Titanium oxide antibacterial surfaces in biomedical devices PDF

Preview Titanium oxide antibacterial surfaces in biomedical devices

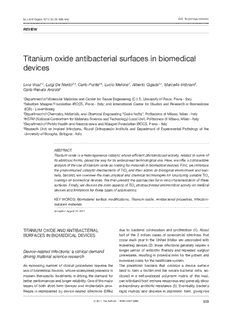

Int J Artif Organs2011;34(9):929-946 DOI: 10.5301/ijao.5000050 rEViEW Titanium oxide antibacterial surfaces in biomedical devices Livia Visai1,2, Luigi De Nardo3,4, Carlo Punta3,4, Lucio Melone3, Alberto Cigada3,4, Marcello Imbriani5, Carla Renata Arciola6 1Department of Molecular Medicine and Center for Tissue Engineering (C.I.T), University of Pavia, Pavia - Italy 2 Salvatore Maugeri Foundation IRCCS, Pavia - Italy; and International Center for Studies and Research in Biomedicine (ICB) - Luxembourg 3Department of Chemistry, Materials, and Chemical Engineering “Giulio Natta”, Politecnico di Milano, Milan - Italy 4INSTM (National Consortium for Materials Science and Technology) Local Unit, Politecnico di Milano, Milan - Italy 5Department of Public Health and Neuroscience and Maugeri Foundation IRCCS, Pavia - Italy 6 Research Unit on Implant Infections, Rizzoli Orthopaedic Institute and Department of Experimental Pathology of the University of Bologna, Bologna - Italy ABSTRACT Titanium oxide is a heterogeneous catalyst whose efficient photoinduced activity, related to some of its allotropic forms, paved the way for its widespread technological use. Here, we offer a comparative analysis of the use of titanium oxide as coating for materials in biomedical devices. First, we introduce the photoinduced catalytic mechanisms of TiO and their action on biological environment and bac- 2 teria. Second, we overview the main physical and chemical technologies for structuring suitable TiO 2 coatings on biomedical devices. We then present the approaches for in vitro characterization of these surfaces. Finally, we discuss the main aspects of TiO photoactivated antimicrobial activity on medical 2 devices and limitations for these types of applications. KEy wORDS: Biomaterial surface modifications, Titanium oxide, Antibacterial properties, Infection- resistant materials Accepted: August 31, 2011 TITANIUM OXIDE AND ANTIBACTERIAL due to bacterial colonization and proliferation (1). About SURFACES IN BIOMEDICAL DEVICES half of the 2 million cases of nosocomial infections that occur each year in the United States are associated with indwelling devices (2): these infections generally require a Device-related infections: a clinical demand longer period of antibiotic therapy and repeated surgical driving material science research procedures, resulting in potential risks for the patient and increased costs for the healthcare system. An increasing number of clinical procedures requires the The planktonic bacteria that colonize a device surface use of biomedical devices, whose widespread presence in tend to form a biofilm and the sessile bacterial cells, en- modern therapeutic treatments is driving the demand for closed in a self-produced polymeric matrix of this kind, better performances and longer reliability. One of the major can withstand host immune responses and generally show issues of both short-term devices and implantable pros- extraordinary antibiotic resistance (3). Eventually, bacteria theses is represented by device-related infections (DRIs) rapid multiply and disperse in planktonic form, giving rise © 2011 The Authors - ISSN 0391-3988 929 TiO antibacterial surfaces 2 Fig. 1 - Surface modification approaches in medical devices aimed at obtaining antibacterial properties. to a chronic infection that is not easy to eradicate by con- resents the focus of several ongoing research programs ventional antibiotic therapy. In some cases, there are no (5) aimed at improving current bulk biomaterials with a early signs of bacterial infections and their outbreaks are wide variety of chemical and physical patterns in order masked by the ongoing tissue inflammation due to the to control in vivo cell size, shape, spatial organization, surgical procedure. Hence, DRI diagnosis often occurs and proliferation (6). It is important to note that for some when a full-blown infection has already damaged tissues applications the study of new surfaces is also a distinc- of the host organism (1), thus making reoperation of in- tive departure from “standard” products (7), which are fected implants mandatory. mainly marketing-driven. Specific guideline practices have been designed with Several surface modification approaches aimed at in- the aim of minimizing the risks of infection on biomedi- troducing surface-assisted antibacterial properties have cal devices (1-3). However, implantation procedures are been described so far, and comprehensive and excellent increasingly performed in a population that comprises reviews have been published (1, 4, 8-10): a scheme of relatively older and more immunocompromised patients, the possible strategies for antibacterial surface coatings with growing risks of morbidity and mortality. Although is shown in Figure 1. systemic therapies can be used in DRI treatment, these There is a number of efforts addressed at designing sur- methods are potentially not effective due to impaired faces that provide the release of an antibacterial agent: blood circulation and the need for a high concentration polymers and polymer coatings represent a potentially of antibiotics (4). A promising alternative to a conven- interesting approach when controlled drug release of or- tional systemic therapy is represented by the design of ganic molecules or inorganic antimicrobial compounds device surface properties aimed at locally modulating is envisaged (11-15). Drug release from a loaded matrix interfacial interactions between implanted devices and has intrinsic disadvantages involving the duration and host tissues. Bacterial colonization of medical devices effectiveness of the antibacterial action, since they are leading to DRIs is, in fact, a surface-mediated process, limited by loading and release kinetics (1). An alternative one that poses challenging problems to biomaterial sci- is represented by covalent immobilization of antibiotic entists. molecules, which show the ability to prevent bacteria The modulation of device properties via chemical com- adhesion (16). A completely different approach is based position and structure modification of the surface rep- on inorganic (or hybrid organic-inorganic) coatings, in 930 © 2011 The Authors - ISSN 0391-3988 Visai et al pair (e--h+) may undergo either fast recombination, in a time range of picoseconds, or charge trapping, if in the presence of suitable e- or h+ scavengers (for example molecular oxygen and water, respectively). In the latter case, a photocatalytic reaction occurs, leading to the development of a wide range of useful processes. Titanium dioxide (titania, TiO ) is undoubtedly the most 2 commonly employed of the n-type semiconductors, thanks to its high photoactivity and stability, relatively low cost, and non-toxicity. Often metal-doped in order to increase the λ radiation adsorption, it is the photo- catalyst of choice in organic synthesis (25-29) for the preparation of smart-materials with self-cleaning and Fig. 2 - Band energetic structure (a) and mechanism of photo-irradi- self-sterilizing surfaces, and for environmental purifica- ation (b) of a semiconductor. tion (air and water) (24, 30-32). TiO exists in three main polymorphs: anatase, rutile, 2 and brookite. Anatase shows a band gap of 3.2 eV, cor- which both an antimicrobial compound release and an responding to a UV wavelength adsorption of 385 nm. intrinsic antibacterial activity are possible. In this review, In contrast, rutile has a smaller band gap (3.0 eV), with we will focus our attention on the latter approach, based excitation wavelengths that extend into the visible light particularly on titanium oxide, whose antibacterial prop- range (410 nm). Nevertheless, anatase is generally con- erties primarily relate to the semiconductor nature of this sidered the most photochemically active phase of titania. oxide. The reason for this higher activity should be attributed to the combined effect of the higher surface adsorptive Photocatalytic activity in titanium oxide capacity of anatase and its higher rate of hole trapping. surfaces Recently, studies have shown that mixtures of anatase- rutile or brookite-anatase were more active than anatase alone (33, 34). Photocatalytic activity in semiconductors Photooxidations promoted by TiO : the role of 2 O and H O In the last three decades, photocatalytic processes pro- 2 2 moted by semiconductors (SC) have found a widespread application in many fields, including water splitting, en- when TiO -surfaces are irradiated with suitable photon 2 ergy production, air and water purification, surface ster- energies under aerobic conditions, leading to the forma- ilization and organic synthesis (17-23). The reasons for tion of the e--h+ pairs (Eq. 1), molecular oxygen can act this increasing interest in photocatalytic protocols are as an electron scavenger, providing the corresponding the growing demand for reducing environmental pollu- superoxide radical (Eq. 2). This reaction, which com- tion and for developing more eco-friendly and cheaper petes with the fast electron-hole recombination, repre- processes. It is well known that a SC is characterized by sents the initiation phase of a free-radical chain promot- a band energetic structure, with a band gap between the ed by water (Eq. 3), leading to the formation of hydroxyl lower valence band (VB), entirely filled with electrons, (•OH) radicals (Eqs. 4 and 5, Scheme 1). and the unoccupied, higher energetic conduction band •OH radicals, which can also be generated via direct (CB) (Fig. 2a). when the SC is photo-irradiated by light oxidation of water and adsorbed hydroxide ion (Eqs. 7 with photon energy (hν) at least equal to the band gap, and 8, Scheme 2) by means of photo-generated holes electrons present in the occupied band are photoexcited (35, 36), were found to be present on irradiated TiO sur- 2 and move to the CB, leaving a positive charged hole in faces by spin trapping experiments with EPR spectros- the VB (Fig. 2b) (24). Once formed, the electron and hole copy (32). © 2011 The Authors - ISSN 0391-3988 931 TiO antibacterial surfaces 2 TiO2 + hν e-CB + h+VB (1) R + O2 ROO (13) O2 + e- O2 - (2) ROO + RH ROOH + R (14) H2O OH- + H+ (3) ROOH + e- RO + OH- (15) O - + H+ HOO (4) 2 HOO + H+ H2O2 (5) Scheme 4 - Formation of active oxygen-centered radi- H2O2 + e- ( OH)ads + OH- (6) cals by means of O2. ads = adsorbed The role of water in photocatalysis on TiO is no less im- 2 portant. If the promotion of photoxidative processes ap- Scheme 1 - Mechanism of photoinduced formation of pears clear from its capability to generate hydroxyl radi- hydroxyl radical from O . cals on TiO -surfaces, its inhibition action by site blocking 2 2 must be stressed as well (42). Site blocking may occur H2O + h+ ( OH)ads + H+ (7) through two different routes, one according to which wa- ter occupies key adsorption and/or reaction sites on the OH- + h+ ( OH)ads (8) surface, and the other one in which the access of reac- tants on the surface is inhibited by a solvent effect (24). Scheme 2 - Mechanism of photoinduced formation of hydroxyl radical from water. Mechanisms of self-disinfection activity on TiO 2 Once formed, these highly reactive radical species One of the main advantages of photocatalytic sterilizing seem to play a key role in promoting the indirect oxida- surface is the fact that they operate without electrical pow- tion of organic substances (Eqs. 9-11, Scheme 3). er or chemical reagents, since light, oxygen and water are the only required ingredients. TiO surfaces are not poison- 2 ous and do not cause environmental pollution. These char- ( OH) + RH R + H O (9) ads 2 acteristics make self-sterilizing TiO materials the products 2 R + ( OH)ads (ROH)ads (10) of choice for future medical applications. The antibacterial properties of irradiated TiO -surfaces de- (ROH)ads + ( OH)ads RO + H2O (11) 2 rive from the combination of two different characteristics of these materials, namely, their self-cleaning and self- Scheme 3 - Indirect oxidation of organic substances disinfection properties. Self-cleaning can be considered promoted •OH radicals. an indirect action against bacteria. In fact, degradation of organic substances (Eq. 16) by total oxidation (43), accord- Nevertheless, more recently Fox (37, 38) and Tachika- ing to the mechanism previously disclosed, prevents from wa (39, 40) have demonstrated that in many cases the bacteria and biofilm adhesion on material surfaces. same products could also be formed via direct oxida- tion by holes (Eq. 12), partially reconsidering the over- organic TiO2, O2 intermediate CO + H O (16) estimated role of •OH radicals. contaminant hν > band-gap radical species 2 2 As far as the direct antibacterial activity by irradiated TiO - RH + h+ R + H+ (12) 2 surfaces is concerned, the real mechanisms which regu- late bacterial killing are still under debate. In this context, O has not only the role of electron Matsunaga et al (44, 45) explained the mechanism of steril- 2 scavenger in the initiation phase (Eq. 2), it is also in- ization by TiO powders on Escherichia coli cells evaluating 2 volved in further reactions with organic radical species, the concentrations of coenzyme A (CoA). It is known that leading to products of partial or total oxidation (Eq. 13- CoA mediates an electron transfer between the cell and an 15, Scheme 4) (41). electrode or a semiconductor. They showed that the de- 932 © 2011 The Authors - ISSN 0391-3988 Visai et al Fig. 3 - Three-step proposed mechanism for photokilling of bacteria on irradiated TiO-surfaces. 2 STRATEGIES TO OBTAIN TITANIUM OXIDE crease of CoA in the bacterial cells is related to the irradia- SURFACES ON MEDICAL DEVICES tion time and to the increase of the dimeric CoA concen- tration, causing inhibition of respiration. However, different types of experimental evidence have shown that the killing Surface modification technologies for antibacte- action of irradiated TiO is primarily due to membrane and 2 rial properties in biomedical devices cell wall damage. In a recent review Dalrymple et al (46) have presented details of the kinetic aspects of the kill- ing mechanism and explored the theoretical development The interest in titanium oxide as biomaterial surface is of a model for photocatalytic disinfection based on lipid originally due to the performances of Ti and its alloys (Ti peroxidation. alloys, hereafter) commonly used in biomedical device In particular, Sunada et al (47) proposed a three-step manufacturing. Ti alloys are covered by a thin (nanometric) mechanism for photokilling of bacteria on irradiated TiO - TiO film, that spontaneously grows on their surfaces in air. 2 2 surfaces (Fig. 3): (a) attack of cell walls by reactive oxygen This nanometric layer preserves the properties of the bulk species; (b) disordering of the inner cytoplasmic mem- material and interacts with biological fluids, resulting in a brane and killing of the cell; (c) decomposition of the toxic modulation of specific responses with the contact biologi- ingredients of bacteria. cal tissues (48). The comprehension of the role of TiO film 2 In the first stage the outer membrane is partially damaged. on biomedical Ti alloys paved the way to intense research This first attack does not particularly affect the vitality of activity focused on technologies for modifying and struc- the cell, but it changes the permeability of bacterium to- turing the natural oxide layer in order to increase its resis- wards reactive species, which can enter the cell and attack tance and give rise to novel properties (see, for instance, the cytoplasmic membrane by lipid peroxidation (second the results obtained in increasing the corrosion resistance step). It is at this stage that the structural and functional of Ti alloys by increasing the oxide layer thickness in (49)) disordering of the inner membrane leads to cell death. (48, 50-52). The third step is what makes photocatalytic sterilization Industrial applications of photoactive materials, such as the most effective technique when compared with classi- antifogging and self-cleaning surfaces, became popular cal antibacterial treatments. At longer reaction times, dead in the last decade: however, their medical applications are bacteria were found to be completely mineralized mainly still limited and seem to be still under development (4). To to CO and H O, once again due to the before-mentioned take advantages of the photo-activated processes of TiO 2 2 2 self-cleaning property of photo-irradiated TiO -surfaces over the wide range of bulk biomaterials, several studies 2 (Eq. 16). have been conducted in order to deposit thin and adherent © 2011 The Authors - ISSN 0391-3988 933 TiO antibacterial surfaces 2 films, with specific crystallographic phases (i.e., anatase or wires made of stainless steel as bulk material and tested its rutile). It is generally accepted that crystalline phases (even photo-activated antiadherent properties (on Streptococ- in their nanostructured forms) possess photo-activated an- cus mutans, which are the cause of dental caries) and its timicrobial behavior. However, a study from Choi and co- antibacterial properties (on S. mutans and Porphyromonas workers showed that even the natural oxide layer covering gingivalis, the former causing periodontitis) of these sur- commercially pure Ti possess antimicrobial behavior, with faces. They found that the bacterial mass that bound to the no significant differences among non-treated, anodic, and TiO -coated orthodontic wires remained unchanged after 2 thermal-treated specimens (53). This finding could be ex- adhesion tests, whereas uncoated wires increased their plained by taking into account that in a native, essentially mass by 4.97%. Furthermore, the TiO -coated orthodontic 2 amorphous, titanium oxide film a certain degree of short- wires had a bactericidal effect on both strains; since one range order in the nanometer range is likely to occur (54). of the main causes of failure in orthodontic treatment is It becomes evident that a tuning of the surface properties of the development of dental plaque initiated by the adhesion this oxide paves the way for the exploitation of structured- of S. mutans to the tooth surface or orthodontic devices, TiO properties, by maintaining the bulk material properties this treatment appears of particular interest for this specific 2 of Ti alloys and, mainly, of materials other than Ti alloys. In device (64). the following section we offer an overview of the available This example allows us to point out that materials other surface technologies allowing the deposition and/or struc- than Ti alloys can be treated in order to add a thin titanium turing of TiO films with antibacterial properties. A particu- oxide layer onto their surface: results of this sort have been 2 lar emphasis is placed on the methods that can be easily achieved by other authors on different organic and inor- scaled-up to large production of medical implants. For the ganic substrates (4, 70-73). Another advantage of using the sake of simplicity, we will classify these surface modifica- sol-gel technique is the possibility of incorporating metal tions according to the involved technologies. ions, nanometric clusters, and bactericidal molecules that in most cases have antibacterial properties per se, namely Chemical and electrochemical methods Ag ions/nanoparticles (61, 63, 74-76), or Cu ions (69, 73). The presence of these dopants on TiO structure plays a 2 synergistic role in photokilling bacteria, since they can act Sol-gel as: (i) antimicrobial species, when directly released in con- centration enough to directly kill the bacteria species; (ii) Sol-gel is a wet chemical technology based on a sequence charge separator enhancers, enhancing the efficiency of of synthesis steps similar to an organic polymerization for the redox reactions; (iii) oxidants (e.g., Cu2+ has been dem- the synthesis of inorganic and organic-inorganic hybrid onstrated to reduce to Cu+ and react with H O in a Fenton- 2 2 oxides (55). It is generally realized by means of hydrolysis Type reaction, resulting in the production of •OH radicals). and condensation of metallorganic alkoxide precursors, Obviously, these synergistic effects, deriving from doping although inorganic precursor synthesis is also commonly TiO structures are not peculiar of sol-gel technology, and 2 used (55). Using this technique, bioactive silica-based thin have hence been explored also using other technologies, films for biomedical applications have been produced (56- as discussed below. 58). By using suitable Ti precursors, thin TiO coatings, Several examples other than those reported here can be 2 based on either conventional (59) or the Stepwise Surface found in literature (4, 61, 63, 69-77), and we suggest the process (60), can be obtained on different substrates. Sur- reader refer to each of these works to have an overall idea face modifications aimed at obtaining antibacterial proper- about ongoing research studies. However, some general ties using sol gel TiO coatings have been realized by sev- conclusions on this technique can be drawn. Sol-gel al- 2 eral research groups (12, 61-71), even if in some cases it is lows the treatment of different bulk materials, without af- difficult to compare the results due to scarce homogeneity fecting the morphology at the micrometric scale. Different in surface preparation, chemico-physical characterization, allotropic forms can be deposited and their tuning depends and the selected bacteria strains and methods (this point on the chemical-physical steps involved in the preparation will be further elucidated in the next section). of sol and following film deposition and curing. Moreover, Chun et al (64) proposed the modification of orthodontic it is quite an economic solution, providing that surfaces are 934 © 2011 The Authors - ISSN 0391-3988 Visai et al correctly prepared and devices have a simple 3D shape to be either totally amorphous or in some cases partially (sol-gel coatings can be deposited mainly either via dip or crystalline (82). spray coating). The presence of the anatase phase has been shown to As a general suggestion to the reader, this technique ap- play an important role in the reduction of bacterial coloni- pears particularly useful in producing advanced antibacte- zation on low-voltage anodized surfaces (87). Del Curto et rial coatings: due to the simple industrial scale-up and the al proposed an anodization followed by a heat treatment esthetic quality of the resulting film, it represents a power- to induce phase conversion of the TiO layer; the resulting 2 ful tool in medical device design that has yet to be fully surfaces exhibited a remarkable reduction in the attach- exploited. ment of three streptococcal strains. when anodization is carried out at higher voltages local Electrochemical technologies melting and re-crystallization processes result in the in- corporation of ionic species with a concentration gradi- Electrochemical surface modifications are based on elec- ent along the oxide: the electrolytic bath affects the final tric polarization of electrical conductive substrates in three chemical composition of the grown oxide. An interesting different modes: anodic oxidation, cathodic polarization (or treatment has been proposed by Song et al (88): they ob- Electrolytic Deposition (ELD)), and electrophoretic deposi- tained Ag- or Pt-containing coatings on Ti-based implants tion (EPD). Cathodic polarization is generally used for the by performing MAO in a bath composed of silver and plati- deposition of calcium phosphate coatings and for this rea- num salts. Antibacterial properties were evaluated by using son will not be further discussed in this review. S. aureus and E. coli. Lower Ag-containing coatings exhib- ited in vitro antibacterial activity with no cytotoxicity, while Anodic oxidation higher Ag concentrations had a cytotoxic effect. These two examples allow us to draw some main conclu- Anodic polarization allows thick and conveniently struc- sions: the anodization process can be effectively applied tured Ti oxide films to be achieved only over the surface for titanium modification and coating preparation for bio- of Ti alloys: electrode reactions in combination with elec- medical applications, taking advantage of both the mor- trical field-driven metal and oxygen ion diffusion lead to phological and chemical results of such treatments, since the formation of an oxide film at the anodic surface (48, these films show controlled porosity, morphology, chemi- 78). (The explanation for the electrochemical processes cal composition, and allotropic structure (50, 89-92). Anod- involved in anodization can be found in several works (48- ic modification technology thus appears interesting when 50, 79-84).) The anodic oxide film growth is a two-stage complex devices made of Ti alloys need to be treated in process that results in either a thin or thick titanium oxide order to obtain antibacterial properties. film: up to 160 V of applied voltage drop in the electro- Electrophoretic deposition chemical cell, a linear growth in the nanometric range of the TiO film is achieved (50); when anodization is carried 2 out at higher voltages, an increased gas evolution and Electrophoretic deposition allows the deposition of coating often sparking are obtained, resulting in titanium oxide from almost any material class, including metals, polymers, films up to tenth µm thickness. The latter process is gen- and ceramics (93-96). The mechanism of electrophoretic erally called Micro-arc oxidation (MAO) or Anodic Spark deposition involves electrophoresis, in which charged par- deposition (ASD) (48, 78). ticles move toward an electrode of opposite charge, and Morphological and structural features of oxides can be deposition, due to the motion of charged particles and hence tuned using anodization over a wide range, resulting their local accumulation. Coating formation is achieved via in films of increased oxide thickness, porous coatings, and particle coagulation (93-96). selected crystallographic forms. Moreover, ion insertion EPD appears of particular interest in surface modifications in TiO structure is also possible, providing that a suitable of materials for biomedical application (48, 78) because 2 electrochemical bath is selected, although TiO ion doping the deposition of either inorganic or hybrid coatings with 2 at low voltage anodization is actually a controversial issue high purity is possible on complex geometries. Promis- (80, 81, 85, 86). Diffraction studies showed the oxide films ing results have also been obtained in TiO antibacterial 2 © 2011 The Authors - ISSN 0391-3988 935 TiO antibacterial surfaces 2 coatings: Santillán et al (97) studied the synthesis of TiO – material to be treated in a plasma under a high volt- 2 Ag composite nanoparticles and the fabrication of TiO age bias (104-106). The term plasma is used to define 2 and TiO –Ag coatings on titanium substrates by EPD. Ag a state of matter (“the fourth state of matter”) char- 2 nanoparticles ( Ag) were directly formed and grown on acterized by the presence of a significant number of NP the surface of TiO nanoparticles ( TiO ) from nucleophilic electrically charged or ionized atoms and/or molecules 2 NP 2 reaction catalyzed by alkalis. They were able to demon- having the fundamental characteristic of exhibiting a strate the feasibility of EPD of TiO –Ag coatings on titanium collective behavior due to long-range Coulomb inter- 2 substrate and that all the developed coatings showed in actions (107). The surface of the materials treated with vitro bioactivity, with a degree of bioactivity qualitatively the plasma can be modified by implanting new ionic decreasing as Ag content in TiO coatings increased. How- species into the original materials. In this way a thin 2 ever, the authors did not evaluate the bacterial response of layer of the material surface is doped, allowing modifi- these coatings. cation of mechanical, chemical and/or electrical prop- erties. This process is generally called Plasma Immer- Chemical Vapour Depositions (CVD) sion Ion Implantation (PIII or PI3). when a deposition of matter is performed by forming a thin layer of material, The growth of TiO films can also be pursued by using an the process is called Plasma Immersion Ion Implanta- 2 RF plasma enhanced chemical vapor deposition method tion and Deposition (PIII&D or PI3&D). The plasma tech- (PECVD), which is a variant of the chemical vapor de- niques have a wide field of application, such as wear position (CVD). This technique allows the deposition of and corrosion protection, microelectronics, and medi- thin films of different materials (for example silicon diox- cal-device manufacturing (108). ide or silicon nitride) starting from their precursors and A number of authors have achievd the coating of different operating at lower temperatures due to the plasma ac- materials like metals, glasses, silicon wafers, and ceram- tion that facilitates the occurrence of the chemical reac- ics with TiO with PIII&D techniques. Baba and Hatada 2 tions. For example, with regard to the titanium dioxide, (109) reported the deposition of a TiO thin film onto fused 2 Szymanowski et al (98) reported the deposition of TiO quartz glass and silicon wafer through PIII&D using titani- 2 onto glass slides and Rashig rings in order to create TiO um tetraisopropoxide as precursor. The plasma was gen- 2 film having photo-induced antibacterial properties. They erated by a 50 w antenna irradiating RF power at 13.56 used titanium tetrachloride diluted in argon as source of MHz at 1.3 Pa pressure. Negative pulses of 20 kV having Ti and gaseous O as source of oxygen. The gaseous a duration of 50 µs and a repetition rate of 100 Hz gave 2 mixture was injected in a vacuum chamber (79.8 Pa) and TiO films with a thickness of 318 nm after annealing at 2 irradiated with a RF power of 20 w to 300 w for 30 min- temperatures between 673 K and 1023 K for 1 h. Similar utes. The TiO film thickness grew up to more than 500 results were obtained by Jing et al (110). 2 nm depending on the deposition power. The antibacterial Shiraishi et al (111) described the preparation of anti- capability was tested with E. coli strains (DH5α) show- bacterial metal implant (titanium and SUS316 stainless ing good bacterial inhibition while increasing the TiO film steel) with a TiO using a plasma source ion implantation 2 2 thickness. Other techniques frequently used are based on followed by annealing. The TiO layer conferred photo- 2 magnetron sputtering (99-101), ion beam sputtering (102) catalytic bactericidal effect against S. aureus under UVA and spray pyrolisis (103). irradiation. The bactericidal effects of TiO under UV-light irradiation 2 Physical methods is particularly useful for sterilizing the contaminated sur- face of dental implants as reported by Suketa et al (112). The authors used a plasma source ion implantation to de- Plasma Immersion Ion Implantation posit a layer of TiO onto metallic titanium and tested the 2 photobactericidal effectiveness of the resulting surfaces One of the most widely used physical techniques for the on Actinobacillus actinomycetemcomitans and Fusobac- generation of TiO thin film on the surface of a large class terium nucleatum, two microorganisms responsible for 2 of biomedical items is based on the immersion of the infections of the oral cavity. 936 © 2011 The Authors - ISSN 0391-3988 Visai et al Plasma spray Plasma spraying is a different and also widely used tech- nique to form ceramic and oxide coatings on a wide class of inorganic substrates. The process is based on the action of an electric arc that melts and sprays materials onto a solid surface. Generally the material to be deposited is in- jected in powder form using an inert gas (argon) as carrier. Both nanometric and micrometric powders can be used in order to obtain a different surface roughness (113). This technique presents several advantages, such as high de- position rates (80 g/min), thick deposits (hundreds of mi- crometers to several millimeters), and low costs. Moreover, the resulting coatings have a surface morphology charac- terized by a good degree of roughness that is particularly Fig. 4 - Outer layers of bacteria: (a) Gram-negative (b) Gram-posi- suitable in the orthopedic applications of titanium because tive. it favors osteoblast adhesion (114). Mixtures of TiO and other oxides, like as Al O , can also 2 2 3 be deposited on stainless steel surfaces by atmospheric et al (72). The difference is usually ascribed to the differ- plasma spraying technique as described in (115). Often ence in cell wall structure and peptidoglycan thickness be- the TiO powders are mixed with silver powders in order tween Gram-positive and Gram-negative bacteria. The cell 2 to have antibacterial activity even without light irradiation wall in Gram-positive bacteria is essentially composed of (116). The biocompatibility and the antibacterial activity of a very thick peptidoglycan layer whereas in Gram-negative the TiO coating onto titanium slides can also be improved bacteria it has a thin inner peptidoglycan layer externally 2 by grafting collagen and eventually loading it with gentami- surrounded by an outer membrane mainly enriched of lipo- cin, an aminoglycoside antibiotic (117). polysaccharide (LPS) and lipoprotein (Fig. 4). Peptidoglycan is a peptide-crosslinked polysaccharide which surrounds bacterial cells and confers rigidity to IN VITRO EVALUATION OF TIO ANTIBACTE- maintain shape and internal pressure: in Gram-positive 2 RIAL ACTIVITy bacteria it accounts for as much as 90% of the cell wall whereas in Gram-negative bacteria it accounts for only Since the demonstration of its antimicrobial activity, UV-ac- 10%. But in Gram-negative bacteria, the outer membrane tivated TiO has been used in suspension, in liquids, or im- is the first external line of defense whereas in Gram-posi- 2 mobilized on surfaces for the destruction of Gram-negative tive bacteria it is the thick peptidoglycan layer. However, it and Gram-positive bacteria, including endospores, fungi, is not clear if the peptidoglycan layer is the critical target algae, protozoa, viruses as well as for the inactivation of of attack by radicals or simply retards the diffusion of oxi- microbial toxins and prions (45, 72, 118-127). Ions such dants to the underlying vital sites (phosholipid bilayers) of as Cu2+ and Ag+ in combination with TiO were reported bacterial cells. 2 to enhance its antimicrobial activity (72). Furthermore, the Up to now, most studies have been performed against E. photocatalytic activity of TiO was reported as performed coli strains, but other Gram-negative bacteria have also 2 against pure bacterial cultures, mixed cultures (128) and been reported to be susceptible to TiO photocatalytic ac- 2 natural communities (129-131). tivity. Regarding Gram-positive bacteria, species of 17 dif- As a general concept, photocatalytic surfaces or suspen- ferent genera, including aerobic and anaerobic endospore sions are referred to as being self-disinfecting rather than formers, were shown to be killed by TiO photocatalytic 2 self-sterilizing. Photocatalysis has been shown to be ca- activity (details in ref. (72)). Furthermore, the planctonic pable of killing more Gram-negative than Gram-positive cells were less resistant to photocatalytic disinfection than bacteria as reported in an excellent mini-review by Howard endospores. The killing mechanism of photoactivated TiO 2 © 2011 The Authors - ISSN 0391-3988 937 TiO antibacterial surfaces 2 has been studied in Gram-positive and Gram-negative In general, microscopic studies showed morphological bacteria. changes suggestive of cell wall disruption of UVA irradiat- ed TiO surfaces/suspensions. On E. coli cells, various de- 2 In vitro evaluation techniques to asses antibacte- grees of cell disruption including plasmolysis, intracellular rial properties vacuoles ghost and cell debris was observed; in particular, the outer membrane is the first to be attacked, followed by Different type of methods can be used to assess killing of the complete degradation of the cytoplasmic membrane. microorganisms by photocatalysis such as i) evaluation of On S. aureus treated cells, a separation of cytoplasmic bacterial survivability, ii) determination of intercellular com- membrane from the peptidoglycan layer or cell distortion ponents leakage (cations, RNA and protein), iii) microscopy was observed. Photocatalytic killing for Gram-negative observations, up to iv) determination of lipid peroxidation and Gram-positive bacteria occurred without substantial products by spectroscopic studies and v) evaluation of kill- visible degradation of peptidoglycan. ing of bacterial cells throughout biofilm. Confocal Laser Scanning Microscopy (CLSM) can be ef- fectively performed to show cell membrane damage us- Evaluation of bacterial survivability ing LIVE-DEAD® BacLight™ Bacterial Viability Kit. The kit includes two fluorescent nucleic acid stains: SyTO9 that Adhesions and proliferation assays are the first methods to penetrates both viable and nonviable bacteria, and prop- perform for evaluating the killing efficacy of titanium oxide idium iodide that penetrates bacteria with damaged mem- surfaces or suspensions. Cell survival can be expressed branes and quenches SyTO9 fluorescence. Dead cells, as the ratio of the Colony Forming Units (CFU) from bac- which take up propidium iodide, fluoresce red, and cells teria treated with irradiated TiO surfaces/suspensions and fluorescing green are deemed viable. 2 CFU from untreated bacteria (87, 92). Furthermore, a test Spectroscopic studies with 3-(4,5-dimethylthiazole-2-yl)-2,5-diphenyl tetrazolium bromide (MTT) can be performed at different times of incu- bation to evaluate the mitochondrial activity of the bacte- X-ray diffraction (144), laser kinetic spectroscopy and at- rial cells. The former method is the most reliable it is time tenuated total reflection Fourier Transform Infrared Spec- consuming whereas the latter is more rapid. troscopy (FTIR) (134, 145-147) were used to show cell dis- ruption due to lipid peroxidation or direct oxidation. Lipid Evaluation of changes in membrane permeability peroxidation occurs when polyunsaturated fatty acids (lin- oleic acid) are attacked by ROS such as hydroxyl radicals The leakage of intercellular components can be an indirect and H O produced by irradiated TiO surfaces. Malondial- 2 2 2 method for the assessment of bacterial membrane dam- dehyde (MDA) is released as a product of membrane deg- age. Various studies performed on Streptococcus sobri- radation. It has been suggested that the free radicals •OH nus, E. coli and S. aureus with TiO showed leakage of po- and H O were responsible for killing close to the TiO , with 2 2 2 2 tassium ions from the bacteria and the parallel decrease in H O acting at a distance (118, 148-152). Direct oxidation 2 2 cell viability (70, 72, 132-135). of bacterial components is feasible when cells are in direct contact with the surface of TiO . The oxidation occurs di- 2 Microscopy observations rectly on the membrane components without production of reactive oxygen species as intermediates. Trasmission Electron Microscopy (TEM), Scanning Elec- Evaluation of killing of bacterial cells throughout tron Microscopy (SEM) and Atomic Force Microscopy biofilm (AFM) images of TiO -treated bacterial cells such as S. 2 mutans (132), Pseudomonas aeruginosa (136), E. coli (47, 137-142), S. aureus (143), MRSA and methicillin-sensi- Bacterial biofilms are associated with various pathological tive S. aureus (137), and Streptococcus pneumonia (143) conditions in humans such as cystic fibrosis (P. aeruginosa), were used to show membrane damage and progressive colonization of indwelling devices (S. aureus and Staphy- destructions of cells if compared to untreated cells (72). lococcus epidermidis) and dental plaque (oral streptococ- 938 © 2011 The Authors - ISSN 0391-3988

Description: