Welding Journal - April 2011 PDF

Preview Welding Journal - April 2011

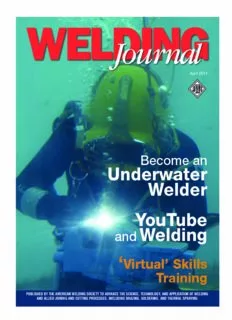

April 11 Cover 2 Underwater:4/06 Cover 3/9/11 3:29 PM Page C1 April 2011 W E L D I N G J O U R N A L • V O L Become an U M E 9 Underwater 0 N U M B Welder E R 4 • A P R I L 2 0 YouTube 1 1 Welding and ‘ Virtual’ Skills Training PUBLISHED BY THE AMERICAN WELDING SOCIETY TO ADVANCE THE SCIENCE, TECHNOLOGY, AND APPLICATION OF WELDING AND ALLIED JOINING AND CUTTING PROCESSES, INCLUDING BRAZING, SOLDERING, AND THERMAL SPRAYING select arc:FP_TEMP 3/8/11 9:47 AM Page C2 For Info go to www.aws.org/ad-index fronius:FP_TEMP 3/8/11 9:43 AM Page 1 Virtual Welding Train - Simulate - Perfect The welding education of the future has a name: Virtual Welding. Trainees learn to weld under realistic conditions of torch, work-piece and welding Realistic 3D simulator parameter combinations. The arc and weld seam are created based on the technique of the student and allows progressive improvement. Compact Space Saving Design Realistic, simulator based learning. Compact. Safer. Economical. FRONIUS USA, LLC Reduced Waste 10421 Citation Drive, Suite 1100, Brighton Michigan 48116, USA Tel: 1-810-220-4414, Fax: 1-810-220-4424 email: [email protected], www.fronius-usa.com For Info go to www.aws.org/ad-index greiner:FP_TEMP 3/8/11 9:44 AM Page 2 We were excited about being the job shopfor providing the heavy-duty steel fabricated girders for the stadium seating sections of the Pittsburgh Steelers’ Heinz Field. Raker Girders 133-ton Transfer Girder Steelers fans may not appreciate our specialty capabilities for heavy-duty fabrication, but steel fabricators and others pick us for project work because we’re a valuable team player. Whether we’re fabricating 38 specialized steel raker girders for the seating in the Pittsburgh Steelers stadium, a 12-foot by 129-foot long steel girder weighing 145,000 pounds for a Norfolk Southern railroad bridge, a transfer girder weighing 133 tons for an indoor swimming pool midway up a New York City high-rise, or other projects that require big and heavy capability, people turn to Greiner. Why?Because we have the facilities, the people • Structural Steel Fabrication • Steel Plate & Sheet Metal Fabrication and the certifications to deliver a job well done – time after time. And • Miscellaneous Metals when the safety of more than 65,000 people at a Steelers game is on the • Machining line, we take our job as a steel fabricator very, very seriously. • Rolling & Forming Services • Cutting Services You can count on Greiner! • Industrial Coatings • Industrial & Electrical Contracting Call us at 800-782-2110 for a free quote on your • Crane Rental & Trucking Services • Heat-Bending Services next project. (AISC Certified for Major Steel www.greinerindustries.com Bridge Fabrication) For Info go to www.aws.org/ad-index April 11 Layout:Layout 1 3/10/11 10:17 AM Page 3 CONTENTS April 2011 (cid:129) Volume 90 (cid:129) Number 4 AWS Web sitewww.aws.org Features Departments 38 Exploring Welding through YouTube This social medium gives welding a window to the world Editorial............................4 38 A. Cullison et al. Washington Watchword..........6 42 What It Takes to Be an Underwater Welder Press Time News..................8 Underwater welding can be adventurous, but it is a News of the Industry............10 demanding occupation that requires both physical and Aluminum Q&A..................14 mental endurance K. Campbell Brazing Q&A......................22 Letters to the Editor ............22 49 Developing Guidelines for Numerical Welding Simulation Welding simulation gives an alert to problems such as Book Review......................24 distortion and residual stresses before the arc is struck New Products....................26 C. Schwenk Coming Events....................54 52 Latest Developments in Welding Skills Training Certification Schedule..........58 42 Virtual welding as a tool in the training cycle is evaluated Welding Workbook..............60 S. Keitel and C. Ahrens Society News....................61 Errata AWS D3.6M:2010......62 Guide to AWS Services..........82 New Literature....................84 Personnel ........................88 Welding Research Supplement Welding School Profiles........92 Classifieds......................105 55-s Filler Metal Influence on Weld Metal Structure of Advertiser Index................107 Microalloyed Steel Three different filler metal formulas were evaluated as to their 52 affect on the mechanical properties of X65 steel welds N. Bajic et al. 63-s A New Chromium-Free Welding Consumable for Joining Austenitic Stainless Steels The performance of a new Ni-Cu-based welding consumable to weld 304L stainless steel was studied for weldability and fume control of Cr(VI) J. W. Sowards et al. Welding Journal (ISSN 0043-2296) is published monthly by the American Welding Society for 77-s Calorimetric Measurement of Droplet Temperature in $120.00 per year in the United States and posses- sions, $160 per year in foreign countries: $7.50 GMAW per single issue for domestic AWS members and A calorimetric measurement system showed droplet temperature $10.00 per single issue for nonmembers and reaching a minimum at the transition from globular to spray $14.00 single issue for international. American Welding Society is located at 550 NW LeJeune Rd., transfer Miami, FL 33126-5671; telephone (305) 443-9353. E. J. Soderstrom et al. Periodicals postage paid in Miami, Fla., and addi- tional mailing offices. POSTMASTER: Send address changes to Welding Journal, 550 NW LeJeune Rd., Miami, FL 33126-5671. Canada Post:Publications Mail Agreement #40612608 Canada Returns to be sent to Bleuchip International, P.O. Box 25542, London, ON N6C 6B2 Readers of Welding Journal may make copies of articles for personal, archival, educational or research purposes, and which are not for sale or resale. Permission is granted to quote from arti- cles, provided customary acknowledgment of authors and sources is made. Starred (*) items excluded from copyright. On the cover: A student practices underwater welding at the Interna- tional Diving Institute (IDI), LLC, North Charleston, S.C. (Photo courtesy of IDI.) WELDING JOURNAL 3 Editorial April 2011:Layout 1 3/9/11 1:09 PM Page 4 EDITORIAL Founded in 1919 to Advance the Science, Technology and Application of Welding IIW 2012 — A World Welding Officers President John L. Mendoza Summit Lone Star Welding Vice President William A. Rice Jr. OKI Bering It’s not too early to spread the word about an international event in the world of weld- ing that will soon be coming to the United States. The International Institute of Welding Vice President Nancy C. Cole (IIW) will hold its 2012 Annual Assembly July 8–14, 2012, at the Hyatt Regency Hotel NCC Engineering in Denver, Colo. It is an infrequent occurrence for IIW to meet in North America, and this upcoming meeting will provide a special opportunity for everyone involved in the Vice President Dean R. Wilson welding industry to meet with their counterparts from all over the world. Kimberly-Clark Global Safety Though it is held every year, the IIW Annual Assembly has only come to the United Treasurer Robert G. Pali States three times in the past 63 years (New York City, 1961; Boston, 1984; and San J. P. Nissen Co. Francisco, 1997). The 2012 event in Denver presents a special opportunity for welding experts throughout North America to attend what can truly be described as a world weld- Executive Director Ray W. Shook ing summit. In addition to meeting the world’s most influential welding experts at the American Welding Society meetings, social events, and technical visits, you will have a chance to attend a major IIW International Conference on July 12 and 13, “Welding for Repair and Life Extension of Directors Plants and Infrastructure.” Many of the participants will also take advantage of this chance to tour the beautiful T. Anderson (At Large), ITW Global Welding Tech. Center state of Colorado, with its four National Parks: Rocky Mountain, Mesa Verde, Great Sand J. R. Bray (Dist. 18), Affiliated Machinery, Inc. Dunes, and Black Canyon of the Gunnison. Combine the IIW Annual Assembly with J. C. Bruskotter (Past President), Bruskotter Consulting Services Colorado’s magnificent outdoors in mid-summer, the state’s most welcoming time of year. The International Institute of Welding was founded in 1948 by the welding institutes D. B. DeCorte (At Large), RoMan Mfg., Inc. and societies of 13 countries (including the United States) to promote best joining prac- G. Fairbanks (Dist. 9), Fairbanks Inspection & Testing Services tices on a worldwide level. Another goal was to provide an international platform for the T. A. Ferri (Dist. 1), Thermadyne Industries exchange of evolving welding technologies and applications. Today, with 54 member countries, IIW has become a global reference, providing a respected forum for informa- D. A. Flood (Dist. 22), Tri Tool, Inc. tion exchange about welding technology. The scope of IIW interest, through its 25 M. V. Harris (Dist. 15), Valley National Gases Technical Commissions and Working Units, includes joining, cutting, and surface treat- R. A. Harris (Dist. 10), Consultant ment of metals and nonmetals by means of welding, brazing, soldering, thermal cutting, D. C. Howard (Dist. 7), Concurrent Technologies Corp. thermal spraying, adhesive bonding, and microjoining. Allied fields covered by IIW work include quality assurance, nondestructive testing, standardization, health and safety, J. Jones (Dist. 17), Thermadyne Industries training, qualification, and design. W. A. Komlos (Dist. 20), ArcTech, LLC The 2012 IIW Annual Assembly will be officially hosted by the IIW American D. Landon (Dist. 16), Vermeer Mfg. Co. Council, which consists of the American Welding Society, Edison Welding Institute, and R. C. Lanier (Dist. 4), Pitt C.C. the Welding Research Council. AWS has put together a dedicated planning committee of American Council members and other welding experts who are working hard to T. J. Lienert (At Large), Los Alamos National Laboratory ensure the event will be an outstanding success. The planning committee is cochaired by J. Livesay (Dist. 8), Tennessee Technology Center Damian Kotecki and Tom Mustaleski, both of whom are AWS past presidents. Dr. D. L. McQuaid (At Large), DL McQuaid & Associates Kotecki is also IIW treasurer, and AWS Executive Director Ray Shook currently serves V. Y. Matthews (Past President), Lincoln Electric Co. (ret.) as IIW vice president. My personal role on the planning committee is to raise funds to support the 2012 IIW S. Mattson (Dist. 5), Mattson Repair Service Annual Assembly. Your role, or your company’s, can be to become known internation- S. P. Moran (At Large), ESAB Welding & Cutting Products ally as a Bronze, Silver, Gold, or Platinum sponsor of the event. Even greater exposure K. A. Phy (Dist. 6), KA Phy Services, Inc. is available by advertising your company’s products or services in a special promotional magazine on the 2012 IIW Annual Assembly that will be sent with the AWS Welding W. R. Polanin (Dist. 13), Illinois Central College Journalto its more than 67,000 subscribers all over the world. For more information on R. L. Richwine (Dist. 14), Ivy Tech State College either of these opportunities, please contact me directly at [email protected]. D. J. Roland (Dist. 12), Marinette Marine Corp. Further information about the 2012 IIW Annual Assembly is available online at N. Saminich (Dist. 21), Desert Rose H.S. and Career Center www.iiw2012.com. Under continuous development, this Web site will be the place to go for sponsorship information, to learn about accompany- N. S. Shannon (Dist. 19), Carlson Testing of Portland ing tours and social events, and to register to attend the T. A. Siewert (At Large), NIST Annual Assembly. H. W. Thompson (Dist. 2), Underwriters Laboratories, Inc. The 2012 IIW Annual Assembly will truly be a world- R. P. Wilcox (Dist. 11), ACH Co. class event in welding. Please plan now to be there, and to support it in every way you can. We hope to see you in M. R. Wiswesser (Dist. 3), Welder Training & Testing Institute Denver in July 2012. William A. Rice AWS Vice President 4 APRIL 2011 thermadyne:FP_TEMP 3/8/11 9:52 AM Page 5 For Info go to www.aws.org/ad-index Washington Watchword April 2011:Layout 1 3/9/11 1:31 PM Page 6 WASHINGTON BY HUGH K. WEBSTER WATCHWORD AWS WASHINGTON GOVERNMENT AFFAIRS OFFICE New White House Manufacturing Position ulatory actions because of concerns about the potential impact Created on businesses. The more controversial is a proposal to restore a column for work-related musculoskeletal disorders (MSDs) on OSHA Form The new position of assistant to the president for manufac- 300, Log of Work-Related Injuries and Illnesses. While many em- turing policy was recently announced by the White House. This ployers are already currently required to keep a record of work- position is within the National Economic Council, which advises place injuries and illnesses, including work-related MSDs, the the president on U.S. and global economic policy and is consid- vast majority of small businesses are not required to keep such ered part of the executive office of the president. It’s unclear records. According to the Bureau of Labor Statistics, MSDs ac- whether this position is in addition to, or replaces, the senior ad- counted for 28% of all reported workplace injuries and illnesses viser for manufacturing policy job within the Treasury Depart- requiring time away from work in 2009. ment that was created in late 2009 and has been generally known OSHA also has withdrawn a proposed new interpretation of as the “manufacturing czar.” There is also an assistant secretary its existing Noise Standard. Late last year, OSHA proposed to of manufacturing and services within the Commerce Depart- require more employers to effect “administrative or engineering ment. Regardless, it’s assumed that an assistant to the president controls” to maintain noise at acceptable levels, rather than rely- post will have enhanced influence and greater access to the ing on personal protective equipment, such as ear plugs and president. earmuffs. Administration Seeking to Establish USCIS Reaches H-1B Limit ʻPublic Engagement Platformʼ H-1B visa petitions reached the statutory cap of 65,000 for The White House is developing a draft concept for what it’s fiscal year 2011 earlier this year, according to the U.S. Citizen- calling a “next-generation citizen consultation,” namely a gov- ship and Immigration Services (USCIS). This is several months ernment-wide software tool and process to elicit expert public later than previous years and is presumed to be a result of unfa- participation. Tentatively named ExpertNet, this effort is intended vorable economic conditions. H-1B visas are used by U.S. busi- to tap the expertise of the public in a manageable and structured nesses to hire skilled foreign workers. format. The goal of ExpertNetis to enable government officials to search for and communicate with citizens who have expertise NIST Outlines Future R&D Grant Directions on a topic, giving them the opportunity to participate in a public consultation relevant to their areas of interest and know-how, and pose questions to and interact with the public to receive use- The National Institute of Standards and Technology (NIST) ful, relevant, and manageable feedback. has issued a “Three-Year Plan” outlining the topics of possible fu- More information is available at the White House blog, ture competitions for R&D funding under the agency’s Technol- www.whitehouse.gov/blog. ogy Innovation Program (TIP). The research funding roadmap, which looks three years past the current fiscal year, proposes a ʻRead the Bill,ʼ Other Transparency Rules range of TIP competitions in the fields of civil infrastructure, man- ufacturing, energy, health care, water resources, complex networks, Adopted by Congress and sustainability. The TIP provides cost-shared funding, on a competitive basis, The U.S. House of Representatives has adopted a new rule for high-risk technology R&D that offers solutions to specific crit- that no bill may be voted on without being available online for at ical national needs. least three calendar days. The rule reads, “it shall not be in order The TIP Three-Year Plan is available at www.nist.gov/tip/ to consider a bill or joint resolution which has not been reported upload/tip_programmatic_plan_fy2011_fy2014_01_25_2011.pdf. by a committee until the third calendar day…on which such meas- ure has been publicly available in electronic formhttp Regulatory Impediments to Manufacturing Similar transparency rules have been approved for House Cited Committees, such as requiring that the text of legislation to be marked up must be made public no less than 24 hours before the markup, and all committee hearings and markups must be web- In response to a request from the House Oversight and Gov- cast and made available online. ernment Reform Committee, several manufacturers and manu- In the U.S. Senate, the long-standing practice of “secret holds” facturing trade associations have identified those ongoing or has been barred. This tactic allowed individual senators to anony- pending regulatory programs they believe have the potential to mously block any bill from proceeding. Under the new rule, sen- create the greatest burden on U.S. manufacturers. Among those ators are required to publish their holds in the Senate Calendar listed are Environmental Protection Agency initiatives to regu- and Congressional Recordwithin two legislative days. In addition, late greenhouse gases, tighten regulation of industrial and com- so-called “truth-in-testimony” forms, which disclose sources of mercial boilers, and reconsider the National Ambient Air Stan- federal funding for witnesses in committee hearings, must be dards. A current effort by the Occupational Safety and Health posted online within a day after a hearing. Administration to mandate a standard for employer safety and health programs was also highlighted. Two Proposed Regulatory Actions The salutary effects of these initiatives will also be weighed by the House Committee to determine if the burden on manu- Withdrawn by OSHA (cid:2) facturing is unnecessarily high. The U.S. Occupational Safety and Health Administration Contact the AWS Washington Government Affairs Office at (OSHA) has recently withdrawn, temporarily, two proposed reg- 1747 Pennsylvania Ave. NW, Washington, DC 20006; e-mail [email protected]; FAX (202) 835-0243. 6 APRIL 2011 miller electric:FP_TEMP 3/8/11 9:47 AM Page 7 For Info go to www.aws.org/ad-index PTN April 2011:Layout 1 3/9/11 2:49 PM Page 8 PRESS TIME NEWS Publisher Andrew Cullison Seif Joins American Welding Society Editorial The American Welding Society, Miami, Fla., has en- Editorial Director Andrew Cullison gaged Richard Seif, recently retired from The Lincoln Elec- Editor Mary Ruth Johnsen tric Co., Cleveland, Ohio, as special assistant to the execu- Associate Editor Howard M. Woodward tive director. Seif will work on behalf of AWS to expand Associate Editor Kristin Campbell and facilitate international growth for the Society’s prod- Peer Review Coordinator Erin Adams ucts and services; assist the AWS Foundation in its welding workforce development activities; promote and develop the Publisher Emeritus Jeff Weber AWS Certified Welding Sales Representative program; and Graphics and Production other related responsibilities. Production Manager Zaida Chavez “We are extremely pleased to have Dick Seif join us,” Senior Production Coordinator Brenda Flores said Ray Shook, AWS executive director. “He is well known and highly respected throughout the welding industry, and Advertising he brings a proven background in marketing innovation to National SalesDirector Rob Saltzstein Richard Seif the position.” Advertising Sales Representative Lea Garrigan Badwy Seif served The Lincoln Electric Co. for 40 years, most Senior Advertising Production Manager Frank Wilson recently as senior vice president, global marketing and product development. Joining the firm in 1971, he held several positions of increasing responsibility, including vice Subscriptions president of sales and marketing, Lincoln U.S., and president, Lincoln Canada. He holds Subscriptions Representative Edalia Suarez a bachelor of science degree in electrical engineering and master of business adminis- [email protected] tration from Michigan State University. American Welding Society Ohio State Researchers Invent Chromium-Free Alloy 550 NW LeJeune Rd., Miami, FL 33126 (305) 443-9353 or (800) 443-9353 A new nickel alloy consumable invented by Gerald Frankel and John Lippold, pro- Publications, Expositions, Marketing Committee fessors of materials science and engineering at The Ohio State University, was devel- D. L. Doench, Chair oped to lessen welders’ risk of breathing toxic fumes on the job. It was developed to aid Hobart Brothers Co. military and commercial welding personnel who work in tight spaces. S. Bartholomew, Vice Chair During tests, welds made with the consumable proved just as strong and corrosion ESAB Welding & Cutting Prod. resistant as welds made with commercial stainless steel consumables. When melted, the J. D. Weber, Secretary alloy does not produce hexavalent chromium fumes. Frankel and Lippold have begun American Welding Society further testing of their alloy with Euroweld, Ltd., Mooresville, N.C. The university will D. Brown, Weiler Brush license the alloy and its applications. J. Deckrow, Hypertherm The university has three issued U.S. patents and a pending European patent applica- D. DeCorte, RoMan Mfg. J. R. Franklin, Sellstrom Mfg. Co. tion covering a series of alloys, based on nickel and copper but with no chromium. D. Levin, Airgas The research was funded by the Strategic Environmental Research and Develop- E. C. Lipphardt, Consultant ment Program, a partnership of the Department of Defense, the Environmental Protec- R. Madden, Hypertherm tion Agency, and the Department of Energy. D. Marquard, IBEDA Superflash For more information, read “A New Chromium-Free Welding Consumable for Join- J. Mueller, Thermadyne Industries ing Austenitic Stainless Steels,” on page 63-s of this Welding Journal. J. F. Saenger Jr., Consultant S. Smith, Weld-Aid Products Matheson K-Air India to Invest $100 Million, Build Plant D. Wilson, Kimberly-Clark Global Safety P. Wittke, Lincoln Electric Co. N. C. Cole, Ex Off., NCC Engineering Matheson K-Air India Private Limited, a joint venture between Matheson Tri-Gas, L. G. Kvidahl, Ex Off., Northrup Grumman Ship Systems Inc., an American Welding Society Sustaining Company Member, and K-Air India Pri- S. Liu, Ex Off., Colorado School of Mines vate Limited, will undertake a series of investments totaling in excess of $100 million. J. L. Mendoza, Ex Off., Lone Star Welding This includes constructing a new, 200 ton per day air-separation plant in Pune, India. S. P. Moran, Ex Off., ESAB Welding & Cutting Prod. Expected to be fully operational by December 2012, it will produce liquid oxygen, nitro- E. Norman, Ex Off., Southwest Area Career Center gen, and argon for delivery to end-user customers and distributors located primarily R. G. Pali, Ex Off., J. P. Nissen Co. within a 300-km radius of the facility. R. W. Shook, Ex Off., American Welding Society H. Villarreal, Ex Off., WELDCOA Genesis Plastics Welding to Expand Facility, Create Jobs Copyright © 2011 by American Welding Society in both printed and elec- Genesis Plastics Welding will expand its operations in Fortville, Ind., creating up to tronic formats. The Society is not responsible for any statement made or 54 new jobs by 2014. The company plans to invest more than $3.3 million to add 50,000 opinion expressed herein. Data and information developed by the authors of specific articles are for informational purposes only and are not in- sq ft of production space at its existing facility. Currently, Genesis is accepting applica- tended for use without independent, substantiating investigation on the tions for production workers and plant supervisors; visit www.genesisplasticswelding.com part of potential users. for contact information. In addition, the Indiana Economic Development Corp. offered the company up to $340,000 in performance-based tax credits based on its job creation plans. Construction (cid:2) is scheduled to be completed by December. MEMBER 8 APRIL 2011

Description: