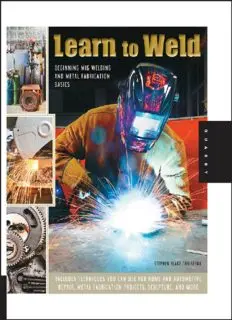

Learn to Weld: Beginning MIG Welding and Metal Fabrication Basics PDF

Preview Learn to Weld: Beginning MIG Welding and Metal Fabrication Basics

BEGINNING MIG WELDING AND METAL FABRICATION BASICS STEPHEN BLAKE CHRISTENA Contents Introduction Part I: Welding 101 Chapter 1 Welding: Start Here How Welding Works The Arc The Filler Metal Flux and Shielding Gas The Ground Spatter Why Learn MIG Welding? Buying Tools and Equipment Chapter 2 Getting Started Your Studio Electrical Ventilation and Lighting Studio Layout Safety and Protective Gear First Aid Sparks Are Flying Protective Gear Equipment and Tools The Chop Saw The Angle Grinder The Welder Other Cutting Tools Chapter 3 Selecting, Buying, and Prepping Your Metals Hot Roll vs. Cold Roll Filler Material Decorative Options Buying Metal How to Order Preparing Your Metal Let’s Prep Chapter 4 How It Works Technique The Puddle Stance and Comfort Vision Hand Position Angle of the Gun Heat vs. Thickness Clamps and Tacking Exercise 1: The Draw Part II: Using Your MIG Chapter 5 The Basics Basic Joints Technique Exercise 1: Butt Joints Exercise 2: Corner (or Fillet) Welds The Rest of the Joints Corner Joints Lap Joints The Edge Joint Exercise 3: Jigs Other Welding Situations and Positions Vertical Welding Cross Body Welding Chapter 6 Projects Project 1: The Cube Project 2: The Welding Table Project 3: The Runner Gallery Glossary Resources About the Author Acknowledgments Index Introduction W hile I was growing up in Flint, Michigan, my dad, brother, and I would make and fix all kinds of things. My dad instilled his philosophy in me at a young age: “Why pay someone else to do something you can do yourself?” We enjoyed fixing everything from cars to bicycles, dishwashers, and TVs. We re-roofed houses and rewired radios. We built wooden tool chests, skateboards, snowboards, and hockey sticks. We were always working on a wide variety of projects using everything under the sun and all kinds of cold connections like nuts and bolts, screws, nails, glue, epoxy, fiberglass, solder, pop rivets—you name it; we used it. I grew up into a confident handyman and consummate tinkerer with an appreciation for three-dimensional construction. By the time I started college I was no stranger to creating sculptures, furniture, art, and all sorts of other things using traditional woodworking and cold connection methods. But then in my first metal sculpture class, I cut into a piece of 11 ga mild steel with an oxy-acetylene gas torch and I was hooked. Metalwork and fabrication amazed me and became my passion. The way this cold, hard, and seemingly uncooperative material was so easily cut, formed, and manipulated still astounds me. As I learned how to weld, heat, bend, and cut various metals, I could not believe how these incredibly durable materials became as easy to work with as clay. Exploring the unlimited potential of metal work became the compass for the rest of my life. I never stopped welding. After graduation, I moved to Chicago and set up my first shop on the south side, equipped with only a small 120 V Hobart MIG welder and grinder. Over the years, I moved my shop around a few times, expanded my gear, and worked in a wide range of fab shops, learning as much as I could along the way. By the time I started my first fabrication company, I had worked for some of the top designers in the furniture industry and for world-class architects, and I’d worked side by side with amazing metal artists, fabricators, and sculptors. Each of them influenced my perspective and expanded my knowledge of metal work, for which I am grateful. “Exploring the unlimited potential of metal work became the compass for the rest of my life.” Then a few years ago some motorcycle friends approached me and asked about learning to weld and chop frames for their race bikes. After a few basic lessons in welding, they were asking me to teach them how to make their own bikes lighter, how to weld and fabricate new parts, and how to build custom components. Before I knew it I was teaching community welding classes at my metal studio, Midwest Metalworks. After a lesson recently, one of my students said to me, “You can pretty much make anything, knowing how to weld.” He had an amazed expression of bewilderment at the vast potential of this new medium that he had just learned. He had realized the fantastic new world of possibilities that I had discovered almost two decades before. Now you can too. If you enjoy working with your hands, learning metalwork will give you a wealth of knowledge that will expand and challenge your ability to create. There are so many different techniques, styles, and methods to learn in welding, and in this book, I hope to introduce to you the enormous possibilities that come with each one. The key place to start is learning the basics of Metal Inert Gas (MIG) welding, which we’ll learn in the following pages. You’ll learn the basic rules and principles of welding that can be applied to other processes such as Stick and Tungsten Inert Gas (TIG) welding. MIG is just the beginning. It takes time and practice to become a good welder, but I hope through this text you will soon instinctively recognize a good weld that is laid properly. Just like an excellent musician knows when they are in tune or have played a bad note, an experienced welder understands their craft. The more arc time you log and the more projects you fabricate, the more the world of metalwork will open up to you. —Stephen Blake Christena, Chicago 2013 I Welding 101