Heat Transfer Coefficients for Liquid Mercury and Dilute Solutions of Sodium in Mercury PDF

Preview Heat Transfer Coefficients for Liquid Mercury and Dilute Solutions of Sodium in Mercury

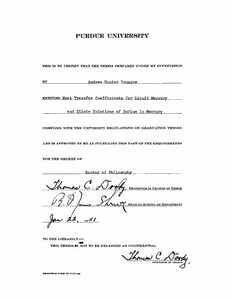

PURDUE UNIVERSITY THIS IS TO CERTIFY THAT THE THESIS PREPARED UNDER MY SUPERVISION BY Andrew Hunter Vrm-nger enTIT-LED Heat Transfer Coefficients for Liquid Mercury______ __________ and Dilute Solutions of Sodium in Mercury________ COMPLIES WITH THE UNIVERSITY REGULATIONS ON GRADUATION THESES AND IS APPROVED BY ME AS FULFILLING THIS PART OF THE REQUIREMENTS FOR THE DEGREE OF Doctor of Philosophy Professor in Charge of Thesis Head of School, or Department <r/ 19 TO THE LIBRARIAN:----- -W THIS THESIS $S NOT TO BE REGARDED AS CONFIDENTIAL. C.Ai PROFESSOR IX C REGISTRAR FORM 10—7-47—1M HEAT TRANSFER COEFFICIENTS FOR LIQUID MERCURY AND DILUTE SOLUTIONS OF SODIUM IN MERCURY A Thesis Submitted to the Faculty of Purdue University by Andrew Hunter Younger In Partial Fulfillment of the Requirements for the Degree of Doctor of Philosophy January, 1951 ProQuest Number: 27714260 All rights reserved INFORMATION TO ALL USERS The quality of this reproduction is dependent upon the quality of the copy submitted. In the unlikely event that the author did not send a complete manuscript and there are missing pages, these will be noted. Also, if material had to be removed, a note will indicate the deletion. uest ProQuest 27714260 Published by ProQuest LLC (2019). Copyright of the Dissertation is held by the Author. All rights reserved. This work is protected against unauthorized copying under Title 17, United States Code Microform Edition © ProQuest LLC. ProQuest LLC. 789 East Eisenhower Parkway P.O. Box 1346 Ann Arbor, Ml 48106 - 1346 TABLE OF CONTENTS ABSTRACT....................................................... 1 INTRODUCTION...................................................X PREVIOUS WORK..................................................1 METHOD......................................................... 6 Approach*........................................... *•••6 Apparatus................................................ 7 Procedure............................................... 2X DATA AND RESULTS............................................. 24 Materials.......................................... ....*24 Calculation of the Heat Transfer Coefficient..... 25 Calibration Data........................................ 30 Mercury Data................ 32 Mercury Data Correlation. ...... •••36 Mercury Sodium Data.. ................................*41 Mercury Sodium Data Correlation....................... .44 Discussion of Data.............. 49 RECOMMENDATIONS............................................... Improvement in the Apparatus........... *55 Further Work............ ............ .......... ....**56 CONCLUSIONS. ............................................... APPENDIX A....................................................59 Physical Properties of the Materials .............••••59 APPENDIX ........................................ 60 Orifice Calibration. * .................. GO APPENDIX C....................................................69 Sodium Analysis........................... 69 APPENDIX D....................................................74 Statistical Methods.....................................74 NOMENCLATURE..................................................78 LITERATURE CITED............................................. 80 ACKNOWLEDGMENT The author wishes to acknowledge the helpful assistance and guidance of Dr. T. C. Doody under whose direc tion this work was carried out. LIST OF FIGURES Figure Page 1. Mercury Heat Transfer Data and Suggested Equations 4 2. Diagram of Apparatus............................... 8 3. Heat Exchanger Detail............. 9 4. End Piece Detail.............. 11 5. Fluid Circulating System..................... . 12 6. Heating and Cooling Systems........................ 15 7. Thermocouple Positions........................... 17 8. Thermocouple Grooves in Pipe Wall................ 19 9. Thermocouple Entrances in H. E. Wall...... * 20 10. Hot Water Thermocouple Installation. ......... 22 11. Fluid Thermocouple Installation.............. 22 12. Electrical Circuit. .................... 23 13. Temperature Distribution Along Test Section........ 28 14. Butanol Heat Transfer Coefficient................ 31 15. Mercury Data Correlation. ...................... 41 15A. Comparison of Equation for Different ^ of Sodium.. 45 16. Mercury Sodium Data Correlation.................... 47 17. Comparison of Author* s Equations with Previously Suggested Correlations......................... 50 18. Orifice Calibration Curve for Butanol; Orifice Diameter = 1/8 inch. 61 19. Orifice Calibration for Butanol; Orifice Diameter = 3/l6 inch. 62 20. Orifice Calibration for Mercury; Orifice Diameter = l/s inch. 64 21. Orifice Calibration for Mercury; Orifice Diameter = 3/16 inch. 65 Figure Page 22. Sodium Analysis. ........................... 70 23. Deviation of Mercury Data........................... 76 24. Deviation of Mercury Sodium Data.................. 77 LIST OF TABLES Table Page 1. Surface Tension of Sodium in Mercury Solution..... 5 2. Butanol Heat Transfer Coefficients.................. 32 3. Mercury Experimental Data........................... 33 4. Mercury Correlation Data............................ 37 5* Mercury Sodium Experimental Data.............. 42 6. Coefficient of the Heat Transfer Equation for dif ferent % of Sodium........................... 44 7* Mercury Sodium Correlation Data. ............... 46 8. Heat Balances....... 51 9. Physical Properties of the Materials........ 59 10. Butanol Orifice Calibration Data. ......... 60 11* Mercury Orifice Calibration Data. ....... 63 12. Sodium Analysis Data................................ 72