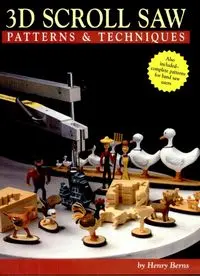

Table Of Content3D SCROLL SAW

PATTERNS & TECHNIQUES

Three-Dimensional

Scroll Saw Patterns

and Techniques

by Henry Donald Berns

X BOOKS 5 ,

Fox Chapel Publishing Co., Inc

This One

08ZE-UWJ-Z2YR

A Scroll Saw Menagerie

Dozens of designs for people and animals.

© 1998 by Fox Chapel Publishing Company, Inc.

Publisher: Alan Giagnocavo

Project Editor: Ayleen Stellhorn

Desktop Specialist: Robert Altland, Aldand Design

Cover Photography: Robert Polette

ISBN 1-56523-090-6

Three-Dimensional Scroll Saw Patterns and Techniques by Henry Berns is a brand new

work first published in 1998 by Fox Chapel Publishing Company, Inc. All rights reserved. No part

of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording or otherwise, without prior writ-

ten permission of the publisher. The patterns included in this book are copyrighted by the

author. Artists may use these patterns to create their own projects, but the patterns themselves

may not be duplicated for resale or distributed in any form.

To order your copy of this book,

please send check or money order

for $12.95 plus $2.50 shipping to:

Fox Chapel Book Orders

1970 Broad Street

East Petersburg, PA 17520

Try your favortte book supplier first!

Acknowledgement

I would like to thank my wife, Marilyn, for her constant encouragement and assistance in the

development of my miniature patterns and in writing this book. I also want to acknowledge the

support given by my children Dan and Beth. In particular | want to thank Beth for the

professional assistance given by Buffington Design & Ilustration in getting the pattern drawings

converted to computer files. My appreciation also goes back to my childhood days when my

parents allowed me to work with wood and develop such an interesting hobby. It has been a

pleasure that the Lord has given me a talent that I can enjoy and share with others. It is my wish

that others find this activity as satisfying as I have. Finally I would like to thank Alan Giagnocavo

at Fox Chapel Publishing Company, Inc. for making it possible to publish this book and share my

hobby with others.

Table of Contents

Chapter One

Power Tool Operation. ......0. 6.6 ce cece eee eee eee 1

Chapter Two

3-D Pattern Techniques ............. 62.6 e eee eee eee eee 11

Chapter Three

Finishing Operations .... 0.2... 66. e cece seen 1D

Chapter Four

Simple Animal Patterns. ..........00000 000 c cece eee eee ee 27

Rabbit and Duck . -

Puffin and Cat... .. ‘ .

Squirrel/Skunk and Camel SEARS GHAR Ee EGR SIE RAG kx new 38

Goat and Donkey .- 6 sccieseewee eens wawewes saa 39

Sheep and Cardinal See eee ....40

Giraffe and Sea Horse . 2. ee mnie ase 4M

Rooster and Horse... eee 42

Chapter Five

Detailed Animal Patterns ......... siete eine ies oie woe eine eee wee 2 EE

Eagle and Flamingo... 22.0. eee 22. dD

Ostrich and Stork... eee ... 50

Sea Gull and Elephant » ss ess 6.6 imeecweiwan ime ere)

Deer and Moose... 2: esecseaesaeweecuwawams . .. 52

Honey Bee and Dog 2... ccc ease eyes eee omens 53

Polar Bear and Road Runner... 2.00.2 eee 4

Chapter Six

People Type Projects.

Coyote and Siesta Sam... eee 63

Hillbilly and Mandarin Man . . . bees 64

Bishop and The Farmer and His Wi ife See eee 12. OS

Shepherd and Wise Mand ........

Wise Man 2 and Wise Man 3 .

Joseph and Mary

Mermaid and Penguin .......... 60sec ee eee eee en

Teddy Bear... 2000 ee

Chapter Seven

Patterns Using Special Techniques .. 2... 0.0.66 ee eee 71

Flamingo and Turkey

Pegasus and Unicorn... 2.0... eT tee 77

Angel and Jesus... 0.0.0.0 ccc eee eee nates F .. 78

Pitch Fork, Staff and Cactus... 0.000000 cc ee eee wee YD

Chapter Eight

Gift Ideas and Grouped Item Projects. ..........0202000 eee ee 80

Chess Set... See eee eee 85

Barn... ee

Stable...

Ark

Introduction

The historical use of scroll saws has been to create thin two dimensional craft projects.

Wall plaques, silhouettes, and puzzles are typical examples. The creation of miniature craft

items has recently become a very popular hobby activity. This has remained, however,

mostly a two dimensional activity. Some of the small items have been sawed from thicker

stock and painted to look three dimensional.

This book gives hobbyists that enjoy making miniatures, a whole new dimension to

their work. Almost all of the pattern books that are currently available are for two dimen-

sional flat patterns. Silhouette wall plaques and puzzles are good examples of these 2-D

projects. This book adds the third dimension to the art of creating miniature craft items.

They are truly three dimensional and are detailed miniatures as well. There are a variety of

different birds, animals and people type craft items that can be made in different sizes.

They can be displayed as individual curio items or combined in group projects such as a

Nativity scene, Noah's Ark, or a Barn scene.

Patterns are included for both small and large size versions of the craft items. The

patterns can also be photocopied to other sizes to make very small, intermediate or even

larger items. The small size patterns are best to begin with. Both sizes of the patterns can

be used with the better quality scroll saws that can handle material that is two inches

thick. The large size patterns can also be used with band saws that have the new one six-

teen inch wide blades. The larger size items are an excellent first step for learning how to

do miniature hand carved items. Small powered rotary sanding tools or hand carving can

be used to finish many details. No additional finishing or only rounding of some of the

square corners is all that is needed to finish many of the 3-D items.

The chapters are organized by their level of detail and required skill. The first set of

simple animal patterns can be made with a minimum of skill after becoming familiar with

the operation of a scroll saw. The second set of detailed animal patterns are easy to do

after practicing with the simple items. The third set of patterns are for "people type" fig-

ures (this includes animals standing up on their back legs) and are more challenging. They

require some special finishing techniques for the "arms" or front legs. The fourth set of

patterns also require some special finishing techniques but produce additional detail to

the finished craft items. These special projects will be very rewarding after the hobbyist

has become familiar with the special sawing and finishing techniques.

The last Chapter has suggestions of how the craft items can be used to make grouped

projects. Some are quite easy to do as they are simply arrangements of the craft items.

Other special projects may require the construction of other craft items such as a Noah's

ark shelf, a barn for a farm scene, or a stable for a Nativity scene, etc. The addition of wire

hooks and earring wires allows the craft items to be used as dangle-type earrings or

Christmas tree decorations. The craft items can be brightly painted or left as carvings with

wood grain detail showing. They can be displayed individually or as caricature groups.

Chapter One

Power Tool

Operation

The projects in this book assume that the reader is already familiar with

the safe operation of a scroll saw and a band saw and does not need a

long discussion of the use of these tools. Basic information about these

tools can be found in their operation manuals and in the books listed in

Appendix A. Always read and follow the instructions in the operator's

manual for any power tools you may use to insure that you are using

them in a safe manner. This chapter will discuss the basic sawing tech-

niques and how they relate to the making of three-dimensional craft

items.

SCROLL SAW OPERATION

There are two basic types of scroll saws available to the hobbyist:

the C-Frame and the Parallel Arm. The C-Frame type of saw has the two

ends of the blade tensioned between the two ends of a deep "C-shaped"

open frame. With this type of machine, the stroke of the saw is pro-

duced by pivoting the complete frame at a point below the table and

near the back of the frame. A disadvantage of this type of saw is that

the blade does not remain vertical. It tips back at the top end on the

up stroke and to the front on the down stroke. This action may produce

a faster more aggressive cutting motion because the blade moves into

the stock on the down stroke. While this may be useful for thin stock

on two-dimensional projects, it could be a problem on thicker three-

dimensional projects where very sharp turns are made. With sharp

turns in thick stock it is best if the blade remains vertical during the

whole cutting stroke to produce the best results.

A typical Parallel Arm machine is shown in

Figure 1.1. The parallel upper and lower arms

hold the blade at their front ends. Both arms have

a pivot point about two-thirds of the way to the

back. The upper arm pivot is directly above the

lower arm pivot. The blade tension is held by a rod

that is tightened between the two arms at their

back end. The stroke of the saw is produced by

moving the lower arm up and down at a point near

the front. The arms, blade and tension rod form a

parallelogram that always keeps the blade vertical.

This can be an advantage for cutting thick materi-

al when very small turns are made. It does require

some type of pivoting blade holder for both ends

Figure 1.1 of the blade where they join the upper and lower

This well-built quality parallel arms.

arm scroll saw was used for With the very small blades used in the three-dimensional minia-

both sizes of craft items in tures, it is important to allow the blade holders to pivot so the blade

this book. A smaller or less ends are not bent as the parallelogram is flexed during the cutting

capable scroll s action. Adequate tension in the blade will then keep it from bending

limited to the smaller sized and will avoid a fatigue failure after a minimum of use. Proper use of a

patterns. saw will require blade changing after the blade becomes dull from an

extended cutting time rather than breakage.

You should study your scroll saw, and be sure it is safe for making

thicker cuts with very small turns. There are many different brands of

saws that have large variations in price. They may have a number of fea-

tures that would be helpful, such as variable speed, counterbalanced

drive, quick blade change, dust blowers and support legs. The most

important features are, however, the ability to cut accurately in thicker

stock and the ability to be able to make very small turns. This will

require the use of thin, narrow blades. A universal No. 2 or smaller

scroll saw blade can be used for the small patterns. Most of the small

pattern projects in this book were done with a blade that was 0.015

inch thick by 0.037 inch wide with 14 teeth per inch. The large pat-

terns will need at least a No, 7 blade to accomplish the thicker cuts that

are needed.

If the blade is too small for the thickness being cut, it will bow back

with the cutting force. This becomes a significant problem when trying

to make a sharp turn! As the turn is made, the cutting is no longer ver-

tical. If the center piece being sawed loose from the rest of the block

will not slide out of the main block after a cut has been done, the blade

is too small, dull or it may be under-tensioned. Tension in the blade

must be in accordance with the manufacturers recommendation in

order for the blade to operate properly.

Power Tool Operation

BAND SAW OPERATION

The size of the band saw blade is

the key to this procedure for making

miniatures. New narrow !/16-inch

blades can be purchased from various

tool sources in custom lengths to

match existing band saws. A very

helpful accessory to go with the nar-

row blade is a special set of compos-

ite material guide blocks as shown in

Figure 1.2. (Note the blade guard

has been temporarily removed to

show the guide blocks and the blade

support bearing; always operate your power tool with all the safety fea-

tures in place.)

These blocks are made from a type of composite material that is

self-lubricating. They replace the usual metal blocks that had to be posi-

tioned so the teeth on the blade were in front of the slot between the

blocks. With the new narrow blades, there would be very little blade

material behind the teeth to slide between the guide blocks. As a result,

a very small forward movement of the blade would leave it with no side

to side stability. The blade support bearing behind the back of the blade

should be adjusted to keep the blade in the middle of the composite

guide block: shown in Figure 1.2. This bearing will react to the cut-

ting force during operation as it does with ordinary blades.

Blade movement may happen if you need to move backward in the

saw kerf and inadvertently pull the blade forward out of the guide

blocks. Sometimes it is necessary to move backward in the saw kerf if

you are making a very sharp turn, and you want to widen the saw kerf

to assist with the turn, The composite guide blocks can be set so the

blade is completely between them as shown in Figure 1.2. Since the

blocks are a soft material they will not harm the saw blade teeth or the

set in the teeth as would happen with metal blocks. As a result, the

blade will still be guided if it is subjected to a small forward movement.

The end of the guide blocks will wear with time from the set in the

blade teeth, but can easily be replaced or the ends resurfaced to again

give maximum blade stability.

It will be helpful if the saw table insert around the blade has a small

opening to give maximum support to the material being cut. It may be

necessary to obtain or make a special insert that has a reduced opening

around the blade, as shown in Figure 1.2, Another way to minimize the

saw table opening is to use a saw table cover made from a hard pressed-

board material or thin, smooth plywood. Make a saw cut from the back

3

Figure 1.2

“Composite” guide blocks in

position with a '/16 inch blade

on a band saw. The blade is

set in the middle of the guide

block ends so a small forward

movement of the blade will

oot pull it free of the blocks.

Note the saw blade guard has

been temporarily removed to

take the picture.

3—-D Scroll Saw Patterns and Techniques

Figure 1.3

‘Typical scroll saw cutting of

the smaller pattern for the

Horse. Note that the wood

block is much longer than the

patterns to assist in directing

the cutting and holding the

block down on the saw table,

edge of the table cover, forward to the blade posi-

tion to allow it to be put in place after the blade is

installed in the band saw. You can glue small strips

on the bottom edges to make lips that fit over the

edges of the table. The cover could also be held in

place with double-sided tape, clamps and stove

bolts.

It is also very important to have the band saw

blade and the saw table adjusted so the blade is per-

pendicular to the table. Improper adjustment will

result in irregular width and thickness of the small

parts on the craft items, such as legs, arms and

antlers, Small details, such as an antler, require a turn

at the end of the item. The second part of the cut-

ting will be done in the opposite direction but par-

allel to the first part of the cut. If the blade is not perpendicular to the

table, the small detail will not be of uniform thickness.

PREPARATION OF WOOD BLOCKS

Creation of the rectangular blocks used for the projects will also

Figure 1.4

Cutting the side view pattern for the large Horse. The wood block is much longer than the

patterns to assist in holding the block and directing the saw cuts without having the blade

near your fingers.