MC Aktiv 2-2015 here PDF

Preview MC Aktiv 2-2015 here

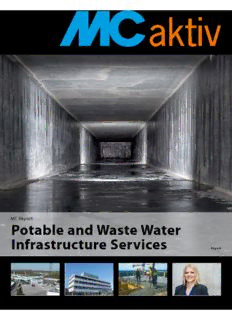

THE MAGAZINE FOR EMPLOYEES AND CUSTOMERS OF MC-BAUCHEMIE 2-2015 M C Report Potable and Waste Water Infrastructure Services Page 6 MC Inside MC News MC News MC Inside MC headquarters in Bottrop Prime protection for A gem within Poland's Career paths further expanded Page 3 Dublin Airport buildings Page 4 hotel landscape Page 17 at MC Page 19 MC Editorial Dear Reader, Water is life. Or to put it another Proven product systems of MC-Bauchemie are, of course, used for a way, without water there is no wide range of construction and rehabilitation activities, whether for life. That, in a nutshell, shows the airport in Dublin, for embankment consolidation in Germany, for the importance of water for our sewerage systems in Spain or for a hotel refurb and expansion project existence. Whilst countries in the in Poland. See the project reports in this issue of MC aktiv for more infor- Third World suffer from a lack of mation. With all this plus a selection of news items and articles relating potable water, and sewage flows to our company, I hope you will enjoy the read. onto the streets, into rivers, into lakes or into coastal waters, in Finally, I would like to thank you once again for participating in our developed countries the avail- readers survey and providing us with your feedback. Your responses will ability of reliable drinking water help us make our magazine even better going forward. supply networks and waste water treatment and disposal systems is taken for granted. However, the protection and repair of such facilities are essential – so that, each day, they can continue to provide these vital Yours, services. That is why, in this edition of our magazine, we have dedicated our report section to this field of activity. Follow with us the water cycle and discover our proven product systems for the repair and protection of structures and infrastructure carrying potable water and sewage. Dr.-Ing. Claus-M. Müller Contents Cover Photo MC Inside The cover photo shows the inside of the wa- 3 M C Brazil takes over Argatex 15 Results of the readers survey ter tower known as "Auf der Hardt" in Düs- MC Brazil is growing and moving into High rate of return and positive response. seldorf, Germany, which has a total capacity of 25,000 cubic meters. Following extensive new market segments. 16 Sewage pipes rehabilitated with tube liners investigations, the Düsseldorf municipal au- MC headquarters in Bottrop City of Terrassa uses MC's tube liner process for the first time. thorities decided that the approx. 60 year further expanded old reservoir was worthy of a full rehabilita- MC has enlarged the entrance to its 17 A gem within Poland's hotel landscape tion. As it has two chambers, the work was factory site in Bottrop. Hotel refurbishment and expansion project in Arłamów, to be carried out without taking the tower with various product systems from MC deployed. off line. For repairing the internal walls, the 18 Career paths at MC clients and planning consultants opted for Julia zur Loye (32) moves from the back office MC Report our mineral and cement-bound potable wa- to field sales after 10 years with MC. ter grade coating system MC-RIM PW. This 6-10 Potable and waste water infrastructure services provides for a highly resistant, impermeable Running well! Follow with us the water cycle and learn of our expertise in and durable coating guaranteed ensure the MC at the VIVAWEST Marathon the repair and protection of water and sewerage structures. long-term protection of the concrete. MC Innovation MC News 12 New processing aid for moulded concrete products Credits 4 P rime protection for Murasan Hydrotech 884 helps prevent the occurrence of Dublin Airport buildings Clients and planning consultants opt for primary efflorescence under critical ambient conditions. Publisher: MC solutions for two projects. MC-Bauchemie Müller GmbH & Co. KG Screeds ready for overlaying after just four days Am Kruppwald 1–8 5 Tailored shotcrete solutions MC-Screed Protect RM4 seals screed with a high residual 46238 Bottrop, Germany moisture content, helping to save time and money. MC admixtures help with embankment con- solidation and construction of an entry tunnel. Tel. +49 (0) 20 41/1 01-0 13 Innovative injection system for Fax +49 (0) 20 41/1 01-688 horizontal barrier provision 11 Inauguration of Tjumen plant MC Russia welcomes 150 guests to the official Oxal HSC offers effective protection against rising damp. www.mc-bauchemie.com opening of its new factory. [email protected] Fast system for solid crack repair in screeds MC-Estrifan RIS-SL is easy to use and quickly and 14 MC at ICOLD 2015 Responsible for content/conception: cleanly seals cracks and joints. Saki Moysidis Floating concrete canoes MC Personnel Editorial role and design: MC at RO-KA-TECH 2015 MGE MEDIA GROUP ESSEN GmbH, Expert conference on 19 Welcome to the team 45141 Essen, Germany separator rehabilitation 14 apprenticeships get off the ground MC at the World Tunnel Congress New Dangerous Goods Safety Officer 2 | MC aktiv 2_2015 MC Inside MC Brazil takes over Argatex Bird's eye view of the Argatex site. At the beginning of this year, MC Brazil acquired Argamassas Argatex market segments for our activities, and significantly increase our produc- Ltda-EPP, a Brazilian manufacturer of tile adhesives, speciality mortars tion capacities," says Jaques Pinto, Managing Director of MC Brazil. With and joint mortars with 25 employees and a modern, automated pro- MC Brazil having been previously active primarily in the fields of infrastruc- duction plant in Campo de Vila, Santana do Parnaiba (near São Paulo). ture, industry and construction, this acquisition opens up a new market segment in the retail sector and, particularly, the DIY segment, thus pro- Argatex has been operating on the Brazilian market for 50 years, supplying viding new opportunities for growth. Argatex is currently listed in 450 DIY the retail trade and do-it-yourself outlets with its products. "This acquisition stores in Brazil's south-east. is an important step for MC Brazil. With Argatex, we are able to improve our portfolio in the field of powder products and mortars, open up further [email protected] MC headquarters in Bottrop further expanded MC-Bauchemie acquired the site of Minova BWZ GmbH, a manufacturer roads were added and the green areas planted with trees and bushes to of fixing and anchor systems, which was located to the immediate left of mark the completion of the construction project. Aside from a new truck MC’s former truck entrance. The purpose was to expand the entrance area and car access area, the rebuilt entrance also contains a new weighbridge, leading to the truck loading section and the MC factory site. The demoli- a new gatehouse and additional truck and car visitor parking bays. MC's tion work on the former Minova site began in spring 2014, and the recon- headquarters have thus been given quite a facelift. In the coming months, struction work was finally completed around one year later in April 2015. the loading and logistics areas are also to be expanded. "This project is our response to ever-increasing sales volume in recent years. It will enable us Following extensive excavation, asphalting, paving and construction work, to create capacity for further growth going forward," says Michael Schilf, at the beginning of April 2015 the markings for the car parks and access Head of Operations in Bottrop. The new entrance to MC's factory site in Bottrop. MMCC aakkttiivv 22__22001155 || 33 MC News The headquarters of the Irish airline Aer Lingus at Dublin Airport before and after the rehabilitation work. Prime protection for Dublin Airport buildings Last year MC-Bauchemie solutions were selected for two projects at Dublin Airport: the high-quality Nanoperm coating now serves to exten- sively protect the headquarters of airline company Aer Lingus against both carbonation and soiling; and – following work performed around the same time – the car parks of Terminal 1 have also now been fully rehabilitated with an MC coating system. Refurbishment of the new Aer tionally open to water vapour dif- ment system Nafufill KM 250. Finally a building refurbishment and upgrade Lingus headquarters fusion. It is chloride-resistant, does coating of Betonflair Uniprimer, with project also involved the application The Dublin Airport Authority (DAA) not chalk and will not lose its layers Emcephob Nanoperm P, was applied. of a highly resistant and aesthetically explicitly specified Nanoperm P as over the years like an acrylic coat- This solution provides Aer Lingus with attractive surface protection coating. the surface protection coating for ing. The repair and protection sys- a long-lasting and visually attractive, The client, the DAA, decided on the this flagship building. Offering excel- tems of MC were used right from sustainable infrastructure coating for its Betonflair W system as a proven solu- lent abrasion resistance, anti-carbon- the start in the refurbishment of the building with no retouching needed tion for guarding concrete surfaces ation protection and easy cleanabil- Aer Lingus HQ. MC provided a spec- for many a year to come. against aggressive atmospheric pol- ity, the pigmented surface protection imen surface with a sample coating lutants coupled with anti-carbonation system met all the requirements of of Emcephob Nanoperm P back in Car parks of Terminal 1 protection and aesthetic colour coating. the DAA. Its nanotechnology restricts 2011. Three years later, in 2014, this An MC solution was also specified for organic growth and ensures that dirt still looked as good as new. the car parks of Dublin Airport’s Ter- The system structure comprised an particles are washed away with the minal 1. The repair of approximately initial layer of Betonflair Uniprimer rain. Even recalcitrant graffiti can be The application of the coating was 80,000 square metres of concrete sur- – which went straight onto the old removed. This high-performance coat- completed using a proven MC system face area in multi-storey car parks A, coatings without any problems. This ing corresponds to a concrete cover combination: First came the bond and B and C represents one of the largest was then overcoated with the surface of more than 4 meters to the steel anti-corrosion coat Zentrifix KMH. This expanses in Ireland to be provided protection compound Betonflair W. reinforcement, yet remains excep- was followed by the concrete replace- with an anti-carbonation coating. The Competitors tendering for the project were offering products that required multiple coats to achieve the speci- Visually attractive and resistant – the surface coating of car parks A – C of Dublin Airport’s Terminal 1. fied level of performance. With MC’s products, the requisite resistance to carbonation is achieved after just two coats, with overcoating also possible within the same day. This meant MC had a decisive product advantage resulting in major economic and time benefits for the client. At the same time, the MC systems achieved over and above the EN 1504 Part 2 mini- mum requirements. [email protected] 4 | MC aktiv 2_2015 MMCC NNeewwss Embankment consolidation in the Spessart region, with shotcrete accelerator Centrament Rapid 640. Tailored shotcrete solutions Shotcrete is primarily used in tunnel construction, for excavation pit support and embankment consolidation. With admixtures from MC, its properties can be specifically aligned to application requirements, something that was very much needed both in the stabilisation of cuttings during construction of a new railway line through the Spessart region of Bavaria, and for the construction of an entrance tunnel in the Weserbergland region of Germany. Embankment consolidation have already been successfully con- made full use of the concrete know- the latest MC polymer technology and The 160 year old Schwarzkopftun- solidated. The project is still ongoing, how and admixtures provided by MC. provides for higher final strength val- nel in the Spessart region was no with completion scheduled for 2016. Because of its high early strength val- ues combined with even faster early longer able to cope with the new Logistically, the project constituted a ues, cost-efficiency, low dosage lev- strength attainment. With these two high-speed railway services. Hence major challenge, with the shotcrete els and minimal rebound, here again admixtures, fast and cost-efficient exe- it is to be bypassed by a new rail- accelerator having to be supplied Centrament Rapid 640 was used. To cution of the work was assured. way line currently under construc- in winter with thermal protection ensure optimum overhead application, tion. As major portions of the new and stored on site in heated facilities. the concrete technologists from MC's Shotcrete application started in March link between the towns of Laufach Esslingen Service Centre, working in 2015, with weather conditions partic- and Heigenbrücken are being made Construction of an entrance tunnel collaboration with the ready-mix con- ularly adverse. Here again, therefore, by the cut-and-cover method, the In Pegestorf (Weserbergland), an entrance crete provider, developed a concrete the concrete had to be supplied to the ensuing embankments have to be tunnel had to be constructed for the formulation which was then exten- site ready heated. The work is sched- consolidated up to a height of 16 m, Knauf company to enable future gyp- sively tested for suitability. They used uled to finish by the end of September. with the work being carried out all sum mining operations. The client and the high-performance superplasticiser year round while the trains continue planning consultants decided to carry MC-PowerFlow SC 21, which had been [email protected] [email protected] to run. This challenging work was out the work with shotcrete, and chose especially developed for the require- [email protected] entrusted to the specialist applicator the applicator firm Feldhaus (Schmal- ments of a number of major projects Spesa of Nordhausen, a subsidiary of lenberg) to perform the work. Feldhaus in southern Germany. It is based on the Bauer company (Schrobenhau- sen), which put its faith in admixtures Addition of the high-performance superplasticiser MC-PowerFlow SC 21 generates higher final strength values and faster hardening, so that overhead spraying is also possible. provided by MC. The first phase of this work began in November 2013. The applicator chose the shotcrete accelerator Centrament Rapid 640 because it could be relied upon to provide the necessary early strength values with small dosages and low rebound. Because the following lay- ers could be applied more quickly and in larger thicknesses of 15 to 20 cm per pass, production capac- ity increased significantly, with cor- responding reductions in working time. Large areas of embankment MC aktiv 2_2015 | 5 MC Report Potable and waste water infrastructure services Day after day, we turn the tap on, drink a glass of water, wash our dishes or water our plants – the constant availability of potable water of excellent quality and in unlimited quantities is something that we have come to take for granted. And it is not only the supply of drinking water that goes largely unnoticed, but also the treatment and disposal of the waste product – sewage. Most people are unaware of the complexity of the systems that lie behind this constant availability. What better reason, then, to take a closer look at the water cycle? Water is one of the is taken, partly mixed with precipita- cement. A frequent consequence is This gives rise to a high degree of dis- most important tion water, via the sewerage system to a washed concrete appearance with solution resistance and minimises any basic requisites for treatment plants where it is cleaned exposed aggregate at the surface. tendency towards elution. Porosity, a modern, healthy and returned to the waterways. Thus, The quality of the water must not structural voids and the capillary life. Indeed, it is the water passes through a large number be adversely affected either in pores responsible for leaching most essential sub- of different structures which regularly terms of its colour, smell and processes are reduced to a 188 stance involved in the have to be maintained and repaired. taste or in its microbio- negligible minimum, mak- billion support of life. The And MC has proven product systems logical content. Modern ing the coating highly supply and disposal designed to ensure the long-term reha- mineral coatings from cubic metres of resistant, impermeable of water thus take bilitation and protection of such facilities. MC, applied as a sur- water constantly kept and durable. As usage on special impor- face protection layer in Germany's water tanks. continues, the DySC® tance. Potable water Water tanks: reservoirs on the concrete, make technology results in a is largely extracted for the elixir of life sure that such require- further increase in imper- from ground water Germany is a water-rich country. It ments are safely met. meability and resistance. resources, although always has over 188 billion cubic metres The water tank of Hinterbrühl lakes and valley of water ready for consumption in its MC-Bauchemie has developed the in Lower Austria has, for example, reservoirs, spring water tanks so as to ensure a contin- mineral and cement-bound coating been repaired using products from water and bank uous supply to all households. Unlike systems of the MC-RIM PW family with the MC-RIM PW family. Because of filtrates are also in many other countries, this water integrated DySC® technology specifi- corroded reinforcing steel, the struc- important sources. is already of potable quality, which cally to meet the higher requirements tural stability of the single-chamber The water thus means that it can be drunk without encountered in water tank applications. tank, useful capacity 2,000 m3, was obtained is further treatment. Covered by test certificates evidenc- in jeopardy. After removal of the old treated in water ing its suitability, MC RIM PW contains coating, the reinforcing steel was works, ducted The water tanks are predominantly selected latent hydraulic and pozzolanic cleaned of rust and then provided for storage to constructed from reinforced concrete binder components which, together with the corrosion protection coat- water tanks and which, because of its resistance to pota- with an especially controlled particle ing MC-RIM PW CP, while flaws were towers, and from ble water, is a material well suited to its sized distribution, create a structure repaired using the concrete replacement there supplied storage. However, reinforced concrete characterised by highly dense sphere system MC-RIM PW 20. Then, MC-RIM to consumers also has its weaknesses: depending packing. Moreover, the binder matrix PW 10 was applied to the wall and via a network of on the hardness of the water and the undergoes continuous further densi- overhead areas, with MC-RIM PW 30 piping systems. impermeability of the concrete, disso- fication and solidification as the result being used to coat the floor. As a result, Once it becomes lution phenomena can leach, soften of a complex, innate process known the potable water tank now boasts waste water, it and ultimately destroy the hydrated as Dynamic SynCrystallisation (DySC®). a safe and durable surface coating. 6 | MC aktiv 2_2015 MC Report Clients and planning consultants put their faith in the durable coating system MC-RIM PW from MC, certified for potable water applications, both for the "Auf der Hardt" water tower in Düsseldorf (left) and for the water tower in Hinterbrühl, Lower Austria (right). Subterranean infrastructure sponding to 13.5 times the circum- In many countries, only a very small ference of the Earth. This figure does portion of the water supplied to house- not include private sewerage systems, holds in high-quality potable grade is which, incidentally, are thought to be actually drunk. Of the approximately more than double that length. There 121 litres that, for example, are con- are around 13.5 million public sewer- sumed on a per capita basis each day age manholes, and some 96% of Ger- in Germany, by far the largest portion many’s inhabitants are connected to is used as service water, i.e. for wash- the public system. Each year, Germans ing laundry, flushing toilets, showering generate around 10 billion cubic metres and the like. Thereafter it is frequently of waste water. The sewerage network ducted into the sewerage system and is thus extensively utilised on a daily on to the municipal treatment plant. basis, so fulfilling an important role in the water cycle. The origins of today's sewerage systems go back to the 19th Century. At that time, Today's sewerage systems are largely cities expanded rapidly and the waste made up of concrete or earthenware water quantities increased in proportion. pipes and ducts, although plastic mate- The disastrous hygiene conditions that rials are being increasingly used. The resulted ultimately led to the construc- systems have to be leak-tight in order tion of subterranean sewerage systems. to ensure that no sewage seeps out to However, waste water systems did not contaminate the ground water or pol- just come about with the inception of lute the environment. However, infiltra- industrialisation – they have, in fact, been tions also have to be avoided because around since ancient times. One of the these cause wastage of valuable ground oldest sewerage networks in the world water and, because of the increased is a 4,000 year old drainage system near volume of sewage, also cause treat- to the River Indus in Pakistan. And the ment costs to rise. Subterranean move- Romans are also well known for their ments, dynamic or changing superim- Whether for sewerage system rehabilitation (top left) or the special coating of a manhole (right), the highly developed sewerage systems. posed loads, ageing and construction product portfolio of the ombran division of MC includes highly resistant material systems for the reprofiling and coating of subterranean sewage structures. defects mean that damage and leaks Today, Germany has around 541,000 are always likely to occur. Consequently, Sewage treatment plant (bottom photo): With MC-RIM PROTECT PLUS, MC has a highly sulphate- kilometres of public sewerage, corre- sewerage systems need to be regu- resistant surface coating system that offers optimum concrete protection for all component surfaces. MC aktiv 2_2015 | 7 MC Report Reprofiling and coating of an accessible sewer in Hamburg (left and centre). Automated manhole rehabilitation with the MRT truck and ombran MHP-SP (right). larly inspected and, where required, an alternative, there is the tube (aka a length of 240 metres, covering an In the case of structures exposed to repaired. These tasks were frequently hose) liner option in the form of, area of over 2,000 m2, offering a com- extreme attack, such as encountered in neglected in the past, but are a legal say, the Konudur Homeliner pro- bination of good workability, a broad grease and light mineral liquid separa- requirement in many countries now- cess from MC, which is specifically application spectrum – being suit- tors, or manholes and sewers exposed adays. Conservative estimates indi- designed for the holistic rehabilita- able for both reprofiling and coat- to biogenic sulphide corrosion, even cate that currently around 20% of tion of non-accessible sewage pipes. ing – and early resistance to water a high-performance cement-bound the sewerage and manholes in Ger- Requiring minimal time and materi- exposure. With these properties, the mineral coating from the ombran many are in need of rehabilitation. als, this no-dig process employs an system also enabled the sewer to be MHP family is unlikely to be suffi- epoxy-resin-impregnated inversible quickly re-commissioned. cient. However, long-term and effective If faults occur in the form of, for exam- needle felt tube to create a new, protection for these facilities can be ple, leaky sleeve sockets, internal load-bearing pipe within the old pipe. Automated manhole rehabilitation achieved by using the highly cross- debris or cracks in the pipes and Manholes can also be coated with linked and vapour-diffusible hybrid sewers, these need to be quicSkalnyi ereruc-ngspAotcecnetsiaslible sewers and waste water high-tech mortar – and with enhanced silicate technology available in the tified. Depending on the scope and structures are reprofiled and coated efficiency where these are used in form of ombran CPS for manholes type of the damage involved, there using the highly sulphate-resistant, combination with the unique MRT and pump sumps, and ombran FT are various approaches that can be fibre-reinforced, cement-bound mor- technology of HDT GmbH, a sister for separators. The dense matrix that taken. The short liner process in the tars of the ombran MHP family, formu- company of MC-Bauchemie. The MRT these create is able to withstand even form of MC's Konudur LM-Liner tech- lated to provide long-lasting protec- truck is a complete, self-propelled very low pH values. A combination of nique is suitable for specific long- tion against the aggressive ambient system for the automatic rehabilita- ombran MHP and ombran CPS was term sealing applications and the conditions encountered in sewer- tion of manholes, with the coating used to repair sewerage structures stabilisation of a locally defined dam- age. The high-performance mineral materials being spun (centrifuged) in Stuttgart's inner city – with the aged area. This involves positioning coating ombran MHP-SP, applied by into place for the cost-efficient and system still operating. The solution a silicate-resin-impregnated glass fibre spraying and spinning, was used, for reliable repair of vertical surfaces. ensured that the sewerage was effec- fleece at the damaged location and example, in the rehabilitation of a tively protected long-term from, for then expanding it to create a sleeve large-diameter (DN3000) intercep- example, aggressive chemical attack which hardens and cures in situ. As tor in Hamburg. It was applied over resulting from aerated water. Snow & rain Consumers Condensation Precipitation Evaporation Water treatment plant Return flow into the sea River Sea Sewage treatment plant Sewer RTeaslseprveorrier Return flow into the sea tunnel Ground water River Bank filtration 88 || MMCC aakkttiivv 22__22001155 MC Report Concrete used in the construction of sewage treatment plants is subject to a wide range of attack - MC-RIM PROTECT PLUS is extremely resistant, with long-term experience confirming its excellent performance and durability. Sewage treatment plants stage removes the carbon and nitrogen larly abrasive and the occurrence of used for internal and external surfaces The sewerage ducts the waste water compounds through the addition of biogenic sulphuric acid in covered and is particularly suitable for the pro- into the treatment plants, of which oxygen that aids the action of specif- constructions can give rise to especially tection of open waste water channels, there is a huge number in Europe: in ically cultured microorganisms. The serious damage to component surfaces. rainwater spillway basins, preliminary the 28 countries of the European Union, final chemical treatment processes MC offers a proven product system treatment and final sedimentation plus Iceland, Norway and Switzerland, eliminate particularly recalcitrant to combat these different forms of tanks, and also screening buildings. there are around 71,000 facilities in substances such as phosphorus com- attack: MC-RIM PROTECT PLUS. The Product systems from MC-Bauchemie operation. In Germany alone, some pounds. These are bound, usually product family consists of fibre-rein- thus ensure that water and sewage 10,000 sewage treatment plants through the addition of iron salt forced and highly sulphate-resistant, treatment structures are effectively serve to clean municipal waste solutions, and then removed cement-bound coatings that offer repaired and durably protected, under- water which, each year, with the activated sludge. optimum protection for all component pinning the provision of essential water amounts to around 10 The sewage sludge that surfaces in sewage treatment plants. supply and treatment services. 10,000 billion cubic metres. Of occurs at each of these The use of a precisely aligned binder sewage this figure, some 5.2 treatment stages is bio- technology results in a positive change For enquiries regarding our product treatment plants billion cubic metres degraded in digestion in the morphological properties of the systems and for further references, is sewage and around are in service in Germany. towers and the biogas binder matrix: microfine binders and please contact our experts below: 4.8 billion cubic metres that is produced in the pozzolanic substances, including layered is infiltration and precip- process is collected and silicates, combined with appropriate Potable water tanks & sewage treatment facilities: itation water. used as an energy source. w/c ratios, give rise to high-density sphere packing to give high resis- [email protected] [email protected] In modern sewage treatment plants, the As in the case of potable water tanks, tance values. The modified binder sewage is cleaned in three purification concrete is the most important material matrix exhibits very high resistance ombran/underground structures: stages. The first, that of mechanical used in the construction of sewage to sulphates, chloride diffusion and [email protected] treatment, takes out the bulky, solid treatment plants. And here again it is hydrolysis. Long-standing experience [email protected] components together with sand, oil exposed to various forms of mechan- confirms the outstanding, sustained Technical Director PT: and grease in an aerated sand and ical and chemical attack. The action effect (see article on page 10) of such grease trap. The biological cleaning of scrapers, for example, is particu- coating systems. The product can be [email protected] Snow & rain Consumers Condensation Precipitation Evaporation Water treatment plant Return flow into the sea River Sea Sewage treatment plant Sewer RTeaslseprveorrier Return flow into the sea tunnel Ground water River Bank filtration MMCC aakkttiivv 22__22001155 || 99 MC Report The sludge thickener of the Dresden-Kaditz sewage treatment plant was coated with MC-RIM. Certified: decade-long concrete protec- tion for sewage treatment facilities Back in 1985, MC-Bauchemie launched MC-RIM, a cement-bound mineral coating system for sewage treatment plant applications. The objective was to achieve minimal total pore volumes, high resistance to leaching, sulphates and chlorides, and high acid resistance. The result was a product family which, to this date, is still writing its success story In order to ascertain the durability of the MC-RIM Investigations performed by Kiwa MPA Bautest and, following its further development coating system, a total of six test cores were drill- GmbH confirmed that the MC-RIM coating sys- in 2013, now offers even better product ed out of the wall of the sludge thickener serving tem will continue to offer many years of reliab- properties under the name MC-RIM the Dresden-Kaditz sewage treatment plant. le protection to the concrete structure. PROTECT PLUS. It provides concrete constructions in sewage treatment authority Kiwa MPA Bautest GmbH, mined that the coating had a residual facilities with long-term protection which received the commission 17 service life of at least 15 to 20 years. confirmed by extensive investigations. years later to determine the current condition of the coating, assess its Expected service life 30 – 35 years Dresden-Kaditz sewage treatment plant ongoing durability and determine In all, the investigation results indicated This can be readily seen in the Dres- its residual service life. The results of that the 17 years of usage of the sludge den-Kaditz sewage treatment plant, the the study were impressive indeed: thickener had not given rise to any most modern and biggest of its kind the sample cores drilled out of the major changes to the speciality coating in the Dresden area. In 1994, a sludge walls were first inspected visually to provided by MC. And if we combine treatment facility was constructed determine whether the coating had this outcome with the results from here for the purpose of dewatering undergone any changes. However, previously performed investigations and thermally drying the sludge pro- there were no cracks, no flaking and on the rain spillway basin in Viernheim duced by the treatment process. The no structural defects. Even after 17 years, and the "Moos" sewage treatment plant sludge thickener, component num- the coating had remained compact and in Amriswil (Switzerland), it appears that ber B0202A, was constructed with an intact. Comparative specimens from the life expectancy of such coatings MC-RIM coating in order to provide non-protected concrete revealed sig- lies in the region of 30 to 35 years. Thus continuous and constant protection for nificant damage after just a few years. the MC-RIM PROTECT PLUS product the concrete against aggressive attack. family can be extensively relied upon Moreover, the investigations showed that to provide durable protection to such Inspection after 17 years the coating had provided the concrete concrete structures. A comprehensive inspection was carried with outstanding protection. Having out by the independent material testing analysed these results, the KIWA deter- [email protected] 10| MC aktiv 2_2015

Description: