Table Of ContentMaking

KODAK

Film

Expanded Second Edition

visions

PLUS-X

Kodak Reversal

7276 50D/7203

ft

SB

OAVlIOMt

KODACOLOR

GOLD

24UL. 200

Kodak Film

Robert L. Shanebrook

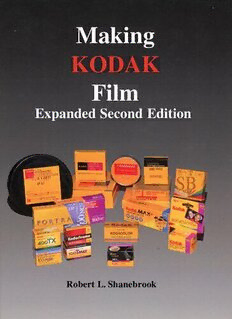

Making Kodak Film

Expanded Second Edition

4. 00 A ADJ(DN) CALC 87/28/91 01:14

a. 29 e. be

JSER 59271b LOG H (REF (cid:127) -1.9999) BTCH« 442299

ALIGN AT 1. 008 DISPLACEMENT 6. 150 0. 008 -0. 150

Robert L. Shanebrook

©2016 Robert L. Shanebrook

ISBN: 978-0-615-41825-4

Library of Congress Control Number: 2010910580

All rights reserved. No part of this document may be reproduced in any form or by any

electronic, chemical, or mechanical means, including information storage and retrieval

systems, without permission in writing from the author, except by a reviewer who may

quote brief passages in a review.

The content of the book, including the views and opinions expressed, are solely

attributable to the Author and do not reflect any official policy or practice of Eastman

Kodak Company, its subsidiaries or affiliates. Kodak’s permission should not imply any

approval or verification by Kodak of the factual and opinion contents of the book.

Trademarks will be in italics to distinguish them from generic words that describe

products. The Kodak trademarks, trade dress, and product packaging shown on the covers

and throughout the book are the trademark and copyright property of Eastman Kodak

Company (“Kodak”) and are used with permission.”

Contax is a trademark of Zeiss International

Cronar, Dacron, and Mylar are trademarks of E. 1. du Pont de Nemours and Company

Eastman 910 is a trademark of Eastman Chemical Company

Carbowax PEG is a trademark of Dow Chemical

Phenidone is a trademark of Harman Technology Limited

Photokina is trademark of Koenlmesse, Cologne, Germany

Leica, Contax, Hasselblad, Mamiya, Nikon, Bronica, Pentax, Fuji, Rolleiflex, Linhof,

Microsoft, Kathabar, and Technicolor are trademarks of their respectively named

companies.

Those listed below provided various types of illustrations that are used with permission

in this book. In some cases, the illustrations are modified for use.

Eastman Kodak Company

George Eastman Museum

Eastman Gelatine Corporation

Jack H. Coote, Illustrated History of Colour Photography, Fountain Press 1993.

Harald Doell and Hans Ulrich Kaspar, TSE Troller AG, Murgenthal, Switzerland.

Peter Schweizer, Polytype Converting AG, Freiburg, Switzerland.

R. G. Mowrey, Photographic Emulsion Making, Coating, and Testing, 2011.

Unless noted all the photographs made after 2003 were made by Robert Shanebrook.

Back cover photograph by Todd Gustavson and Robert Shanebrook

Published by Robert L. Shanebrook, Rochester, NY, USA

Made in United States of America

Acknowledgements

1 thank my wife and best friend, Lynne, for her patience and ideas that allowed me to

complete this work.

I am grateful to Todd Gustavson, Curator of the Technology Collection, George

Eastman Museum. Todd’s knowledge and judgement have been very helpful.

Thank you to the staffs of:

George Eastman Museum, Rochester, New York

Department of Rare Books, Special Collections, and Preservation, River Campus

Libraries, University of Rochester

This book would not be possible without the work of past and present Kodak employees

around the world and others in the photographic community. They applied their skills,

ingenuity, and energy to make and use silver halide photographic materials. Below is a list

of some of the experts who contributed to this book in several different ways. Any errors

are mine not theirs.

P. Z. Adelstein Mark Erbelding Douglas Lang Kevin Prinzing

Ronald Andrews Robert Esker Robert LaRossa Tom Pritchard

John Babbitt Martin Feinberg P. Loughney Derek Pullen

Thom Bell Melvyn Forbes James Lyon Keith Purves

Richard Bom Ricky Francis Richard Mackson Kenneth Ruschak

Richard Bourns Henri Freisz John Marchant Robert Rutz

Nick Brandreth Rolf Fricke Alan Masson Gene Salesin

Thomas Braun James Friday Brian McBride Jonathan Schwartz

Thomas Brennan Robert Gabbey Tom McEatee Martin Scott

Gordon Brown Ira Goldman Don McLaen John Sexton

D. Carrol-Yacoby Wm. Grabenstetter John Mitcham Martin Scott

Harold Cator Edward J. Hahn T. J. Mooney Lynne Shannon

Howard Chou Steven Hedges J. Michael More Michael Smalter

Philip Cianciotto M. J. Hellyar Phillip L. Morse Deborah Smith

J. Dexter Clifford Richard Hibbs James Moser Andy Sperr

Kathy Connor Chris Holmquist R. G. Mowrey Wm Staudmayer

Paul Crough Alain Jouy Mridula Nair Paul Stone

Arthur Cosgrove Tony Kaye R. D. Nicholas Scott Strock

Prof. Frank Cost Dan Kennedy Reid O'Connell Robert Surash

Patricia Cost Fiona Kinsey Jon O’Connor Robert Thompson

Gerald Curran Carl Kotlarchik Mark Osterman Gary VanScoter

Randy DeFrank Gerry Krueger Francis Parrish Steven Weinstein

Raymond DeMoulin Joseph LaBarca Elizabeth Patton Richard Wien

Nancy Dibella Matt Lane James E. Patton Phillip Wightman

Virginia Dodier William Lane Jack Paulson Michael Yager

Harald Doell Charles Lang Jesse Peers

Table of Contents

1. INTRODUCTION 1

2. HOW FILM PHOTOGRAPHY WORKS 4

Photography 5

Photographs of Film 13

Schematic Cross Section of 400 Speed Color Negative Film 22

Motion Picture Color Print Film 29

3. FILM DESIGN 31

Technology Implementation 31

Specifications 34

Measuring Tools, Evaluation, and Modeling 34

Meeting Customer Needs 37

4. COMMERCIALIZATION PROCESSES 39

Kodak Operating System (KOS) 39

Manufacturability Assurance Process (MAP) 39

Kodak Materials Commercialization Process (KMCP) 40

5. KODAK PROFESSIONAL PORTRA FILMS, AN EXAMPLE 43

Portra Films’ Product Goals 43

Customer Testing of Film 44

Portra Films’ Performance 44

Portra Film Packaging 5 1

Portra Film Product Line Extensions 53

Portra Film Upgrades 53

6. MAKING SILVER HALIDE PHOTOGRAPHIC FILM 57

Safety and the Environment 57

Protecting the Film During Manufacturing 57

A Brief Description of the Film Manufacturing Process 64

Raw Materials and Processes for Color Film 65

State-of-the-Art Film Manufacturing 66

Building 38: Features and Benefits 68

7. PHOTOGRAPHIC PLATE AND FILM BASE 70

Photographic Glass Plates 70

History of Flexible Film Base 72

Cellulose N itr ate Base 77

Base Manufacturing Buildings 79

Safety Cellulose Acetate Film Base 8 1

Cellulose Triacetate Base 82

Vinyl Support 82

Polyethylene terephthalate 95

Making Estar Film Base 97

Universal Film Base 108

Annealed Polyethylene Naphthalate 1 08

Photographic Support in the 2 1s t Century 10 9

8. SYNTHETIC CHEMICALS 112

iv

9. FILM EMULSION MANUFACTURING AND COATING 114

Introduction to Raw Materials 1 15

Introduction to Raw Material Sourcing 11 5

Introduction to Chemicals Preparation in Sensitizing 11 6

Introduction to Emulsion Making and Finishing 11 6

Introduction to Melting 11 6

Introduction to Coating 1 17

Introduction to other areas 11 7

10. FILM EMULSION MANUFACTURING 119

Raw Materials 119

Dispersions 128

Making Light-Sensitive Silver Halide Crystals 13 7

Historic Making Equipment 13 7

Forty Years in The Film Emulsion Department 141

Conventional Silver Halide Emulsion Making 15 3

Advance Making of Silver Halide Crystals 15 7

Emulsion Finishing/Chemical Sensitization 16 3

Post Emulsion Finishing Spectral Sensitization 165

Lemur, One-Tenth Scale Emulsion Making and F inishing 16 8

Emulsion Melting 17 0

11. FILM EMULSION COATING 181

Coating Technology Evolution 18 1

History of Rochester Film Coating Facilities 19 8

History of Kodak’s Film Emulsion Coating 2 12

Building 38: Melt Delivery and Emulsion Coating 222

Thread-Up and Coating 227

Conveyance 227

Station # 1 Curtain Coater 237

Station #2 Curtain Coater 238

Coating Control Room 24 1

Setting the Gelatin ' 243

Drying 245

Scanning 248

Film Windup 250

Handling of Master Rolls 251

Casket Handling 25 1

Recycling Master Rolls 252

Manufacturing Strategy 253

Coating Tactics 253

Emulsion Testing 255

First Building 38 Sensitized Coating 259

Production Scheduling 260

Building 38 Film Coating Crew 261

12. FINISHING AND FILM PACKAGING 263

Photographic Film Packaging Requirements 263

Finishing 266

Finished Film Configurations 267

Still Camera Film Finishing 267

Graphic and X-ray Film Finishing 298

Motion Picture Film Finishing 299

13. SUMMARY OF THE FILM MANUFACTURING PROCESS 316

v

14. FILM QUALITY 318

Sensitometric Testing 3 1 9

Other Photographic Measurements 324

Physical Testing 327

Film Imperfection Codes 331

Practical Pi iotograpi iy 333

Film Product Release 334

Film Performance in the Real World circa 2003 335

15. WORLDWIDE FILM MANUFACTURING 341

Rochester's Role 341

Film Products by Coating Manufacturing Sites 342

Kodak Park, Rochester, NY 345

Other Manufacturing Sites 360

Eastman Gelatine, Peabody, MA, USA 360

A'od/iatFilm Supply Chain 367

16. FILM IDENTIFICATION ' 368

Coating Types 368

CAT No 369

Emulsion Number 370

Film Expiration Dating 370

Final Film Code Numbering Scheme 372

17. FILM PRODUCTS 375

Kodak Films made in 19 88 375

Kodacolor Film History 388

Professional Color Negative Film History 393

KodachromeVw.m History 404

Ektachrome Film History 4 1 2

Kodak Motion Picture Film History 4 1 4

Graphics Film History 422

X-ray Film History 423

Scientific Film and Plates History 426

Aerial Film History: Aircraft and Satellite Photography 428

18. WORKING ON KODAK FILM IN THE LATE 1980’S 430

19. DOES THE FILM MANUFACTURING PROCESS WORK? 438

20. KODAK FILM MANUFACTURING IN 2016 439

21. GEORGE EASTMAN 440

22. GLOSSARY 441

23. INDEX 447

24. AUTHOR AND PHOTOGRAPHER 454

Table of Figures

Figure 1. The Color Wheel........................................................................................... 6

Figure 2. Color Reproduction of a simple color negative film................................ 8

Figure 3. Diagram of neg-pos photography with no color correction. ................... 8

Figure 4. Density of available dyes and perfect dyes. ..............................................9

Figure 5. Negative color corrected with colored couplers....................................... 10

Figure 6. D1(A)R Effect................................................................................................ 1 1

Figure 7. Diagram of the B&W negative formed in color reversal film ................ 1 1

Figure 8. Color reproduction diagram for color reversal photography ..................1 2

Figure 9. B&W still camera films, raw stock. ........................................................... 13

Figure 10. Kodachrome Films raw stock ................................................................... 14

Figure 1 1. Ektachrome Films: raw stock showing emulsion and backing............. 14

Figure 12. Color negative films: raw stock showing emulsion and backing......... 15

Figure 13. Professional color negative films ............................................................. 16

Figure 14. Samples of films made in Building 38 in 2015. ..................................... 16

Figure 15. X-ray Films (2016)..................................................................................... 16

Figure 16. Kodak T-Max 400 Film, cross section, undeveloped............................. 18

Figure 17. Kodak T-Max 400 Film, undeveloped, magnified 10,000X ................. 19

Figure 18. Kodak Tri-X Film, cross section, undeveloped....................................... 20

Figure 19. Kodak Ultra Max 400 Film cross section, undeveloped .......................2 1

Figure 20. Kodak Vision3 500T Film, cross section, undeveloped......................... 21

Figure 21. Two-page cross section diagram of 400 speed color negative film. ...23

Figure 22. Ultra-Max 400 Film, cross section, exposed and developed................ 27

Figure 23. Vision3 500T Film, cross section, exposed and developed................... 27

Figure 24. Kodak Ultra Max 400 Film, emulsion side, undeveloped..................... 28

Figure 25. Kodak Vision3 500T Film, emulsion side, undeveloped....................... 28

Figure 26. Kodak Ultra Max 400 Film, back side, undeveloped ............................2 8

Figure 27. Kodak Vision3 500T Film, back side, undeveloped............................... 28

Figure 28. Cross section of developed Vision Color Print Film 2383 / 3383. ....... 29

Figure 29. Composition of Eastman Color Print from a 1994 US Patent.............. 30

Figure 30. Eastman Color Print Emulsions from US Patent 1994.......................... 30

Figure 31. MTF curve.................................. * ..............................................................3 5

Figure 32. KMCP Process Pocket Card, 1994........................................................... 42

Figure 33. Key performance characteristics of Portra Films.................................. 45

Figure 34. Portra Films: benefits and technology. ................................................... 46

Figure 35. Color of Portra Films (1998) vs. Vericolor III Film/VPS (1982). .....4 7

Figure 36. Portra Film CIE L*a*b* color gamut. .................................................... 47

Figure 37. Prints from Portra Films. .......................................................................... 47

Figure 38. Printing consistency of Kodak color negative films .............................. 48

Figure 39. Image structure of Portra 16 0 Films and VPS. ................................. 49

Figure 40. Portra Film process co-variability.......................................... 49

Figure 41. Processed Portra Film has improved scratch resistant.......................... 50

Figure 42. Portra Films’ sensitometry after two years. ...........................................5 0

Figure 43. Portra Film packaging............................................................................... 5 1

Figure 44. Kodak Professional Color Negative Films Wall Chart, part 1, 2001. .51

Figure 45. Kodak Professional Color Negative Films Wall Chart, part 2, 2001 . .52

vii -

Figure 46. The 2002 Portra Film Family................................................................... 53

Figure 47. Antenna dyes............................................................................................... 54

Figure 48. Portra Film 2006, the fast cyan emulsion has finer grain..................... 54

Figure 49. Portra Film 2006 fast magenta emulsion has finer grain...................... 55

Figure 50. Characteristics of Portra Films 2006-2016. ...........................................5 6

Figure 5 1. “Bright” hallway area outside a spooling room...................................... 58

Figure 52. Film-safe display panels. ........................................................................... 58

Figure 53. Darkroom LED ceiling lights.................................................................... 58

Figure 54. Green LEDs are used for high speed films. ............................................5 9

Figure 55. Head-mounted infra-red image intensifier viewer................................. 59

Figure 56. Personnel elevator to salt mine................................................................. 63

Figure 57. Control film storage in the mine’s freezer ..............................................6 3

Figure 58. Walk-in freezer for storing film in the salt mine.................................... 63

Figure 59. Diagram of film manufacturing................................................................ 64

Figure 60. Materials and processes used to make a typical color film................... 65

Figure 61 . Building 38 Film Manufacturing System Features and Benefits .........6 8

Figure 62. Building 38, Kodak Park in 2009............................................................. 69

Figure 63. Photographic bases: periods and introduction dates.............................. 73

Figure 64. Eastman ’s American Film, 24 exposures, 18 84..................................... 74

Figure 65. Eastman’s American Film in 1884................................. , ........................7 4

Figure 66. Kodak Camera and Kodak Film, 18 88/1889........................................... 76

Figure 67. Kodak Film for the 1888 Kodak Camera................................................. 76

Figure 68. Kodak American Film image. ................................................................... 77

Figure 69. Kodak Transparent Film (1889) for Kodak Camera, No. 1. .................. 78

Figure 70. Eastman's Transparent Film for Eastman-Walker Roll Holder............ 78

Figure 71. Eastman's Transparent Film for Pocket Kodak 1898. ........................... 78

Figure 72. Blair and Waterman Photographic Film Apparatus............................... 79

Figure 73. End of Kodak’s manufacturing of cellulose nitrate in the LIS.............. 82

Figure 74. Schematic of acetate casting (roll coating) machine.............................. 85

Figure 75. Thread-up of actual acetate casting machine.......................................... 85

Figure 76. Cotton linter and cellulose acetate. .......................................................... 86

Figure 77. Cellulose triacetate (CTA) pellets with delivery rail car....................... 86

Figure 78. CTA Dope Holding Tank.......................................................................... 86

Figure 79. Base casting wheel 1930. ..........................................................................8 6

Figure 80. Film base casting wheel ............................................................................8 7

Figure 81 . CTA Casting Station.................................................................................. 87

Figure 82. CTA Coating Slot ...................................................................................... 87

Figure 83. CTA Process Control Display next to the coating station..................... 89

Figure 84. Roller in pan/trough subbing coater......................................................... 90

Figure 85. CTA Optical Scanner................................................................................. 91

Figure 86. CTA Winder................................................................................ 91

Figure 87. Acetate Solvent Safety System................................................................. 92

Figure 88. Building 53, Kodak Park, January 1 1, 2009. .......................................... 93

Figure 89. Overhead duct containing a conveyer...................................................... 93

Figure 90. 401 Machine Belt-coating Station............................................................ 94

Figure 91. 401 Machine Dryer Section ...................................................................... 94

viii

Figure 92. Process for making PET mixture......................................................... 97

Figure 93. PET pellets. .........................................................................................9 8

Figure 94. Estar Manufacturing Machine............................................................. 98

Figure 95. PET Supply Control Room.................................................................. 99

Figure 96. Building for a Estar Base Machine..................................................... 99

Figure 97. Utilities for PET making, B317, 2015................................................. 99

Figure 98. Screw plasticizing extruder................................................................. 99

Figure 99. Estar Base being peeled from on the wheel. ....................................... 100

Figure 100. Estar Base after it came off the casting wheel. ................................. 100

Figure 101. Coating being applied to Estar Base................................................. 100

Figure 102. Estar Base manufacturing drafting cabinets...................................... 101

Figure 103. Estar Base web clips as they are being attached to the web.............. 102

Figure 104. Estar Base Tentering Cabinets.......................................................... 102

Figure 105. Estar Base post-forming operations.................................................. 103

Figure 106. Particle Transfer Roller (PTR) for 35 mm film................................. 104

Figure 107. Knurling on Estar Base..................................................................... 104

Figure 108. Estar Base passing through the opposed knurling wheels. ...............1 04

Figure 109. Scanning Estar Base while it is on the machine................................ 104

Figure 1 10. Estar Base Windup stand, rolls can be up to 10,000 feet long.......... 105

Figure 111. Visual inspection station. .................................................................. 105

Figure 1 12. Estar Base Quality Standard. ............................................................ 105

Figure 1 13. Relative physical properties of CTA and polyester films.............. ....106

Figure 1 14. Characteristics of glass, CTA, and Estar Bases. ............................... 107

Figure 115. Light piping of developed 8 mm CTA and 35 mm Estar Base......... 109

Figure 11 6. Benefits of Vision Color Print Film 2383.......................................... 1 11

Figure 1 17. Examples of color couplers............................................................... 1 12

Figure 1 18. Synthetic Chemical Division logo, 2015........................................... 112

Figure 1 19. Synthetic Chemical Division manufacturing building. ..................... 113

Figure 120. Recognition of the OASIS Team contribution. ................................. 118

Figure 121. Eastman Gelatine's Manufacturing Process for Type IV Gelatin...... 119

Figure 122. Gelatin has several physical forms.................................................... 120

Figure 123. Flake gelatin made in Kodak Park 1948. .......................................... 121

Figure 124. Volleyball-sized ore sample containing silver ..................................1 22

Figure 125. Silver filament with some copper...................................................... 122

Figure 126. Silver ingots on pallets as received from silver suppliers .................1 22

Figure 127. 1,000 troy ounce silver ingots. .......................................................... 123

Figure 128. Silver ingots in the Bullion Reactor containing nitric acid ...............1 23

Figure 129. Silver nitrate crystals and granules.................................................... 123

Figure 130. Silver nitrate pellets........................................................................... 123

Figure 131. Content of silver nitrate used to make silver halide. ......................... 124

Figure 132. Silver Nitrate Tote............................................ 124

Figure 133. Dry salt hoppers. ............................................................................... 125

Figure 134. Potassium bromide............................................................................ 125

Figure 135. Two of 26 High Volume Make and Dispensing Stations.................. 127

Figure 136. HVMD Dispensing Station. .............................................................. 127

Figure 137. Coriolis Principle Mass Flowmeter................................................... 128

ix