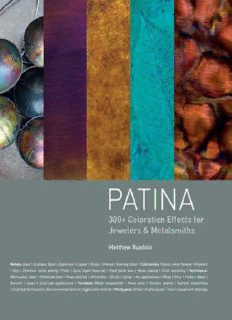

Patina: 300 Coloration Effects for Jewelers & Metalsmiths PDF

Preview Patina: 300 Coloration Effects for Jewelers & Metalsmiths

PATINA 300+ Coloration Effects for Jewelers & Metalsmiths Matthew Runfola Contents Introduction About this book CHAPTER 1 Metal coloration in context Coloration gallery CHAPTER 2 Safety, tools, and workspace Finishing studio layout Tools, equipment, and workspace CHAPTER 3 Aesthetic decisions The importance of the finish Observing Recording Color theory Comparing common metals CHAPTER 4 Choosing and controlling coloration methods Choosing a coloration method Comparing coloration processes Variables affecting colorations Metal surface protection CHAPTER 5 Surface preparation and colorant application Surface preparation: mechanical cleaning Surface preparation: chemical cleaning Preparing colorant solutions Heat oxidation coloration Immersion application: cold Immersion application: hot Brush application: cold Spray application: cold Hot application Wrap and bury applications Fume application Masking Burnishing Layering CHAPTER 6 Patination directory Steel Stainless steel Aluminum Copper Brass 230 and 260 Bronze 220 and 655 Sterling silver Colorant formulas Glossary Index Credits Suppliers Copyright Introduction In 2003 I was in my second year of what now has been a 12-year teaching position at the Evanston Art Center, located just north of Chicago, Illinois. The Metal Sculpture Department had a rebirth of sorts, and we were looking to expand the courses we offered our students. Most in our shop were working with fabricated steel and looking for finishing alternatives to rust, paint, or bare metal. I brought in Ron Young of Sculpt Nouveau to teach a ferrous metal finishing workshop at the school. This is how I became involved in the world of metal patination. For me, patination is the right balance of science and art and it satisfies my dual-minded persona. Though I trained as a mechanical engineer I decided to delve into art full-time to better fulfill my creative ambitions. I enjoyed playing “mad” chemist with the various colorants while applying them in a meaningful, artistic manner to my colorants while applying them in a meaningful, artistic manner to my objects. I immersed myself in the field: reading, sharing with other artists, and experimenting. For a time, metal patination was the most important part of my work. My fabricated forms were merely a vehicle or surface to display the colorations on. I became, and still am, a painter with chemicals. I love the ability to be expressive not just with the form, but with the finish as well. In 2004 I launched Runfola Studios, which focuses on patinated contemporary metal furnishings and accessories. MATTHEW RUNFOLA From above Color and color pattern take center stage on this wall hanging (90 × 42in/229 × 107 cm), transforming a static two-dimensional triptych into a flowing continuum. The use of masked and layered patinas, pigments, and dyes give visual depth and a sense of movement to the panels. Today, I continue to teach, create, exhibit, and sell both sculptural and functional objects and perform metal finishing services for other artists and artisans. I teach metal finishing workshops that focus on the fundamentals of the patination process, with methods to personalize the colorations to the object at hand. I hope I have achieved those same goals in this book. Happy patinating to you all! achieved those same goals in this book. Happy patinating to you all! About this book Structure Chapter 1: Metal coloration in context There are a multitude of different patination and coloration effects that can be applied to metals. This part features examples of work by the best jewelers and metalsmiths working with colored metals, and compares their methods and approaches. Chapter 2: Safety, tools, and workspace An in-depth discussion on the tools and equipment used for metal colorations, and how to set up a safe and efficient workspace. Chapter 3: Aesthetic decisions This chapter delves into the many factors influencing the metalsmith’s decision about what coloration to use. Chapter 4: Choosing and controlling coloration methods Numerous elements can influence the overall outcome of the coloration result within the basic process chosen. Runfola covers the variables that can be controlled, easily or not so easily, so the jeweler can obtain the overall look and feel he/she requires. The base metal composition and surface quality, the coloration and application methods chosen, and the final metal protection method are covered. Different coloration methods are compared in this chapter to enable choices to be made. Chapter 5: Surface preparation and colorant application This section discusses and compares the most common, accessible coloration techniques, including patinas, pigments, dyes, and heat tempering, with notes on durability of each finish. The core techniques for applying coloration to the metal surface are explained using large format step-by-step pictures. Health and safety is an important aspect of these techniques and precautions that should be taken for each technique are fully explained.

Description: