[Magazine] The Biblical Archaeologist. Vol. 37. No 4 PDF

Preview [Magazine] The Biblical Archaeologist. Vol. 37. No 4

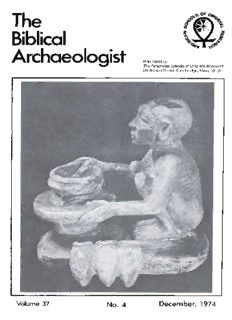

The Biblical Archaeologist Publishedb y The AmericanS choolso f OrientalR esearch 126I nmanS treet, Cambridge,M ass. 02139 . Volume3 7 No. 4 December, 1974 86 THE BIBLICAL ARCHAEOLOGIST (Vol. 37, The Biblical Archaeologist is published quarterly (March, May, September, December) by the American Schools of Oriental Research. Its purpose is to provide readable, non-technical, yet thoroughly reliable ac- counts of archaeological discoveries as they relate to the Bible. Authors wishing to submit unsolicited articles should write the editors for style and format instructions before submitting manuscripts. Editors: Edward F. Campbell, Jr. and H. Darrell Lance, with the assistance of Floyd V. Filson in New Testament matters. Editorial correspondence should be sent to the editors at 800 West Belden Avenue, Chicago, Illinois 60614. Art Editor: Robert H. Johnston, Rochester Institute of Technology. Editorial Board:tG. Ernest Wright, Harvard University; Frank M. Cross, Jr., Harvard University; William G. Dever. Jerusalem: John S. Holladay, Jr., University of Toronto. Subscriptions: $5.00 per year, payable to the American Schools of Oriental Research, 126 Inman Street, (ambridge, Massachusetts 02139.A ssociate members of ASOR receive the BA automatically. Ten or more subscriptions for group use, mailed and billed to one address, $3.50p er year apiece. Subscriptions in England are available through B. H. Blackwell, Ltd., Broad Street, Oxford. Back Numbers: $1.50p er issue, 1960t o present; $1.75p er issue, 1950-1959$; 2.00p er issue before 1950.P lease remit with order, to ASOR office. The journal is indexed in Art Index, Index to Religious Periodical Literature, Christian Periodical Index, and at the end of every fifth volume of the journal itself. Second class postage PAID at Cambridge, Massachusetts and additional offices. Copyright by American Schools of Oriental Research, 1974 PRINTED IN THE UNITED STATES OF AMERICA,B Y TRANSCRIPTP RINTING COMPANY PETERBOROUGH,N . H. Contents The Biblical Potter, by Robert H. Johnston ......................................... 86 An Israelite Horned Altar at Dan, by Avram Biram ................... ............... 106 Cover: An early Egyptian potter using the tournette, dating from the fifth to sixth dynasty (roughly 2500-2200 B. C.). Courtesy of the Oriental Institute of the University of Chicago. The Biblical Potter ROBERT H. JOHNSTON* Rochester Institute of Technology, Rochester, New York So I went down to the potter's house, and there he was working at his wheel. And the vessel he was making of clay was spoiled in the potter's hand, and he reworked it into another vessel, as it seemed good to the potter to do. Jeremiah 18:3-4 The serious study of the pottery from a given site began in 1891 when Sir W.M. Flinders Petrie published the results of his excavation at Tell el-Hesi. He realized the chronological value of sherds from a stratified site and began to establish a corpus of pottery forms arranged in relative chronological sequence. Since that time, every expedition report has contained photo- graphs and drawings, with detailed descriptions and comparative typological *Robert H. Johnston is Dean of the College of Fine and Applied Arts and Director of the School for American Craftsmen at the Rochester Institute of Technology. He serves as the art director for the BA. 1974, 4) THE BIBLICAL ARCHAEOLOGIST 87 studies, of the pottery forms found. Since fired clay is almost indestructible, the greatest proportion by far of the artifacts found at a site consists of thousands of pottery fragments, along with some whole vessels. Petrie wrote in Tell el-Hesy (1891), p. 40: Once settle the pottery of a country, and the key is in our hands for all future explorations. A single glance at a mound of ruins .. . will show as much to anyone who knows the styles of the pottery, as weeks of work may reveal to a beginner. When G. Ernest Wright wrote his doctoral thesis in 1937, he observed that, while Petrie's use of ceramics was basic and of great value in establish- ing chronology, there was more that could be learned from the study of ancient pottery. As he puts it on the first page of his The Pottery of Palestine from the Earliest Times to the End of the Early Bronze Age: But a detailed study of the value of pottery for the history of human culture has yet to appear. Its greatest value at present is undoubtedly chronological; yet more expert studies in the future will perhaps allow the student of ethnology, commerce, and related subjects, to make far-reaching deductions from ceramic evidence, for which at present there is so little solid ground. Dr. Wright had a vision of conducting an excavation of major importance on which specialists of all types could study excavated material and each add his expertise, leading toward a more complete understanding of the data un- earthed. This would involve ethnologists, pollen analysts, geologists, paleo- zoologists, paleo-botanists, ceramic technologists, and all their special tools. The vision was to set a precedent for future excavations in the Mediterranean world. I had the privilege of working with Dr. Wright in the capacity of ceramic specialist for four years, studying material from Idalion, Bab edh- Dhra, Shechem, and other sites. Another influence has also played its part in calling forth studies such as those I shall describe here. Frederick R. Matson of Penn State University developed a new thrust to the study of ancient ceramic materials built around an ecological approach. He has taught a small number of devoted students to use their ceramic studies to better understand the cultural context in which the vessels were produced. He puts it this way in Ceramics and Man (1965), p. 202: Ceramic ecology may be considered as one facet of cultural ecology, that which attempts to relate the raw materials and technologies that the local potter has available to the functions in his culture of the products he fashions. 88 THE BIBLICAL AR CHAEOL0 GIST (Vol. 37, In what follows, I want to carry on a conversation both between the potter and his culture, and between the ancient potter and his modem equivalent in the villages of such places as Cyprus, where age-old techniques are still prac- ticed, informed by long tradition. In all probability the techniques are much the same, so I shall move back and forth without apology. The Potter and His Clay The potters of ancient Palestine played a major role in the life of their times. The role of the craftsman was to produce a variety of objects needed for daily life - the pots and pans of antiquity - as well as special vessels for ceremonial occasions. He also assisted in the production of bricks, roof tile, drain tile, bee hives, cultic stands and other cultic objects, writing materials, kilns, and ovens. The ancient craftsman must have been an important member of his community, although he probably never achieved great political status by practicing his craft. We get a sense of the craftmen's status from a passage in the Apocrypha, where in Ecclesiasticus (Ben Sirach) 38:31- 34 this is said about a variety of craftsmen: All these rely upon their hands and each is skillful in his own work. Without them a city cannot be established and men can neither sojourn nor live there. Yet they are not sought out for the council of the people, nor do they attain eminence in the public assembly. They do not sit in the judge's seat, nor do they understand the sentence of judgment; they cannot expound discipline or judgment, and they are not found using proverbs. But they keep stable the fabric of the world, and their prayer is in the practice of their trades. (All biblical and apocryphal quotations in this article are from the RSV.) The clay used by the biblical potter was an earthenware clay usually found in the immediate vicinity or brought in from no great distance. Village potters in Jordan and adjacent areas today still secure clay from nearby beds. Clay is a material of secondary origin, resulting from the weathering and disintegration of certain types of primary rocks. It is a hydrated aluminum silicate mixed with small proportions of iron compounds, calcium carbonates, quartz, sand, organic matter, and alkalies. The iron compounds bring about the colors of the fired ware and the varying amounts of impurities condition the nature of the clay. Almost all of the village potters I have studied for nine summers, who produce village functional ware, seek and use "thixotropic" clays, clays that are extremely plastic in the forming stage and set up almost immediately when the piece is completed. This immediate hardening of thixotropic clays is very important to the potter, who must work briskly and expeditiously to produce the daily quota of functional pottery. Additives are mixed with the 1974, 4 THE BIBLICAL ARCHAEOLOGIST 89 clay as binders or to slow the drying of attached parts such as handles. The materials so used today are threshing-floor straw, dung, cat-o-nine tail fuzz, and ashes. When one studies ancient sherds with a binocular microscope these same additives can be identified. The addition of non-plastic material to plastic clay reduces excessive shrinking and helps prevent cracking in the pottery during the drying phase. The non-plastic additives also open the clay body and increase the porosity of the ware, an important factor in the storage of water, since it allows cooling by evaporation. The effects of thermal shock when the vessel is fired are also lessened by these additives. The biblical potters and brick makers added threshing floor straw to their clay as noted in Exodus where the Israelites had to go out and search for stubble to add to clay. You shall no longer give the people straw to make bricks, as heretofore; let them go and gather straw for themselves. Exodus 5:7 Thus says Pharaoh, "I will not give you straw. Go yourselves, get your straw wherever you can find it; but your work will not be lessened in the least." So the people were scattered around throughout all the land of Egypt, to gather stubble for straw. Exodus 5:10-12 The practice of adding these materials is continued today, the technique passed on from potter to potter, brick maker to brick maker, over several thousand years. The clay of the ancient potters was used as it was found in nature, except for the removal of large stones. This material sufficed for the manufacture of heavy functional ware and ovens, but for finer, burnished ware a finer clay was needed and this was secured by letting the clay stand in settling basins where the heavier particles would sink to the bottom and the upper layers of fine clay could be skimmed off. After repeated settling, a very fine, watery clay, called "slurry," resulted, which, after the excess water had evaporated, became an excellent clay for throwing and for slip-decorating. Today, village potters sometimes mix several clays from different sources to get just the right clay "body" for the manufacture of the ware they wish to make. Presumably the ancient potter did the same thing. Potters seek, and would have sought in ancient times, colored clays on the slopes of nearby hills where it is the product of the disintegration of certain sedimentary rocks. Red ocher, an earthy form of hematite mixed with clay, was one of the types sought, as were kaolin and white marl, a mixture of clay and calcite useful for making a white slip. Incidentally, this mixing of clays from several sources can cause problems for the modern researcher who is testing ancient sherds for the so-called trace elements of the clay, hoping to be able to find the original clay bed by matching the pattern of trace elements in the sherd with 90 THE BIBLICAL ARCHAEOLOGIST (Vol. 37, what occurs in the modern beds. The ancient potter may have mixed up modern scientists by mixing his clays! Decoration of Palestinian pottery was done by applying clay slips watery solutions of clay - before firing; slips were less liable to rub off or chip than would paint or "wash" applied after firing. Information about the locations of clay beds and deposits of clays good for colored slips was passed from potter to potter, and the rights to beds probably becaihe an important aspect of the potter's survival. When a clay bed was exhausted, the potter might have to make radical changes in the amount of ware he produced, as well as in the form of the vessels he could satisfactorily make. Some special clays were no doubt transported over considerable dis- tances, and therefore constituted an aspect of commerce. An example from modern times is the shipping of "Ball clay" from England to the American colonies. In fact, Ball clay got its name from the fact that it was sold by the ball. Some clays will produce a burnished surface when rubbed with a bone or stone at the leather-hard stage of drying. During the rubbing a fine micro- layer of clay is brought to the surface and forms a sheen. The potter would sometimes get himself a surface for burnishing by dipping wares made of coarse clay bodies in a suspension of clay in water, thereby giving the entire surface a slip. This slip could then be burnished or polished whereas the coarser clay without the slip could not have been. After a satisfactory clay was secured and mixed to the plastic consistency wanted, the potter had to "wedge" or de-air it. Unless this was done, the water distribution would have become uneven in the clay and air pockets would have remained; on firing, these pockets would gather and hold steam, and eventually blow out, shattering the fired ware. One of the ways of wedging clay is fast foot treading, an activity described by two Old Testament prophets. In Isaiah 41:25, we sense this part of the potter's work in a striking word-image: "I stirred up one from the north and he has come from the ris- ing of the sun, and he shall call on my name; he shall trample on rulers as on mortar, as the potter treads clay." Similarly, but here in the brick-making process, Nahum 3:14: "Draw water for the siege, strengthen your forts; go into the clay and tread the mortar, take hold of the brick mold!" Village potters still wedge their clay by treading or by kneading or clap- ping balls of clay together. It is the first step in the manufacturing process and one of the most important if breakage is to be averted (there will be some anyway, as any potter knows). Potters and their apprentices often pride themselves in treading the clay in a rhythmic fashion, forming exact patterns in the clay as they work it. During the wedging process, large stones or pieces of other foreign matter are removed, since they would cause cracking as the plastic clay dries and shrinks. The tempering ingredients - threshing-floor straw, animal dung, 1974, 4) THE BIBLICAL ARCHAEOLOGIST 91 cat-o-nine tail fuzz, shell or sand - are added at this point and worked into the clay to improve the workability and reduce shrinkage. As the potter or his apprentice-helper wedges the clay, he also brings it to the final consistency he wants. If it is too wet and too sticky he can add dry clay. To clay that is too dry, he adds more water and kneads it into the mixture. The potter gauges the consistency of his clay by the way it feels. Fig. i. Side and top views of a small vessel made by the pinch-pot technique. The scale is in centimeters. The Making of Pots The biblical potter used a variety of methods to build and shape his pottery. The earliest evidences of the potters' techniques indicate that hand- building was the means used. Some ware was made by the pinch-pot method: 92 THE BIBLICAL ARCHAEOLOGIST (Vol. 37, a piece of clay is held in the palm of one hand and the walls formed by pinch- ing the clay with the other hand until the walls have been raised and thinned. This method was used for making small containers, such as votive dishes or miniature pots (see Fig. 1). An experienced potter can work very swiftly with this technique and produce a large variety of small forms. The process is de- scribed by Henry Hodges in his 1964 book called Artifacts, p. 25, as follows: A ball of clay is formed and this is held in the palm of one hand, the thumb of the other hand being dug into the clay ball. The ball is then rotated slowly while the clay is gently squeezed between the thumb and fingers of the shaping hand. The process is continued until a pot is formed. Fig. 2. Impression of straw matting in the base of a cooking pot from Ezion Geber. The matting would have been the "bat" on which the piece was made. From R. Amiran, Ancient Pottery of the Holy Land (1970), p. 301. Pottery made in this manner was usually scraped down to refine the form when it was leather hard, and sometimes burnished or polished. A layer of slip could be applied, as we have noted, to take the burnish. Another early technique used to form vessels was the coil method, or a combination of the coil method with a paddle and anvil process. A base of fairly thick clay was laid down on a "bat" made of woven material, bark, stone, or even a piece of broken pottery. This bat allowed the potter to move 11997744,, 44)) TTHHEE BBIIBBLLIICCAALL AARRCCHHAAEEOOLLOOGGIISSTT 9933 Fig. 3. Wood paddles and fired clay anvils used in the paddle and anvil process of hand-building pottery. the piece around as he worked and to carry it to the drying area later. Ancient sherds have been found with the impression of woven material in the base - the imprint of the bat on which the pot was made (Fig. 2). Alfred Lucas (see the 1962 edition of his Ancient Egyptian Materials and Industries, edited by J. R. Harris) suspects that this technique may have had an early start in Egypt: In the early days of pottery making in Egypt, that is during neolithic, Badarian and predynastic times, pots were made by hand, though it is possible that in shaping some predynastic pottery the clay was placed on a mat which could be rotated on the ground. Such a technique was 94 THE BIBLICAL ARCHAEOLOGIST (Vol. 37, Fig. 4. A village potter forming a vessel on a tournette. using the stroking method.