became widely available (cid:1)1980. The development of the CHEMKINs soft- wareinthe1980s,whichdealtwiththemostcommondata-handlingissuesand 4 WILLIAMH.GREEN,JR. also incorporated a reliable stiff differential equation solver that evolved from Gear’s algorithm, was a major step-forward in chemical kinetic modeling (Kee et al., 1989). Toward the end of the last century, modelers benefited tremen- dously from the rapid improvements in computer hardware and from major advances in the capability to solve multidimensional, multi-species kinetic simulations.Buttherearestillmanyimportantreactortypeswhosesimulations are plagued by numerical issues and by hardware limitations; at present there are only a handful of well-tested widely distributed solvers with error control, and these solvers work only for specific idealized reactor types. As the numerical solvers have become capable of solving rather complicated chemicalkineticsimulations,modelershavehadtoacceptthatwedonotreally know the chemistry of most processes as well as one might hope, and in some cases the reacting mixtures are so complicated that it is doubtful anyone could write down all the reactions occurring, even if we did know all the chemistry. (Forcomplicated reactorgeometries, there isasimilarproblem associatedwith constructing a suitable mesh for solving the transport equations.) The problem of complex chemistry was recognized even before CHEMKIN became widely available, and has led to the development of dozens of automated mechanism- constructionprogramsoverthepasttwodecades(Blurock,2004a,b;Broadbelt et al., 1994; Chevalier et al., 1990; Chinnick et al., 1988; Dente et al., 1979; DiMaioandLignola,1992;Hillewaertetal.,1988;Kojima,1994;Matheuetal., 2003a;PrickettandMavrovouniotis,1997a,b,c;QuannandJaffe,1992;Ranzi et al., 1995; Tomlin et al., 1997; Warth et al., 2000; Zarth et al., 2002). These programs have been successful in modeling some systems, but as discussed below there are many significant unresolved technical issues which have pre- vented these programs from having a broad impact on the field. A very im- portant problem is that most of the model-construction software is not sufficiently flexible; in particular, it is rather hard to add additional chemistry and modify the rate parameters as knowledge improves. As a result, the soft- warecaneasilybecomeobsolete.Also,itisverydifficulttocheckorpeer-review large complicated simulations; this combined with the tendency for postdic- tive modeling makes many researchers skeptical about the usefulness of large simulations. For most of the 20th century, the only solid basis for assigning a numerical value to a rate parameter was experimental data. However, in most experi- mental systems, the number of parameters determinable from the experimental ratedataismuchlessthanthenumberofrateparametersneededinthechemi- calkineticmodel.Benson(1976)andothersproposedmethodstoestimatesome rate parameters, (primarily by analogy) to reactions whose rate constants had beenmeasured,buttherewerestillalargenumberofreactionsthatcouldnotbe estimated at all, and it was hard to know how confidently one could use the analogy-based estimates. Of necessity, researchers developing large kinetic models developed rules-of-thumb to estimate reaction rates for the reaction familiesofgreatestimportanceinthesystemstheyweresimulating,butthiswas PREDICTIVEKINETICS 5 necessarily very ad hoc in the absence of any data with which to check the estimates. In the last decade of the 20th century, computation of reaction rates (and thermochemistry) using quantum chemistry became feasible, making it possible to check the accuracy of the analogy-based estimates. With the quantumchemistry techniquesavailableatthat time,this wasmost feasible for thermochemistry, and several researchers, notably Melius (Melius and Allendorf, 2000; Zachariah and Melius, 1998) and Bozzelli (Lay and Bozzelli, 1997a, b; Lay et al., 1997) and their collaborators, used quantum chemical calculations to significantly improve the quality of thermochemical (and some rate) estimates used in combustion models. By the end of the 20th century, similar techniques were being widely used to improve barrier height and A-factor estimates, usually using transition state theory (Truhlar et al., 1996). Sumathi and Green (2002) reviewed the state of the art in rate estimation for large-scale kinetic modeling around the turn of the century. Finally, there are multiple hurdles that made it difficult to appropriately compare kinetic model predictions with experimental data in the 20th century, and which still make it very difficult today. As discussed in Section IV below, there are some numerical issues which make it hard to determine definitively whether or not a model is consistent with a data set. If the model is consistent, one shouldbe able torefinethe model parameters using theexperimentaldata, but this is numerically challenging when one is working with large-scale non- linear kinetic simulations and large data sets. Response surface methods were used successfully for this parameter refinement step toward the end of the 20th century (Aghalayam et al., 2000; Frenklach et al., 1992). Abiggerproblemthanthenumericalissuesisthedifficultyincomingupwith the data and the error bars needed to make a meaningful comparison between the model and experiment. Very often one can no longer locate all the original experimentaldatainordertomakeacomprehensivecomparison,andeventhe dataonecanfindseldomcomeswithreliableerrorbars.Also,researchersrarely compute the error bars in a large chemical kinetic model’s predictions. So, althoughthousandsofkineticmodelvs.datacomparisonswerepublishedinthe 20thcentury,inmostcasestheseplotsareinsufficienttodetermineconclusively whether the model is really consistent with the data, and it would usually be difficult-to-impossible to determine the error bars on any of the model para- meters based on the published comparison. Withthishistoryofdifficultiesinmind,inthenextsectionwereconsiderwhat are the real goals of chemical kinetic modeling. B. THE GOAL OF CHEMICAL KINETIC MODELING The primary goal of chemical kinetic modeling is to make predictions: given our current understanding of chemistry, what do we expect to happen in a particularreactingmixtureunderspecifiedreactionconditions?Ifdesired,these 6 WILLIAMH.GREEN,JR. FIG.1. TheModel-Prediction-Dataloop.Thisarticleisfocusedonthestepsontheleftside,from model-constructionthroughconsistencytesting. modelpredictionscanthenbequantitativelycomparedwithexperimentaldata, to determine if the two are consistent, Fig. 1. If the model and the data are inconsistent, at least one of them must be wrong, and we have identified an interesting opportunity to learn something new. If the model and the data are consistent within the error bars on each, then we say the model has been validated (never proven), and the experimental data can be used to refine the model parameters. To the extent that we have confidence in the predictions of chemical kinetic models,we couldthen usethese models todesign newproducts, processes,and reactors to plan new experiments, to design model-based control systems and safety systems, and to inform critical business and public policy decisions. However, to develop the required level of confidence in the model predictions, the loop in Fig. 1 must be functioning effectively. Inthepresentpaperwefocusonafewofthestepsinvolvedintheleftsideof the loop shown in Fig. 1: (1) Construction of predictive chemical kinetic models (2) Efficient and accurate numerical solution of chemical kinetic simulations, and (3) Quantitative tests whether the model and data are consistent. Each of these three steps is addressed in a separate section below.

The list of books you might like

Shatter Me Complete Collection (Shatter Me; Destroy Me; Unravel Me; Fracture Me; Ignite Me)

As Good as Dead

Rich Dad Poor Dad

The Silent Patient

CENTRO DE CIÊNCIAS BIOLÓGICAS – CCB DEPARTAMENTO DE ANATOMIA / CCB Sala da

Human-in-the-Loop Machine Learning: Active learning and annotation for human-centered AI

Tau Lepton Reconstruction and Identification at ATLAS

Greek Government Gazette: Part 2, 1993 no. 615

Objektorientierte Programmierung mit JavaScript: Direktstart für Einsteiger

Did I Mention I Miss You?

DISCOVERY OF SUBULARIA-AQUATICA L IN COLORADO AND THE EXTENSION OF ITS RANGE

Духовные христиане молокане в Амурской области во второй половине XIX - первой трети ХХ вв

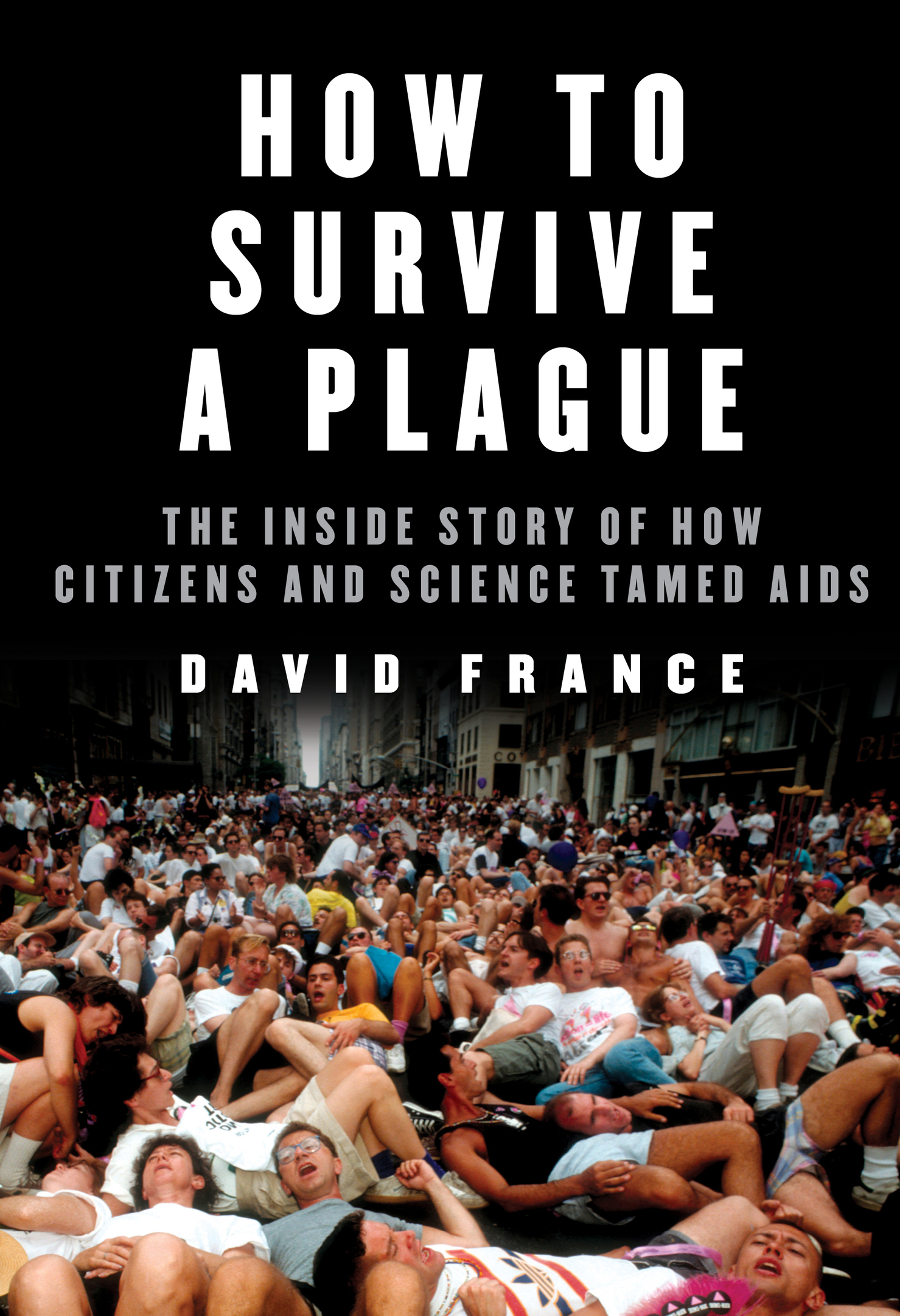

How to Survive a Plague

By Aaron Grothe NEbraskaCERT

TCPS 1262-2549: Jointed Paper Grass

DTIC ADP023953: Space Power for War Fighters

By: Abu Ja'far Muhammad ibn Ali ibn Hussein ibn Musa ibn

Advancements in Genetic Linkage Maps and Quantitative Trait Locations of Aquatic Farming Animals

ERIC EJ746033: Should Academic Unions Get Involved in Governance?

Overview of Boundary Layer Transition Research in Support of Orbiter Return To Flight