Printing architecture: innovative recipes for 3D printing PDF

Preview Printing architecture: innovative recipes for 3D printing

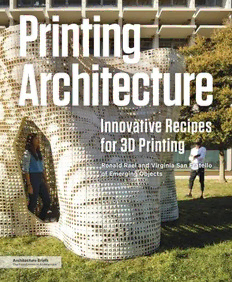

Printing Architecture Innovative Recipes for 3D Printing Ronald Rael and Virginia San Fratello of Emerging Objects Princeton Architectural Press New York 6 Foreword 9 Introduction Back to Mud Emerging Objects Dries Verbruggen, and Unnatural Unfold Materials 15 3D-Printing Methods 1 2 Salt Sawdust 18 32 C o nt 22 3D Printing with Salt 36 3D Printing with Sawdust e n and Newsprint ts 28 Objects 40 Objects 3 4 Coffee, Tea, Rubber 46 62 and Wine 66 3D Printing with Rubber 68 Objects 50 3D Printing with Coffee, Tea, and Wine Waste 52 Objects 5 6 Bioplastic Sand 72 96 76 3D Printing with Bioplastic 98 3D Printing with Sand 80 Objects 108 Objects 7 8 Cement Clay 114 138 s t n 118 3D Printing with Cement 142 3D Printing with Clay te n o 126 Objects 152 Objects C 9 Recipes 160 161 Liquid Binder 168 Acknowledgments 162 Powders 170 Project Credits 172 Notes 164 DIY Recipes 174 Image Credits Back to Mud Mud. Or, more specifically, a few dozen of 3D printing: the first is “Manufacturing PowerPoint slides of intriguing vernacular complexity is free.” Unlike in traditional man- mud constructions. That’s all that was need- ufacturing processes, where extra complexity ed for me to understand that the work of requires more expensive tooling, there is Emerging Objects was more deeply connect- no such penalty with 3D printing. And hence ed with our own discourse at Unfold than I we witness a flood of algorithmic designs had previously realized. While I was intimate- straight from the future that exploit this free- ly familiar with Ronald Rael and Virginia dom as if the objects were unbound by the San Fratello’s research on 3D printing archi- laws of physics, the limits of real-world mate- tectural components with sustainable and rials, or the age-old traditions and heritage F o locally sourced materials, I had somehow of making things. r e w o missed their shared, longtime fascination for But what Ron presented onstage was not r d earthen architecture. That is, until I sat down a story about elaborate computational design on the cozy chairs of the California College but a love story for the mundane material of the Arts auditorium in 2015 during the that is mud: how it is ingrained in the tradi- Data Clay Symposium, where Ronald and I tion of building worldwide, how “one half of each gave a presentation about our respec- the population lives, works, or worships in tive practices in architecture and design. buildings constructed of earth.” The story of In recent years we’ve witnessed an un- architecture for thousands of years has been paralleled explosion of creative expression the story of mud. And where clay or earth and experimentation with 3D printing—not has not been easily sourced, similar narra- only as a practical tool, but increasingly tives can be told with wood, rocks, or ice as a medium in its own right. A lot of media playing the lead role. It was at that point that attention has gone to the wild and often I understood that this love for the historic baroque geometric-form languages that have and contemporary use of earth in architec- been unlocked by the underpinning charac- ture is the root of Emerging Objects’ quest teristics of 3D printing. Hod Lipson described to find a role for new technologies while in his book Fabricated: The New World of respecting the codes of how we’ve been con- 6 3D Printing the ten fundamental principles structing our dwellings for ages—with locally sourced, renewable materials that possess to the act of bricklaying as possibly one of intrinsic, enduring architectural qualities: the oldest additive manufacturing methods. humidity regulation, structural stability, natu- The work of Emerging Objects has, since ral cooling, and so on. its inception, been mostly focused on binder Only a handful of slides in that presen- jetting 3D-printing processes that fuse a pow- tation were devoted to 3D printing, but for dered dry material. The company has been me they brought the story full circle, and the internationally recognized for pushing the lim- project shown—the Cool Brick masonry sys- its of this technique by introducing new ma- tem—is probably my favorite among the proj- terials into a normally closed-source machine. ects you’ll find in this book. The Cool Brick Since a 3D object printed with binder jetting provides passive evaporative cooling similar is always supported by the powder with which to how buildings were cooled in ancient it is constructed, this process offers some Oman before the advent of refrigeration, with of the greatest freedom of form of all 3D- a system called the Muscatese window, con- printing techniques. As such, it seems like a sisting of a porous ceramic jar sheltered from regression that Virginia and Ronald recently the sun by a wood mashrabiya latticework. started venturing into extrusion-based wet The design of the Cool Brick combines these clay printing, a process with much greater lim- d elements in a brick-size ceramic lattice that itations in regard to obtainable form freedom. or w absorbs moisture and cools the air that flows My studio, Unfold, developed this process re o F through its open structure. In a clever way, in 2009 out of an interest in bridging digital the Cool Brick exploits the benefits of Lip- manufacturing and the age-old clay-forming son’s first principle, “Manufacturing complex- technique called coiling. But judging by the ity is free,” while handily cycling around the impressive and rapidly developing body of pitfall of craftsmanship mimicking excessive work that Emerging Objects has gathered un- ornamentation that is so often associated der the moniker GCODE.clay, it certainly feels with 3D printing. In a final act, the individual as though using wet clay, with its intrinsic lim- bricks have been assembled in an unapolo- itations and quirky behavior, might be some getic way by setting them in mortar, alluding sort of a homecoming—a return to the mud. Dries Verbruggen With his partner, Claire Warnier, Dries Verbruggen leads Antwerp-based design studio Unfold. Together they wrote Printing Things: Visions and Essentials for 3D Printing. 7 In t r o d u c t io n 8