NASA Technical Reports Server (NTRS) 20110008749: Creep Behavior of Hafnia and Ytterbium Silicate Environmental Barrier Coating Systems on SiC/SiC Ceramic Matrix Composites PDF

Preview NASA Technical Reports Server (NTRS) 20110008749: Creep Behavior of Hafnia and Ytterbium Silicate Environmental Barrier Coating Systems on SiC/SiC Ceramic Matrix Composites

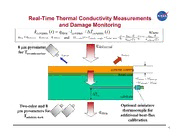

Creep Behavior of Hafnia and Ytterbium Silicate Environmental Barrier Coating Systems on SiC/SiC Ceramic Matrix Composites Environmental barrier coatings will play a crucial role in future advanced gas turbine engines because of their ability to significantly extend the temperature capability and stability of SiC/SiC ceramic matrix composite (CMC) engine components, thus improving the engine performance. In order to develop high performance, robust coating systems for engine components, appropriate test approaches simulating operating temperature gradient and stress environments for evaluating the critical coating properties must be established. In this paper, thermal gradient mechanical testing approaches for evaluating creep and fatigue behavior of environmental barrier coated SiC/SiC CMC systems will be described. The creep and fatigue behavior of Hafnia and ytterbium silicate environmental barrier coatings on SiC/SiC CMC systems will be reported in simulated environmental exposure conditions. The coating failure mechanisms will also be discussed under the heat flux and stress conditions. CCrreeeepp BBeehhaavviioorr ooff HHaaffnniiaa aanndd YYtttteerrbbiiuumm SSiilliiccaattee EEnnvviirroonnmmeennttaall BBaarrrriieerr CCooaattiinngg SSyysstteemmss oonn SSiiCC//SSiiCC CCeerraammiicc MMaattrriixx CCoommppoossiitteess Dongming Zhu*, Dennis S. Fox*, Louis J. Ghosn** and Bryan Harder* * Durability and Protective Coatings Branch, Structures and Materials Division ** Applied Structural Mechanics Branch, Mechanical and Fluid Systems Division NASA John H. Glenn Research Center Cleveland, Ohio 44135, USA TThhee 3355tthh IInntteerrnnaattiioonnaall CCoonnffeerreennccee oonn AAddvvaanncceedd CCeerraammiiccss && CCoommppoossiitteess January 23-28, 2011 1 Revolutionary Ceramic Coatings and Composites Impact TTuurrbbiinnee EEnnggiinnee TTeecchhnnoollooggyy – Advanced environmental barrier coatings and SiC/SiC CMC combustor and turbine airfoil component technologies are being developed for reduced cooling and NO emission under NASA programs x – Next generation environmental barrier coating-CMC development require more sophisticated laboratory testing to simulate turbine engine temperature and stress environments Instability CMC Control Fuel Liners Staging Multipoint Injection Low emission combustor Advanced core technologies – HPT first stage CCMMCC vane wiitthh siigniiffiicanttlly redduce coolliing requirements 2 NASA Environmental Barrier Coating – CMC System DDeevveellooppmmeenntt:: TTeemmppeerraattuurree aanndd SSttrreennggtthh GGooaallss • Emphasize temperature capability, performance and durability requirements • Help fundamental understanding, database and design tool development • Increase the coatingg Technologgyy Readiness Levels for enggine apppplications Current NASA Program Goals Step increase in the material’s temperature capability TTeemmppeerraattuurree - 3000°F* SiC/SiC CMC combustor and turbine vane CCaappppaabbiilliittyyyy ((((TT//EEBBCC)))) ssuurrffaaccee EEBBCC ((2200-3300kksii****)) 3000°F+ (1650°C+) 2800°F+ TRL5-6 - 2800°F* ERA combustor EBC Combustor 2700°F (1482C) TBC (APS) - 2700°F* SiC/SiC CMC blade IInnccrreeaassee iinn TT EBC ((30-50ksi**)) aaaaccccrrrroooossssssss TTTT////EEEEBBBBCCCC 2500°F - 2600°F* ERA turbine vane EBC Turbine TBC (EB-PVD) CCeerraammiicc MMaattrriixx CCoommppoossiittee 2400°F (1316°C) TRL4 SSSSiiiinnnngggglllleeee CCCCrrrryyyyssssttttaaaallll SSSSuuuuppppeeeerrrraaaallllllllooooyyyy 2000°F (1093°C) GGeenn.. IIVV GGeenn IIIIII GGeenn IIII ––CCuurrrreenntt ccoommmmeerrcciiaall Challenges: GGeenn II YYYYeeeeaaaarrrr * Recession: <5 mg/cm2 per 1000 hr (40-50 atm, Mach 1~2) ** Component strength and toughness requirements 3 Outline ─ Advanced creep and fatigue testing development for environmental barrier coating – CMC systems • Higgh heat flux thermal fatiggue test rigg – ppast expperience • New heat flux mechanical test rigs • High heat flux tensile creep rupture rig • High heat flux ball-on-ring creep/fatigue test rigs •• FFEEMM aannaallyyssiiss aanndd mmooddeell vvaalliiddaattiioonn ─ Creep testing of candidate model environmental barrier coating systems for SiC/SiC CMC airfoils and combustors • YYtttterbbiium siilliicatte • HfO and HfO Rare Earth Aluminosilicate EBCs 2 2 • The coating degradation and delamination under thermal cycle and creep conditions ─ Preliminary failure mechanisms and modeling ─ Summary 4 Laser High Heat Flux Approach – Turbine level high-heat-flux tests crucial for CMC coating system developments • Existing high heat testing High power CO laser high-heat-flux rig (up to 315 W/cm2) 2 Turbine: 450°F across 100 microns Combustor:1250°F across 400 microns Heat flux e c a f T r u s m o rr f e c n a t s i D TTeesstt rriigg cooling 5 Real-Time Thermal Conductivity Measurements aanndd DDaammaaggee MMoonniittoorriinngg k (t) q l / T (t) ceramic thru ceramic ceramic Where qthru qdelivered qreflected qradiated and Tceramic(t)Tceramicsurafce Tmetalback 0lbond kqthru (Tdl) 0lsubstrate k qthru d(lT) bond substrate q 8 m pyrometer delivered for T ceramic-surface q q reflected radiated ceramic coating bond coat TT TT q ceramic measured thru T T substrate bond T ttcc subbsttratte Optional miniature Two-color and 8 thermocouple for m pyrometers for qq tthhrruu additional heat-flux T substrate-back calibration 6 Typical Thermal Cyclic Behavior of EBC Systms – Sintering and delaminations of coatings reflected by the apparent thermal conductivity changes 2.0 CCyycclliicc TTeessttiinngg ooff 8YSZ/mullite/mullite+20wt%BSAS/Si on SiC/SiC: K T 1482°C/T 1175°C - surface interface m / WW 11.5 Steady-state , y t i v i t c Steady-State Testing of 8YSZ/on Rene N5 u dd SSuperalllloy: n o T 1371°C/T 1163°C surface interface c 1.0 l a m r ee h T 0.5 00 1100 2200 3300 4400 5500 Time, hours 7 Delamination in a High Heat Flux Thermal Cycling CCoonnddiittiioonn M TTrraannssiieenntt TTeemmppeerraattuurree E , h 11660000 P 1 1 11550000 delamination crack SSuurrffaaccee interface EEvvaannss aanndd 1111444400000000 IIIInnnntttteeeerrrrffffaaaacccceeee CC CCrraacckk OOppeenniinngg SSuurreeffaaccee E2,2 Hutchinson model, ooure, ure, 11330000 TT==~~550000˚˚CC Surface Coating atat11220000 erer Technology, 2007 pp mm11110000 TeTe G111EhT T 2 11000000 61 1 1 S 0 1 990000 880000 Temperature, oC 1467 oC 1315 oC 00..0000 00..0055 00..1100 00..1155 00..2200 TTiimmee,, sseecc CCCCrrrraaaacccckkkk EEEExxxxtttteeeennnnssssiiiioooonnnn FFFFoooorrrrcccceeee GGGG aaaassss aaaa ffffuuuunnnnccccttttiiiioooonnnn ooooffff ttttiiiimmmmeeee 11006666 ooCC ffoorr 22..00mmmm hhaallff ddeellaammiinnaattiioonn lleennggtthh aanndd ccrraacckk ddeepptthh ooff 00..0088mmmm a)a)a) 88..00 333222 a)a)a) PPP PPP GGG GGG 000 77..00 222888 000 55522 000 ~~~mm 222 force (E=force (E=force (E=ng ng ng orce G, J/orce G, J/n Fn F 565644......000000 111222222666404040 orce (E=~orce (E=~orce (E=~g fog fog fo on drivion drivion drivixtensioxtensio 33..00 44mmmm ddeellaammiinnaattiioonn lleennggtthh 111222 n drivinn drivinn drivin nsinsinsik Ek E 22..00 888 siosiosio eeecc nnn ck extck extck extCraCra 11..00 444 k extek extek exte aaa ccc CrCrCrCCC 0000..0000 000000 rararaCrCrCr 00..0000 00..1100 00..2200 00..3300 00..4400 00..5500 TTiimmee,, sseecc The FEM model 8 Experimental: HHiigghh-HHeeaatt-FFlluuxx TTeennssiillee CCrreeeepp RRuuppttuurree TTeesstt RRiigg - Integrated with a High Power CO laser system 2 - Allows very high temperature, high heat flux cooled thermal gradient testing uunnddeerr ttuurrbbiinnee bbllaaddee ssttrreessss ccoonnddiittiioonnss, aanndd LLoonngg-tteerrmm tteessttiinngg ccaappaabbiilliittyy - Accommodates conventional 6” tensile dog-bone and also other configuration specimens - Specifically designed for CMC turbine airfoil system development Laser beam delivery optic ssyysstteemm CCoooolliinngg sshhooweerr head jets High temperature extensometer Test specimen 9