production • processing • distribution • use PDF

Preview production • processing • distribution • use

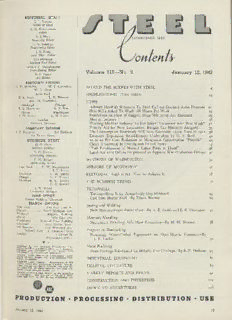

EDITORIAL STAFF E. L. Shaner Editor-in-chief E. C. Kreutzbero Editor A. J. Hain Managing Editor G. W. Birdsall Engineering Editor J. D. Knox Steel Plant Editor Guy Hubbard Machine Tool Editor Arthur F. Macconochie Contributing Editor Volume 110—No. 2 January 12, 1942 D. S. Cadot Art Editor ASSOCIATE EDITORS G. H. Manlove W. J. Campbell BEHIND THE SCENES WITH STEEL 4 W. G. Gude New Yor\ HIGHLIGHTING THIS ISSUE 19 B. K. Price L. E. Browne. John H. Caldwell NEWS Pittsburgh Chicago Industry Marshals Resources To Meet Call for Doubled Arms Program 21 R. L. Hartford E. F. Ross Plate Mills Asked To Work 368 Hours Per Week ....................................... 24 Detroit Washington A. H. Allf.n L. M. Lamm Restrictions on Flow of Copper, Brass Mill Scrap Are Extended 25 London Men of Industry ............................................ 28 Vincent Delport Washing Machine Industry To Get Relief “Consistent with War Work” 31 ASSISTANT EDITORS Priority Aid for New Locomotive, Freight Car Materials Assigned.... 35 J. C. Sullivan Jay DeEulis Tin Consumption Restricted; Will Save Estimated 15,000 Tons in 1942 36 La Verne Nock Extensive Expansion, Rehabilitation Undertaken by U. S. Steel 42 BUSINESS STAFF 10 to 20 Per Cent Reduction in Manganese Consumption “Possible”. 43 G. O. Hays Closer Teamwork by Canada and United States............................................. 45 Business Manager “Full Employment of Normal Labor Force at Hand”.............................. 46 R. C. Jaenke Local Antitrust Offices Empowered to Approve War Production Groups 47 Advcrtising Manager C. H. Bailey WINDOWS OF WASHINGTON 32 Advertising Service New Yort{ E. W. Kreutzbero MIRRORS OF MOTORDOM .................. 39 B. C. Snell Pittsburgh...........................S. I-I. Jasper EDITORIAL—Goal Is Set; Now to Achieve It 48 Chicago..............................L. C. Pelott Cleveland...........................R. C. Jaenke THE BUSINESS TREND 49 D. C. Kiefer J. W. Zuber TECHNICAL Circulation Manager Tooling—Strip It for Action!—By Guy Hubbard 54 MAIN OFFICE Cast Steel Mortar Shell—By Edwin Bremer .............................. 62 Pcnton Building, Cleveland BRANCH OFFICES Joining and Welding New Yo;7(.....................no East 42nd St. Chicago 520 North Michigan Avc. New Mercury-Vapor Power Plant—By A. R. Smith and E. S. Thompson 52 Pittsburgh.......................Koppers Building Detroit ..................6560 Cass Ave. Materials Handling Washington National Press Building Mechanical Handling Aids Plant Expansion—By H. H. Slawson 58 Cincinnati .................1734 Carcvv Tower San Francisco 1100 Norwood Ave. Progress in Steeltna\ing Oakland, Calif., Tel. Glencourt 7559 London......................................... Caxton St. Protecting Water-Cooled Equipment on Open-Hearth Furnaces—By Westminster, S.W. 1 ). B. Luckic.......................................................... 7° . © . Metal Finishing iwSif1“?.1 Mb,i T,lK PENTON PUBLISHING CO.. 5Pp2IL8gSi »lJiu UdliiK, TCrleeavseulraenrd; , OGh. io.o . E.H La. ySsh, anVkicke, Paint Coatings Substituted for Metallic Zinc Coatings—By E. F. Hickson 74 resident; 1*. o. Stkinebach, Secretary. Audit Bureau of Circulations; Asso- Bliushh£erLs' AAUssslonc^iwat i,ol na.Pere tuc., and National Pub INDUSTRIAL EQUIPMENT 80 E jS S fver>' Monday. Subscription In the ri.ho an(l Possessions, Canada. Mexico, HELPFUL LITERATURE............................ 85 two v n ^ S nii.d sPuth America, one year *0: i al1 othcr countries, one year SI2. ©ingle copies (current issues) 25c. second class matter at the postofllce MARKET REPORTS AND PRICES ................................ 91 cCoopDyvrriiBghhit 1i69j4l2i nbKCyr itihhee P<)ocnl toonf -NPulabrlcihs h3in* g 18C7o9.- CONSTRUCTION AND ENTERPRISE x:o INDEX TO ADVERTISERS 116 PRODUCTION • PROCESSING • DISTRIBUTION • USE January 12, 1942 17 Y OUR finished product is your customer’s raw material —the first step in mass-production that measures accuracy in thousandths. Morgan Four-Strand Rod Mills are producing rod at four- fifths of a mile per minute per strand, within ± .005 inch speci fied diameter. Uniformity such as this is a Morgan characteristic. It will hold your customers—as it has ours—both now and also after the Emergency. 18 /T E E L H I G H L I G H T I N G THIS I S S U E OF 9 INDUSTRY already is in the throes of mak on mining machinery and on repair parts ing good on its promise to manufacture arma for heat treating furnaces. . . . Rigid restric ment (p. 21) on the huge scale requested by tions will conserve our tin supply (p. 36). . . . President Roosevelt last week. It is apparent Prices on brass and bronze ingots have been re that great hardship and dislocation will be en vised (p. 37) ; aluminum priority orders have countered during the changeover period. First been extended. . . . Tin and lead scrap are un major group to be affected (p. 39) is the auto der priorities (p. 32) ; vending machine produc mobile industry which, incidentally, does not see tion will be cut ; OPA will discuss .prices with a place for CIO leaders in its management. The the drop forging industry. . . . Vacuum cleaner potentialities of many other industries as manu output (p. 31) is ordered cut. . . . Segregation facturers of armament now are under active of aluminum scrap (p. 25) is mandatory. study and their mobilization into the war effort is expected to materialize rapidly. . . . To en able its readers to function effectively under rul Guy Hubbard, S teel’si machine tool editor, ings of the OPM and the OPA, Steel this week says “Let’s strip tooling for action” and then is published in two sections; Section Two, folded he proceeds to tell (p. 54) how to do it, informa into the main section, is entitled “Priorities, tion especially timely with Allocations, Prices.” _ . the present need to speed pro- Let s Speed duction by every possible Tooling means. . . . Edwin Bremer A new system for increasing production of describes (p. 62) how two plates is in operation and is expected to prove sizes of steel mortar shell are being cast at successful (p. 24); consumers are asked to co the foundry of Auto Specialties Mfg. Co., St. operate by using strip instead Joseph, Mich. . . . Cooling of certain parts of 168-Hour P*ates wherever possible. . open-hearth furnaces by circulating water . . Steel production declined 1 Week through them, combined with proper use of in point last week (p. 27) be sulation, can increase life up to 250 heats, ac cause of the scrap shortage cording to J. B. Luckie who details (p. 70) many and further drops are feared. . . . A 10 to 20 designs of this type of equipment. per cent reduction in manganese consumption (p. 43) is held possible. . . . Interchange of goods between! the United States and Canada (p. 45) is to be expedited. . . . Local antitrust To show how to conserve zinc for urgent war officers have been empowered (p. 47) to ap requirements, a section of OPM recently asked prove the formation of groups of manufacturers National Bureau of Standards to prepare a dis to engage in war production through pooling cussion of suitable alternative their facilities. finishes that could be used in Galvanizing stead of metallic zinc coat- Substitutes ings. E. F. Hickson presents Producers of power-driven lift trucks have the results of this study (p. greater priority assistance (p. 34) ; adequate 74). . . . A. R. Smith and E. S. Thompson ex supplies of plumbing, heating and electrical plain one of the latest types of mercury-boiler supplies will be available; power-generation constructions and give details makers of hoists, cranes and (p. 52) of welding procedure that was employed derricks, also ceramics equip to make 5000 pipe welds in the boilers without a ment builders, are under price single leak. . . . H. H. Slawson tells how (p. 58) ceilings. . . . Priorities have mechanical handling equipment helped to in been set for material for new cars and locomo crease plant output from 700 to 1800 units per tives (p. 35) ; similar action has been taken day. January 12, 1942 Mr. Charles Brinley, President of the. Baldwin Locomotive IVorfci speaking at ceremonies when Baldwin’s first M-3 tank teas turned oi'er to the Army. ahle to heat the official schedule. This illus © Baldwin needed steel immediately for a tration is typical of the service Ryerson is model tank to be constructed quickly as a rendering daily to manufacturers working on guide to future production. Speed was the the National Defense Program. important factor, so Baldwin turned to Ryer- Thousands of emergency calls have cut son stocks for immediate shipment of the down our large stocks of steel, however, we necessary steel. Ryerson alloy and carbon are still serving thousands of customers in steels were shipped from stock the same day accordance with the OPM plan and believe permitting work to begin at once. we will be able to continue this service even Through this quick cooperation and the if on a restricted basis, for the duration of help of many other suppliers, Baldwin was our national emergency. Joseph T. Ryerson & Son, Inc., Chicago, Milwaukee, St. Louis, Detroit, Cincinnati. Cleveland, Buffalo, Boston. Philadelphia, Jersey City. R Y E R S O Industry M arshals Resources To Meet Call for Doubled Arms Program ♦ Conversion of present production facilities studied as President asks for a plane every four minutes and a tank every seven minutes . . . Automobile producers to be first to make all-out changeover ♦ WASHINGTON materials to the limit of their ca week, “farm out” jobs or parts of B MOBILIZING industrial re pacities. jobs that they cannot do promptly, sources at a rate previously consid The industry principally will be and increase their output in other ered fantastic—to meet the great used to manufacture machine guns ways. est war production goal in world and other light pieces of ordnance, 3. Shifting more of the capacity history—got under way with a gun carriages and tanks, and will of consumer goods industries, like flourish last week. play a larger role in aircraft con textiles and food products, from civ: When the President called for the struction. ilian to military use. By and large, production of 185,000 airplanes, 120,- Facilities may be pooled. Auto this does not involve conversion of 000 tanks, 18,000,000 tons of mer makers may supply parts for ma facilities. chant ships and 55,000 antiaircraft chine tool builders. No machines 4. Expansion of all types of train guns within the next two years, in will be idle if they can be used pro ing for workers in war industri.es. dustry responded: “It shall be done.” ductively. Meetings with many industry This response was no mere out The auto industry has been asked committees have been held or are burst of patriotic fervor. It was the to assume a five billion dollar slice being planned, and committees will considered promise of men cognizant of the increased arms program. be organized for some additional in of the tremendous difficulties in That, however, will be a relatively dustries to work with the OPM, the volved—of the necessity for speed small part of the total program, esti armed services, and other govern ing up the rationing system, still mated by the President in his budget ment agencies on conversion and further cuts in consumers durable message to cost more than 52 bil other problems. goods production, shortages in al lions in fiscal year 1943 and about 24 Members of the rubber industry, most every line of business, shifts billions in the current fiscal year- whose total production was order.ed and dislocations in both labor and for war production alone. curtailed about 53 per cent after the industrial concentration, increasing flow of rubber from the East In government controls over business, 168 Hours Per Week dies was interrupted by the outbreak and stupendous monetary cost. of war, are conferring individually To execute such a program—en Conversion of virtually all manu with OPM engineers and other of tailing production of an airplane facturing capacity to war produc ficials to offset curtailed civilian pro every four minutes and a tank every tion will be required. And this, as it duction by increased war work. seven minutes—will require the proceeds, will bring problems as yet Approximately 3714 per cent of the marshaling of all the resources and largely unexplored. industry’s present output is for war, all the materials that can be utilized. Guinea pig in the conversion ef and its nonmilitary output is com Details are yet to be worked out, fort is the automobile industry, ideal posed chiefly of truck tires necessary but at week’s end OPM was attack for the purpose and an industry that to maintain vital transportation. ing the problem along these lines: already has made great progress in Military production by the indus that direction. 1. Converting additional facilities try has been scheduled to rise be Representatives of the major au of the durable goods industries from ginning in January, until in June it tomakers and parts suppliers have peace-time production to weapons reaches about 50 per cent of the to been given the shopping list of the of war. tal. Many of the small companies Army and Navy and asked to begin 2. Getting more of the existing in the industry are currently convert immediate plans for producing the arms plants to work 168 hours a ing to the manufacture of gas January 12, 1942 21. NEW DAY, NEW PURPOSE: Sunrise silhouettes blast furnaces, foundry and power house at Ford's River Rouge plant—■ "mightiest industrial unit." Last week as the government announced its war-time plans for the automobile industry this plant was reported working "24 hours a day for the Army and Navy." NEA photo masks, and the Civilian Defense Ad turers, immediate increases in war spe.ed up production by doing so, and ministration is seeking funds with production are being sought in ex to report facilities of theif own that which to order 50,000,000 masks for isting arms plants. are partially idle and could be civilians in areas near the coasts. In the machine tool industry, for brought into production by the ad Possibilities of placing additional example, some manufacturers are dition of a minimum of equipment. war orders with manufacturers of now working 160 hours a week while Similar steps to speed up produc farm equipment are being explored, others are considerably short of tion are being taken in the greatly but this field is limited by the de that goal. The latter are being expanded aircraft and shipbuilding mand for farm equipment to main urged to man their machines to the industries, and in factories already tain food supplies. maximum, leaving them idle only making tanks, guns, and ammuni The pulp and paper industry is long enough for necessary mainte tion. nearing completion of a survey of nance and repairs. Machine tool In the field of consumer goods, the facilities of that industry suit manufacturers are also being asked further shifts from production for able for war work. This survey, to enlist facilities of other industries, civilian use to military use are in which is being made by the indus under subcontracts, when they can prospect. Items involved, for ex try itself, is to be turned over to ample, are cotton duck for uniforms, the OPM as soon as it is completed. drill for lining, and osnaburg (a Another field in which additional loos.ely-woven cloth) for sandbags. conversions are under study is in It also is planned to convert some dustrial and office machinery. “Who Wants Them ?” additional plants in industries turn Still another involves electrical aD- ing out small metal items. Such plianccs and consumer durable WASHINGTON capacity can be used in manufac goods. H Addressing the automakers, Mr. turing equipage—that is, a soldier’s OPM officials have had explora Knudsen said: “We want to know individual equipment, such as mess tory discussions with manufactur where some of these things will flow kits, helmets, and bayonets. ers of cooking appliances and domes from. We want to know if you can In addition, many plants are ex tic refrigerators, regarding the ad make them or want to try to make pected to devote the ma.ior part, if visability of concentrating civilian them.” not all of their capacity, to the production in some plants and free As he announced the list of items manufacture of field equipment. For ing the remainder for conversion to wanted the OPM chieftain acted example, a plant that formerly made war work. somewhat in the role of an auc kitchen ranges for the home will Manufacturers of radio tubes are tioneer. “We want more machine now make tent stoves and field bak trying to find substitute materials guns. Who wants to make machine eries. with which to maintain civilian pro guns?” Some shifting of output in the duction until expected increases in And so on through the list, with food canning industry is contem military requirements are definitely the automobile men occasionally in plated, mainly because of the short known. dicating they would produce the ma age of tin for cans. For instance, Through group meetings and con terial named. canners of luxury items will be ferences with individual manufac asked to switch over the major part 22 /■TEEL iW IC I FOB of their plants to Army rations and of major assemblies for M and 1 looking forward to turning out foods needed by America’s allies. M-4 tanks, gun mounts, shells, trainload of 28-ton tanks a day. Em The container industry is another cartridge cases, etc. ployment at the arsenal will be where the war’s impact will be felt Tooling for the various programs greatly increased. Engineers, tool increasingly. For instance more is now under way at Flint plants, experts and mechanics now are en plants formerly used in the manu while additional defense work is be gaged in pushing the expansion pro facture of folding boxes for civilian ing negotiated. gram. use will be devoted to the manufac Ground has been broken for the ture of boxes for small ammunition. General Motors tank plant on the Cold Wave Closes Plants west side of U. S. 10 near Grand ta Blanc, Mich., and will involve ex Natural gas shortage affected in Kanzler Becomes Chief of penditure of several million dollars dustrial operations in the Pitts OPM Automotive Branch in plant, equipment and tooling. burgh district as a result of the The Automotive, Transportation The Melrose Park, 111., aviation cold wave. Shenango works, Car- and Farm Equipment Branch of engine plant built by Buick has been negie-Ulinois Steel Corp., New OPM has been divided and Ernest completed ahead of schedule and op Castle, Pa. was shut down when the Kanzler, president, Universal Cred erations have been under way for public utility company supplying the it Corp., has been appointed chief several weeks. The facilities were plant was unable to maintain sup of the Automotive Branch. An completed in a period of eight plies. About 2000 men were out of drew Stevenson continues a chief months from the time ground was work while the plant, which pro of the Transportation and Farm broken. Equipment includes better duces hot rolled tin plate, was down. Equipment Branch. than 3000 new machines and about Another hot tin mill was also forced 20,000 tools, jigs, fixtures and gages. to suspend, the Canonsburg works The change was made because of of Carnegie-Ulinois at Canonsburg, the broadened programs for both Two major plants at the Flint divi Pa. sion have been converted for man branches. ufacture of major parts and subas Coke Plants Awarded semblies going into the Pratt & Buick’s Aircraft Engine Whitney 1200-horsepower engine S A contract for building a 75- which is being assembled at the Program Is Doubled oven by-products coke at the War Illinois plant. ren, O., plant of -Republic Steel ■ Army Air Corps has authorized Meanwhile, it is reported studies Corp. has been awarded to Semet doubling of the Buick aviation en are being pushed aggressively rela Solvay Co. The same builder was gine production program, under tive to the conversion of the Buick awarded the new coke plant at terms of which employment on air gray iron foundry to the production Gadsden, Ala., for Republic. Kop- craft motors alone in the new Chi of aluminum alloy castings. pers Co., Pittsburgh, has been cago plant and in the Buick plants awarded the company’s new plant Tripling at Tank Arsenal at Flint, Mich., will range between at Cleveland. The Warren plant 25,000 and 30,000. This is exclusive Production at the Chrysler Tank will supply coke to the new blast of other war material programs al Arsenal this year will be tripled furnace being built at Youngstown, ready undertaken for the production from the present rate. Officials are O., by Defense Plant Corp. A W eek for H istory’s Pages “Conversion’5 Consumed by Automobile Per cent of Total Material: Industry, Tons. 1940 U.S. Supply STEEI........................................7,185,01(5 15.7 RUBBER 47:1,(500 80.0 LEAD ..............................228,000................. 34.2 Breath - Taking ’ ’ COPPER 113,000 13.7 ALUMINUM 21,000 •• 0.7 TIN .....................................10,000................................11-4 ZINC 70,000 . •.......................12.1 War Production goal, outlined by the President to Congress: NICKEL ..........................20,000................................23.0 60,000 planes, including 45.000 combat planes this year; 125,000 Employes, 1041 ........................ 450,000 ^r'nnn103' ’nc*u<bn9 100,000 bombers and fighters, in 1943. Output, cars ami trucks, U. S., 1940 . 4,460,354 Output, cars and trucks, I). S., 1041 . 4,818,000 ?nnnn tCmks lhis Year; 75'000 in 1943- Cumulative defense orders to automobile indus R nnn nnnntiaircrait 9Uns this Year- 35'000 in 1943- try, January, 1042 - - --....................................85,000,600,000 nnn dea<fweight tons oi merchant shipping this year, 10,000,- 000 tons in 1943. (For Detroit’s interpretation of Conversion-to-War order see Mirrors of Motordcm, Page 39.) Commensurate production of all other munitions of war. (For editorial comment, see page 4S.) January 12, 1942 23 Continuous Operations for Plate Mills; 1944. Most 1941 business was in the iron and steel division. Foreign business is confined to Consumers Urged To Use Strip the Western hemisphere. Construc tion of a complete steel plant in Brazil will start early this year and probably require about two years. WASHINGTON location Order No. 1—Plates” Recent contracts in Canada will run a A COMPREHENSIVE program have been revised in an effort to for at least a year. to increase the production of steel clarify procedure and effect bet plates, vital for shipbuilding, was ter control. Copies of the revised Armco Will Fight instructions are enclosed. I announced last week by C. E. Adams, chief, Iron and Steel should like to call your particular Proposed NLRB Order attention to two of the changes Branch, Office of Production Man we have made: ■ National Labor Relations Board agement. These steps have been 1. We are requesting all com last week announced a proposed taken: panies to operate their plate- order, which, if made final, would 1. All steel companies are re producing facilities as close to require the American Rolling Mill quested to operate platemaking fa 168 hours per week as possible. Co. to disestablish the Armco Em cilities 168 hours a week. Please note Paragraph 2. ployes Protective Association and to 2. Daily reports on plate ship 2. We are providing for a daily cease discouraging membership in ments to the Army, Navy and report of plate shipments for SWOC of its employes at its Ash Maritime Commission will be made the Army, Navy and Maritime to the branch. Commission. The demands for land, Ky., plant. Proposed order 3. Weekly reports on total pro plates for these needs are so also directs the company to restore urgent that it is imperative 22 employes, allegedly discriminated duction will be made. that we be informed regarding against for union activity, to their 4. A plan for greater use of con this situation on a day-to-day former positions and to give back tinuous strip mills for the produc basis. Please note Paragraph pay to all except one. tion of plates has been adopted. 8 (A). C. H. Murray, assistant to the Consumers are asked to co-operate, II. A plan for the greater use of president of Armco, said the com to use strip in place of plates where continuous strip mills for plate pany would oppose the entering' of practical. production has been adopted. the proposed order. If the board en 5. Each producer has been asked (Copies enclosed.) This, we be to name a liaison man to keep lieve, is a very important part ters the order, company will fight in contact with the branch on of the overall program. Kindly the case through the courts. advise whether your company “The case was completed two and plates. will take immediate action to one-half years ago,” Mr. Murray 6. Steps are being taken to im place this plan in effect in con said. “In the meantime, the public prove and simplify plate orders so nection with your operations. lost confidence in the fairness of that greater production may be III. Individual conferences with the former board to such an extent achieved. producers on the subject of plate that a house-cleaning was effected 7. Conferences are being sched production are being scheduled. as a result of a congressional in uled with individual producers to These will be completed by the vestigation. None of those who were iron out local problems that inter end of January. members of the labor board when fere with greater production. IV. Steps are being taken to im the case was tried are members of prove the character of the plate December Was Record Month orders issued in connection with the present board. The trial exam The program is expected to re the shipbuilding program so that iner who heard the case has been re this tonnage may be rolled on a lieved from participating .in its de sult in an appreciable increase in larger number of mills and plate cision. The board’s attorneys in the plate production. January output production on all mills can be in case are no longer associated with is expected to be 12 per cent high creased. Progress has already the board. It is therefore difficult er than December, 1941, which was been made along these lines. to understand how the new members an all-time record month for the V. We have asked each producer to of the board could have a clear un industry. By March a further in name a man in his company as derstanding of the case, the testi crease of 10 per cent is expected. the contact with the Iron and mony of which covered more than These increases are on present fa Steel Branch in respect to plates. 40,000 typewritten pages.” cilities and do not take into ac Please be sure that the roan se count any new facilities now being lected by your company is well qualified by experience and has Harvester Lays Off 1475, constructed. been given adequate authority Plates are under complete alloca to assure proper and prompt ac Awaiting Arms Work tions system, the first material to tion on these matters. be so handled. December produc CHICAGO tion was slightly under 600,000- H International Harvester Co. last McKee Has Contracts for tons. ! week laid off about 1475 employes at The plans were reviewed with the $100,000,000 Construction its three plants in this area, the re Iron and Steel Defense Advisory duction being made to adjust out Committee at a meeting Dec. 31, S Arthur G. McKee & Co., Cleve put to the 83 per cent production and all details and forms have been land, has paid a dividend of 75 cents quota for 1942, as established by sent to platemakers. In an accom per share as the initial disburse OPM. panying letter Mr. Adams stated: ment for 1942. In 1941 five divi About 1000 workers were dropped “No problem has been brought dends were paid, aggregating $4.50 at the McCormick works, 175 at the more forcibly or more often to my per share the largest in the history Tractor works, and 300 at the West attention than that of the need for of the company. Unprecedented ac Pullman works. None of these em a greater tonnage of steel plates. tivity marked the year, especially ployes has had more than 18 months “Dependent on the supply of this during fourth quarter. Cost of of service with the company. product are such important phases plants under design and construc It is stated that the workers will of our war effort as our two-ocean navy and our great shipbuilding tion totals more than $100,000,000 be re-employed just as rapidly as program. . . . and all contracts now on books can the company is able to acquire ad I. Instructions under “General Al not be completed before the end of ditional arms work. Restrictions on Flow of Copper, importance of scrap in the produc tion of brass. Not only is better brass made from copper scrap than from pure copper, but it may be Brass Mill Scrap Are Extended used over and over without any de terioration in quality. The order does not apply to retail ■ TO KEEP a constant flow of cop filled first and authorizations for sales of copper or brass junk by an per scrap and copper alloy scrap the residual supply will be made at individual to a collector, who will into and through war industries, the discretion of the director of pri sell it in turn to a scrap dealer. OPM has revised Order M-9-b to orities. provide that no deliveries of copper Fabricators, with the exception of Privately-Imported Copper or brass scrap may be made except railroads and utilities, may not use Under Full Priority Control to a scrap dealer, or, in the case of or remelt scrap generated in their brass mill scrap to a brass mill, own operations, or dispose of it ex Privately-imported copper, here without specific authorization of the cept by sale, without specific au tofore not subject to specific regu director of priorities. thorization. lation, has been plac.ed under full The amended order revokes P-61, No fabricator may keep on harfd priority control in a revision of which assigned an A-10 rating to more than 30 days’ accumulation of General Preference Order M-9-a. certain users of copper and brass scrap unless the total is less than 5 Other steps to tighten copper con scrap and changes the provisions of tons. Those who generate more than trol were taken in the revision, M-9-b which permitted deliveries on 2000 pounds in a month must report which extends the order to June 30. such ratings. Under the new rulings complete scrap inventoi'ies by the The original M-9-a was due to ex deliveries may be made only as 15th of the following month. pire Jan. 1 and was extended until specifically authorized, with the ex Other provisions of the order are publication of the revision. ception of dealers and brass mills. unchanged. Other main changes in the order Form PD-130 is provided for appli OPM copper officials described the are: cations for such authorization. order as "tapping a huge new copper Toll agreements relating to the All military requirements will be mine above ground” because of the processing of copper must now be approved by the director of priori ties. The exception permitting unregu 62—and His Suggestion Speeds Production 40 Per Cent lated delivery of less than 50-pound orders of copper in any one month is revoked. A rating of A-9 is assigned to warehouses to permit replenishing of stock sold for war orders. A quota basis, on 1941 sales, is set up as an additional check on the appli cation of this preference rating. Segregation of Aluminum Scrap Made Mandatory Segregation of aluminum scrap, by alloy content and form, is made mandatory by Supplementary Order M-l-d, issued by the Priorities Divi sion. Importance of the new segrega tion program is indicated by OPM estimates that 100 per cent segrega tion of sheet scrap alone will pro vide, at the rate of production next July, enough high-grade aluminum each month for several hundred air planes, and at the same time save enough magnesium for the manu facture of thousands of incendiary bombs. Strict segregation by type of aluminum scrap has not in the past been a general practice in the in dustry. Much of the scrap gener ated was formerly lumped and sold for use in products not requiring high-grade material. The comprehensive order, clamp B A 62-year-old machinist's idea for doing his job 40 per cent faster has earned ing air-tight controls over the treat °r ®750, largest award presented by Westinghouse Electric & Mfg. Co. for ment and disposition of all types of 6 suggestions accepted in 1941 from East Pittsburgh Works employes. Albert aluminum scrap, requires that, be uc ofer, winner, is shown operating a steel cutting tool as it grooves slots in a ginning March 1, every plant gen r°!°r- su9gested a compressed air device to lift the tool while the 14-ton rotor erating 1000 pounds or more of such ® 1 63 ^ack in position for another stroke. Formerly the tool was dragged through scrap per month, segregate at the e resh cut on the backward stroke. The suggestion “Speeds production of machine, the types resulting from rotors 40 per cent, eliminates tool breakage" its operations. January 12, 1942 25 Daily, M onthly, Yearly Records Set by operators were honored at a civic luncheon in Cleveland last week for their accomplishment in shipping 80,116,360 tons of iron ore during December and 1941 Pig Iron O utput 1941, an increase of 15,000,000 tons over the prior record. That an even greater effort will H PIG IRON output in December ferromanganese and spiegeleisen, be required this season was indicated and in 1941 shattered all previous averaged 14.58 per cent. December by Charles E. Adams, chief of the daily, monthly and yearly records. output of merchant iron, including OPM Iron and Steel Branch, who Total output for the year was 55,- ferromanganese and spiegeleisen, said 4,700,000 tons of additional pig 918,086 net tons. This was an in was 714,925 net tons, while the year’s iron capacity would be completed by crease of 19.24 per cent over the output came to 8,151,427 net tons. May 1. This, steel men said, would 46,894,676 net tons that flowed from Five furnaces were brought into necessitate the movement of 83,000,- the stacks in 1940 and of 58.36 per production in December. One of 000 tons of ore. cent over 35,310,042 tons of 1939. these was the new 850-ton stack of December output was 5,014,995 net Weirton Steel Co. at Weirton, W. tons, up 6.97 per cent from the 4,707,- Va., which took the blast Dec. 19. December Ingots 194 net tons produced in the 30-day Youngstown Sheet & Tube Co. blew November period. The rate of oper in its Brier Hill No. 2 stack on Dec. ations in December averaged 104.1 1 instead of on Nov. 28 as had pre W ithin 1% of Best per cent daily, up 5.1 points from viously been reported. Great Lakes November, and the highest daily Steel Corp. blew in a stack on Dec. operating rate in history. 9. Woodward Iron Co. blew in its M onth in History Daily production in December av Woodward No. 3 stack on Dec. 6 and eraged 161,774 net tons, a new rec its No. 2 stack on Dec. 11; both are ord. The previous all-time high was on merchant iron. Furnaces going \B CLOSE to 83,000,000 tons of steel the 157,378-ton mark of last Sep out of production included a Sharon were produced by the American tember. Steel Co. stack on Dec. 17 and steel industry during 1941, or near Stacks active on Dec. 31 numbered Duquesne No. 3 stack of Carnegie- ly 25 per cent more than the previ 218, compared with 215 (a corrected Illinois Steel Corp. on Dec. 24. An ous p.cak output achieved in 1940, figure) on Nov. 30. other stack on the idle list is Bethle the American Iron and Steel Insti Of the December output 14.26 per hem Steel Co.’s Lackawanna “A” tute reported last week. cent of the total was accounted for which went out on Nov. 30. The industry ended the year with by merchant iron, including ferro a production rate that brought out manganese and spiegeleisen; during SCaptains and chief engineers of put in December within 1 per cent the year merchant iron, including Great Lakes ore carriers, and vessel of the best monthly total on record, despite a growing shortage of cer tain of raw materials, principally PIG IRON STATISTICS scrap. Output in the last quarter of the year was ahead of any prior KATE OF FURNACE OPERATION DECEMBER IRON PRODUCTION quarter on record. (Relation of Production to Capacity) Net Tons The total of 82,927,557 net tons ol 1941' 1940s 1939s 1938* Jan................ 95.5 85.4 51.0 33.6 No. in blast - -Total Tonnages— open-hearth, bessemer and electric Feb................ 95.3 75.0 53.5 33.0 Dlaesct. daNyo ov£. Merchant meNrochna-nl furnace steel ingots and castings March 96.3 69.5 56.1 34.2 Alabama ... 19 17 124,483 204,292 produced in 1941 compares with out April 91.8 68.9 49.8 33.4 Illinois 20 20 121,136 372,151 put of 66,981,662 tons in 1940. The May 94.1 74.2 40.2 29.4 Indiana . .. . 19 19 21,759 537,934 . June 95.7 83.6 51.4 25.5 New York... 15 15 133,145 210,756 1941 tonnage exceeds by 65 per cent July.............. 97.0 86.1 55.0 28.2 Ohio ........ 46 46 148,190 981,129 the peak output during World War Aug.............. 97.4 89.9 62.4 34.8 Penna.......... . 70 71 131.921* 1,416,102* I, 50,467,880 tons in the year 1917. Sept............... 99.3 91.5 69.7 40.5 Oct................ 98.9 94.2 85.2 48.0 MCoiclohriagdaon .... 35 43 11 During 1941, the industry’s plants Nov.............. 99.0 96.4 90.3 55.0 Minnesota . 2 2 \ 13,347* 218,191* operated at an average of 97.4 pel Dec................ 104.1 96.4 88.5 51.4 Tennessee . 3 3 I cent of capacity, which compares Utah .......... 1 ij 'First six months are based on ca with a rate of 82.1 per cent in 1940, pacity of 57,503,030 net tons, Dec. 31, Kentucky . 2 21 and 90.8 per cent in 1917. Maryland . 7 7 1940—last six months on capacity of Mass............ 1 1 1 20,944* 359,512 Production in December totaled 57,830,610 net tons, June 30, 1940; 'capac Virginia . .. 1 1 7,163,999 tons, as against output oJ ity of 55.628,060 net tons, Dec. 31, 1939; West Va. . .. 4 3 J ! capacity of 56,222,790 net tons, Dec. 31, 6,969,987 tons in November, and 6,- 1938; * capacity of 56,679,168 net tons, Total ... . 218 215 714,925* 4,300,070* 495,357 tons in December, 1940. Dec. 31, 1937. Capacities by American •Includes ferromanganese and spiegeleisen. Iron and Steel Institute. Bethlehem Exceeds All MONTHLY IRON PRODUCTION AVERAGE DAILY PRODUCTION Prior Output Records Net Tons Net Tons S Bethlehem Steel Co., Bethlehem, 1941 1940 1939 1941 1940 1939 1938 Jan........... 4,666,233 4,024,556 2,436,474 Jan......... 150,524 129,825 78,596 52,201 Pa., made an all-time record in 1941, Feb 4,206,826 3,304,368 2,307,405 Feb 150,244 113,943 82,407 52,254 producing 12,155,476 net tons oi March. . .. . 4,702,905 3.270,575 2,680,446 March. . 151,707 105,502 86,465 53,117 steel ingots, it is announced by April. .. .. 4,340,555 3,139,043 2,301,965 April. . . 144,685 104,635 76,732 51,819 E. G. Grace, president. This com May. . . . 4,596,113 3,497.157 1,923,625 May. .. . 148,262 112,811 62,052 45,556 June . 4,551,040 3.813.092 2,373,753 June . . . 151,701 127.103 79,125 39,601 pares with the prior record of 10,- July......... . 4,766,216 4,060.513 2.63S.760 July___ 153,749 130.984 85.121 43,827 704,741 tons in 1940. Aug.......... . 4,7S4,639 4,234,576 2,979,774 Aug. . .. 154,343 136,599 96,122 54,031 December output was the largest Sept.......... . 4,721,337 4,172,551 3,218,940 Sept. . .. 157,378 139.0S5 107,298 62,835 Oct........... 4,860,033 4,437,725 4,062,670 Oct......... 156,775 143,152 131,053 74,697 for any single month in the com Nov.......... 4,707,194 4,397,656 4,166,512 Nov. . .. 156,906 146,589 13S,S83 85,369 pany’s history, reflecting continued Dec........... 5,014,995 4,542,S64 4,219,718 Dec......... 161,774 146,544 136,119 79,643 operations through the holidays. Total. .. 55,918,086 46,894,676 35,310,042 Ave......... 153,200 128,128 96,740 57,962 The month’s record was 1,067,499 tons. 26 /■TEEL

Description: