Table Of ContentApproved by

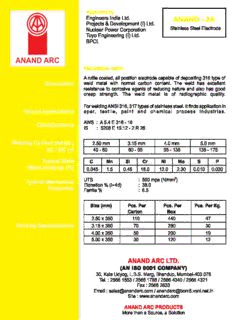

Engineers India Ltd. ANAND - 2A

Projects & Development (I) Ltd.

Stainless Steel Electrode

Nuclear Power Corporation

Toyo Engineering (I) Ltd.

BPCL

ANAND ARC

TECHNICAL DATA

Arutile coated, all position electrode capable of depositing 316 type of

Description weld metal with normal carbon content. The weld has excellent

resistance to corrosive agents of reducing nature and also has good

creep strength. The weld metal is of radiographic quality.

ForweldingANSI316,317typesofstainlesssteel.Itfindsapplicationin

Typical Applications aper, textile, paint and chemical process industries.

AWS : A5.4 E 316 - 16

Classifications

IS : 5206 E 19.12 - 2 R 26

Welding Current (Amps.) 2.50 mm 3.15 mm 4.0 mm 5.0 mm

AC / DC (+) 40 - 60 60 - 95 95 - 135 135 - 175

Typical Weld C Mn Si Cr Ni Mo S P

Metal Analysis (%)

0.045 1.5 0.45 18.0 12.0 2.30 0.010 0.030

UTS : 590 mpa (N/mm2 )

Typical Mechanical

Elonation % (I=4d) : 38.0

Properties

Ferrite % : 6.5

Size (mm) Pcs. Per Pcs. Per Pcs. Per Kg.

Carton Box

2.50 x 350 110 440 47

Packing Specifications 3.15 x 350 70 280 30

4.00 x 350 50 200 19

5.00 x 350 30 120 12

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

Approved by

Engineers India Ltd. ANAND - 1A

Projects & Development (I) Ltd.

Stainless Steel Electrode

Nuclear Power Corporation

Toyo Engineering (I) Ltd.

BPCL

ANAND ARC

TECHNICAL DATA

Arutile coated, all position electrode capable of depositing 308 type of

weldmetalwithnormalcarboncontent.Thebeadfinishisgoodandslag

removal is easy. The weld metal has excellent resistance to corrosion

Description

and cracking and it has good creep strength. The weld metal is of

radiographicquality.

For welding ANSI 301, 302 ans 304 types of stainless steel. It finds

Typical Applications application in food and chemical process industries. It can be used to

weldsteelwithpoorweldability.

Classifications AWS : A5.4 E 316 - 16

IS : 5206 E 19.9 - R 26

Welding Current (Amps.)

2.50 mm 3.15 mm 4.0 mm 5.0 mm

AC/DC (+)

40 - 60 60 - 95 95 - 135 135 - 175

Typical Weld C Mn Si S P Cr Ni

Metal Analysis (%)

0.045 1.50 0.45 0.015 0.030 19.5 10.0

UTS : 590 mpa (N/mm2 )

Typical Mechanical

Elonation % (I=4d) : 40.0

Properties

Ferrite % : 6.5

Size (mm) Pcs. Per Pcs. Per Pcs. Per Kg.

Carton Box

2.50 x 350 110 440 47

Packing Specifications 3.15 x 350 70 280 30

4.00 x 350 50 200 19

5.00 x 350 30 120 11

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

Approved by ANAND PLUS

Bureau of Indian Standards

Indian Register of Shipping - Gr.2 All Purpose

M.S. Electrode

Uhde India Ltd.

L&T

IS 814

CM/L2007327

ANAND ARC TECHNICAL DATA

A medium rutile coated, all position electrodes with smooth operating

characteristics. The electrode gives medium penetration and east

Description spatter.Theelectrodehasuniformweldbeadeasilydetachableslagand

radiographic quality weld metal. The electrode is ideally suited for

structuralworkandgeneralfabrication.

Forfabricationoftanks,bargesships,railwaywagonsboilersetc.Andfor

Typical Applications

structuralwork,grillworkandgeneralfabrication.

AWS : A5.1 E 6013

Classifications

IS : 814 ER 4222 X

Welding Current (Amps.) 2.50 mm 3.15 mm 4.0 mm 5.0 mm 6.3 mm

AC/DC (-) 60 - 90 90 - 140 140 - 175 175 - 210 210 - 270

C Mn Si S P

Weld

Metal Analysis (%)

0.10 Max 0.15 - 0.40 0.08 - 0.30 0.030 Max 0.030 Max

UTS : 500 mpa (N/mm2 )

Typical Mechanical YS : 420 mpa (N/mm2 )

Properties Elonation % (I=4d) : 24.0

o

ZCVN Impact at 0 C : 60 Joules

Size (mm) Pcs. Per Pcs. Per Pcs. Per Kg.

Carton Box

2.50 x 350 275 1100 60

Packing Specifications 3.15 x 350 150 600 36

3.15 x 450 150 600 28

4.00 x 350 105 420 18

5.00 x 350 70 280 11

6.30 x 450 40 160 7

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

Approved by ANAND MIG-1

R. D. S. O

IRS CLASS - I Copper Coated

MIG Welding Wire

L & T

ANAND ARC

TECHNICAL DATA

ANANDMIG-1isadoubledeoxidisedCopperCoatedMIGWeldingWire

for general engineering and structural applications. The cast, helix

Description

tensile strength and chemistry of the wire are controlled to yield high

qualityweldswithleastspatter.

It is ideally suited for continuous welding of unalloyed and structural

steels. Finds extensive use in the automobile and container industry.

Typical Applications

Also used for welding bicycle frames. Railways bogies earth moving

equipmentsetc.

AWS : A5.18 ER 70S - 6

Classifications

IS : 6419

Welding Current (Amps.) Size (mm) 0.8 1.0 1.2 1.6

DC (+) Amps 50 - 160 80 - 200 110 - 250 200 - 400

Weld C Mn Si S P

Metal Analysis (%)

0.08 1.50 0.80 0.016 0.018

o

UTS YS EL CVN Impact at - 30 C

Typical Mechanical (mpa (N/mm2 ) (mpa (N/mm2 ) % (Kg/m )

Properties

585 455 26.0 5.0

Spoolof12.5Kg.Nett.Wt.InMoistureresistantpacking

Packing Specifications

DrumPackingavailable.

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-1

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

ANAND MELT-1 is an agglomerated Flux designed for SubmergedArc

Welding of mild, medium and high tensile steels in combination with

Description

ANAND SAW-1 (EL8) Grade wire, to yield weld metal with excellent

chemicalandmechanicalproperties.Theslagremovaliseasyandweld

metal has a smooth and shiny finish. Weld metal also of a radiographic

quality.

ANAND MELT-1 Flux in a combination with ANAND SAW-1 Wire is

Typical Applications suitable for welding mild, medium and high strength steels. Extensively

usedinweldingofthickplates.S.A.WPipes,Girders,offshorePlatforms

andMachinesBuildingapplicationsetc.

Classifications AWS/SFA5.17 F7AZEL8

Typical weld metalAnalysis (%)

C Mn Si S P

When Used With

ANAND SAW-1(EL8) Wire 0.07 1.10 0.40 0.015 0.020

Typical Weld Metal UTS : 525 N/mm2

Mechanical Properties YS : 425 N/mm2

When Used With Elongation (%) (I-4xd) : 26.0

ANAND SAW-1 (EL8) Wire CVN Impact : at RT 80 J

Packing Specifications 25Kgs.Net.PackedinKraftPaperBagswithHDPELiningfrominside.

Redrying Instructions It is recommended to redry the Flux at 3500C for 2 hours before use for

bestresults..

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-2

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

ANAND MELT-2 is an agglomerated Flux designed for SubmergedArc

Welding of mild, medium and high tensile steels in combination with

Description

ANAND SAW-2 (EH14) Grade wire, to give excellent mechanical

properties and impacts down to -200C with extreme resistance to

cracking.Owingtoinsensitivitytorust,scale,primeronthesurfacetobe

welded,hasexcellentx-raycharacteristicsandslagremoval.

ANAND MELT-2 Flux in a combination with ANAND SAW-2 Wire is

Typical Applications suitableforweldingmediumandhighstrengthsteel.Extensivelyusedin

welding ofPressure Vessels, Ships Building, Earthmoving Equipments,

MachinesBuildingApplicationsetc.

Classifications AWS/SFA5.17 F7A2EH14

Typical weld metalAnalysis (%)

C Mn Si S P

When Used With

ANAND SAW-2(EH14) Wire 0.10 1.40 0.50 0.03 0.03

Typical Weld Metal UTS : 530 N/mm2

Mechanical Properties YS : 440 N/mm2

When Used With Elongation (%) (I-4xd) : 27

ANAND SAW-2 (EH14) Wire CVN Impact : 27 J at-200C

Packing Specifications 25Kgs.Net.PackedinKraftPaperBagswithHDPELiningfrominside.

Redrying Instructions It is recommended to redry the Flux at 3500C for 2 hours before use for

bestresults..

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-3

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

ANANDMELT-3isanagglomeratedaluminaterutiletypeflux.Relatively

High Silicon pick up is achieved with the flux, when used with EL8 wire

Description average Manganese pick up also results.ANAND MELT-3 enables the

use of very high speed welding with twin, tandom, and multiwire

technique.Theweldmetalisnotsusceptibletoporositywhenweldedon

work place contaminated by rust, scale etc. It is particularly resistant to

arcburnthrough.

Typical Applications It is used for welding general Structural Steels, Pressure Vessels, Pipe

Steels as well as Fine Grain Steels, Boiler Drums etc. On account of its

good slag detachability ANAND MELT-3 is very commonly used for

weldingfillets.ANANDMELT-3isparticularlysuitedforpipeweldingwith

highspeeds.ThisFluxcanbeweldedonACorDCup1000Amps(with

singlewireprocess).

General Basicity Index 0.6

Classifications Granulometry 10X150 B.S.S.

Classifications AWS/SFAF7AZEL8

Typical weld metalAnalysis (%) C Mn Si S P

When Used With

0.070 1.30 0.45 0.018 0.018

ANAND SAW-1(EL8) Wire

Typical Weld Metal UTS : 560 N/mm2

Mechanical Properties YS : 460 N/mm2

When Used With

Elongation (%) (I-4xd) : 25.0

ANAND SAW-1 (EL8) Wire

CVN Impact : at RT 80 J

Packing Specifications 25Kgs.Net.PackedinKraftPaperBagswithHDPELiningfrominside.

o

Redrying Instructions Fluxshouldbekeptdry.ItisrecommendedtoredrytheFluxat350Cfor2

hoursbeforeuseforbestresults.

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-4

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

Description ANAND MELT-4 is an agglomerated aluminate basic type flux.Silicon

pick up is achieved from the flux when used with EL8 wire adequate

Manganesepickupalsoresults.

It is used for welding general Structural Steels, Pressure Vessels, Pipe

Steels as well as Fine Grain Steels, Boiler Drums etc. This flux is

Typical Applications particularlywellsuitedfortwin,tandom,multiwireweldingathighspeed.

ANAND MELT-4 is most suitable for Narrow Gap WeldingApplications.

Productionoflargepipesespeciallyspiralpipesisatypicalapplicationof

ANANDMELT-4.OnaccountofitsgooddetachabilityANANDMELT-4is

verycommonlyusedinweldingfillets.

General Basicity Index 1.6

Classifications Granulometry 10X150 B.S.S.

Classifications AWS/SFAF7A4EL8

Typical weld metalAnalysis (%) C Mn Si S P

When Used With

0.07 1.60 0.40 0.019 0.020

ANAND SAW-1(EL8) Wire

Typical Weld Metal UTS : 540 N/mm2

Mechanical Properties YS : 430 N/mm2

When Used With

Elongation (%) (I-4xd) : 28

ANAND SAW-1 (EL8) Wire o

CVN Impact : at - 40 C 40 J

Packing Specifications 25Kgs.Net.PackedinKraftPaper BagswithHDPELiningfrominside.

o

Redrying Instructions Fluxshouldbekeptdry.ItisrecommendedtoredrytheFluxat350Cfor2

hoursbeforeuseforbestresults.

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-5

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

ANAND MELT-5 is a basic aluminate type flux which has very good

welding characteristics both in single and multi wire system. It is

Description weldableonbothAC&DCandcancarryreasonablyhighcurrents.The

flux being basic gives very low Hydrogen and Oxygen contents in weld

o o

metal and gives excellent impact values down to -40 C, -50 C. The

required weld metal strength is achieved by selection of suitable

unalloyed (plain) and alloyed wires and the alloying elements are

obtainedmainlyfromthewire.

Basicity Index 1.6

General

Granulometry 10X150 B.S.S.

Classifications

Current DC orAC

AWS 5.17 F6A4EL8

Classifications F7A4EM12K, F7A5EH14

AWS 5.23 F11A4EG

With Wire C Mn Si S P Cr Ni Mo

EL8 0.070 1.10 0.36 0.016 0.17 - - -

Typical Weld Metal

EM12K 0.082 1.40 0.38 0.017 0.16 - - -

Analysis (%)

EH14 0.100 1.50 0.40 0.017 0.16 - - -

EF5 0.090 1.60 0.36 0.016 0.16 0.60 2.30 0.50

TS YS Elong CVN Impact in J

With Wire N/mm2 N/mm2 (L=4xd) -30o C -40o C -50o C

Typical Weld Metal

EL8 440 370 29 - 60 -

Mechanical Properties

EM12K 520 420 28 - 54 -

EH14 560 470 28 - - 30

EF5 820 730 23 - 35 0

Packing Specifications 25Kgs.Net.PackedinKraftPaper Bagslaminatedfrominside.

o

Itisrecommendedtore-drytheFluxat350Cfor2hoursbeforeusefor

Recommendations

bestresults.

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

ANAND MELT-6

Submerged

Arc Welding Flux

ANAND ARC

TECHNICAL DATA

ANAND MELT-6 is an agglomerated Flux designed for submerged arc

weldingofmediumandhightensileincombinationwithANANDSAW-1

Description (EL8).GradeWireANANDSAW-3(EM12K)wiretoyieldweldmetalwith

excellent chemical and mechanical properties with respect with impact

o

values down to -20 C. The slag removal is easy and weld metal has

smoothandshinyfinish,isalsoofradiograhicquality.

ANAND MELT-6 Flux is combination with ANAND SAW-1 / ANAND

SAW-3. Wire suitable for welding medium and high strength steels.

Typical Applications

Extensively used in welding of thick plates, S.A.W. Pipes. Grinders, Off

Shore Platforms, Penstock Shells and Machine Building applications

etc.

Classifications AWS : SFA5.17 F7AOEL8/F7A2EM12K

Typical weld metalAnalysis (%) C Mn Si S P

When Used With

ANAND SAW-1(EL8) Wire 0.07 1.40 0.40 0.015 0.020

ANAND SAW-3 (EM12K) Wire

0.08 1.70 0.50 0.018 0.018

UTS YS EL(%) CVN Impact

Typical Weld Metal

Mechanical Properties N/mm2 N.mm2 1=4xd) InJ

When Used with

o

ANAND SAW-1 (EL8) Wire 515 410 24 At 0 C 50

ANAND SAW-3 (EM12K) Wire o

575 492 25 At -20 C 31

Packing Specifications 25Kgs.Net.PackedinKraftPaper BagswithHDPELiningfrominside.

o

Redrying Instructions It is recommended to redry the Flux at 350 C for 2 hours before use for

bestresults.

ANAND ARC LTD.

(AN ISO 9001 COMPANY)

30, Kala Udyog, L.B.S. Marg, Bhandup, Mumbai-400 078

Tel. : 2566 1853 / 2566 1788 / 2566 4340 / 2566 4321

Fax : 2566 2833

Email : [email protected] / [email protected]

Site : www.anandarc.com

ANAND ARC PRODUCTS

More than a Source, a Solution

Description:It can be used to weld steel with poor weldability. Classifications. Welding Current (Amps.) AC/DC (+). ANAND ARC. Size (mm). Pcs. Per. Pcs. Per. Pcs. Per Kg. ANAND MIG-1 is a double deoxidised Copper Coated MIG Welding Wire for general engineering and structural applications. The cast, helix.