Safe, Reliable, Permanent PDF

Preview Safe, Reliable, Permanent

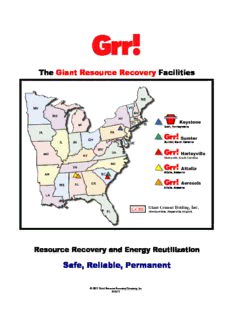

The Giant Resource Recovery Facilities Keystone Bath, Pennsylvania Sumter Sumter, South Carolina Harleyville Harleyville, South Carolina Attalla Attalla, Alabama Aerosols Attalla, Alabama Giant Cement Holding, Inc . GCHI Headquarters: Alexandria, Virginia Resource Recovery and Energy Reutilization Safe, Reliable, Permanent © 2017 Giant Resource Recovery Company, Inc 9/18/17 Table of Contents Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Facilities and Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Kiln Process Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 GRR – Sumter Sumter, SC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Containerized and Bulk Contact Information . . . . . . . . . . . . . . . . . . . 4 Liquids, Solids, and Sludges Permit Status. . . . . . . . . . . . . . . . . . . . . . . . 4 Permitted Waste Codes. . . . . . . . . . . . . . . . 6 Waste Approval Procedures . . . . . . . . . . . . 7 Manifest Information . . . . . . . . . . . . . . . . . . 7 GRR – Attalla Attalla, AL Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Services – Fuel Blending. . . . . . . . . . . . . . . 9 Containerized and Bulk Contact Information . . . . . . . . . . . . . . . . . . . 8 Liquids, Solids, and Sludges Permit Status . . . . . . . . . . . . . . . . . . . . . . . . 8 Permitted Waste Codes . . . . . . . . . . . . . . .10 Waste Approval Procedures . . . . . . . . . . . 11 Manifest Information . . . . . . . . . . . . . . . . . 11 GRR Aerosols Attalla, AL Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Aerosols in Metal Containers Contact Information. . . . . . . . . . . . . . . . . . 12 Permit Status. . . . . . . . . . . . . . . . . . . . . . . 12 Aerosols Process Diagram . . . . . . . . . . . . 13 Permitted Waste Codes, Guidelines . . . . . 14 Waste Approval Procedures . . . . . . . . . . . 15 Manifest Information . . . . . . . . . . . . . . . . . 15 Continued © 2017 Giant Resource Recovery Company, Inc 9/18/17 Continued - Table of Contents GRR – Harleyville Harleyville, SC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 B ulk Liquids and Solids Contact Information . . . . . . . . . . . . . . . . . . 16 Permit Status . . . . . . . . . . . . . . . . . . . . . . . 16 Process Diagram . . . . . . . . . . . . . . . . . . . . 17 Waste Acceptance Guidelines . . . . . . . . . . 18 Metals Guidelines . . . . . . . . . . . . . . . . . . . 19 Permitted Waste Codes . . . . . . . . . . . . . . 20 Waste Approval Procedures . . . . . . . . . . . 21 Manifest Information . . . . . . . . . . . . . . . . . 21 Kiln Process Diagram . . . . . . . . . . . . . . . . .3 Keystone Cement Bath, PA Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Services. . . . . . . . . . . . . . . . . . . . . . . . . . . 22 B ulk Liquids Contact Information . . . . . . . . . . . . . . . . . . 22 Permit Status . . . . . . . . . . . . . . . . . . . . . . . 22 Waste Acceptance Guidelines . . . . . . . . . 23 Permitted Waste Codes . . . . . . . . . . . . . . 24 Waste Approval Procedures . . . . . . . . . . . 25 Manifest Information . . . . . . . . . . . . . . . . . 25 Kiln Process Diagram . . . . . . . . . . . . . . . . .3 Information to Complete Manifests . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Contacts for Further Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Giant Cement Holding, Inc. Giant Resource Recovery, Inc. A History of Resource Recovery and Energy Reutilization Giant Cement Holding, Inc., (GCHI) manufactures high quality Portland cement through its subsidiaries Giant Cement Company in Harleyville, SC, and Keystone Cement Company in Bath, PA. For almost forty years, the facilities have carefully blended and beneficially reused hazardous and non-hazardous wastes as supplemental fuel in their cement production processes. Giant Resource Recovery, Inc. (GRR), a subsidiary of GCHI, is the environmental and waste management division responsible for the resource recovery and waste fuels programs. GRR-Harleyville is co-located with Giant Cement while the resource recovery operation in Bath shares the Keystone name. In 1998, GRR furthered its dedication to resource recovery through the addition of M&M Chemical and Equipment, a waste processing and container management facility located in Attalla, AL. A year later, GRR acquired the Sumter, SC, waste management and solvent recovery operation previously known as Omni-Southeastern Chemical and Solvents. As members of the Giant family, these facilities are now named GRR-Attalla and GRR-Sumter. GRR grew yet again in early 2002 with the opening of GRR Aerosols, Inc., in Arvonia, VA. GRR Aerosols offers the unique capability of disposing of wastes in aerosol containers by recycling 100% of the components in an innovative closed-loop system. GRR Aerosols expanded and relocated to Attalla, AL, in late 2007. With increased capacity and a broadened list of acceptable hazardous waste codes, GRR Aerosols handles a greater volume and more types of aerosol wastes than any company in North America. Since its inception, GRR has developed significant proprietary technology to efficiently use solid industrial wastes as a reliable fuel source. The Harleyville facility completed an extensive $130 million expansion in 2005 which maximizes the use of solid fuel. The following year, Keystone unveiled a $230 million modernization project. Complemented by GRR’s industry-leading ability to process waste into fuel, Giant Cement and Keystone Cement are two of the most advanced cement plants in the United States. As its history shows, GRR actively seeks out new technologies and methods of resource recovery and energy reutilization. By combining more than 130 years of experience with a demonstrated commitment to environmental stewardship, the GRR family of companies provides generators with an unparalled range of safe, reliable, and permanent waste management services. 1 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Giant Resource Recovery Facilities GRR–Sumter Processes containerized and bulk Sumter, SC liquids, solids, and sludges GRR–Attalla Processes containerized and bulk Attalla, AL liquids, solids, and sludges GRR Aerosols Recycles and destroys aerosol cans; Attalla, AL processes steel drums for reconditioning GRR–Harleyville Co-located with Giant Cement; Harleyville, SC blends and burns bulk solid and liquid waste-derived fuel Keystone Cement Co-located with Keystone Cement Bath, PA manufacturing facility; blends and burns bulk liquid waste-derived fuel 2 © 2017 Giant Resource Recovery Company, Inc 9/18/17 3 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Giant Resource Recovery – Sumter Giant Resource Recovery – Sumter, Inc. Phone: (803) 773-1400 P.O. Box 1755 (877) 473-6664 755 Industrial Road Fax: (803) 775-4145 Sumter, SC 29151 (803) 775-7016 Facility Contacts: Carol Morse – Customer Service Manager Phone – (803) 773-1400, Ext. 205 David Ormond – Approvals Manager Phone – (803) 773-1400, Ext. 222 Odoberto (Junior) Ramos – Sales Broker Manager Phone – (803) 773-1400, Ext. 239 Permit Status: EPA ID No. SCD036275626 RCRA Part B Permit for storage – Originally issued 1/28/1987; expires 7/1/2021 Solid Waste Processing Permit No. 432675-2001 – Issued 7/7/1999; no expiration Air Quality Operating Permit No. 2140-0038 – Issued 9/23/2005; expires 5/31/2022 NPDES Stormwater Permit No. SCR000000 – Issued 7/22/2004; expires 9/30/2021 Permitted Capacity: Container Storage – 1,578 drums hazardous 2,510 drums non-hazardous Bulk Storage and Treatment Tanks – 496,810 gallons hazardous 256,500 gallons non-hazardous GRR-Sumter is the largest fuel blending facility on the East Coast. It is located one mile south of Sumter, SC, and only 56 miles from its sister facility, Giant Cement in Harleyville, SC, where blended waste fuel is burned in the manufacture of cement. GRR-Sumter processes various liquids, solids, and sludges in bulk, drums, and other containers. In addition to fuel blending, GRR offers many other services as described on page 5. 4 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Services GRR – Sumter Industrial Waste Services and Capabilities Fuel Blending – Hazardous and non-hazardous wastes; liquids, sludges, and certain solids in bulk, drums, cubic-yard boxes, roll-off containers, tote tanks, and supersacks Non-Hazardous Solid Waste – Processing for landfill and waste-to-energy Non-Hazardous Water – Processing by treatment and discharge to a POTW or stabilization and landfill Hazardous Water – Collection and bulking Industrial Oil – Collection and processing for fuels blending or resale Laboratory Services – Certified for TCLP analysis Special Wastes – Processing of toxic and corrosive wastes and other wastes requiring special handling that others may refuse because of potential difficulties Waste Bulking – Collection and processing of solid wastes to be sent to GRR-Harleyville and incinerators for thermal destruction 5 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Permitted Waste Codes GRR – Sumter Characteristic Codes: D001 D002 – Acceptable when associated with D001, F001, F002, F003, F004, and/or F005 D004 through D043 Primary Listed Codes: F001 K025 U002 U117 U210 F002 K030 U031 U140 U220 F003 U043 U154 U226 F004 U052 U159 U227 F005 U057 U161 U228 F037 U077 U165 U239 F038 U078 U169 U359 U080 U171 U112 U196 Secondary Listed Codes – Acceptable when associated with a primary listed code (not a characteristic code) and present in a lesser concentration than the primary listed code: K083 U019 U121 K085 U037 U122 K169 U044 U127 K170 U070 U128 U072 U131 U075 U211 U105 6 © 2017 Giant Resource Recovery Company, Inc 9/18/17 Waste Approval Procedures GRR – Sumter To obtain approval for a new waste stream, please submit the following prior to shipment: 1. GRR-Sumter Facility Profile Form 2. Credit Application – New customers only 3. Any available analytical data, SDSs, and Product Record Sheets to substantiate and clarify accuracy and facilitate quick approval. Samples are not required unless the waste is unusual or could present processing problems. Contact Customer Service or Sales prior to submitting a sample. Completed profiles and other information should be mailed or faxed to: Customer Service GRR-Sumter P.O. Box 1755 Sumter, SC 29151 Phone: (803) 773-1400 Fax: (803) 775-4145, (803) 775-7016 Typical approval time is 3-4 days but overnight approvals are available. For questions concerning approvals, please call David Ormond at (803) 773-1400, Ext. 222. Prior to shipment, drum top labels are provided to the generator so that he can indicate the stream number for each drum and the nature of the contents (such as liquid, sludge, processible solids, or non-processible solids). Below is the official information needed to complete manifests for materials approved into GRR-Sumter: Giant Resource Recovery-Sumter, Inc. 755 Industrial Road Phone: (803) 773-1400 P.O. Box 1755 Fax: (803) 775-4145 Sumter, SC 29151 US EPA ID No. SCD036275626 Contact: Carol Morse – (803) 773-1400, Ext. 205 [email protected] 7 © 2017 Giant Resource Recovery Company, Inc 9/18/17

Description: