Table Of ContentS

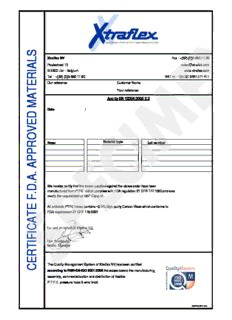

L Xtraflex NV Fax : +(32)-(0)3-680.11.99

A

Paaiestraat 13 [email protected]

I B-2500 Lier - Belgium www.xtraflex.com

R

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

E

Our reference Customer Name

T

Your reference

A

Acc to EN 10204:2005 2.2

M

Date :

D

E

V

O

R Material type

Hose Lot number

P

P

A

.

A

.

D We hereby certify that the hoses supplied against the above order have been

manufactured from PTFE which complies with FDA regulation 21 CFR 177.1550 and also

.

F meets the requirement of USP Class VI.

E

All antistatic PTFE hoses contains <2.5% high purity Carbon Black which conforms to

T FDA requirement 21 CFR 178.3297

A

C

For and on behalf of Xtraflex NV,

I

F

I Tom Rombouts

T

Quality Manager

R

E

C The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERFDA 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

B-2500 Lier - Belgium www.xtraflex.com

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

E Our reference Customer Name

T Your reference

A

Acc to EN 10204:2005 2.2

C

Date :

I

F Type hose :

Length hose :

I

T Quantity :

R

Connection 1 type :

E

Connection 2 type :

C

T

S

:

E

T Tested by :

Inspection :

E

R We hereby certify that the materials described above have been 100% tested and

withstood the specified pressure without leaking.

U

S

S

E

R

For and on behalf of Xtraflex NV,

P

Tom Rombouts

Quality Manager

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERTEST 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

B-2500 Lier - Belgium www.xtraflex.com

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

Our reference Customer Name

L Your reference

A Acc to EN 10204:2005 3.1.

I

R

Date :

E :

T Description :

A

M

Part type Material type Certificate of material

F

O

E

T

A

C

I

F

I

T

R

We hereby certify that the materials described above are in accordance

E with your order and in accordance to our specifications hereby enclosed.

C

For and on behalf of Xtraflex NV,

Tom Rombouts

Quality Manager

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERMAT 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

B-2500 Lier - Belgium www.xtraflex.com

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

Y Our reference Customer Name

T Your reference

I

M Acc to EN 10204:2005 2.2.

R Date :

Type Hose :

O

Length Hose :

F Quantity :

N

O

C

Connection 1 Type :

Connection 2 Type :

F

O

E We hereby certify that the materials used in this assembly are in accordance

T with your order and according to our specifications hereby enclosed.

A

C

I

F

I

T

R

E

For and on behalf of Xtraflex NV,

C

Tom Rombouts

Quality Manager

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERCON 2.2 2014 v2.0

4

0

0 Xtraflex NV Fax : +(32)-(0)3-680.11.99

2 Paaiestraat 13 [email protected]

/

B-2500 Lier - Belgium www.xtraflex.com

5

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

3

9 Our reference Customer Name

1 Your reference

C Regulatory Compliance Statement for Food Contact Materials

E Date :

E We hereby declare that all our bulk hoses and hose assemblies are made from following PTFE grades

C

- Dupont Teflon® 62-N and 62XT

N - Dyneon TFM™ 2070Z

- Daikin F303

A

I All of these suppliers declare that the PTFE has the following status relative to food contact regulations

L

in Europe and the USA:

P

M European Union

Compliant with European Regulation EC1935/2004 and its amendments

O

( specifically European Regulation EU10/2011).

C

USA

F Compliant with the FDA regulation 21 CFR 177.1550 § (a) (2) and (b) when used to manufacture

O moulded/extruded articles.

Xtraflex also had migration tests carried out by an independent laboratory on representative pieces of

N

the above tubing to make sure that all of our PTFE hose products have been processed following the

O Good Manufacturing Practises Regulation EC 2023/2006EC. These tests were all positive so all is

compliant to article 3 of Regulation EC 1935/2004.

I

T This migration test certificate ( IBE-BVI - CFP-11.144 ) can be received upon request.

A

For and on behalf of Xtraflex NV,

R

A

Tom Rombouts

L

Quality Manager

C

E

The Quality Management System of Xtraflex NV,has been certified

D

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERFOOD 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Y

Paaiestraat 13 [email protected]

T

B-2500 Lier - Belgium www.xtraflex.com

I

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

L

Our reference Customer Name

A

U Your reference

Q Acc to EN 10204:2005 2.1.

C Date :

I

T

A

T

S

-

I

T

N

We hereby certify that the hoses supplied against the above order have been tested

A

in accordance with EN ISO 8031:2009 Clause 7 and meet the

requirements of Appendix A having a resistance of between 10³ Ω and 10⁸ Ω

F

between the inside of the hose and end fitting.

O

E

T

A

C

I

F

For and on behalf of Xtraflex NV,

I

T

R

Tom Rombouts

E Quality Manager

C

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERAS 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

Y

B-2500 Lier - Belgium www.xtraflex.com

T

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

I

Our reference Customer Name

M

Your reference

R

Acc to EN ISO 8031:2009 dd. 12/2009 and CLC/TR 50404 dd. 06/2003

O

F

Date :

N

O

C

X We hereby certify that the materials used in this assembly are in accordance with EN

ISO 8031:2009 dd. 12/2009 and CLC/TR 50404 dd. 06/2003.

E

T

Electrostatic properties of these hoses allow use in explosive environments in following

A industries:

F

Surface industries:

O Dusty environments in areas type 20, 21 and 22 (according to guideline 1999/92/CE).

Gas environments group IIA ,IIB & IIC in areas types 0, 1 & 2 (according to guideline

E (1999/92/CE).

T

Mining industries:

A

All extraction types & depths.

C

I

F

I

T For and on behalf of Xtraflex NV,

R

E Tom Rombouts

Quality Manager

C

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERATEX 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

B-2500 Lier - Belgium www.xtraflex.com

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

Our reference Customer Name

E

Your reference

T

Acc to EN 10204:2005 2.2.

A

Date :

C

Type hose :

I

Length hose :

F

Quantity :

I

T

Connection 1 type :

R

Connection 2 type :

E

C

Vacuum tested : 95 %

T

S

E We hereby certify that the materials described above have been vacuum tested and

T withstood the specified vacuum.

M

U

U

C

A

V

For and on behalf of Xtraflex NV,

Tom Rombouts

Quality Manager

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CERTESTVAC 2014 v2.0

C

E

/

3

2

/

7

9

Xtraflex NV Fax : +(32)-(0)3-680.11.99

E

Paaiestraat 13 [email protected]

V

I B-2500 Lier - Belgium www.xtraflex.com

T

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

C

Our reference Customer Name

E

R Your reference

I

D Declaration of conformity according to directive 97/23/EC

O

Date :

T

G

Description :

N

Type-, Serial-, Identification-No :

I

D Max. allowable pressure PS :

Allowable max./min. Temperature TS :

R

Diameter DN :

O

Year of manufacturing :

C

Test pressure PT :

C

Testfluid :

A

Corresponds to the Pressure Equipment Directive 97/23/EC.

Y

Applied conformity assessment procedures:

T

I Certificates which are included:

M

-Certificate of conformity No. :

R

-Certificate of material No. :

O

-Testcertificate No. :

F

N

O

C

F For and on behalf of Xtraflex NV,

O

N Tom Rombouts

O Quality Manager

I

T

A

R The Quality Management System of Xtraflex NV,has been certified

A according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

L assembly, commercialisation and distribution of flexible

C

P.T.F.E. pressure hose & wire braid.

E

D

CERPED 2014 v2.0

Xtraflex NV Fax : +(32)-(0)3-680.11.99

Paaiestraat 13 [email protected]

B-2500 Lier - Belgium www.xtraflex.com

Tel : +(32)-(0)3-680.11.90 VAT nr : ON-BE 0464.871.411

Y Our reference Customer Name

T Your reference

I

M Degreasing Acc to EN 10204:2005 2.2.

R Date :

Type hose :

O

Length hose :

F Quantity :

N

Connection 1 type :

O Connection 2 type :

C

F

O

We certify that the assemblied hoses have been degreased, dried and were equipped

with dust caps. They have been packed in seperate plastic bags.

E

T We hereby certify that the materials used in this assembly are in accordance

with your order and according to our specifications hereby enclosed.

A

C

I

F

I

T

R

E

For and on behalf of Xtraflex NV,

C

Tom Rombouts

Quality Manager

The Quality Management System of Xtraflex NV,has been certified

according to NBN-EN-ISO 9001:2008.the scope covers the manufacturing,

assembly, commercialisation and distribution of flexible

P.T.F.E. pressure hose & wire braid.

CLEANING 2014 v2.0

Description:Good Manufacturing Practises Regulation EC 2023/2006EC. These tests were all positive so all is compliant to article 3 of Regulation EC 1935/2004. This migration test certificate ( IBE-BVI - CFP-11.144 ) can be received upon request. P.T.F.E. pressure hose & wire braid. For and on behalf of Xtrafle