Table Of ContentARGUS

Page 1

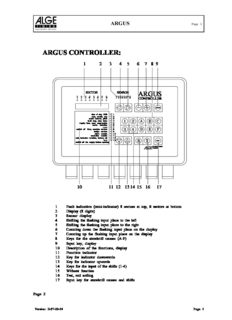

ARGUS CONTROLLER:

1 2 3 4 5 6 7 8 9

ARGUS

SECTOR SENSOR

1 2 3 4 5 6 7 8 12345678 CONTROLLER

time of day, RPM 1

year, month, day 2

sound volume, pitch 3

fault stop, stop delay 4

inquiry time, error suppression 5

sector selection 6

code 7

switch off time, machine number 8

design number 9

stitch counter 10

revolution counter 11

call, indicator variation, battery off 12

test 13

switch off the supply before opening

ELECTRONIC

TIMING

10 11 12 1314 15 16 17

1 Fault indication (mini-indicator) 8 sectors at top, 8 sectors at bottom

2 Display (8 digits)

3 Sensor display

4 Shifting the flashing input place to the left

5 Shifting the flashing input place to the right

6 Counting down the flashing input place on the display

7 Counting up the flashing input place on the display

8 Keys for the standstill causes (A-F)

9 Input key, display

10 Description of the functions, display

11 Function indicator

12 Key for indicator downwards

13 Key for indicator upwards

14 Keys for the input of the shifts (1-4)

15 Without function

16 Test, rail soiling

17 Input key for standstill causes and shifts

Page 2

Version: E-97-09-24 Page 1

ARGUS

Page 2

ATTENTION:

Only your qualified personnel is allowed to open the

ARGUS Controller. Please keep the key at a safe

place.

The electrical installation must be executed in ac-

cordance with the local provisions.

Touching the electrical wires means

danger to your life!

Version: E-97-09-24 Page 2

ARGUS

Page 3

Table of contents

1. CHARACTERISTICS..............................................................................................................................4

2. PARTS OF THE UNIT............................................................................................................................5

3. DISPLAY FUNCTIONS..........................................................................................................................6

3.1. FUNCTION 1: time of day and RPM...................................................................................7

3.2. FUNCTION 2: date ................................................................................................................7

3.3. FUNCTION 3: sound volume (L) and pitch (H)..................................................................7

3.4. FUNCTION 4: fault stop and stop delay.............................................................................8

3.5. FUNCTION 5: inquiry time and error suppression............................................................8

3.6. FUNCTION 6: sector selection ............................................................................................9

3.7. FUNCTION 7: code ...............................................................................................................9

3.8. FUNCTION 8: switch off time and machine number......................................................10

3.9. FUNCTION 9: design number...........................................................................................10

3.10. FUNCTION 10: stitch counter ............................................................................................. 10

3.11. FUNCTION 11: revolution counter......................................................................................10

3.12. FUNCTION 12: special functions........................................................................................ 10

3.13. FUNCTION 13: test program............................................................................................... 12

4. PRODUCTION DATA..........................................................................................................................13

4.1. Machine statistics ..................................................................................................................... 13

4.2. Input of shifts............................................................................................................................. 13

4.3. Input of standstill reasons........................................................................................................13

5. TECHNICAL DATA..............................................................................................................................14

5.1. ARGUS Controller ....................................................................................................................14

5.2. ARGUS Indicator ...................................................................................................................... 15

6. DATA COLLECTION BY THE PC..................................................................................................... 16

7. CONNECTING TERMINALS .............................................................................................................18

7.1. Sensor........................................................................................................................................ 18

7.2. Sector......................................................................................................................................... 18

7.3. Stop............................................................................................................................................. 18

7.4. Alarm ..........................................................................................................................................18

7.5. Special........................................................................................................................................ 18

7.6. 380V/220V/0V/earth (supply)..................................................................................................19

7.7. Out .............................................................................................................................................. 19

7.8. Bus.............................................................................................................................................. 19

7.9. Indicator......................................................................................................................................19

7.10. Loudspeaker..............................................................................................................................19

8. MOUNTING AND INSTALLATION.................................................................................................... 20

9. PUTTING INTO SERVICE ................................................................................................................. 26

9.1. Basic settings............................................................................................................................ 26

9.2. Setting of sensor 1....................................................................................................................26

9.3. Setting of sensor 2....................................................................................................................27

9.4. Advice concerning the switch bar, inquiry time and fault suppression ............................. 27

10. MAINTENANCE................................................................................................................................... 28

11. TROUBLE SHOOTING....................................................................................................................... 29

11.1. Some causes of gross faults of the unit ................................................................................29

11.2. Some causes of hidden faults.................................................................................................30

11.3. Test with regard to reduced insulating resistance of the bars............................................ 30

11.4. Trouble shooting by means of the test program................................................................... 30

11.5. Function check of sensor 3 to 7.............................................................................................. 32

11.6. Function check of the switch bars (divided into sectors).................................................... 32

11.7. Auxiliary indicator at the Controller ........................................................................................ 32

11.8. Indicator does not display........................................................................................................32

12. EXCHANGE OF PROGRAM (EPROM) AND TK-RAM................................................................. 33

ARGUS manual copyright by: ALGE-TIMING

AUSTRIA

Version: E-97-09-24 Page 3

ARGUS

Page 4

1. CHARACTERISTICS

Stop motion control device equipped with the most modern electronics in an industrial metal

case:

- recognizes immediately any thread breakage and loose threads;

- signals these defects acoustically and optically;

- provides for the machine stop;

- signals the recognized faults even with stopped machine.

The ARGUS disposes moreover of some helpful finesses:

- Quartz clock continuing its function even with switched off device, with display of the hour and

date.

- Speed counter (revolutions per minute).

- Five stitch counters.

- Five revolution counters.

- Switch clock for the machine cutoff.

- Code protection.

- System for the production data collection.

The principle of function of the ARGUS:

Each thread is controlled by an electromechanical contact (switch bar). In case of thread breakage,

this one makes contact over the machine mass (contact rail).

At the embroidery machine, all the threads are tensed only during a short moment of the stitching

cycle. The fault interrogation must take place exactly during this period. ARGUS seizes this moment

by means of an electronic contact transmitter (sensor).

Should a thread breakage occur, it is evaluated through the central electronics (CONTROLLER)

and signalled acoustically and optically by means of the indicating panel (INDICATOR). Each

machine sector disposes of its own indicating section allowing a quick localization and discovery of

the broken thread.

Version: E-97-09-24 Page 4

ARGUS

Page 5

2. PARTS OF THE UNIT

A complete stop motion control unit must be composed of the following equipment:

- Electromechanical contact (contact rail with switch bars):

Each thread is electromechanically controlled by a switch bar.

- Sensor/s:

The sensors transmit the most important data of the embroidery machine to the ARGUS Control-

ler. The electronic contact transmitters 1 and 2 must be NPN make contacts. The debouncing

time of sensor 3 to 7 amounts to appro. 5 sec.

For the stop motion function there is required the sensor 1 which is controlled by the top and

bottom needle track shaft and which determines the moment of the fault interrogation. Sensor 2

is required to compute the card meters and embroidery percentages. Electronic contact

transmitters are usually used for sensor 1 and 2 (needle and drive shaft). No particular demands

with regard to the speed are made on the sensors 3 to 7. Electrical contact transmitters or limit

switches with gold contacts are admissible.

- ARGUS Indicator:

Indicating panel for the optical (LED) and acoustic (loudspeaker) fault signalling.

- ARGUS Controller:

Central device with input keyboard, display elements, power supply and supply terminals.

- Evaluation program:

A computer to collect, read and evaluate the data provided by the ARGUS Controller (from up to

30 embroidery machines).

Version: E-97-09-24 Page 5

ARGUS

Page 6

3. DISPLAY FUNCTIONS

A LED arrow (11) indicates the set function. The desired function can be selected by means of the

key ((cid:217)) (up) or ((cid:218)) (down). The corresponding data appear on the display.

The variable data of the ARGUS (f.ex. hour, date, loudness etc.) are input in accordance with the

following scheme:

Adjustment:

Selection of functions: Push the key ((cid:218)) or ((cid:217)). The function indicator is

shifted upwards or downwards and the display

changes.

Modification of the setting: Push the (ENTER) key, the flashing place can be

changed.

Increase the number or ON: by means of the (+) key

Reduce the number or OFF: by means of the (-) key

Selection of next number, counter or test: by means of the key (<) (left) or (>) (right)

Memorize the setting: push the ENTER key.

Setting error: the display flashes and indicates (cid:147)ERROR(cid:148). The input

can be repeated.

Input over the computer:

Should the ARGUS be linked within a data network with a central PC, all important settings can be

input over the PC as well.

Code protection:

All the functions can be protected by means of a code against any unintentional or unauthorized

variation. The input of the code is described in item 3.7. (page 9).

Forgotten code: Should the functions be protected by means of a code and should this code not

be known, then this is equivalent to the loss of a key. Help will be given to you

by the company ALGE or by the ALGE agent.

Should there be inserted a central PC, an intervention can be made through the PC.

Protection of the settings:

All the settings are preserved even with switched-off ARGUS.

Version: E-97-09-24 Page 6

ARGUS

Page 7

3.1. FUNCTION 1: Time of day and RPM

Time of day:

The daily hour is indicated in hours and minutes. The setting is required at putting into service as

well as at change between summertime and wintertime. The integrated quartz clock is battery

buffered and maintains its function even with switched-off ARGUS (see also function 12, page 11).

With the key "<" and ">" you can change the starting time form shift 1, 2, 3, and 4.

RPM:

The speed is indicated in rpm. The pulses required for the measurement are provided by the sensor

2 (drive shaft). Should the sensor 2 not exist, the ARGUS recognizes its absence and gets the

pulses from sensor 1 (needle shaft). This means: no stitches, no display.

Start of a shift:

Display function and changing see point 3.1. "Time of day".

3.2. FUNCTION 2: Date

The display shows: Year, month and day (e.g. 93-07-11). The date is provided by the internal

quartz clock (see also function 12, page 11).

3.3. FUNCTION 3: Sound volume (L) and pitch (H)

Sound volume:

Loudness from 0 to 5, with 0 meaning the switched-off condition and 5 the maximum loudness.

Basic setting: 3

Setting range: 0 to 5

Pitch:

The tone height can be changed in order to differentiate the machines. There is available a range

from stage 1 (deepest tone) till stage 9 (highest tone).

Basic setting: 1

Setting range: 1 to 9

Version: E-97-09-24 Page 7

ARGUS

Page 8

3.4. FUNCTION 4: Fault stop and stop delay

Fault stop:

Indicates the number of faults to precede a machine stoppage. If the fault stoppage 0 is input, the

stop function is not activated.

Basic setting: 10

Setting range: 0 to 99

Stop delay:

The command (cid:147)stop the embroidery machine(cid:148) (stop relay) is released only after the stoppage delay.

The stoppage delay of modern embroidery machines is 0. In the event of older types without ma-

chine brake it must be set in a way to let the needles have already left the fabric.

Basic setting: 0

Setting range: 0 to 99 (corresponding to 0 to 792 ms)

3.5. FUNCTION 5: Inquiry time and error suppression

Inquiry time:

This is the time, that the thread contact must be without contact in order to have a error free inquiry

time. With the impulse of senor 1 it starts the check time t (fix duration of 80 ms). During this time it

P

makes the inquiry.

Adjustment of sensor 1 see point 9.2.

Example: t = 18 ms (adjusting 6)

A

Evolution: t = 5 ms = decision "still error"

1

t = 25 ms = decision "no error"

2

t = 10 ms = no effect for decision

3

Version: E-97-09-24 Page 8

ARGUS

Page 9

As longer the inquiry time is, as easier it is to detect not clear errors like loose threads. On the other

hand there is a very short time for the tensed threads when the machine is running fast (high rpm).

Correct setting:

Simulate a error. If the signalisation (LED indicator or speaker) is rytmic with every stitch, it means

that the inquiry time is correct adjusted. If this is not the case increase the inquiry time until the LED

group shows the error regular.

Basic setting: 4 (= 9 ms)

Setting range: 1 (= 3 ms) 3 (= 6 ms) 5 (= 12 ms)

2 (= 4 ms) 4 (= 9 ms) 6 (= 18 ms)

Error suppression:

Indicates how many of the recognized faults are suppressed before there takes place an acoustic

(loudspeaker) or optical (indicator) warning. The setting is made as at function 1.

Basic setting: 2

Setting range: 0 to 4

Note: Long stitches, big bore holes and repeat changes can release fault messages. In order to

suppress them, the fault suppression can be set as follows:

0.............textured yarn and macrame

1.............high speed

2.............standard

3.............colour and repeat change

4.............silks and tulle fabrics

Attention: The shuttle display might go lost in case of a high setting !

3.6. FUNCTION 6: Sector selection

The sectors are indicated on the display (2). Those sectors where no embroidery takes place can

be switched off.

The sectors which are not supervised due to the selected Indicator variant are marked by means of

centre lines.

Basic setting: all sectors ON

3.7. FUNCTION 7: Code

The ARGUS is supplied by ALGE with deactivated code protection (C=000000). In order to protect the

input values against any unauthorized manipulation, any code composed of 6 digits can be input.

Basic setting: C=000000 (code protection deactivated)

Setting range: C=000000 until C=999999.

Version: E-97-09-24 Page 9

ARGUS

Page 10

3.8. FUNCTION 8: Switch-off time and machine number

Switch-off time: A switch-off time can be input in order to have the machine switched off at a

specific daytime (hours and minutes). If the switch-off time 0.00 is input, no

machine stoppage takes place at a given time.

Machine number: Should the ARGUS be part of a data network, each one receives its own number

between 1 and 30.

Basic setting: 0 (no communication with the PC)

Setting range: 0 to 30

3.9. FUNCTION 9: Design number

For the statistic evaluation by the PC, a number (max. 8 digits) can be assigned to the embroidery design.

3.10. FUNCTION 10: Stitch counter

Sensor 1 (needle shaft) supplies the pulses to be counted.

The 1st counter is a summation counter (8 digits) without reset possibility with its content being

memorized even after having switched off the ARGUS.

The counters 2,3,4 and 5 (6 digits) are assigned to the corresponding shifts. The counter content is

memorized only until a new shift is selected.

The different shifts or the summation counter can be selected by means of the (cid:147)<(cid:147) and (cid:147)>(cid:148) key.

3.11. FUNCTION 11: Revolution counter

This function is available only if sensor 2 (drive shaft) is existing.

The 1st counter is a summation counter of 8 digits without reset possibility, with its content being

memorized even after having switched off the ARGUS.

The counters 2,3,4 and 5 (6 digits) are assigned to the corresponding shifts. The counter content is

preserved only until a new shift is selected.

The different shifts or the summation counter can be selected by means of the (cid:147)<(cid:147) and (cid:147)>(cid:148) key.

3.12. FUNCTION 12: Special functions

1. Call.L: Volume of Call-function

2. Call.D: Duration of Call-function

3. Batt: Switch ON/OFF the clock battery

4. Ind.Set: Setting of the Indicator variants

5. Buf.: Erase memory

6. Full: Warning "memory 90% full" on or off

The input proceedings are a little bit different from the usual ones: After having pushed the (ENTER) key,

the function (cid:147)CALL(cid:148) can be switched on or off by means of the (+) and (-) key. The next special function

is reached by pushing the (>) key.

Version: E-97-09-24 Page 10

Description:Note: Long stitches, big bore holes and repeat changes can release fault messages. In order to suppress them, the fault suppression can be set as follows: 0.textured yarn and macrame. 1 . high speed. 2 . standard. 3.colour and repeat change. 4 . silks and tulle fabrics.