Product Submittal: Simpson Strong-Tie AT-XP Anchoring Adhesive PDF

Preview Product Submittal: Simpson Strong-Tie AT-XP Anchoring Adhesive

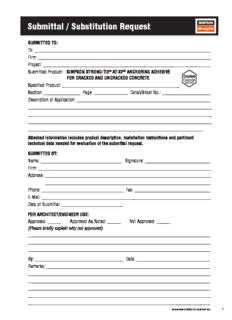

Submittal / Substitution Request Submitted tO: To: ______________________________________________________________________________ Firm: ____________________________________________________________________________ Project: __________________________________________________________________________ Submitted Product: SimpSOn StrOng-tie® At-Xp® AnCHOring AdHeSiVe FOr CrACKed And unCrACKed COnCrete Specified Product: ____________________________________________________ Section: ________________ Page: _______________ Detail/Sheet No.: ______________________ Description of Application: ____________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ _____________________________________________________________________________ Attached information includes product description, installation instructions and pertinent technical data needed for evaluation of the submittal request. Submitted by: Name: ____________________________________ Signature: _____________________________ Firm: ____________________________________________________________________________ Address: _________________________________________________________________________ _________________________________________________________________________ Phone: ____________________________________ Fax: __________________________________ E-Mail: ___________________________________________________________________________ Date of Submittal: ___________________________ FOr ArCHiteCt/engineer uSe: Approved: ______ Approved As Noted: ______ Not Approved: ______ (Please briefly explain why not approved) _________________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ By: _______________________________________ Date: _________________________________ Remarks: _________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ _________________________________________________________________________________ © SIMPSON STRONG-TIE COMPANY INC. 1 Table of Contents Simpson StrongTie® ATXP Anchoring Adhesive Product Information Product Information Design Data in NormalWeight Concrete IAPMO UES ER263 (for Cracked and Uncracked Concrete) City of Los Angeles Research Reports RR25960 (for Cracked and Uncracked Concrete) Certificate of NSF 61 approval for potable water applications AT Anchoring Adhesive Safety Data Sheet This product submittal was compiled by the Simpson StrongTie Submittal Generator web app and is current as of 8/3/2015. Information included in this submittal is subject to change; see www.strongtie.com for the latest information. 2 New! High Performance, Down Cold AT-XP® Anchoring Adhesive for Cracked and Uncracked Concrete The latest innovation from Simpson Strong-Tie, AT-XP® anchoring adhesive has been formulated for high-strength anchorage of threaded rod and rebar into concrete under a wide range of conditions. AT-XP adhesive dispenses easily in cold or warm environments with little to no odor, and when mixed properly is a teal color for easy post-installation identification. Code-listed per IAPMO UES ER-263 in accordance with ICC-ES AC308 and IBC 2009 requirements for cracked and uncracked concrete in static or seismic conditions, AT-XP anchoring adhesive has demonstrated superior performance in reduced-temperature testing (14°F (-10°C)), has NSF/Standard 61 certification (43.2 in2/1000 gal), and is made in the USA. Features: • AT-XP adhesive has passed the demanding adverse- condition tests of ICC-ES AC308 pertaining to reduced temperature, elevated temperature and long-term creep • Code-listed per IAPMO UES ER-263 • Can be used under static and seismic loading conditions in both cracked and uncracked concrete • Low-odor formula dispenses easily at below-freezing temperatures without the need to warm cartridge • Cures in substrate temperatures as low as 14°F in 24 hours or less • Easiest hole-cleaning method – no power brushing needed • When properly mixed, adhesive will be a teal color for easy identification • Available in 9.4 oz., 12.5 oz. and 30 oz. cartridges for jobsite versatility Applications: • Threaded rod anchoring into concrete • Rebar doweling into concrete • Suitable for horizontal, vertical and overhead applications For installation instructions, visit www.strongtie.com or our Anchoring and Fastening Systems for Concrete and Masonry catalog. AT-XP® Adhesive Cartridge System AT-XP13 Capacity AT-XP10 (AT-XP30 similar) AMN19Q Model Cartridge Carton Dispensing Mixing ounces No. Type Qty. Tool Nozzle (cubic in.) Cure Schedule 9.4 AT-XP10 coaxial 12 CDT10S Base Material (16.9) Temperature Gel Time Cure Time 12.5 (min.) (hrs.) AT-XP13 side-by-side 10 ADT813S °F °C (22.5) AMN19Q 14 -10 30 24 ADT30S, 30 AT-XP30 side-by-side 5 ADTA30P or 32 0 15 8 (54) ADT30CKT 50 10 7 3 1. Cartridge estimation guides are available at www.strongtie.com/apps. 68 20 4 1 2. Detailed information on dispensing tools, mixing nozzles and other 86 30 1.5 30 min. adhesive accessories is available at www.strongtie.com. 100 38 1 20 min. 3. Use only Simpson Strong-Tie® mixing nozzles in accordance with Simpson Strong-Tie instructions. Modification or improper use of mixing nozzle may impair AT-XP adhesive performance. For water-saturated concrete (including damp or 4. One AMN19Q nozzle and one nozzle extension is supplied with each cartridge. water-filled holes), the cure times must be doubled. ©2013 Simpson Strong-Tie Company Inc. F-SAS-ATXP13 12/12 exp. 12/14 AT-XP® Fast-Curing Anchoring Adhesive for Cracked and Uncracked Concrete Design Information Installation Information and Additional Data for Threaded Rod and Rebar in Normal-Weight Concrete1 Nominal Anchor Diameter (inch) / Rebar Size Characteristic Symbol Units 3⁄8 / #3 1⁄2 / #4 5⁄8 / #5 3⁄4 / #6 7⁄8 / #7 1 / #8 1-1⁄4 / #10 Installation Information Drill Bit Diameter for Threaded Rod dhole in. 7⁄16 9⁄16 11⁄16 13⁄16 1 1 1⁄8 1 3⁄8 Drill Bit Diameter for Rebar dhole in. 1⁄2 5⁄8 3⁄4 7⁄8 1 11⁄8 1 3⁄8 Maximum Tightening Torque Tinst ft-lb 10 20 30 45 60 80 125 Permitted Embedment Depth Range2 Minimum hef in. 2 3⁄8 2 3⁄4 3 1⁄8 3 1⁄2 3 3⁄4 4 5 Maximum hef in. 7 1⁄2 10 12 1⁄2 15 17 1⁄2 20 25 Minimum Concrete Thickness hmin in. hef + 5do Critical Edge Distance cac in. 3 x hef Minimum Edge Distance cmin in. 1 3⁄4 2 3⁄4 Minimum Anchor Spacing smin in. 3 6 1. The information presented in this table is to be used in conjunction with the design criteria of ICC-ES AC308. 2. Minimum and maximum embedment depths are set so as to fit the ICC-ES AC308 design model. Tension Design Data for Threaded Rod in Normal-Weight Concrete1,11 Nominal Anchor Diameter (inch) Characteristic Symbol Units 3⁄8 1⁄2 5⁄8 3⁄4 7⁄8 1 1 1⁄4 Steel Strength in Tension Minimum Tensile Stress Area Ase in2 0.078 0.142 0.226 0.334 0.462 0.606 0.969 Tension Resistance of Steel: - ASTM F1554, Grade 36 4,525 8,235 13,110 19,370 26,795 35,150 56,200 - ASTM A193, Grade B7 9,750 17,750 28,250 41,750 57,750 75,750 121,125 Threaded Rod - Type 410 Stainless (ASTM A193, Grade B6) Nsa lb. 8,580 15,620 24,860 36,740 50,820 66,660 106,590 - Type 304 and 316 Stainless (ASTM A193, Grade B8 & B8M) 4,445 8,095 12,880 19,040 26,335 34,540 55,235 Strength Reduction Factor - Steel Failure ϕ - 0.758 Concrete Breakout Strength in Tension (2,500 psi ≤ f'c ≤ 8,000 psi) Effectiveness Factor - Uncracked Concrete kuncr - 24 Effectiveness Factor - Cracked Concrete kcr 17 Strength Reduction Factor - Breakout Failure ϕ - 0.6510 Bond Strength in Tension (2,500 psi ≤ f'c ≤ 8,000 psi) Characteristic Bond Strength7 τk,uncr psi 1,390 1,590 1,715 1,770 1,750 1,655 1,250 Temp. Range 1 for Uncracked Concrete2,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 72 13⁄⁄82 21 30⁄4 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Characteristic Bond Strength7,12,13,14 τk,cr psi 1,085 1,035 980 950 815 800 700 Temp. Range 1 for Cracked Concrete2,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 73 1⁄ 2 130 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Characteristic Bond Strength7 τk,uncr psi 1,390 1,590 1,715 1,770 1,750 1,655 1,250 Temp. Range 2 for UCnTrcearmcakcpek.de Rd C aConongncerc e2rte efto3e,r43, ,54,5 CPPheerrammraiicttttteeeddri sEEtmmicbb Beeoddnmmdee Snntttr DDeneegppttthhh7 ,RR12aa,1nn3,gg14ee MMMMaaiinnxxiiiimmmmuuuummmm τhhkee,cffr piinns..i 1772,03 1138⁄⁄⁄ 8225 12,1103 3003⁄ 45 11933228 11 11⁄⁄088⁄⁄22 933115 1155⁄⁄022 11833771 33 11⁄⁄544⁄⁄22 822440000 722550550 12/12 exp. 12/14 SSttrreennggtthh RReedduuccttiioonn FFaaccttoorr -- DWrayt eCBro-oSnnacdtr ueSrttearteendg Ctho ninc rTeetension - Bond Strength Reduction Factϕϕodrssrayt for Co--ntinuous Special Inspe0c.6ti5o9n 0.459 0.559 S-ATXP13 A ASSdttrrdeeinntiggottnhha RRl Feeaddcuutccottrii oofnno rFF Waaccattooterrr ---S WDartayut reCarot-Besnodacn trCuderot aSenttcerrdee ntCegotnhc irne tTeension - Bond Strength Reduction FaϕcϕKtdssoararytts for P---eriodic Sp0e.5ci4a6l Inspec0t.i5o5n9 00..747569 00..946569 mpany Inc. F-S 231...A dTwTMTdeehiiatmmteihxo ppi inmnteehafrruoelaa mrttFdmuuae rrlascoeetitn gioRRognrnaa- nn ctfpeorggrrireetme e Ws12r eit::aaen MM mttoeeaafprd xx-Ie CsiiirmmnaCa ttuut-uuhEmmrriSsea sstAtoehhaCfdboo 73 lrrCe50tt-- o°8ittseeFn, . rrt ecmmoxr ec bttteeeeepmm ut sppaeeesdrr maa ittnuuo rrdceeiofi ooneffjdu 11 nb18ce00tli°°ooFFwn.. . 190. . uctTThoshheemee d avvb pKaaaipnsnlluuraadoeett i ptooohrnffie asϕϕ tr eoe aa qfv- ppuAappilCrulliieIeee m3ss o 1ewwf8n ϕhh tAsee.0 pnno.p fb4b eSoo6ntte6dhhci xtttihh oCeen a llDooreaa4 dd.u4 scc(eoocd)mm ,f bboreiirnn0 fCeaa.6rttoii 5oontonn6d ssiSt ieooocffn tAA iBoCCn aII rD33e114 m88.5 eSS ttoee. cc Id0ftt iieo.ot8htnnee1 r 996mlo..22ian daae rr ee mpson Strong-Tie Co 4. MShaoxrimt-tuemrm l ocnogn-ctreertme tteemmppeerraattuurrees o afr 1e1 t0h°oFs. e that occur over ucosemdb ainnadt itohnes r oeqf uAiCreI m31e8n tSs eocft iSoenc 9ti.o2n a Dre4 .u4s(ecd) faonrd C tohned rietiqouni rBe mareen mtse ot.f ISf ethctei olona d 2013 Si short intervals (diurnal cycling). D4.4(c) for Condition A are met, refer to Section D4.4 to determine the appropriate © 5. Long-term concrete temperatures are constant temperatures value of ϕ. If the load combinations of ACI 318 Appendix C are used, refer to over a significant time period. Section D4.5 to determine the appropriate value of ϕ. 6. In water-saturated concrete, multiply τk,uncr and τk,cr by Ksat. 11. Sand-lightweight and all-lightweight concrete are beyond the scope of this table. 7. For anchors installed in overhead and subjected to tension resulting 12. For anchors installed in regions assigned to Seismic Design Category C, D, E or from sustained loading, multiply the value calculated for Na F, the bond strength values for 1⁄2", 5⁄8", 3⁄4" and 1" anchors must be multiplied by according to ICC-ES AC308 by 0.75. αN,seis = 0.85. 8. The value of ϕ applies when the load combinations of ACI 318 13. For anchors installed in regions assigned to Seismic Design Category C, D, E or F, Section 9.2 are used. If the load combinations of ACI 318 Appendix the bond strength values for 1-1⁄4" anchors must be multiplied by αN,seis = 0.75. C are used, refer to Section D4.5 to determine the appropriate value of ϕ. 14. For anchors installed in regions assigned to Seismic Design Category C, D, E or F, the bond strength values for 7⁄8" anchors must be multiplied by αN,seis = 0.59. 2 AT-XP® Fast-Curing Anchoring Adhesive for Cracked and Uncracked Concrete Design Information Tension Design Data for Rebar in Normal-Weight Concrete1,11 Rebar Size Characteristic Symbol Units #3 #4 #5 #6 #7 #8 #10 Steel Strength in Tension Minimum Tensile Stress Area Ase in2 0.11 0.2 0.31 0.44 0.6 0.79 1.27 Tension Resistance of Steel - Rebar (ASTM A615 Grade 60) 9,900 18,000 27,900 39,600 54,000 71,100 114,000 Rebar Tension Resistance of Steel - Rebar (ASTM A706 Grade 60) Nsa lb. 8,800 16,000 24,800 35,200 48,000 63,200 101,600 Strength Reduction Factor - Steel Failure ϕ - 0.658 Concrete Breakout Strength in Tension (2,500 psi ≤ f’c ≤ 8,000 psi) Effectiveness Factor - Uncracked Concrete kuncr - 24 Effectiveness Factor - Cracked Concrete kcr 17 Strength Reduction Factor - Breakout Failure ϕ - 0.6510 Bond Strength in Tension (2,500 psi ≤ f'c ≤ 8,000 psi) Characteristic Bond Strength7 τk,uncr psi 1,355 1,365 1,355 1,330 1,280 1,215 1,025 Temp. Range 1 for Uncracked Concrete2,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 72 13⁄⁄82 21 30⁄4 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Characteristic Bond Strength7,12,13,14 τk,cr psi 1,085 1,035 980 950 815 800 700 Temp. Range 1 for Cracked Concrete2,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 73 1⁄ 2 130 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Characteristic Bond Strength7 τk,uncr psi 1,355 1,365 1,355 1,330 1,280 1,215 1,025 Temp. Range 2 for Uncracked Concrete3,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 72 13⁄⁄82 21 30⁄4 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Characteristic Bond Strength7,12,13,14 τk,cr psi 1,085 1,035 980 950 815 800 700 Temp. Range 2 for Cracked Concrete3,4,5 Permitted Embedment Depth Range MMainxiimmuumm hef in. 73 1⁄ 2 130 132 1 1⁄8⁄2 31 15⁄2 137 3 1⁄4⁄2 240 255 Bond Strength in Tension - Bond Strength Reduction Factors for Continuous Special Inspection Strength Reduction Factor - Dry Concrete ϕdry - 0.659 0.559 Strength Reduction Factor - Water-Saturated Concrete ϕsat - 0.459 Additional Factor for Water-Saturated Concrete Ksat - 0.546 0.776 0.966 Bond Strength in Tension - Bond Strength Reduction Factors for Periodic Special Inspection Strength Reduction Factor - Dry Concrete ϕdry - 0.559 0.459 Strength Reduction Factor - Water-Saturated Concrete ϕsat - 0.459 Additional Factor for Water-Saturated Concrete Ksat - 0.466 0.656 0.816 1. The information presented in this table is to be used in conjunction 9. The value of ϕ applies when both the load combinations of ACI 318 Section 9.2 are with the design criteria of ICC-ES AC308, except as modified below. used and the requirements of Section D4.4(c) for Condition B are met. If the load 12/14 2. TMeamxpimeruamtu rloen Rga-ntegrem 1 t:e Mmapxeirmatuumre sohfo 7r5t-°teF.r m temperature of 110°F. cthoem abpipnraotiporniast eo fv AalCuIe 3 o1f8 ϕ A.ppendix C are used, refer to Section D4.5 to determine 12/12 exp. 34.. TMSsehhamooxrrpitmt e-itnrueatmretmur vrl oeacn loRsgn a(-cndtregieuretmre n2 tat:ee lMm mcyappcxeelirirmnaatgtuuu)mr.re e s so hafor 1er1t t-0hte°orFsm. e tthemat poecrcautur roev oefr 1 80°F. 10. ucDTosh4eme.4d vb( aacinnl)ua dfeto i toorh nfCe sϕ or oen aqfd puAitpiiCrolieIen m3s A 1ew 8nah trSsee en omc fbt eiSootte,nh cr 9ettihf.oe2enr a ltDoroea4 dS.u4 esc(ceoctd)mio fanbon irnDd Ca 4ttoh.i4one nd trosiet iqodoufen itA reBeCr mmaI r3eienn1 emt8s te Shotee.f c ISaft pieotphcntre io o9lpon.2ra i daat ree XP13 5. La osniggn-tifiercman ct otinmcere ptee rtieomd.p eratures are constant temperatures over vSaelcuteio onf Dϕ4. .I5f tthoe d leotaedrm cionme bthinea atipopnrso opfr iAatCeI v3a1lu8e A opfp ϕen.dix C are used, refer to S-AT 6. In water-saturated concrete, multiply τk,uncr and τk,cr by Ksat. 11. Sand-lightweight and all-lightweight concrete are beyond the scope of this table. SA 7. For anchors installed in overhead and subjected to tension resulting 12. For anchors installed in regions assigned to Seismic Design Category C, D, E or F, mpany Inc. F- 8. aTSfrcheocecmo tvir oasdnluiun s9egt. a 2otio nfa eϕrIdCe aCulpo-spaEedlSdiei .nAs Ig Cfw, 3tmhh0ee8un llotb tiapyhd le0y c.lt7ooh5amed. v bcaionlumaetib ocinnalsac tuoiolfan AtseC doI ff3 oA1rC8 NI Aa3 p1 p8e ndix C 13. αFtthhoNeer, sbbaeonoisncn =hdd o 0ssr.tts8rr ee5innn.sggtttahhl lvveaadll uuinee ssr effgooirro ##n14s0, a #sr5es,bi g#anr6 e aadnn ctdoh o#Sr8es ir smembuaicsr t D abneecs hmigonur lsCt ipmatlieuegsdot brbyye Cαm,N uD,sl,te iiEps loi=er d0 F .,b7 y5 . Co are used, refer to Section D4.5 to determine the appropriate value of ϕ. 14. For anchors installed in regions assigned to Seismic Design Category C, D, E or F, Strong-Tie the bond strength values for #7 rebar anchors must be multiplied by αN,seis = 0.59. mpson Si 2013 © 3 AT-XP® Fast-Curing Anchoring Adhesive for Cracked and Uncracked Concrete Design Information Shear Design Data for Threaded Rod in Normal-Weight Concrete1,5 Nominal Anchor Diameter (inch) Characteristic Symbol Units 3⁄8 1⁄2 5⁄8 3⁄4 7⁄8 1 1 1⁄4 Steel Strength in Shear Minimum Shear Stress Area Ase in2 0.078 0.142 0.226 0.334 0.462 0.606 0.969 Shear Resistance of Steel: - ASTM F1554, Grade 36 2,260 4,940 7,865 11,625 16,080 21,090 33,720 - ASTM A193, Grade B7 4,875 10,650 16,950 25,050 34,650 45,450 72,675 - Type 410 Stainless (ASTM A193, Grade B6) Vsa lb. 4,290 9,370 14,910 22,040 30,490 40,000 63,955 - Type 304 and 316 Stainless (ASTM A193, Grade B8 & B8M) 2,225 4,855 7,730 11,420 15,800 20,725 33,140 Threaded Rod Reduction for Seismic Shear - ASTM F1554, Grade 36 0.85 Reduction for Seismic Shear - ASTM A193, Grade B7 0.85 Reduction for Seismic Shear - Type 410 Stainless (ASTM A193, Grade B6) αV,seis6 - 0.85 0.75 0.85 Reduction for Seismic Shear - Type 304 and 316 Stainless 0.85 0.75 0.85 (ASTM A193, Grade B8 & B8M) Strength Reduction Factor - Steel Failure ϕ - 0.652 Concrete Breakout Strength in Shear Outside Diameter of Anchor do in. 0.375 0.5 0.625 0.75 0.875 1 1.25 Load Bearing Length of Anchor in Shear ℓe in. hef Strength Reduction Factor - Breakout Failure ϕ - 0.703 Concrete Pryout Strength in Shear Coefficient for Pryout Strength kcp - 2.0 Strength Reduction Factor - Pryout Failure ϕ - 0.704 1. The information presented in this table is to be used in conjunction with the 4. The value of ϕ applies when both the load combinations of ACI 318 Section 9.2 design criteria of ICC-ES AC308, except as modified below. are used and the requirements of Section D.4.4(c) for Condition B are met. If 2. The value of ϕ applies when the load combinations of ACI 318 Section 9.2 are the load combinations of ACI 318 Appendix C are used, refer to Section D.4.5 to used. If the load combinations of ACI 318 Appendix C are used, refer to Section determine the appropriate value of ϕ. D.4.5 to determine the appropriate value of ϕ. 5. Sand-lightweight and all-lightweight concrete are beyond the scope of this table. 3. The value of ϕ applies when both the load combinations of ACI 318 Section 9.2 6. The values of Vsa are applicable for both cracked concrete and uncracked are used and the requirements of Section D.4.4(c) for Condition B are met. If concrete. For anchors installed in regions assigned to Seismic Design the load combinations of ACI 318 Section 9.2 are used and the requirements of Category C, D, E or F, Vsa must be multiplied by αV,seis for the Section D.4.4 (c) for Condition A are met, refer to Section D.4.4 to determine the corresponding anchor steel type. appropriate value of ϕ. If the load combinations of ACI 318 Appendix C are used, refer to Section D.4.5 to determine the appropriate value of ϕ. Shear Design Data for Rebar in Normal-Weight Concrete1,5 Rebar Size Characteristic Symbol Units #3 #4 #5 #6 #7 #8 #10 Steel Strength in Shear Minimum Shear Stress Area Ase in2 0.11 0.2 0.31 0.44 0.6 0.79 1.27 Shear Resistance of Steel - Rebar (ASTM A615 Grade 60) 4,950 10,800 16,740 23,760 32,400 42,660 68,580 Shear Resistance of Steel - Rebar (ASTM A706 Grade 60) Vsa lb. 4,400 9,600 14,880 21,120 28,800 37,920 60,960 Rebar Reduction for Seismic Shear - Rebar (ASTM A615 Grade 60) 0.56 0.80 Reduction for Seismic Shear - Rebar (ASTM A706 Grade 60) αV,seis6 0.56 0.80 Strength Reduction Factor - Steel Failure ϕ 0.602 Concrete Breakout Strength in Shear Outside Diameter of Anchor do in. 0.375 0.5 0.625 0.75 0.875 1 1.25 Load Bearing Length of Anchor in Shear ℓe in. hef Strength Reduction Factor - Breakout Failure ϕ - 0.703 Concrete Pryout Strength in Shear Coefficient for Pryout Strength kcp - 2.0 Strength Reduction Factor - Pryout Failure ϕ - 0.704 1. The information presented in this table is to be used in conjunction with the 4. The value of ϕ applies when both the load combinations of ACI 318 Section 9.2 design criteria of ICC-ES AC308, except as modified below. are used and the requirements of Section D.4.4(c) for Condition B are met. If 2. The value of ϕ applies when the load combinations of ACI 318 Section 9.2 are the load combinations of ACI 318 Appendix C are used, refer to Section D.4.5 used. If the load combinations of ACI 318 Appendix C are used, refer to Section to determine the appropriate value of ϕ. D.4.5 to determine the appropriate value of ϕ. 5. Sand-lightweight and all-lightweight concrete are beyond the scope of this table. 3. The value of ϕ applies when both the load combinations of ACI 318 Section 9.2 6. The values of Vsa are applicable for both cracked concrete and uncracked are used and the requirements of Section D.4.4(c) for Condition B are met. If concrete. For anchors installed in regions assigned to Seismic Design the load combinations of ACI 318 Section 9.2 are used and the requirements of Category C, D, E or F, Vsa must be multiplied by αV,seis for the Section D.4.4 (c) for Condition A are met, refer to Section D.4.4 to determine the corresponding anchor steel type. appropriate value of ϕ. If the load combinations of ACI 318 Appendix C are used, refer to Section D.4.5 to determine the appropriate value of ϕ. This flier is effective until December 31, 2014, and reflects information available as of December 1, 2012. This information is updated periodically and should not be relied upon after December 31, 2014; 800-999-5099 contact Simpson Strong-Tie for current information and limited warranty or see www.strongtie.com. www.strongtie.com ©2013 Simpson Strong-Tie Company Inc. • P.O. Box 10789, Pleasanton, CA 94588 F-SAS-ATXP13 12/12 exp. 12/14 Number: 263 Originally Issued: 11/2012 Revised: 11/21/2014 Valid Through: 11/2015 EVALUATION SUBJECT: rods or deformed steel reinforcing bars. The Manufacturer’s AT-XP® ADHESIVE ANCHORS FOR CRACKED Printed Installation Instructions (MPII) are included with AND UNCRACKED CONCRETE each adhesive unit package as shown in Figure 1 of this report. REPORT HOLDER: Simpson Strong-Tie Company Inc. 3.2 Material information: 5956 West Las Positas Boulevard Pleasanton, California 94588 3.2.1 AT-XP Adhesive: AT-XP adhesive is an injectable, (800) 999-5099 two component, acrylic-based adhesive that is mixed in a 10 www.strongtie.com to 1 volume ratio of resin to initiator. AT-XP is available in 9.4 ounce (280 mL), 12.5 ounce (370 mL) and 30 ounce (885 CSI DIVISION: 03—CONCRETE mL) cartridges. The two components combine and react CSI Section: 03 16 00—Concrete Anchors when dispensed through a static mixing nozzle attached to the cartridge. Cure and gel times after placement into holes CSI DIVISION: 05 00 00—METALS occurs according to conditions given in Table 11 of this CSI Section: 05 05 19—Post-Installed Concrete report. The shelf life of AT-XP in unopened cartridges is Anchors twelve months from the date of manufacture when stored at temperatures between 32⁰F and 80⁰F (0⁰C and 27⁰C) in 1.0 SCOPE OF EVALUATION accordance with the MPII. 1.1 Compliance to the following codes & regulations: 3.2.2 Dispensing Equipment: AT-XP adhesive shall be 2009 and 2006 International Building Code® (IBC) dispensed using Simpson Strong-Tie manual dispensing 2009 and 2006 International Residential Code® (IRC) tools, battery-powered dispensing tools or pneumatic dispensing tools as listed in Tables 9 and 10 of this report. 1.2 Evaluated in accordance with: ICC AC308 3.2.3 Equipment for Hole Preparation: Hole cleaning equipment consists of hole-cleaning brushes and air nozzles. 1.3 Properties assessed: Brushes shall be Simpson Strong-Tie hole cleaning brushes, Structural identified by Simpson Strong-Tie catalog number series ETB. Tables 9 and 10 in this report, and the MPII shown in 2.0 PRODUCT USE Figure 1 provide additional information. Air nozzles shall be equipped with an extension capable of reaching the bottom The Simpson Strong-Tie® AT-XP Adhesive Anchors are of the drilled hole. used to resist static, wind and earthquake (Seismic Design Categories A through F under the IBC) tension and shear 3.2.4 Anchor Materials: loads in cracked and uncracked normal-weight concrete having a specified compressive strength, ƒ′ , of 2,500 psi to 3.2.4.1 Threaded Steel Rods: Threaded anchor rods, having c 8,500 psi (17.2 MPa to 58.6 MPa). The adhesive anchor is an diameters from 3/8 inch to 1-1/4 inch (9.5 mm to 31.7 mm), alternative to anchors described in Sections 1911 and 1912 of shall be carbon steel conforming to ASTM F1554, Grade 36, the 2009 and 2006 IBC. The anchors may also be used where or ASTM A193, Grade B7; or stainless steel conforming to an engineering design is submitted in accordance with ASTM A193, Grade B6, B8, or B8M. Table 3 in this report Section R301.1.3 of the 2009 and 2006 IRC. provides additional details. Threaded rods shall be clean, straight and free of indentations or other defects along their 3.0 PRODUCT DESCRIPTION lengths. The embedded portions of the threaded rods shall be free of mill scale, rust, mud, oil, and other coatings that may 3.1 Product information: The AT-XP Adhesive Anchors impair the bond with the adhesive. The tensile strength of the are post-installed anchors, inserted into hardened concrete threaded anchor rods shall not exceed 145,000 psi (1,000 with an anchor hole diameter not greater than 1.5 times the MPa). anchor diameter, that transfer loads to the concrete by bond between the anchor and the adhesive, and bond between the 3.2.4.2 Deformed Steel Reinforcing Bars (Rebars): adhesive and the concrete. The adhesive anchor system is Deformed steel rebars, having sizes from No. 3 to No. 8, and comprised of the following components: No. 10 shall conform to ASTM A615 Grade 60 or ASTM A706 Grade 60. Table 4 in this report provides additional • AT-XP adhesive packaged in cartridges details. The embedded portions of reinforcing bars shall be • Adhesive mixing and dispensing equipment straight, and free of mill scale, rust, mud, oil, and other • Equipment for hole cleaning and adhesive coatings that may impair the bond with the adhesive. injection Reinforcing bars shall not be bent after installation except as AT-XP adhesive is used with continuously threaded steel set forth in Section 7.3.2 of ACI 318, with the additional Page 1 of 18 Number: 263 Originally Issued: 11/2012 Revised: 11/21/2014 Valid Through: 11/2015 condition that the bars shall be bent cold, and heating of this report. Strength reduction factors, Φ, described in ACI reinforcing bars to facilitate field bending is not permitted. 318 D.4.3, and noted in Tables 3, 4, 5, 6 and 7 of this report, shall be used for load combinations calculated in accordance 3.2.4.3 Ductility: In accordance with ACI 318 D.1, in order with Section 1605.2 of the 2009 or 2006 IBC and ACI 318 for a steel element to be considered ductile, the tensile test Section 9.2. Strength reductions factors, Φ, described in ACI elongation shall be at least 14 percent and reduction of area 318 D.4.4 shall be used for load combinations calculated in shall be at least 30 percent. Steel elements used for anchoring accordance with Appendix C of ACI 318. with a tensile test elongation of less than 14 percent or a reduction of area less than 30 percent, or both, shall be 4.1.2 Static Steel Strength in Tension: The nominal steel considered brittle. Where values are nonconforming or strength of a single anchor in tension, N , in accordance with sa unstated, the steel shall be considered brittle. Except as ACI 318 D.5.1.2, and the corresponding strength reduction modified by D.3.3.4.3 (a) 6 of ACI 318-11 for earthquake factors, Φ, in accordance with ACI 318 D.4.3, are provided effects, deformed reinforcing bars meeting the requirements in Tables 3 and 4 of this report for each anchor type of ASTM A615 or A706 shall be considered as ductile steel referenced in this report. elements. 4.1.3 Static Concrete Breakout Strength in Tension: The 3.2.5 Concrete: Normal-weight concrete shall conform to nominal static concrete breakout strength of a single anchor Sections 1903 and 1905 of the 2009 and 2006 IBC. The or group of anchors in tension, N or N , shall be calculated cb cbg specified compressive strength of the concrete shall be from in accordance with ACI 318 D.5.2. 2,500 psi to 8,500 psi (17.2 MPa to 58.6 MPa). The basic concrete breakout strength of a single anchor in 4.0 DESIGN AND INSTALLATION tension, N , shall be calculated in accordance with ACI 318 b D.5.2.2 using the values of, k , and k , as described in c,cr c,uncr 4.1 Strength Design: Table 5 of this report. Where analysis indicates no cracking in accordance with ACI 318 D.5.2.6, N shall be calculated b 4.1.1 General: The design strength of anchors under the using k and Ψ =1. For anchors in lightweight concrete c,uncr c,N 2009 and 2006 IBC and Section R301.1.3 of the 2009 and see ACI 318-11 D.3.6. The value of f’ used for calculation c 2006 IRC shall be determined in accordance with ACI 318- purposes shall be limited to 8,000 psi (55.1 MPa) maximum. 11 Appendix D and this report. 4.1.4 Static Bond Strength in Tension: The nominal static A design example in accordance with ACI 318-11 for use bond strength of a single anchor or group of anchors in with the 2009 IBC is given in Figure 2 of this report. tension, N or N shall be calculated in accordance with ACI a ag, 318-11 D.5.5. Bond strength values are a function of the Design parameters are based on ACI 318-11 for use with the concrete condition (cracked or uncracked), the installation 2009 and 2006 IBC unless noted otherwise in Sections 4.1.1 conditions (dry or water saturated concrete), and the special through 4.1.11 of this report. inspection level provided. Strength reduction factors, Φ, listed in this section and in Tables 6 and 7 of this report, shall The strength design of anchors shall conform to the be utilized for anchors installed in dry or saturated concrete requirements of ACI 318 D.4.1, except as required in ACI in accordance with the level of inspection specified (periodic 318 D.3.3. or continuous), as applicable. Bond strength values, τ, shall k be modified with the factor Κ , listed below and in Tables 6 sat Anchor categories are as follows: and 7 of this report, for cases where the holes are drilled in water-saturated concrete as follows: Bar Size Continuous Special Periodic Special Inspection Inspection SPECIAL PERMISSIBLE BOND ASSOCIATED INSPECTION INSTALLATION STRENGTH STRENGTH Dry Water- Dry Water- LEVEL CONDITION REDUCTION Concrete saturated Concrete saturated FACTOR ⅜ #3 1 3 2 3 Continuous Dry Concrete τk Φdry,ci ½ #4 1 3 2 3 Continuous Water-saturated τk × Κsat,ci Φsat,ci ⅝ #5 1 3 2 3 Periodic Dry Concrete τk Φdry,pi ¾ #6 1 3 2 3 ⅞ #7 1 3 2 3 Periodic Water-saturated τk × Κsat,pi Φsat,pi 1 #8 2 3 3 3 The bond strength τ in the table above refers to τ or τ , 1¼ #10 2 3 3 3 k k,cr k,uncr and where applicable, the modified bond strengths shall be used in lieu of τ or τ k,cr k,uncr. Design parameters are provided in Tables 3, 4, 5, 6 and 7 of 4.1.5 Static Steel Strength in Shear: The nominal static Page 2 of 18 Number: 263 Originally Issued: 11/2012 Revised: 11/21/2014 Valid Through: 11/2015 steel strength of a single anchor in shear as governed by the Tables 3 and 4 of this report for the types of anchors included steel, V , and the corresponding strength reduction factors, in this report. The nominal bond strength, τ , shall be sa k,cr Φ, complying with ACI 318 D.6.1.2, and D.4.3, respectively adjusted by α as given in the footnotes to Tables 6 and 7 N,seis are given in Tables 3 and 4 of this report. of this report respectively. 4.1.6 Static Concrete Breakout Strength in Shear: The Replace Section 1908.1.9 of the 2009 IBC with the nominal static concrete breakout strength of a single anchor following: or group of anchors in shear, V or V , shall be calculated cb cbg in accordance with ACI 318 D.6.2, based on information Modify ACI 318 Section.3.3.4.2, D3.3.4.3 (d) and given in Table 5 of this report. The basic concrete breakout D.3.3.5.2 to read as follows: strength of a single anchor in shear, V , shall be calculated in b accordance with ACI 318 D.6.2.2 using the values of d as D.3.3.4.2 - Where the tensile component of the strength-level a described in Table 5 of this report for the corresponding earthquake force applied to anchors exceeds 20 percent of the anchor steel. In addition, h shall comply with the range total factored anchor tensile force associated with the same ef given in Table 5 and shall replace l in the calculation In no load combination, anchors and their attachments shall be e . case shall h exceed 8d . The value of f’ shall be limited to designed in accordance with D.3.3.4.3. The anchor design ef a c 8,000 psi (55.1 MPa) maximum, in accordance with ACI 318 tensile strength shall be determined in accordance with Section D.3.7. D.3.3.4.4. 4.1.7 Static Concrete Pryout Strength in Shear: The Exception: nominal static pryout strength of a single anchor or group of anchors in shear, V V shall be calculated in accordance Anchors designed to resist wall out-of-plane forces with cp or cpg, with ACI 318 D.6.3. design strengths equal to or greater than the force determined in accordance with ASCE 7 Equation 12.11-1 4.1.8 Interaction of Tensile and Shear Forces: For designs or 12.14-10 shall be deemed to satisfy Section D.3.3.4.3 that include combined tension and shear, the interaction of (d). tension and shear loads shall be calculated in accordance with ACI 318 D.7. D.3.3.4.3 (d) – The anchor or group of anchors shall be designed for the maximum tension obtained from design load 4.1.9 Minimum Member Thickness, h Minimum combinations that include E, with E increased by Ω . The min, o Anchor Spacing, s and Minimum Edge Distance, c : anchor design tensile strength shall be calculated from min, min In lieu of ACI 318 D.8.1 and D.8.3, values of c and s D.3.3.4.4. min min used for anchor design and installation shall conform to the values provided in Tables 1 and 2 of this report. In lieu of D.3.3.5.2 – Where the shear component of the strength-level ACI 318 D.8.5, the minimum member thicknesses, h , shall earthquake force applied to anchors exceeds 20 percent of the min be in accordance with Tables 1 and 2 of this report. For total factored anchor shear force associated with the same anchors where installation will not be torqued, ACI 318 D.8.4 load combination, anchors and their attachments shall be applies. designed in accordance with D.3.3.5.3. The anchor design shear strength for resisting earthquake forces shall be 4.1.10 Critical Edge Distance, c : In lieu of ACI 318 D.8.6, determined in accordance with D.6. ac values of c shall be determined as follows: ac Exceptions: c = h (τ / )0.4 [3.1 – 0.7(h/h )] Eq. (4-1) ac ef k,uncr 1160 × ef 1. For the calculation of the in-plane shear strength of Where anchor bolts attaching wood sill plates of bearing or non- [h/ h ] ≤ 2.4 bearing walls of light-frame wood structures to foundations ef τ = the characteristic bond strength in uncracked or foundation stem walls, the in-plane shear strength in k,uncr concrete where the permitted values are given in Tables 6 and accordance with D.6.2 and D.6.3 need not be computed and 7 of this report (psi) D3.3.5.3 need not apply provided all of the following are ≤ k ((h × f’)0.5/(π × d )) satisfied: uncr ef c a h = the member thickness (inches) h = the embedment depth (inches) 1.1. The allowable in-plane shear strength of the anchor ef is determined in accordance with AF&PA NDS Table 4.1.11 Design Strength in Seismic Design Categories C, D, 11E for lateral design values parallel to grain. E and F: In structures assigned to Seismic Design Category C, D, E or F under the IBC or IRC, the design shall be 1.2. The maximum anchor nominal diameter is 5/ inch 8 performed according to ACI 318 D.3.3, The nominal steel (16 mm). shear strength, V , shall be adjusted by α as given in 1.3. Anchor bolts are embedded into concrete a sa V,seis Page 3 of 18 Number: 263 Originally Issued: 11/2012 Revised: 11/21/2014 Valid Through: 11/2015 minimum of 7 inches (178 mm). where: 1.4. Anchor bolts are located a minimum of 1-3/ inches T = Allowable tension load (lbf or kN) 4 allowable,ASD (45 mm) from the edge of the concrete parallel to the V = Allowable shear load (lbf or kN) allowable,ASD length of the wood sill plate. ΦN = The lowest design strength of an anchor or anchor n 1.5. Anchor bolts are located a minimum of 15 anchor group in tension as determined in accordance with ACI 318 diameters from the edge of the concrete perpendicular Appendix D as amended in Section 4.1 of this report and to the length of the wood sill plate. 2009 IBC Sections 1908.1.9 and 1908.1.10 or 2006 IBC Section 1908.1.16, as applicable. 1.6. The sill plate is 2-inch or 3-inch nominal thickness. ΦV = The lowest design strength of an anchor or anchor n group in shear as determined in accordance with ACI 318 2. For the calculation of the in-plane shear strength of Appendix D as amended in Section 4.1 of this report and anchor bolts attaching cold-formed steel track of bearing or 2009 IBC Sections 1908.1.9 and 1908.1.10 or 2006 IBC non-bearing walls of light-frame construction to Section 1908.1.16, as applicable. foundations or foundation stem walls, the in-plane shear strength in accordance with D.6.2 and D.6.3 need not be α = Conversion factor calculated as a weighted computed and D3.3.5.3 need not apply provided all of the average of the load factors for the controlling load following are satisfied: combination. In addition, α shall include all applicable factors to account for non-ductile failure modes and required 2.1. The maximum anchor nominal diameter is 5/ inch over-strength. 8 (16 mm). Table 8 provides an illustration of calculated Allowable 2.2. Anchors are embedded into concrete a minimum of Stress Design (ASD) values for each anchor diameter at 7 inches (178 mm). minimum embedment depth. 2.3. Anchors are located a minimum of 13/ inches (45 The requirements for member thickness, edge distance and 4 mm) from the edge of the concrete parallel to the length spacing, described in Tables 1 and 2 of this report, shall of the track. apply. 2.4. Anchors are located a minimum of 15 anchor 4.2.2 Interaction of Tensile and Shear Forces: In lieu of diameters from the edge of the concrete perpendicular ACI 318 Sections D.7.1, D.7.2 and D.7.3, interaction of to the length of the track. tension and shear loads shall be calculated as follows: 2.5. The track is 33 to 68 mil designation thickness. If T ≤ 0.2 T , then the full allowable strength in applied allowable,ASD Allowable in-plane shear strength of exempt anchors, shear, V , shall be permitted. allowable,ASD parallel to the edge of concrete shall be permitted to be determined in accordance with AISI S100 Section If V ≤ 0.2 V then the full allowable strength in applied allowable,ASD, E3.3.1. tension, T , shall be permitted. allowable,ASD 3. In light-frame construction, bearing or nonbearing For all other cases: walls, shear strength of concrete anchors less than or equal to 1 inch [25 mm] in diameter attaching a sill plate or track T /T + V /V ≤ 1.2 Eq. applied allowable,ASD applied allowable,ASD to foundation or foundation stem wall need not satisfy (4-4) D.3.3.5.3(a) through (c) when the design strength of the anchors is determined in accordance with D.6.2.1(c). 4.3 Installation: 4.2 Allowable Stress Design (ASD): Installation parameters are provided in Table 1, 2, 9, 10 and 11 and in Figure 1. Installation shall be in accordance with 4.2.1 General: For anchors designed using load ACI 318-11 D.9.1 and D.9.2. Anchor locations shall comply combinations in accordance with IBC Section 1605.3, with this report and the plans and specifications approved by allowable loads shall be established using Eq. (4-2) or Eq. (4- the building official. Installation of the AT-XP Adhesive 3): Anchor System shall conform to the manufacturer's printed installation instructions (MPII) included in each package unit T = ΦN /α Eq. (4-2) and as described in Figure 1. The nozzles, brushes, allowable,ASD n dispensing tools and adhesive retaining caps listed in Tables and 9 and 10, supplied by the manufacturer, shall be used along V = ΦV /α Eq. (4-3) with the adhesive cartridges. allowable,ASD n Page 4 of 18

Description: