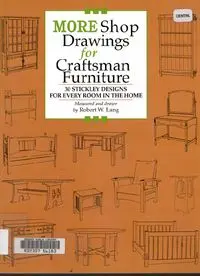

More Shop Drawings for Craftsman Furniture: 30 Stickley Designs for Every Room in the Home PDF

Preview More Shop Drawings for Craftsman Furniture: 30 Stickley Designs for Every Room in the Home

MORE SHop DRAWINGS for CRAFTSMAN FURNITURE MORE Shop Drawings For Craftsman Furniture {30 Sibley Design for Every Room in the Home (© 2002 by Robert W. Lang All sights reserved [No part of this Honk may be reproduced or tannin in any fm ot by any means, cleconc of mechanic ‘aca photcoping, contigo by any infrmatin storage ad etic stem, wot writen permiion ‘om the pblher cpt the nclaion of rq in ve ISBN 1-892836-14-9 First printing: October 2002 ‘Second printing: March 2004 Published by ‘Cambium Press PO Bax 909 Bethel, CT 06801 203-778-5610 Library of Congress Cataloging-in-Publication Data Lang, Robert W. 1953- ‘More shop drawings for Craftsman furniture: 30 Stickley designs for every room inthe home “/roeasured and drawn by Robert W. Lang. pom. Includes index. ISBN 1-892836-14-9 (al. paper) 1. Puriture—Drawings. 2. Measured drawings. 3. Ars and crafts movement. I. Title TT196 .L3497 2002 684.104—de21 2002151911 [Your safety is your responsibility. Neither the author nor the publisher assume any responsibility for any injuries suffered or for damages or other losses incurred that may result from material presented in this publication. DEDICATION 1 would like to thank my wife Joyce and my son Hunter for their patience, ive, and sup- pore during this work. They ae the ones who ‘dd the hard work, and Tam truly grateful to them as wel as for them CONTENTS INTRODUCTION 8 About the drawings 9 Construction Techniques ‘Making the quadralinear leg 10 Teinery deta B ‘Dust Panels 15 Glass doors 15 Laying et end making pts 16 non ig 7 Auembly 9 Upholstery 20 Index 144 No. 552 Gate Leg Table 28 No. 624 Hexagonal Table 32 ial No. 353 Side Chair No. 353A Arm Chair 36 No. 336 No. 347 Bow-Arm Eastwood ‘Morris Chair 80 Chair 72 kK a No, 1292 No. 323 oy Rocker 76 Liprary & DEN page 117 Ty No72 Harvey Elis 2 Maguzine Stand No.74 we Bookrack with Keyed Tenons 118 No. 644 Open Bookcase 120 | ry Noss7 TL Table 131 Limbert Lamp Table 141 ‘Mons Sor Daawines vox Cearrsway Furstrune INTRODUCTION ‘Two years ago, on a perfect Indian-summer aftemoon, Publisher John Kelsey and met to decide which pieces of furniture to include in my first book, Shop Drawings for Crafsman Farnitare. We had spent the morning at an auetion of genuine Craftsman pieces, ad had enjoyed lunch at the Hancock Shaker Village in western Massachusetts. It was a fiting place fr us to meet, for it was here that Ejne Handberg had measured the furniture for his books of drawings of Shaker furniture. “Handlerg’s work had a tremendous influence fon me as a beginning woodworker, and the thought that somebody should do a similar ‘book on Craftsman furniture led me to ereate sy fet book. ebecame immediately apparent that the task ‘was not to decide what pieces to include, but ‘what pieces to lave out. Thad been through the reproduction catalogs and other sources, picking what I thought were good examples ofthe style. arrived witha list of more than ‘wo hundred pices that I thought worthy of inclusion. Kelsey had his own favorites, and there were some pieces at the auction that ‘neither of s had seen before. From this col- lection of about two hundred and fifty excel- lent examples of furniture, we figured that about sixty pieces would make a good book. ‘We decided to group the furniture in cate~ gories: bedroom, dining room, living room, Tibeary or den, By the end of the afternoon, we had the lst down to around one hundred pices of furni- ture, and I made the final cut to sixty some~ thing over the next few weeks. It was difi- ‘alt. The final choices were based on what I ‘personally liked, and when I couldnt make a ‘decision, on what my wife liked, A project like this cart be exhaustive. My aim was to show enough examples of enough different types of furniture for the reader to Ivrnopuerion get good grasp ofthis style of furniture, and to be able to apply the construction tech- niques to other projects, be they reprodue- tions, adaptations, or entirely new designs. [As Tworked on the drawings and the tex for the frst book, we soon realized that there ‘was simply more good material than one ‘book could hold. We decided to divide the ‘material into two volumes. ‘This doesnit mean thatthe pieces of farni- ture included in thie volume are also-rans to the pieces in the first book. The process of choosing sity good examples was difficult cnough, but splitting that group in half was ‘even harder. In many cases, the fip of coin decided which piece went first. Inthe end, 1 ‘think tha cis grouping is equal to or better than the one in the original book. I invited visitors to my website to miggest pieces that they would like to see inched in this or furure works, and nearly all of the sugges tions I received were already on my list. ‘The text portion in this book is also @ con- tinuation ofthe first book, along with some ‘material inchided as a result of questions that wwe have received, The reader who by chance thas picked up this book first needs to know that there is some important material in the first volume, which does not reappear here. "The firt book includes a detailed explana- ‘tion of how to interpret and work with these drawings, techniques for making common joints, and an introduction to material. This ‘book Focuses on assembly techniques, joinery techniques, and upholstery. ‘The legacy of Gustav Stckley provides us ‘with much more than the opportunity t0 reproduce excellent examples of furniture design. As Ihave studied his work and writ- ings, [have also found a wonderful example of the profound importance of the way that wwe perform our daily work, and the impor- tance of working with something genuine, something that will carry the effort we put into it well beyond our passing. Its my hope that the current interest inthis furniture will spark a renewed interest in the philosophy and moral values that led to its original ere= akon. In much the same way that Craftsman furniture can fil a need in our homes, the Craftsman philosophy can also fill need in cour lives. ABOUT THE DRAWINGS ‘A few reminders about the drawings are in ‘order, Firs of ll, we have given all measure- ‘ments in inches and fractions to the nearest sixteenth, followed [in square brackets] by the exact metric equivalent, down to tenths cof millimeter This allows the metric work cr todo his own rounding up or down, to the degre of precision he finds most comfort- able, Dimensions in the drawings are for overall sizes, openings, and exposed areas. For doors and drawers, the numbers give the size ofthe finished opening, and the builder must decide the actual size of the door or drawer font. For panels the numbers show the distance exposed between the stiles and rails so the actual panel willbe slightly larg rand the overall lengths must be longer t0 accommodate the joints. Inthe material lists that accompany the drawings, there are notes reflecting this. Also, in the material lists, pieces with tenons will be listed with an ‘overall size, plus an “exposed” or “between. tenons" dimension 1 tay to include dimensions for parts only ‘once in the view where they make the most sense; for example, length in elevations, ‘width and depth in plans, ete ft seems that a necessary dimension is missing, study all of the views. In some cases you will have to add, suberact, or divide the given dimensions to find the size of an individual part. Time invested in studying the drawings before beginning construction willbe well rewarded ‘once you start to build ‘Mons Suor Daamines ror C MAKING THE, QUADRALINEAR LEG As attractive as the fice of quarterswn white ‘oak can be, the edge grain tends to be down- right ugly, particularly when seen next to a beautify flecked surface. On table tops oF ‘ase tops, the edge generally doeset have ‘enough surface area for this difference in appearance to be real aesthetic problem. Square legs, however, are another story. The Jeg looks funny ifthe quartersawn rays do ‘ot appear on adjacent surfaces, even though icant possible to have rays on both the Face and the edge ofa single board. Gustav Stickley recognized this, and his solution was simply to laminate ewo (or more) pieces of quartersawn stock together, then to veneer over the two side surfaces, ‘There are two ways in which this seemingly reasonable solution can cause problems. The first problem isin finishing — ifthe work is Most shrinkage In this direction Most shrinkage In thie direction Plainsawn to be stained or dyed, the veneer and the solid wood will ach take the stain diferent- require some extra effort to match the color- ing on both types of surfaces. The same problem will alo occur when faring — the tannic acid content ofthe solid wood and of the veneer will be different, unless the veneers were cut fiom the same pieces of ‘wood used forthe solid parts. Again, this i not the end of the world, but some amount of toning or shading will ikely be necessary. ‘The second problem, which is more trouble- some, is that of wood movement between, the solid material and the veneer. Unlike plain-sawn wood, the quartered pieces will expand and contract more in thickness than in width. This movement wos't match the seasonal movement of the veneer, and it is quite likely that the veneer eventually wil crack. The majority of original Gustav Stickley pieces that Ihave seen exhibit this cracking. Usually its rather minor, occurring for an inch or two near the bottom ofthe leg, and I cant honestly say how long it may take for thie cracking to develop, o if wll occur at all, eis troubling, however, to see such a flaw in an otherwise perfect piece of furni- ture, even iit is close to one hundred years ‘old. A thicker veneer, sawn from the same ‘wood that is used forthe other parts of the leg, might reduce the chances of cracking, and might be a better match for color and figure. There are now veneers avilable with backings applied to them, either a second layer of cros-griin veneer, o of paper, or of paper impregnated with phenolic resin ‘These alo may educe the problem of crack- ‘ng, but will introduce their own problems of ‘matching the figure and color in finishing. Leopold Stickley came up with a solution that was both elegant in appearance, and ‘eminently practical for production ina facto~ ry setting. Figure 1 shows his method of ‘Maxine re Quapnatinzan Lee [1 *Quadratineae” construction, and one of the pieces. Four pieces of solid quarter- ‘problems mentioned previously. The legis all soli construction, the core canbe filled with another piece of wood if there has to bbe an exposed tenon, and with the machinery available then, as well a today, relatively simple to produce. ‘The same visual effect could be achieved if the pieces were simply mitered, but with Leopold’ ingenious system, the joints can be clamped together without the rendency to slide apart that simple miters would have. Alo, all four pieces are machined ‘dentcally — there are no rights or lefts or fronts of backs to keep track of so the set ‘up work for milling needs to be done only ‘one time for any number of legs. ‘My guess is cha these legs were originally rlled in the factory in one pass on a shaper or molder, a machine that was in ‘sein factories of the period, but is unfor- tunately not affordable for the average ‘woodworker of today. This joint can easily ‘be cut on a tablesaw, and there are several alternative ways to make a joint that i just as easly assembled, with the same finished appearance. The key to success in any of these methods lis in careful stock prepa- ration, and being absolutely sure that the position of the stock does not change as the wood moves past the cutter, Due to the nature ofthis joint, any err will result ina gap twice as large asthe deviation, For cxample, if you try to make a long miter ‘cut on a board with a how of 1/32" over its length the end result will bea 1/16" gap in the finished joint. Similuey if the board should rise up slightly while moving past ‘the sawblade, a gap of twice that distance will result. Careful set-up, featherboards, Ihold-downs, or a power feeder will go a Tong way toward ensuring the succesful milling ofthis join. Figures 2, 3, & 4 show the sequence of ‘ute to make this joint with a tablesaw. Fint, two grooves ae milled in the back face ofthe board. Note that these grooves axe offset; the exact distance will depend ‘on the thickness and width of the wood. ‘The groove that is closest to the edge could be the width of the saw blade, but I generally cut it with the dado head since that wil bein the saw for cuting the other groove. Next, a miter is eut from one out side comer t0 the bottom comer of this groove. Lastly, the opposite edge ‘mitered, leaving a flat-bottomed rabbet. ‘Take great care when cutting this last miter, since the Mat surface that i left to bear against the saw table is rather smal. If a feather boar is used, locate it away fom the fence so that it bears on the flat ofthe ‘workpiece. Use push stick, which should also bear on the middle of the board. Pressure on the board close to the saw feoce will cause that edge of the board to 1