The Vapor Phase Hydration of Ethylene Oxide PDF

Preview The Vapor Phase Hydration of Ethylene Oxide

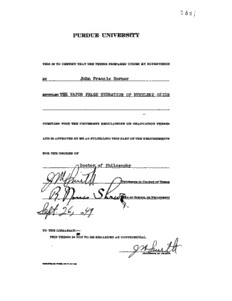

PURDUE UNIVERSITY THIS IS TO CERTIFY THAT THE THESIS PREPARED UNDER MY SUPERVISION John Francis Horner by______________________ THE VAPOR PHASE HYDRATION OP ETHYLENE OXIDE ENTITLED COMPLIES WITH THE UNIVERSITY REGULATIONS ON GRADUATION THESES AND IS APPROVED BY ME AS FULFILLING THIS PART OF THE REQUIREMENTS FOR THE DEGREE OF Doctor, of Philosophy toFBssoR in Charge of Thesis of School or Department TO THE LIBRARIAN:---- m THIS THESIS IS NOT TO BE REGARDED AS CONFIDENTIAL. THE VAPOR PHASE HYDRATION OF ETHYLENE OXIDE A Thesis Submitted to the Faculty of Purdue University by John Francis Horner In P artial Fulfillm ent of the Requirements for the Degree of Doctor of Philosophy February, 1950 ACKNOWLEDGMENT The author wishes to express his appreciation to Dr# J. M. Smith, the director of this research, for his in terest, encouragement, and advice during the course of these investigations, and to Messrs* Cartmell, Galloway, Olson, Trice, and Langer for their contributions to the prelim inary phases of this work. ProQuest Number: 27714099 All rights reserved INFORMATION TO ALL USERS The quality of this reproduction is dependent upon the quality of the copy submitted. In the unlikely event that the author did not send a complete manuscript and there are missing pages, these will be noted. Also, if material had to be removed, a note will indicate the deletion. uest ProQuest 27714099 Published by ProQuest LLC (2019). Copyright of the Dissertation is held by the Author. All rights reserved. This work is protected against unauthorized copying under Title 17, United States Code Microform Edition © ProQuest LLC. ProQuest LLC. 789 East Eisenhower Parkway P.O. Box 1346 Ann Arbor, Ml 48106 - 1346 TABLE OF CONTENTS Page ABSTRACT ................................................................................................... i INTRODUCTION .......................................................................................... 1 Uses and Properties of the Ethylene Glycols . . . . . . 1 Ethylene Glycol .......................................................... 1 Diethylene Glycol ............................................................ 2 Triethylene G lycol........................................................... 2 Manufacture of Ethylene Glycol . . . . . . . . . . . . . . . . . . . 3 Chlorohydrin Process ........................................ ! Dichloride Process ........................................................... duPont Synthesis ............................................ Processes Based upon Ethylene Oxide .............. Liquid Phase Hydration ............................... 6 Vapor Phase H ydration................................. 6 Purpose of the Project ................................................. 7 Review of Previous Experimental Work . . . . . . . . . . . . . 8 Thermodynamic Considerations .................................. 8 Equipment for Preliminary Studies •••.............. 10 Results of Preliminary Work .................. 11 DESCRIPTION OF EQUIPMENT ............................................................... 15 * Design Conditions .......................................................... 15 Metering and Control System for Ethylene Oxide ••• 19 Metering and Control System for Steam .................. 23 Preheating the Reactants .................................................... 25 The Catalytic R eacto r........................................................ 28 Dowtherm System ............................................................... 31 Product Separation and Collection System ............ 33 Temperature Recording ........................................... 35 TABLE OF CONTENTS (Continued) PRELIMINARY EXPERIMENTAL WORK.................................................... Development and Calibration of the Ethylene Oxide Metering System ........................................... Development and Calibration of the Steam Metering and Control System ............................................ Product Analysis by D is tilla tio n ................ Analysis for Ethylene Oxide in Mixtures with Glycols ....................................................................................... Analysis for Total Converted Organics by Oxidation COMPLETE OPERATING PROCEDURE...................................................... The Warm-up Period .............................................................. Run Operation ..................................................... Shut-down....................................................................................... Mis cellaneous ................................................. RESULTS..................................................................................................... Study of the Variance of Catalytic A ctivity .......... Physical Condition of the Catalyst . . . . . . . . . Effect of On-Stream Time on A ctivity . . . . . . . . . Study of the Effect of Operating Variables on Total Conversion ..................................................... SUMMARY OF RESULTS AND CONCLUSIONS ........................................ BIBLIOGRAPHY ................................................................................... APPENDIX A. COMPLETE RUN DATA.................................................. APPENDIX B. CALIBRATION OF ETHYLENE OXIDE FLOWRATOR• • Bl. Tempe rature-Density Plot ............................. B2. Calibration Data ................................... B3* Calibration Curves ....................................... TABLE OF CONTENTS (Continued) Page APPENDIX C. CALIBRATION CURVES FOR WATER FLOWRATOR .. 105 APPENDIX D« SAMPLE CALCULATIONS .......................... 108 Dl# Calculation of Flowmeter Settings «....109 D2« Calculation of Yields and Conversions from D istillatio n Analysis Data ........... 110 D3« Total Conversion Calculation from Oxidation Analysis Data • ............. 112 Dlj-* Sample Calculation for Preparation of Catalyst Number 3 ........................................ lli{- APPENDIX E, REFRACTIVE INDEX - COMPOSITION PLOTS ... I l6 APPENDIX F. PHYSICAL CONSTANTS FOR THE ETHYLENE GLYCOLS .................................................................... 120 VITA...................................................................................................... 122 LISTS OF TABLES AND FIGURES L ist of Tables Table Page 1. Tabulation of Data for Check Runs on Catalytic A ctivity ..................................... 70 2. Tabulation of Data for Check Runs on Catalytic A ctivity - Total Conversion. ... 74 3. Data for Conversion Studies at l53- l 60°C •••• 79 4* Data for Conversion Studies at 129-132°C .. .. 82 5. Data for Conversion Studies at 188-190°C .... 84 6# Data for Yield Studies at 188-190° C ................... 86 7. Conversion Studies with Temperature and Pressure as Variables ................................. 86 8. Table of Complete Run Data .......................... 97 9- Ethylene Oxide Flowrator Calibration Data Steel Float ....................................................... 100 10. Ethylene Oxide Flowrator Calibration Data Glass Float .................... 101 11. Physical Constants for the Ethylene Glycols . 120 List of Figures Figure Page 1. Pilot Plant Flow Sheet ......................... l 6 2. Panel View Photograph of Equipment ............. 17 3. Rear View Photograph of Equipment •••................. 18 4* E lectrical C ircuits Diagram .............. 21 5. Preheater .............................. 26 6. Reactor ........................... 29 List of Figures (Continued) Figure Page 7# Photograph of New and Used Catalyst P a rtic le s................. 66 8» Section View of a Particle from Catalyst No.7 6? 9* Section View of a Particle from Catalyst No.3 68 10. Effect of On-Stream Time on Conversion and Yield at Constant Conditions ...................... 71 11. Effect of On-Stream Time on Total Conversion at Constant Conditions ..................... 75 12. Conversion Studies at l 53- l60°C ....................... 80 13. Conversion Studies at 129-132°C ........... 83 li|.. Conversion Studies at l 88-190°C ............... 85 15. Effect of Temperature on Total Conversion at Constant Conditions ............... 89 16. Temperature - Density Plot for Ethylene Oxide 99 17. Calibration Curve for the Ethylene Oxide Flowrator with Steel Float «................................ 103 18. Calibration Curve for the Ethylene Oxide Flowrator with Glass Float ............... lOij. 19. Calibration Curve for the Water Flowrator with Light Float ...................................... 106 20. Calibration Curve for the Water Flowrator with Heavy Float ........................ 107 21. Refractive Index - Composition Plot for the Water - Glycol System ............. 117 22. Refractive Index - Composition Plot for the Glycol - Diethylene Glycol System . . . . . . . . . 118 23. Refractive Index - Composition Plot for the Di- Triethylene Glycol System ............. 119