View ADM Exhibits PDF

Preview View ADM Exhibits

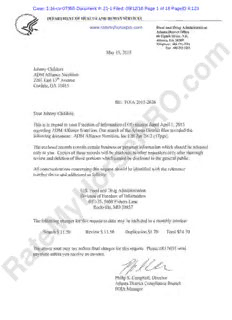

Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 1 of 18 PageID #:123 DEPARTMENT OF HEALTH AND HUMAN SERVICES www.ratemyhorsepro.com Food and Drug Administration Atlanta District Office 60 Eighth Street, N.E. Atlanta, GA 30309 m Telerhonc: 404-253-2254 Fnx: 404-253-1201 May 15,2015 o Jotmny Childers c ADM Alliance Nutrition 220 I East 131 A venue h . Cordele, GA 31015 O RE: FOIA 2015-2636 R Dear Johnny Childers; P This is in regard to your Freedom oflnformation (FOI) request dated April I, 2015 regarding ADM Alliance Nutrition. Our search of the Atlanta District files revealed the following document: ADM Alliance Nutrition, Inc EeIR Jan 2015 (17pgs). The enclosed records contain certain business osr personal information which should be released only to you. Copies of these records will be disclosed to other requesters only after thorough review and deletion of those portions which cannot be disclosed to the general public. r All communications concerning thiso request should be identified with the reference number above and addressed as follows: H U.S. Food and Drug Administration yDivision of Freedom of Information HFI-35, 5600 Fishers Lane Rockville, MD 20857 M The following charges for this request to date may be included in a monthly invoice: e Search $ 11.50 Review $ 1 1. 50 Duplication $1.70 Total $24.70 t a The above total may not reflect final charges for this request. Please DO NOT send payment unless you receive an invoice. R #/~ PhilipS. Campbell, Director Atlanta District Compliance Branch FOIA Manager Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 2 of 18 PageID #:124 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/3112014 Cordele, GA 31015-7114 EI End: 01113/2015 m o TABLE OF CONTENTS c Summary ........................................................................................................................................... 1 Administrative Data .......................................................................................................................... 2 . History ....................................................................................................................O........................... 3 Interstate Commerce. ......................................................................................................................... 4 Jurisdiction ........................................................................................................................................ 5 R Individual Responsibility c1.nd Persons Interviewed .......................................................................... 5 Fim1's Training Program ................................................................................................................... 6 Manufacturing/Design Operations ..............................................P...................................................... 6 Manufacturing Codes ...................................................................................................................... I 0 Complaints ....................................................................................................................................... I 0 e Recall Procedures ............................................................................................................................ ! 0 Refusals ................................................................s........................................................................... 10 General Discussion with Management ............................................................................................ 14 Exhibits Collected ......................................r..................................................................................... 15 Attaclunents ..................................................................................................................................... 17 o SUMMARY H The current inspection of thi~ large, licensed feed mill was conducted in accordance with y Compliance Program 7371.004, Feed Manufacturing Inspections, and Compliance Program 7371.009, BSE/Ruminant Feed Ban Inspections. The current inspection was performed in resoonse to a consumer comMplaint received from the (b) ( 4) regarding a horse death that wa<; possibly linked to a horse feed manufactured at this firm. Refer to Consumer Complaint {b) (4) included as ATTACHMENT 3. On 12/29/14,(b) (4)reported to ATL-DO that they had been notified of a horse death that could be linked to A nM A lli:mr.P. 1? % e (b) (4 ) Horse Feed. Subsequent information provided by (b) (4) revealed that there were six horses that had become t ill, three of which had died. It was reported that all of the horses were boarded at the same equestrian a{b) (4J and had been fed the same feed over an approximately 2-3 week period. The attending veterinarian for the boarding facility sent a sample of the suspect horse feed to the (b) (4 ) R (b) (4 ) and the lab results reported a negative result for ionophores to the listed units of detection, but the report noted that they observed a chromatographic peak consistent with monensin with an area equal to one half of the lowest spike (0.2 ppm); refer to EXIDBIT # 1. Reportedly, the attending veterinarian suspected the low levels of monensin in the horse feed to be the source of the horse illnesses/deaths. The suspect feed, Alliance 12% Horse Feed, was produced at this feed mill. I of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 3 of 18 PageID #:125 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/31/2014 Cordele, GA 31015-7114 El End: 01/13/2015 m The previous FDA inspection of this firm was conducted on 9/16/14 by the Georgia Department of o Agriculture as per the FDA/state feed contract inspection. No objectionable findings were reported and the inspection was classified as NAI (no action indicated). c The current comprehensive inspection found that the fim1 continues to operate as a large, licensed . feed mill that manufactures medicated and non-medicated teeds for various animals. Animal feed is O sold in bulk and bags. The inspection included a walk-through of tl1e facility and covered all routine procedures at the finn including receipt of ingredients, manufacturing operations, storage procedures, and cleaning/flushing procedures. Special emphasis was placed on the operations and records pertaining to the production of Alliance 12% Pellets produced unRder lot GA30714 and GA 14114. Documents reviewed during the inspection included ingredient receiving records, finished feed labels, daily drug inventory, batch production records, master record files, scale calibration records, pest control records, carry-over studies, and medicated fePed assay results. An FDA-2481, Medicated Feeds Inspection Report, was completed during the inspection and is attached to this report (ATTACHMENT 4). No objectionable conditions were fow1d during the inspection and no e evidence was foWld indicating that the Alliance 12% horse feed produced at this facility was contaminated with monensin and was the source leading to the deaths/illnesses of six horses. s Protein sources for feeds manufactured by this firm are from plant protein products and non r prohibited animal protein products (i.e. porcine fat). There were no objectionable findings regarding the BSE Rule. An FDA-3719, Report ofo Inspection for Compliance with 21 CFR 589.2000, was completed and is attached to this report (ATTACHMENT 5). No samples were collected and no refusals were encountered during the inspection. H ADMINISTRATIVE DATA y Inspected firm: ADM AlLiance Nutrition, Inc. M Location: 2201 E 13th Ave P.O. Box 1137 Cordele, GA 31015-7114 e Phone: 912-273-7400 FAX: t Mailing address: 13th Ave & Midway Road a Cordele, GA 31 015 R Dates of inspection: 12/31/2014, 1/6/2015, 1/7/2015, 1113/15 Days in the facility: 4 Participants: Janet B. Gray, Investigator Christina H. Owens, Investigator 2 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 4 of 18 PageID #:126 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/31/2014 Cordele, GA 31015-7114 EI End: 01/13/2015 m At the initiatjon of the inspection, we presented our credentials to Mr. Johnny W. Childers, Plant o Manager, and Mrs. Allison Brown, Assistant Plant Manager. Mr. Childers informed us that he was the most responsible individual present at the plant, and he has the authority and duty to prevent, c detect, and correct violations. The FDA-482, Notice of Inspection, was issued to Mr. Childers. At this time, we explained the purpose of the visit, and Mr. Childers told us he was aware of the situation, and he would help us in any way possible to resolve the problem. The follow.ing documents were provided to and discussed with Mr. Childers: Fact Sheet: The FDOA Food Safety Modernization Act (FSMA) and Registration ofF ood Facilities, Information Sheet-Assessment of Reinspection and Recall Fees by the FDA. and Reportable Food Registry (RFR) At a Glance. The current inspection was a team inspection with FDA Investigators Janet GrRay and Christina Owens. Investigator Owens did not participate in the inspection on 1/13/15. Thls report was written by Janet Gray. P On 1/13/15, I returned to the finn and an additional FDA-482 was issued to Mr. Childers. I presented my credentials to Mr. Childers and Mrs. Brown. At this time, I collected additional records e pertaining to test results for samples of the suspect product collected by the firm. Refer to the Complaint Follow-up section of this report for a detailed description of records reviewed and s collected. r IDSTORY o The firm is registered in accordance with the FSMA Biennial Food Facility Registration requirement H and is registered with FDA as a medicated feed mill under License Number 500-093 (EXHIBIT# 2). The plant operates Monday through Friday, and alternating Saturdays (depending on product demand). They typically operate with 2 shifts; 1st shift (5:00a.m. to 2:00 p.m.) and 2nd shlft (2:00 y p.m. to 11:00 p.m.). The office hours are Monday through Friday, 8:00 a.m.-5:00p.m. The finn has 24 employees. · M Thls firm was formerly known as MoorMan's, Inc. In 1996, the company was purchased by ADM and the name was changed to ADM Alliance Nutrition, Inc. ADM Alliance Nutrition, Inc. is a subsidiarye of Archer Daniels Midland Company (ADM). The corporate office for ADM Alliance Nutrition is: t aADM Corporate Office: ADM Alliance Nutrition, Inc. R 111 1000 N. 30 Street Quincy, IL 6230 I 3 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 5 of 18 PageID #:127 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/3112014 Cordele, GA 31015-7114 El End: 01/13/2015 m ADM Corporate Office/Headquarters: Archer Daniels MidJand Company o 4666 East Faries Parkway Decatur, IL 62526 c ADM Global Headquarters: . Archer Daniels Midland Company O 77 West Wacker Drive, Suite 4600 Chicago, IL 60601 R This location operates under the ADM Ag Services, which includes the following divisions: Grain, Edible Beans, Rice, Peanut, Anjmal Nutrition, Inc., and Terminals. Management located at this P facility includes Jolumy Childers, Plant Manager, and Allison Brown, Assistant Plant Manager. Mr. Childers reports to Eli Starkey, Regional Superintendent of Golden Peanut, and he is located in Camilla, GA. Mr. Starkey reports to Adam Schmidt, Goldeen Peanut Procurement, and he is located in Can1illa, GA. Mr. Schmjdt reports to Jeff Becker, Vice President of Ag Services Operations, and he is located in Decatur, IL. He reports to Joe Taetss, Senior Vice President of Ag Services. Mr. Taets reports to Juan Luciano, the Cruef Executive Officer of ADM. Refer to EXHIBIT# 3 for the ADM Ag Services Organizational Chart. r o FDA correspondence should be sent to: Attn: Johnny Childers, Plant Manager H ADM Alliance Nutrition, Inc. 2201 E. 13111 Ave. Cordele, GA 310 IS y M INTERSTATE COMMERCE This firm operates as a commercial feed mi11 and custom fonnula mixer that produces medicated and e non-medicated feed for a variety of animals including beef and dairy cattle, swine, sheep/goats, horses, poultry rabbits, game birds, alpacas, and deer. In 2014, this facility produced 21,973 tons of t non-medicated feeds and 13,997 tons ofmedicated feeds. According to Mr. Childers, 51.38% ofthe aproducts manufactured at this facility are shipped in interstate commerce. EXHIBIT # 4 is a copy of the interstate documentation for the 11112/14 srupment of 411 bags of Alliance 12% Pellets shipped to G & G Milling in Bamberg, SC from ADM Alliance Nutrition, Inc. in Cordele, GA. This R shipment included one of the suspect lots GA30714. Approximately, 57% of the ingredients used to produce the firm's products are received from suppliers located out of GA. According to Mrs. Brown, ingredients are only purchased from 4 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 6 of 18 PageID #:128 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. El Start: 12/31/2014 Cordele, GA 31015-7114 EI End: 01113/2015 m approved suppliers. Refer l6 EXHIBIT # 5 for the interstate documentation for a one ton load of Pork Choice White Grease shipped to ADM Alliance Nutrition in Cordele, GA from Tyson Fresh o Meats, Inc. in Logansport, IN. Refer to EXHIBIT# 6 for the interstate documentation for the shjpment of 51,180 lbs. of Dynamite Potassium Magnesium Sulfate to ADM Alliance Nutrition in Cordele, GA from Mosaic Crop Nutrition, LLC in Delphos, OH. Refer to EXHIBIT# 7 for cthe interstate documentation for the shipment of 54,200 lbs. ofDyna-K Potassium Chloride to ADM Alliance Nutrition in Cordele, GA from Mosaic Crop Nutrition, LLC in Carisbad, NM.. O Type A medicated articles used in the production of medicated feeds include Amprol 2.5 (Amprolium), AUREO 100 (Chlortetracycline), BMD 60 (Bacitracin Methylene Disalicylate), Bovatec 91 (Lasalocid), Chloratet 90 (Chlortetracycline), Cohan 90 (MoneRnsin), Rumensin 90 (Monensin), Deccox 6% (Decoquinate), Lincomix 50 (Lincomycin), Safeguard 20% (Fenbendazole), Stafac 20 (Yirginiarnycin), and Tylan 40 (Tylosin Phosphate). Safeguard 20% (Fenbendazole) is the only Category II, Type A drug used at this fPirm. A drug reconciliation check is perfonncd daily after each day's production run. The firm includes Selenium with the daily inventory check. Refer to EXHIBIT #'s 8-13 for examples of the daily drug inventory. All drugs e are received from ADM in Des Moines, lA or Effingham, IL. s .JURISDICTION r Refer to EXHIBIT #14 for a list of the poroducts manufactured at this facility. Manufactured feed is distributed in bags and in bulk. The firm does not manufacture feeds containing VFD (veterinary feed directive) drugs. Various medicated and non-medicated feed labels were reviewed during the H inspection. Examples of feed labels are included under EXHIBIT # 15. A medicated feed label for Safe-Guard Cattle and Swine Deworrner that is manufactured with Category II, Type A medicated articles is included under EXHIBIT# 15, page 1. y INDIVIDUAL REMSPONSIBILITY AND PERSONS INTERVIEWED Credentials were presented to and the FDA-482 was issued to Mr. Johnny W. Childers, Plant Manager. eMr. Childers stated that he was the most responsible individual in charge of the day-to-day operations at this facility. He provided accompaniment throughout the inspection and access to requested records. Mr. Childers has worked for the firm for approximately 20 years, and he has been t the Plant Manager of this facility since the summer of2013. As the Plant Manager, Mr. Childers is a responsible for hiring and firing employees and overseeing the production and quality supervisors. He is the most responsible individual at this facility and as such has duty, power, and responsibility R to prevent detect, and correct violations as demonstrated by providing relevant information during the inspection and giving instructions to employees that were observed to be followed. Mr. Childers reports to Mr. Eli Starkey, Regional Superintendent for Golden Peanuts. 5 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 7 of 18 PageID #:129 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/3112014 Cordele, GA 31015-7114 EI End: 01113/2015 m Ms. Allison Brown is the Assistant Plant Manager, and she is responsible for overseeing employee training, performing internal inspections, and quality and safety issues at this location. She is in o charge of operations in the absence of Mr. Childers. Mrs. Brown provided accompaniment throughout the inspection and access to records. She reports to Mr. Childers. c Mr. Danny Young, Operator 1, provided information pertaining to the drug inventory, drug assays, . and batch production records. He provided accompaniment during the review of the drug inventory during the inspection. Mr. Young is responsible for performing the daily drug inveOntory check and reviewing the daily batch production records. Mrs. Brown is responsible for performing the daily inventory check and reviewing the daily production records in his absence. He reports to Mr. Childers and Mrs. Brown. R John Aultman is the Production Supervisor, and he is responsible for producing the production run P schedule for each day's operations. e Jason Hartley, Director of Quality Assurance, was not present at the firm during the inspection; however, he provided information pertaining to samples collected, test results, and internal testing procedures. s r FIRM'S TRAINING PROGRAM o The firm provides new employees with on-the-job training relating to their job description. New hires are put with an experienced Hoperator for step by step instructions, and the employees are not released for indeJ?endent duties until they have had a minimum of 6 months of OJT. All employees receive monthly quality and safety training. Refer to EXHIBIT # 16 for the list of sections covered by the Quality Manuel Tryaining Requirements. M MANUFACTURING!DESIGN OPERATIONS There are no VFD (Veterinarian Feed Directives) feeds produced at this facility. This facility is also e a warehouse for bagged feed products; no retail sales are conducted at this location. Operations consist of one four-ton mixer, a dry line, a wet (texturizing) line, pellet mill, and a bagging station. t Type A medicated articles used in the production of medicated feeds includes Amprolium, aChlortetracycline, Bacitracin, Lincomycin, Lasalocid, Monensin, Decoquinate, Yirginiamycin, Fenbendazole, and Tylosin Phosphate. The firm maintains a daily inventory record for each drug used at the firm. A drug reconciliation check is performed daily after each day's production run. R Refer to EXHIBIT# 9 for the daily inventory check for the 116/15 production date. On 1/6115, we accompanied Mr. Young as he performed the routine inventory check. Bags of medicated articles are stored on pallets in a designated, locked area in the finn's warehouse. When the products are needed for production, the products are then moved to the drug room. Incoming drugs are checked for correct identity, quantity, labeling, and condition of the bags. 6 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 8 of 18 PageID #:130 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. El Start: 12/31/2014 Cordele, GA 31015-7114 EI End: 01/13/2015 m The firm uses a WEM computer system for all operations from receiving to bagging. The Batch o Operator verifies the amount of ingredients for each production run according to formulas maintained in the WEM system. The mill's production is monitored electronically and the system c has multiple alarms programmed to sound if equipment errors occur. The WEM system is used to track inventory and trace production lot codes. The Master Record Files are prepared and checked at the corporate level and are maintained electronically in the Oracle System. The firm's. master record files include formulas, product labels, and production instructions. The Oracle feedOs data to the WEM system. Oracle generates the batch production record, and WEM makes the product. The batch operator is responsible for verifying the active version of the fotmula in the WEM system before he starts to batch. Product formulas are maintained in the Brill ForRmulation System, which is accessed only by ADM's Nutritionists and Formulators in Quincy, IL. Labels are printed by Mr. Young, and the bagging operator is responsible for verifying that the correct label is attached to each bag. The product label is included with each set of batch productiPon records, and the label accuracy is verified during the daily QA checks by Mr. Young or Mrs. Brown. e A diagram for the production flow for each manufacturing step is included as EXHIBIT# 17. Packaged ingredients are received in tractor trailers and the products are visually checked for s damage, product verification, and correct labels prior to being unloaded. The condition of the trucks is checked for damage or unusual odor. This facility receives bulk ingredients by rail car or tractor trailer in the receiving shed. Bulk ingredientsr received include, but are not limited to whole com, wheat midds, distiller's grain, peanut hulls, and soybean hulls. Upon receipt, bulk ingredients are o visually inspected for damage, mold, insects, and foreign materials. A sample from each load of whole com and distiller's grain is collected and checked for aflatoxin levels. Each load of whole com is also checked for fumonisinH. The firm uses a Neogen AccuScan Pro Test for internal mycotoxin testing. Refer to EXHIBIT # 18 for the internal test results for bulk ingredients received from 5/13/14 to 6/5/14 and 10/21/14 to 11/6114. Additional samples of whole and ground com are periodically sent to an outyside lab to be checked for aflatoxin levels. This testing is based on requests from the corporate office. Refer to EXHIBIT # 19 for a copy of the firm's 2014 aflatoxin results for whole com and groMund corn. Bulk ingredients enter the building by a paddle conveyor or screw auger and are transferred to one of the 16-40 ton bulk holding bins. The firm uses a Hayes-Stolz horizontal, double mixer. Mr. Childers stated that the mixer has a 4 ton capacity and was installed in 1980 when the plant was built. According to Mr. Childers, they are required to produce 3-4 ton e batches for each run. t Macro ingredients are added by a computerized bulk scale that is controlled by the WEM system and a monitored by batch control employees. The micro ingredients (i.e. minerals, vitamins) are electronically added from micro bins by the WEM system. Medicated articles are pre-weighed by R hand in the drug room by an experienced employee. The batch operator double checks the drug weights electronically at the weigh scale at the hatching system. All scales ( i.e. truck scales, hatching scale, hand scales) are calibrated every 6 months by Scales System Administration in Sylvester, GA. Stickers are applied to each scale calibrated and the last calibration was performed on November, 11, 2014. Pre-weighed drugs are manually added to the mixer at the hand check scale, 7 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 9 of 18 PageID #:131 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/31/2014 Cordele, GA 31015-7114 EI End: 01113/2015 m and liquids are added after a 10 sec delay. The feed is then mixed for 4 minutes. The milled product is then transferred to a holding bin located at the pellet mill, tcxturized system, dry line system, o bagging station, or the bulk load-out area. Product intended for pellets is conveyed to one of five hoppers at the pellet mill. The pellet mill presses the product into rod shaped pellets by rotating rollers. The pellets are formed and cut into two different size pellets. The pellets arc transfercred to a cooler cyclone to remove heat and decrease moisture. Pellets are then conveyed to either the bagging station, the bulk load-out area, or conveyed to the texturized system to be use.d as a base pellet. The texturized system is referred to as the wet line. This is where wet ingredients like O molasses and oil are added to meal or pelletized product, and then the product is conveyed to the bagging station for final packaging. R Equipment clean-out procedures include physical clean-out, sequencing, and flushing. According to Mr. Childers, they are requir~d to run 2-3 one ton batches of non-medicated feed or standard flush material after the production of medicated feed. The production rePcords for each specific product states the sequencing and flushing required after the production run. For example, refer to EXHIBIT # 20 for a copy of Batch Ticket # 115121, for the production of SafeGuard Cattle and Swine e Wormer produced on ll/20114. The Production Batch Ticket identifies the product as a Medicated Feed and the sequencing instructions are stated on the record. Mr. Childers said they typically clean out the system with a sequencing schedule based ons a pre-planned order of production of feeds. He said they rarely flush the system with bulk ingredients, but when it does occur they label the flush material with the potential drug residuer or use it to produce the same medicated product at a later time. The mixer is cleaned on a monthly basis. The mixer has double doors on the side and the o doors can be dropped down so that the inside walls and the mixer can be cleaned. The mixer is physically cleaned by hand and then it is pressure washed. Equipment such as the mixer, bag bins, pellet cooler, and surge hoppers aHre visually inspected between each run. The surge hopper at the mixer is visually verified that is has been emptied before the start of another run, regardless of the product. y A carry over study with a high potency feed was performed on January of2007 with M Chlortetracycline; see EXHIBIT# 21. Refer to EXHIBIT# 21, pages 9 & 10 for medicated feed labels of product manufactured at this firm using Chlortetracycline. Labels include a medicated feed label for ShowTec Best of the Best Show Pig Formula CTC and a medicated high potency supplemeent label for CTC 4G Without Vitamins. Additionally, the firm conducts periodic copper carry over studies; refer to EXHIBIT # 22 for an email regarding copper carryover results. All stutdies were found to be within specifications and revealed adequate sequencing and flushing. a Drug assays are conducted by Eurofins Labs on products manufactured with Type A Category II drugs, which includes only Safeguard 20% (Fenbendazole). The 2013 and 2014 assays for this R product were reviewed during the inspection, refer to EXHIBIT# 23. We observed that the firm conducts three assays per year. The 2014 assays were observed to be within specification/limit between 7 5% and 125% of the labeled claim amount. The 20 13 assays had one assay that was out of specification for Safeguard Cattle and Swine Dewormer Type B Medicated Feed, batch lot 97927, analysis date 4/26/20 13(EXHIBIT # 23, page 8); however, an internal investigation was performed 8 of 17 Case: 1:16-cv-07355 Document #: 21-1 Filed: 09/12/16 Page 10 of 18 PageID #:132 Establishment Inspection Report FEI: 1030097 www.ratemyhorsepro.com ADM Alliance Nutrition, Inc. EI Start: 12/3112014 Cordele, GA 31015-7114 EI End: 01/13/2015 m and no deviations were found. The firm had the same product as well as a follow-up sample from the next batch tested and the results were both within tolerance of the label claim. Refer to EXHIBIT# o 23, pages 9-11 for the firm's investigation report and findings. c On 1/6/15, we observed the daily drug inventory check performed by Danny Young. All drugs were properly identified and stored. The current drug inventory agreed with the actual amount of drugs on hand. Refer to EXHIBIT # 9 for a copy of the I /6/15 drug inventory check. During t.he inspection, we reviewed randomly selec·ied Daily Drug Inventory records and no discrepanciesO were noted. Pest control is managed by Gregory Pest Control Solutions on a weekly basis. According to Mr. R Childers, the service representative meets with himself or Ms. Brown after each weekly visit to discuss the findings. The Pest Control Log was reviewed, and no deficiencies were observed. No evidence of pests was observed during the inspection. The firm has a fogging system in the P warehouse. They use 1 % Pyrethrin and Diacon II (with methoprene) in the fogging system. Pesticides are maintained in a in a locked cage in the finn's warehouse. e No prohibited materials were observed during the inspection of the plant. Incoming ingredient labels are reviewed to verify the materials do not contain psrohibited materials. The firm uses plant proteins and the only animal protein source is from porcine fat. Refer to EXHIBIT # 5 for a copy of the invoice for White Grease received in bulk. Thre porcine material is stored in an exterior tank that holds 9,237 gallons of product. The fmn requires truck drivers to declare or certify the commodity o previously hauled in their trailers. Each driver has to complete a form, and if a prohibited product had been previously hauled, the drivers are required to have the trailers washed out and provide documentation o"r the wash-out. THhis documentation is attached to each ingredient invoice, refer to EXIDBIT #5, pages 2 and 3, EXHIBIT # 6, pages 2 & 3, and EXHIBIT# 7, page 2. Randomly selected bulk receiving records were reviewed to verify this procedure, and no deficiencies were noted. According to Mr. Cyhilders, the majority of the porcine fat is used to produce swine feed. The firm does not manufacture pet foods, but they do receive bags of cat and dog feed from other ADM locations. These products are stored in a separate location from other bagged feeds in the finished M product warehouse. According to Mr. Childers, they do not salvage or rework any of the torn or damaged bags of pet food. The damaged bags are taped, and either sold to employees at a discount price or donated the product to the local humane society. e t a R 9 of 17

Description: