NASA Technical Reports Server (NTRS) 20150004111: Correlation of Electrical Resistance to CMC Stress-Strain and Fracture Behavior Under High Heat-Flux Thermal and Stress Gradients PDF

Preview NASA Technical Reports Server (NTRS) 20150004111: Correlation of Electrical Resistance to CMC Stress-Strain and Fracture Behavior Under High Heat-Flux Thermal and Stress Gradients

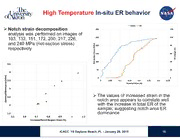

Correlation of electrical resistance to CMC stress-strain and fracture behavior under high heat-flux thermal and stress gradients Matthew Appleby* †, Gregory Morscher*, Dongming Zhu† *The University of Akron, Akron OH † NASA Glenn Research Center, Cleveland OH 39th International Conference and Exposition on Advanced Ceramics and Composites. Daytona Beach, FL January 29, 2015 Introduction (cid:190) Electrical Resistance (ER) monitoring has been shown as a tool for detecting room temperature tensile damage accumulation in woven melt-infiltrated (MI) SiC/SiC CMCs. (cid:190) However, under stress gradients and complex thermo-mechanical loading, mechanisms controlling contributions to ER change are still not well understood. (cid:190) In this study, experiments were chosen to explore the capabilities of ER as a relevant non-destructive evaluation (NDE) technique for testing under high- temperature thermal gradient conditions, with stress concentrations. (cid:190) To overcome the disadvantage of far-field in-situ ER measurement, notched samples provided a highly localized strain field in gage section for ER correlation (cid:190) Acoustic Emission (AE) measurements and Digital Image Correlation (DIC) were also performed to correlate with ER results ICACC ’15 Daytona Beach, FL - January 29, 2015 2 Experimental Material (cid:190) SiC/SiC CMC material (Hyper-Therm HTC) (cid:190) 8 plies, balanced 5 harness satin 2D woven 0°/90°, SiC/BN/SiC (cid:190) Hi-Nicalon Type-S fiber reinforced (cid:190) Produced by molten silicon melt infiltration (MI) (cid:190) Machined into 6 in. tensile bars w = 12.74 mm w = 12.82 mm (10.77 mm) (10.25 mm) t = 2.27mm t = 2.17mm f = 0.141 f = 0.147 High Temperature Room Temperature 0 0 DOUBLE NOTCH SINGLE NOTCH 1.22mm 1.05mm 1.97mm 1.29mm ICACC ’15 Daytona Beach, FL - January 29, 2015 3 Experimental Technique (cid:190) Specimens are loaded in uni- axial tension rig (cid:190) Digital Image Correlation (DIC) is used to determine localized strain fields (cid:190) Nominal strain measurements are taken from using a 25.4 mm extensometer with a ±0.5 mm travel (cid:190) High temperature testing: (cid:190) Face of specimen gage-section heated by a 3.5kW CO high 2 heat-flux laser (cid:190) Asymmetrical heating by laser generates thermal gradients (thru thickness and longitudinal) (cid:190) Thermal gradients can be increased by the addition of active back side air-cooling (cid:190) Front and back temperatures of the heated region are monitored by optical pyrometers ICACC ’15 Daytona Beach, FL - January 29, 2015 4 NDE Measurement Gripped (cid:190) Electrical Resistance (ER) region measured by four-point probe method (cid:190) In order to avoid high temperature exposure during laser heating, ER leads for in- Voltage situ measurement are Constant difference current to outer measured by Modal AE attached within the gripped electrodes inner Sensors areas electrodes (cid:190) Acoustic Emission (AE) sensors are attached ±40 mm from center (cid:190) Post-test ER “inspection” is performed by taking discrete Gripped measurements along the region specimen length ICACC ’15 Daytona Beach, FL - January 29, 2015 5 NDE Principles Modal Acoustic Emission Monitoring (cid:190) Fracture energy of solids released as elastic waves which are detected by the use of wide-band sensors in order to quantify stress-dependent cracking Modal AE initiation and accumulation. Sensors AE event (cid:190) Location of AE events estimated by the difference in arrival times of AE signals (cid:1874) (cid:1876) (cid:3404) (cid:1872) (cid:3398) (cid:1872) (cid:3029)(cid:3042)(cid:3047)(cid:3047)(cid:3042)(cid:3040) (cid:3047)(cid:3042)(cid:3043) (cid:884) Fiber/Matrix Electrical Resistance Measurement Debond Region (cid:190) Damage in the form of matrix cracks and associated fiber debonding/sliding increase the overall electrical Matrix Fiber resistance of the composite specimen (cid:190) Matrix cracking of MI SiC/SiC is especially sensitive due to the highly conductive matrix formed from excess silicon deposits left from processing ICACC ’15 Daytona Beach, FL - January 29, 2015 6 Room Temperature – Single Notch (cid:190) Post-test microscopy revealed high crack densities is the vicinity of the notch, as would be expected from locally increased stress. 8mm (cid:190) However, due to a large density of porosity, another localized Fracture plane strain field was produced, leading to the ultimate failure location Crack densities were therefore calculated for the notched region and the far-field regions -12.7mm < x < -5mm ± 5mm 5mm < x < 12.7mm Crack Density, 2.1 2.5 1.70 mm-1 (far-field/notch) (0.85) 1 (0.68) 1 mm ICACC ’15 Daytona Beach, FL - January 29, 2015 7 Damage Location (cid:190) Damage location determined from AE events in good agreement with DIC strain-field mapping of gage section at peak load σ = 324 MPa Notch Ultimate Failure Plane ICACC ’15 Daytona Beach, FL - January 29, 2015 8 Damage Growth: Notch vs Far-field (cid:190) Acoustic energy has been shown to be directly related to transverse matrix cracking in CMCs (cid:190) AE events separated by each region (cid:190) The cumulative energy was normalized in all regions by the total energy recorded in the notched region (± 5mm from mid-plane of specimen) (cid:190) The area around the notch shows increasing damage at lower stress and higher total energy released; which is in good agreement with AE/DIC location analysis ICACC ’15 Daytona Beach, FL - January 29, 2015 9 In-situ electrical behavior (cid:190) While the elastic region shows little increase, ER begins to increase rapidly with damage onset. (cid:190) The electrical resistance of the entire specimen increases over 500% with an increase in nominal strain of the gage section of 0.5% at failure. (cid:190) ER is monitored over the entire specimen showing both the contribution to localized and far-field damage (including all matrix crack and fiber sliding) (cid:190) However, as previously noted, the damage accumulation is Inner leads being dominated by the stress 25.4mm gage (measurement Outer leads distance = 121mm) concentration region ICACC ’15 Daytona Beach, FL - January 29, 2015 10