Ms. Ann Kehoe, Administration Officer, Office of Licence & guidance, Environmental Protection ... PDF

Preview Ms. Ann Kehoe, Administration Officer, Office of Licence & guidance, Environmental Protection ...

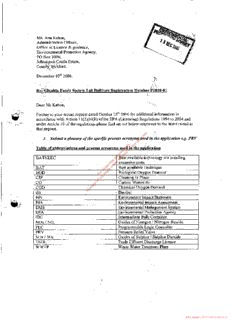

Ms. Ann Kehoe, Administration Officer, Office of Licence & guidance, Environmental Protection Agency, PO Box 3000, JohnstykCastle Estate, County,. %exford. December IOth 2006. f e. us er h ot oses eodn lfy.or any BATNEEC ectionw npeurr rpeBeqxeuicrset sasvivaiel acbolset st echnology not entailing BBOADT For inysripght o BBieoslto agvicaailla Oblxey Tgeecnh Dnieqmuea nd CCCTOOPD o n s e n t of cop CCCahlereabmnoiincn agMl IoOnn xPoylxagicedene Demand C dB Decibel EIS Environment Impact Statement EIA Environmental Impact Assessment EMS Environmental Management System EPA Environmental Protection Agency IBC Intermediate Bulk Container Oxides of Nitrogen / Nitrogen dioxide PLC Programmable Logic Controller PRV Pressure Relief Valve sox/ so1 Oxides of Sulphur / Sulphur Dioxide TEDL Trade Effluent Discharge Licence WWTP Waste Water Treatment Plant EPA Export 25-07-2013:20:54:11 i 2. Resubmit and claria all the information on emissions to surface waters and emissions to sewer, as SW3 is indicated on the Environmental Emissions Points map as a surface water discharge and it is indicated in Table E.2(i) as a discharge from the waste water treatment plant. Table E.2 (i) is resubmitted as Attachment E and suitable scaled drawings are also submitted. 3. Complete the section ‘available waste assimilative capacity’ in Tables E.2(i) Emissions to Surface Waters Table E 2 (i). is completed and see Attachment 1.2.1 for explanatory notes on assimilative capacity in the River Gresse. 4. Complete tables G. I (ii) indicating if each material /substance is List I or List I1 under the Dangerous Substances Directive (76/464L?EC) ‘ 6 3 Table G. 1 (ii) is complete as attachment G i 5. Complete Tables H. I(i) and H. I( io. e. us Tables H. l(i) and H. l(ii) are complete as attachmenth eHr ot 6. Provide a copy of all relevant waste permosiets seo fdn lofy.orr a wny aste contractors used on site. Ain ccloupdye do.f all relevant waste permeicttiso fnw onpeurrr rpweqauisrte contractors used on site is also 7. Submit appropriately scaledF Oor irnysdripnghta once Survey maps showing the location of the off sAit esc sallueddg oer sdtnoarnacgee suu n r iv to e sn sy a e nm tn odfa pcloa pins ds usbpmreiattdeidn gsh aorweainsg ( et.hge. aIr:e 1a0s 0o0f 0la anndd s Ip:r e5a0d0i0n0g) a. nd C off site sludge storage. 8. Complete Table 1.4(i) Groundwater Quality and provide details on groundwater quality, impacts of activity on groundwater quality and mitigation measures to protect groundwater. Provide detaiIs of the impact of historic incidents on soil and groundwater quality, including results of intrusive investigations carried out. The sites operations / activities do not discharge emissions to ground water. The storage of all chemicals is in appropriately sized storage areas. The working stock of chemicals is stored on various mobile bunds through out the plant, and these locations may vary dependent on the activity of the operation. Hydrocarbons used for maintenance on plant and equipment are typically sourced in 251t containers which are stored in mobile bunds prior to use and after use. As part of the EMS on site regular checks are in place to monitor all of the bunds. In quarter one of 2006 a new diesel interceptor (class one) was installed as part of the EMS. The main surface water drains from the entrance, car park and truck refuelling area all flow through this diesel interceptor. Daily inspections are carried out and recorded to monitor the discharge. EPA Export 25-07-2013:20:54:11 As part of the process for securing planning permission for altering the site to facilitate increases in production capacity the site completed an EM. This was completed in 2003. Analysis of the ground waters was completed by an external professional body, Minerex Environmental Ltd. There was some evidence of hydrocarbon located as indicated in the attached report; however the findings of the report clearly stated that these levels did not merit any further investigation or remediation work. The likely source of the material was thought to be the washing of vehicles. This activity no longer takes place is this area. A copy of the report is also included in Attachment 1.2.1 9. Provide details of measures used on site to mitigate against noise. Also submit a copy of the recent noise survey conducted in February 2006. The noise audit carried out in February 23rd/24*2 006 is submitted. Electrical power supply units for the operation of refrigeration units on delivery vehicles and trailers have been installed. The noise generated by refrigeration systems on the delivery fleet operated with electricity as the power source is lower than the same equipment operated with diesel as the power source. This measure has reduced the noise generated by this activity. e. us Extract fans which for operational reasons may not bheer switched off have been fitted ot wapipthr otipmrieartse ttoo trhede uaccet iovpiteyr asotimnge heoxutrrasc atinodons ea sf saeosdnn lofys.ocr aiaarntey e sdw niotcishee lde ovfefl.s and also where Aan dF ufrotlhloerw ninogis teh .es uoruvtecyo wmiell obfe t hcaatre rcstiiueonrdw vnp eouerr urypet qa ubipryp rqouparritaetre t pwroo g2r0a0m7m toe sm woinlli tboer ndoeviseel olepveedl s should they be required. For inysripght o 10. Sthueb ampipt laic Watiaosnte. Dis p o so na s l e np t r ofo ccoepduref or Glanbia Dairies, Ballitore as referenced in C The procedure for waste disposal is submitted in attachment H. “Q 11. Submit a revised site layout plan indicating the locations of the waste management and storage areas referred to in the application (Attachment m. A revised site layout plan is submitted indicating areas of waste management and storage of waste prior to collection is attached with this response. 12. Indicate the source of water used on site. If the source of water is groundwater well supply details of the abstraction capacity. The source of water used by the activities on the sites is from groundwater well and from municipal authorities (Kildare county council). Water sourced from the municipal authority is primarily used for the amenity block and canteen. However it may also be used in the processing of milk in the event of disruption to normal supply. Groundwater well is the principal source of water used on site. Currently there are two boreholes on site, with BH - 01 located at E279720 / N196094 and BH- 02 located at E279720 / N196094. The pumping capacity of BH - 01 is at a rate that varies between 325 and 432m3/d. The pumping capacity of BH - 02 is at a constant rate of 345.6m3/d.F rom pumping EPA Export 25-07-2013:20:54:11 tests it is concluded that at present a combined sustainable yield of approximately 670m3/day is obtainable from both wells. 13. Submit a copy of Attachment 1.2.1 referred to in section 1.2 of Attachment I but not submitted as part of the application Attachment 1.2.1 is attached 14. With regard to nutrient management submit details of fertiliser Nitrogen and Phosphorous requirement for each land parcel. Indicate the contribution of the slurry and sludge to thisf arm. Confirm that the land used is appropriately sized to deal with the land spreading of all sludge’s from the activity. The nitrogen requirement for each land parcel is set at 170 kg / ha as part of the regulation (Good Agricultural practices for the Protection of Waters) SI 378 of 2006. The phosphorous requirement for each land parcel has been determined by soil analysis carried out by Teagasc during July and September of 2006. The Teagasc soil analysis report for each land parcel is included in the original IPPC application. The values and amounts of phosphorous are given under the heading of “Nutrient required” kg / ha and the appropriate amount of fertiliser as determined by Teagasc. The amount of farm slurry returned to the land is deriveusde. from the guidelines issued by the Department of Agriculture and Food in their pheur blication issued in 2006. It ot tTshthaete ea qsm utohaunatnt itct yao tfot lffea droamfi r osynl uselr turoyd gtrweet’ous ryinsee aedrx stp ooe lctdht eegd oels aetnson eeod dnrb l afyei.otsr e aaa np0ny p.t2ri6coimxpia3mt e/a dwte teloye 4k10 4p60a g0m et3o 2 np2ne. erT sa hanennrdue fmboa.r see d oacnc tehpet cthaelc quulaatniotintise sin o tfa sbllued Ig.4e(’isi )f reioctt imiosnw npbtehurer replei qeauvicrteidv itthieast tohfe t hlaen adp pisl iacpapnrto. priately sized to 15. Resubmit Table I.4(iQ and cFoor minyspriplgeht toe columns ‘Volumes of on farm slurry returned c(aidlc u/hlaat)i’o nasnf do r‘ Ethseti J m i g a o u tn ser ee d n ts P o fs cihnoop wonn f. aIrnm a dslduirtrioy n( ckogm Pphleat)e ’. TParbolvei Id.e4 (siaom foprle N itrogen. I Table 1.4 (ii) is submitCted in attachment 1.2.1 16. Provide details of measures to be taken to ensure compliance with the requirements I of the European Communities (Good Agricultural Practice for Protection of Waters) regulations 2006 (S.1 3 78 of 2006). Dairy Sludge’s are spread in according to the requirements of (Good Agricultural Practicef or Protection of Waters) regulations 2006 (S.I. 378 of 2006). The guidance for the spreading of the dairy sludge’s has been taken from the explanatory handbook issued by the Department of Agriculture & Food issued in November 2006. The guidance book details appropriate measures to be taken when spreading on pages 13 and 14. These measures included the following: Spreading of sludge’s must be completed evenly and as accurately as one can. One must not spread use an up ward facing plate or sludge irrigator on a tanker or umbilical system for spreading organic fertiliser or soiled water. One must not spread organic fertiliser or soiled water from a road or passage, even if the passage or road is on ones holding. One must not spread chemical fertiliser, livestock manure, soiled water or other organic fertilisers when: EPA Export 25-07-2013:20:54:11 The land is water logged The land is flooded or likely to flood The land is frozen, or covered with snow. Heavy rain is forecast within 48 hours (one must check with Met Eireann). One must not spread chemical fertilisers, livestock manure, soiled water or other organic fertiliser if the ground has steep slope and if there is a significant risk of causing pollution. When one is deciding whether there is a risk, one must take into account how close one is to waters, what condition the soil is in, the ground cover and how much rainfall there is or how much rainfall is expected. One must not spread chemical fertiliser on land within 1.4 metres of a surface watercourse. Buffer Zones for spreadinv organic fertilisers e. us er h ot oses eodn lfy.or any ectionw npeurr rpequir For inysripght o o n s e n t of cop C An updated non technical summary is also included as Attachment A. Kind Regards, Yours sincerely, Quality & Environme/tal Manager EPA Export 25-07-2013:20:54:11 Glanbia Foods Society Ltd Ballitore Dec 2006 IPPC Documentation Attachment A- 1 Non Technical Summarv Attachment A: e. us er h ot oses eodn lfy.or any ectionw npeurr rpequir For inysripght o o n s e n t of cop C Glanbia Foods Society Ltd. Ballitore Page 1 of6 EPA Export 25-07-2013:20:54:11 , Glanbia Foods Society Ltd Ballitore Dee 2006 IPPC Documentation Attachment A- 1N on Technical Summary Non technical Summary of IPPC Licence Application A non technical summary of the application is to be included here. The summary should identify all the environmental impacts of significance associated with the carrying on of the sites activities and the mitigation measures proposed or existing to address these impacts. This description should also indicate the normal operating and days per week of the activity. The installation and its activities, The applicant Glanbia Foods Society-Ltd here after maybe referred to (Glanbia Consumer Foods Ballitore) is located in Ballitore county Kildare. The plant is located on the eastern outskirts of the village At the Ballitore plant Glanbia Foods Society operates a liquid milk processing and packing facility. The site serves as part of two separate stand alone business entities. The other business entity is the grain trading operation and agribusiness sales and retail outlet. This licence application relates to the processing of milk (clause 7.2.1 of the standard). The applicant wishes to draw the agency’s attention to the planning permission e. pertaining to the site. us er h ot t“hAe sf aspceilciitfyi epdla innn tihneg o preigrminiasls iaopnp lwicaast isoonu tghhet aagnedn coyb tsaohsieons ueeodnld ldf yf.o rrn aoonmyt e Kthialdt adruee c toou an ptyl acnonuendc iel xipna Jnasniouna royf 2dW0ish0c4ihl sa(trr tgehfee # tso i0 tte3hs /e c 4Ra8pi0vae)c.r i tTyG hareen pedls aepn ltanoni n6t g0h0 pames r3nm ooitfs yseieefoctftn ilbou ngew enperneunarr trpn eautqnepuidrd g arIla5ldo0ew mds 3ftho oer f p asl aupnrrofnajiecncegt ewpdea rtiemnrc irsresuianos neo foisf f preeeflrfel uvdaeannyt.t and has not expired”. For inysripght o iTnh oer r gaewn emraatteedri ablys tahned i nasu t x a C i lo l ln i sa a e t nr t i yo of ncmo paterials, other substances and the enerw used Raw Materials The primary raw material used on site is milk for processing. Additional raw materials used on site include fuel for the boilers, waste water treatment chemicals, packaging and cleaning chemicals etc. Energy Usage The energy usage at the plant is approximately 6,000,000 Kwh of electricity to power the plant on annual basis. The duty boiler is fired on marked gas oil (may use alternatives fuels based on economic reasons) and uses an estimated 41 6,000 1o f oil per annum. There is approximately 130,000 m3 of water consumed at the plant per year for the purposes of washing. All energy usage is monitored electronically. The sources of emissions from the installation Emissions to the atmosphere Page 2 of 6 EPA Export 25-07-2013:20:54:11 Glanbia Foods Society Ltd Ballitore Dec 2006 PPC Documentation Attachment A- 1 Non Technical Summarv There are two boilers on site and these boilers are used for steam generation. Boiler Al-1 is the duty boiler and boiler A1-2 is the stand by unit. Each boiler has its own stack and as such there are boiler emission points. ‘ Emissions to surface waters Uncontaminated storm water is diverted to surface waters via surface water drains. The receiving surface water is the River Greese labelled SWl , SW2, & SW3. Waste water produced from the plant operations is diverted to the on site waste water treatment plant. The waste water is treated prior to discharge to the River Greese labelled SW 4. This is a licensed activity carried out in agreement with Kildare County Council. Emissions to Sewer Emissions from domestic toilet usage on site flow directly into the locd authority sewage network labelled SEI. Domestic sewage is generated from a site population of approximately one hundred and fifty people. Emissions to Ground Dairy effluent sludge is produced as a by product of the treatment of waste water on e. site. The waste water is recovered to agricultural land by luasnd spreading. The sludge is er spread on a suitable land bank in Kildare and surroundoitnhg counties. This is carried out in agreement with Kildare County council. oses eodn lfy.or any The conditions of the site of the instaecltiloanw tnpieuorr rpneq.u ir dTehvee tlootpaeld a.r ea of the site is 5.98 heFocr itanysrripeghst oof which 2.64 hectares are currently The nature and quantiti e s oo n f s e f n to orf ecospeeable emissions from the installation into each medium as well as identificC ation of significant effects of the emissions into the environment The main atmospheric emissions from the plant arise from the boilers. Boiler Al-1 has a steam output of 2800 kg / hr and boiler A1-2 has a steam output of 2400 kg / hr. Both stacks produce inter alia sulphur dioxide, oxides of nitrogen, particulate matter and carbon monoxide. The BAT guidance notes do not specify specific emission limits for combustion gases for boilers. However analysis carried out conclude that the emissions conform to the TA Luft Standard. Emissions to Surface Waters A maximum of 70m3 of storm water is discharged on a daily basis, however this is weather dependent. The water is uncontaminated and as such there are no significant effects of the emission on the environment. Waste water is produced from the various activities on site and a potential volume of 440 m3 is discharged on a daily basis. The waste water from the operation is treated separately to comply with the existing emission limit values as specified in the Trade Effluent discharge licence. Page 3 of 6 EPA Export 25-07-2013:20:54:11 Glanbia Foods Society Ltd Ballitore Dee 2006 IPPC Documentation Attachment A- 1 Non Technical Summary Emissions to Ground 1400 m3 approximately of dairy sludge is generated at Glanbia Foods Society Ltd Ballitore and land spread in 2005. The sludge is a by product of the waste water treatment process on site. The sludge is processed in accordance with a nutrient management plan, the code of practice of Good Agricultural Practice and other relevant legislation and guide lines. Compliance with these guidelines and legislation and the use of a nutrient management plan ensures there are no significant effects of the emission on the environment. The proposed technolow and other techniques for preventing or where this is not possible emissions from the installation. - Waste water treatment plant @ The waste water treatment plant ensures compliance with the existing Trade effluent Discharge licence. The flow is balanced in the balance tank and the removal of oils fats & greases is effected by the dissolved air floatation unit. The plant incorporates e. the use of a two stage activated sludge process to reduce BuOs D levels, dosing of er alumimum sulphate to reduce phosphorous levels and aotnh anoxic tank to reduce nitrate levels and a de watering press to increase the odsers yeo dn mlfy.ora atntye r content of the sludge. tBChooamti ltebhrues setimonis seifofinc ioefn fclyu ete gsatisnegs coaf utFhsoree i nnybsriopoge hcitts iloeoignwr npsneu rr iirpfseiq ccuiaronntd eufcfteecdt oonn tah ree egnuvlairro bnamsiesn tto. ensure bWv htehree i nnestcaelslsaatrioyn, m easur e s o fn so e nr t otf hcoep prevention and recovery of waste venerated C Both hazardous and non hazardous waste streams are produced at the site. Hazardous waste includes waste oils, light bulbs, inks, chemicals and batteries. Waste oils, light @ bulbs & inks are recycled and waste chemicals are disposed of in a responsible manner by a licensed operator. Non hazardous waste includes paper, cardboard, wooden pallets and general refuse. To minimise waste re use loops of cardboard are used where possible with suppliers, plastic and cardboard is baled on site recycled on site by a licensed operator. General refuse is collected by a licensed operator and disposed to landfill. Waste water sludge is dewatered and recovered by agricultural land spreading by an appropriated licensed third party operator. Waste by products (internal product loss / product returns) are used for hrther processing at other milk processing facilities. Further measures planned to complv with the veneral principles of the basic obligations of the operator Page 4 of 6 EPA Export 25-07-2013:20:54:11 Glanbia Foods Society Ltd Ballitore Dec 2006 IPPC Documentation Attachment A- 1 Non Technical Summw i. All the appropriate preventative measures are taken against pollution, in particular through application of the best available techniques. The BAT guidance notes on the Best Available Techniques for the Food Sector (EPA draft June 2006) were reviewed to ensure that the appropriate preventative measures were taken against pollution. Water and energy consumption are monitored to ensure efficiency. Emissions to atmosphere and to water are minimised and the protection of ground water and surface is achieved through the best available techniques. Consideration is given to BAT at all stages of the activity at the site, in relation to specific unit operations, cleaning, treatment abatement and disposal, emission limit values and compliance monitoring ii. No significant pollution is caused No significant pollution is caused by the activities conducted on site. r-- Q iii. waste production is avoided in accordance Council Directive 75/442/EEC of July 15 1975 on waste; where waste is produced, it is recovered or, where that is technically and economically impossible, it is disposed of e. while avoiding or reducing any impact on the enusvironment; er h ot dWisapsotes eisd porfe ivne annte edn wvihreornem peonstsailbllye raensdp omnisnibimleoi smsese eoaddn ln fyw.onr eahnrey bny p rliocdeuncseedd, argeecnytcsl.e d or iv. energy is used efficiently ectionw npeurr rpequir Glanbia Foods Society Ltd BallitoFroer i onysrippgeht roates a benchmarking exercise in relation to a wwaidteer ncuomnsbuemr opft ipoenr.f Torhmisa pn r c o e m o in sno e d nt t e i ocsf actothpoer se fafdicdireensts iunsge eolfe cetnreicrigtyy ,a ftu tehle c sointes.u mption and C v. The necessary measures are taken to prevent accidents and limit their consequences; A preventative maintenance programme operated on site; it outlines the essential is maintenance required on the site. The planned is reviewed regularly by the site management team. Standard Operating Procedures are also in place for the various activities onsite. The use of a preventative maintenenance programme and standard operating procedures minimises the possibility of accidents and limits their consequences. In the case of an emergency, Glanbia Foods Society Ltd Ballitore has produced an emergency Preparedness Plan. The plan details the types of potential emergencies, the organisational structures, roles and responsibilities of the relevant parties, communications emergency response process, emergency response plans and emergency shut down of the plan. vi. The necessary measures taken upon definitive cessation of activities to avoid any pollution risk and return the site of operation to a satisfactory state. r Page 5 of 6 EPA Export 25-07-2013:20:54:11