Engineering Design Handbook - Electrical Wire and Cable PDF

Preview Engineering Design Handbook - Electrical Wire and Cable

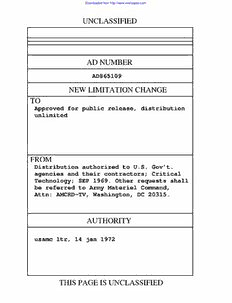

Downloaded from http://www.everyspec.com UNCLASSIFIED AD NUMBER AD865109 NEW LIMITATION CHANGE TO Approved for public release, distribution unlimited FROM Distribution authorized to U.S. Gov't. agencies and their contractors; Critical Technology; SEP 1969. Other requests shall be referred to Army Materiel Command, Attn: AMCRD-TV, Washington, DC 20315. AUTHORITY usamc ltr, 14 jan 1972 THIS PAGE IS UNCLASSIFIED Downloaded from http://www.everyspec.com 'AN C PAMPHLET AMCP 706-125 ENGINEERING DESIGN HANDBOOK ELECTRICAL 'A WIRE AND CABLE _4 Reproduced by the tor Federal Scientific & Techn;cal lntormation Springfield Va. 22151 FEB 19 19 S 11STATWARIT #2 UNCLASS&IID .... ~1adocument is Sbet to spe..- il export controls SX4 trausm4ttal to flTreign '.n ri,,nZentL or foreign nationals xmqr W , madIe ggyj with prior approval o:1---------------- HEADQUARTERS, U.S. ARMY MATERIEL COMMAND SEPTEMBER 1969 . ... ;L6 A Downloaded from http://www.everyspec.com DISCLAIMER NOTICE THIS DOCUMENT IS BEST QUALITY PRACTICABLE. THE COPY FURNISHED TO DTIC CONTAINED A SIGNIFICANT NUMBER OF PAGES WHICH DO NOT REPRODUCE LEGIBLY. Downloaded from http://www.everyspec.com drJ K HEADQUARTERS UNITED STATES ARMY MATERIEL COMMAND WASHINGTON, D.C. 20315 30 September 1969 AMC PAMPHLET No. 706-125 ENGINEERING DESIGN HANDBOOK ELECTRICAL WIRE AND CABLE Paragraph Page " . LIST OF ILLUSTRATIONS .................. ..... xi LIST OF TABLES ............................ xiii LIST OF EQUATIONS - QUICK REFERENCE ........ ... xvi PREFACE .............................. xix CHAPTER 1 CONDUCTORS 1-1 Material Elements .. .......................... 1-1 1--1.1 Copper (ETP and OFHC) .. ..................... 1-1 1--1.2 Copper (Hot Rolled) .. ........................ 1-1 1-2 Wire Size (Solid) .. .......................... 1-1 1-2.1 Gaging Systems ........................... 1-1 1-2.2 Circular Mil Area (CMA) ....................... 1-1 o 1-2.3 Copper Wire Dimensions ....................... 1-2 1-2.4 DC Resistance .. ........................... 1-2 1-3 Coatings ... ............................... 1-2 1-3.1 Methods of Coating ........................... 1-2 1-3.1.1 Tin ... .................................. 1-2 1-3.1.2 Silver .......... ........................ : 1-3 1-3.1.3 Nickel .. ................................. 1-4 1-3.2 Dual Coating ............................... 1-4 1-3.3 Claddings .. ............................... 1-5 1-4 Aluminum ........... ................. i-5 1-4.1 Uses .. .................................. 1-5 1-4.2 Coatings ................................ 1-S 1-5 Alloys ................................. 1-5 I, 0 1-5.1 General Propeties .. ......................... 1-5 " 1-5.2 High Conductivity Types ....................... 1-5 1-5.3 High Conductivity-High Strength Types ............. 1-6 1-6 Stranding ...... ........................... 1-6 1-6.1 Bunched Stranding .. ......................... I- 1-6.2 Concentric Stranding .......................... 1-8 11-k6 .3 Rope Stranding ........................... 1-8 1-7 Soldenng ............................... 1-8 1-7.1 Soldering Stranded Wire .. ...................... 1-9 [ 1-7.2 Heavy Tinned Stra.iding .. ...................... 1-9 1-7.3 Silver-coated Stranding ........................ 1-9 1-7.4 Nickel-coated Stranding . ...................... 1-10 1-7.5 Composite Stranding ......................... 1-10 1-8 Terminations .............................. 1-10 1-8.1 Crimp Termination...........................1-10 1-8.2 Wire Wrap Termination.. ....................... 1-10 1-9 Shielding .................................. 1-11 1-9.1 General .. ................................ 1-11 Downloaded from http://www.everyspec.com AMCP 706-125 Paragraph Page 1-9.2 Braid Terminology........................... 1-11 1-9.3 Computation of Braid Angle and Coverage............. 1-12 1-9.4 Served Shields.............................. 1-13 1-9.5 Shielding Effectiveness......................... 1-13 1-10 Flex-life Comparison-Copper vs Alloy 63..............1-19 U.1-10.1 Test Method........................ ....... 1-19 .. 1-10.2 Comparative Data ................... 1-19 References. .. .. .. .. .. .. .. .. ... .. ... .... 1-25V CHAPTrER 2 INSULATION MATERIALS 2-1 Introductioa............................... 2-1 2-2 The.zmiplastic Insulation Materials.................. 2-1 2-2.1 Polyvinylchioride............................ 2-1 2-2.2 Polyolefins................................ 2-2 2-2.2.1 Low-density Polyethylene....................... 2-2 2-2.2.2 High-density Polyethylene....................... 2-2 .12-2.2-32.2.3 Polypropylene.............................. 2-3 Cros.Iinked Polyolefins........................ 2-3 2-2.4 Nylon.................................... 2-6 2-3 Fluorocarbons.............................. 2-7 2-3.1 Polytetrafluoroethylene (TFE).................... 2-7 2-3.2 Copolymtr of Teirafluoroethylene and . Perfluoropropylene (FEP)...................... 2-7 2-3.4 Polyvinlidenetfluorie (F)...................2-8C 2-3.3 Polyvihlroerifluorehy e (TFE.................... 2-8 2-4 Polyurethanes:.............................. 2-8 2-4.1 Physical Properties .......................... 2-8 2-4.2 Thermal Properties........................... 2-9 2-4.3 Uses..................................... 2-9 2-5 Rubber................................... 2-9 2-5.1 Natural Rubber (Polyisoprene).................... 2-9 2-5.2 Styrene-butadiene Rubbers. .. .. .. .. .. .. .. .. .. ... 2-9 2-5i.3 Chloroprene Rubber. .. .. .. .. .. .. .. .. .. .. .. ... 2-10 2-5.4 Butyl Rubber. .. .. .. .. .. .. .. .. .. .. .. .. .. ... 2-10 2-5.5 Silicone Rubber............................. 2-10 2-5.6 Chlorosulfonated Polyethylene..................... 2-13 I 2.-5.7 Ethylene Propylene Rubber...................... 2-13 2-5.8 Fluorocarbon Rubber......................... 2-13 2-6 Films................................... 2-14 V 2-6.1 Cellulosics................................ 2-14 2-6.2 P31lvcsters................................ 2-14 2-6.3 Fluorocarbons............................. 2-16 2-6.4 Polyimide................................ 2-16 2-7 Fibers................................... 2-17 2-7.1 Cotton....................................2-17 2-7.2 Rayon.................................. 2-17 2-7.3 Nylon................................... 2-17 Downloaded from http://www.everyspec.com AMCP 706-125 I Paragraph Page 2-7.4 Polyester .. ............................... 2-17 2-7.5 Class .. ................................ 2-17 2-7.6 Ceramina ................................ 2-18 2-7.7 Asbestos .....".. ".."..2..-..1..8.............. 2-7.8 Fiber Combination?........................... 2-18 2-7.9 Coated Fibers..............................2-18 $ 2-8 Lacquers. .................................. 2-18 2-8.1 Cellulose Acetate Butyra..t.e. ..................... 2-18 2--8.2 Nylon ..................................... 2-18 9 2-8.6 Bondable Coating.s. ........................... 2-20 2-8.7 PolySImide Coating.s. ....................... ..... 2-20 2-9. Typesiaof PottingCo m..p..o..u..n.d..s.. ........ ........ 2-2 1 2-9.2 Potting - Design Criter.i.a ...................... 2-21 2-9.2.1 Surface Preparation ......................... ... 2-21 2-9.2.2 Mechanical Factors .................... ..... .. 2-21 2-9.2.3 Chemical Factors .......................... ... 2-21 2-10 Inorganic Insulations. .. .. .. .. .. .. .. .. .. .. .. ... 2-21 2-10.1 Magnesium Oxide Insulation .. .. .. .. .. .. .. .. .. ... 2-23 i, 2-10.2 Magnesium Oxide Beads . . . . . . . . . . . . . . . . . . . .. ". 2_23 hJ2-11 Special Environments .. .. .. .. .. .. .. .. .. .. .. .... 2-23 S2-11.1 Fungus Resistance .. .. . . . . . . . . . . . . . . . . . . . . .. 2-23 2-11.2 Radiation Resistance ........................ ... 2-23 References .............................. ... 2-27 CHAPTER 3 DESIGN FACTORS - HOOK-UP AND INTERCONNECTING WIRE 3-1 Scope ..... ............... ................... 3-I 3-2 Factors Influencing Design........................... 3-I1 3-2.1 Environm-mial Factors .. .. .. .. .. .. .. .. .. .. ..... 3-1 3-2.1.1 High Temperature. .. .. .. .. .. .. .. .. .. .. .. .. ... 3--1 3-2.1.2 Low Temperatui . .. .. .. .. .. .. .. .. .. .. .. .. ... 3-1 3-2.1.3 I-lammabiity .. .. .. .. .. .. .. .. .. .. .. .. .. .... 3-1 3-2.1.4 Moisture and Fung.s ... .. .. .. .. .. .. .. .. .. .. ... 3-2 3-2.2 Chemicali Factors ... .......................... 3-2 3-2.2.1 Liquid................................... 3-2 3-2.2.3 Gaseous................................. 3- 3-2.2.4 Corro sion.................................. 3-2 3-2.2.5 O'.!tassing................................. 3-2K. 3-2.3 Mechanical Factois............................ 3-2 3.-2.3.1 Flex'ife ............................... 3-2 3-2.3.2 Abrasion Resistance........................... 3-3 3-.2.3.3 Penetiation................................ 3-3 Wikl Downloaded from http://www.everyspec.com AMCP 706-125 Paragraph Page 3-2.3.4 Tensile Strength ..... .......................... 3-3 3-2.3.5 Elongation ..... ............................ 3,-3 3-2.4 Electrical Factors.............................. 3-3 3-2.41 Dielectric Constant ......................... ..... 3-3 3-2.4.2 Dielectric Strength ......................... ..... 3-3 3-2A.3 Gradient (Electrical) ........................ ..... 3-3 3-2.4.4 Insulation Resistance ........................ ..... 3-4 3.2.4.5 Loss Factor ............................. ..... 3-4 3-2A4.6 Current-carrying Capacity ..................... 3-4 3-2.4.7 Voltage Drop ............................ ..... 3-4 3-2.5 Identification ............................ . ... .. 3-5 3-3 Design Considerations ....................... 3-5 3-3.1 Conductor Choices ..... ....................... 3-5 3-3.1.1 Mechanical Factors ..... ........................ 3-5 3-3.1,2 Thermal Factors .............................. 3-5 3-3.2 Insulation Choices ......................... ..... 3-6 3-3.2.1 Mechanical Considerations ..................... .... 3-6 3-3.2.2 Electrical Considerations ...................... .... 3-6 3-4 Testing To Prove Design ...................... .... 3-6 3-4.1 Electrical Tests ........................... ..... 3-7 3-4.2 Physical Tests ............................ ..... 3-7 3-4.3 Aging Tests ..... ............................. 3-7 3-4.4 Thermal Tests ............................ ..... 3-7 3-4.5 Mechanical Tests .......................... ..... 3-7 3-4.6 Chemical Tects ........................... ..... 3-7 3-5 Hook-up vs Interconnecting Wire ................ ..... 3-7 3-5.1 Hook-up Wire ................................ 3-7 3-5.2 Interconnecting Wire and Cable .................. .... 3-8 3-6 Comparison of Hook-up Wire Types .... .............. 3-8 3-6.1 MIL-W-76 ..... .............................. 3-8 3-6.2 MIL-W-16878D ........................... . 3-11/3-12 3-6.3 MJL-W-81044 .............................. 3-11/3-12 3-6.4 M__L.W-27300 ............................ . 3-11/3-12 3-6.5 MIL-W-22759 ............................ .. 3-11/3-12 3-7 Comparison of Interconnecting Wire Type, ........... 3-11/3-12 3--7.1 MIL-W-5086 .............................. 3-11/3-12 3-7.2 M1L-W4;1044 . ............................ 3-11/3-12 3-7.3 MIL-W,7139 . ............................. 3-11/3-12 3-7.4 MIL-W-8777 ............................. 3-11/3-12 References ................ .............. 3-15/3-16 CHAPTER 4 BUNDLED WIRES 4-1 Laced Bundles ................................. 4-1 4-1.1 Lacing ............................. .. 4-1 4-1.2 Usage - Laced Bundles ....................... 4-2 Prefabricated Bindles ..... ..................... 4- 4-2.1 Construction .................................. 4-1 4-2.2 Components ..... ........................... 4-2 iv Downloaded from http://www.everyspec.com Fm AMCP 706125 Paragraph Page 4-2.3 Color Code .................................. 4-2 4-2.4 Shield ... ................................. 4-2 4-2.5 Jacket ... ................................. 4-2 4-3 Deraiing Factors for Bundled Wires .................. 4-2 4-3.1 Introduction ............................. 4-2 4-3.2 Basic Considerations ... ........................ 4-2 4-4 Derating Calculations ........................... 4-6 4-4.1 Symbols and Their Definitions ... .................. 4-6 4-4.2 Rating Procedure ... .......................... 4-6 4-4.3 Usage --C urrent Rating Procedure .................. 4-7 4-5 Ribbon Cable ... ............................ 4-21 4-5.1 Introductioa .. ............................. 4-21 4-5.2 Usage ... ................................. 4-21 4-5.3 Constnction ............................... 4-21 4-5.3.1 Adhesive Bonding ............................. 4-21 4-5.3.2 Thermal Fusing ... ........................... 4-21 4-5.3.3 Direct Extrusion ... .......................... 4-21 4-5.3.4 Envelope ......... ......................... 4-21 4-5.3.5 Braided or Woven ............................. 4-21 4-6 Comparison - Ribbon Cable vs Round Multiconductor Cable. 4-21 4-6.1 Advantages - Ribbon Cable ...................... 4-21 4-6.2 Disadvantages - Ribbon Cable .................... 4-22 4-7 Tape Cable ................................ 4-22 4-47'.1 Introduction ............................. 4-22 4-7.2 Usage ... ................................. 4-22 4-7.3 Flat Wire ... ............................... 4-22 4-7.3.1 Constructional Factors ......................... 4-23 4-7.3.2 Construction ............................... 4-23 4-7.3.3 D'advantages - Flat Wire ....................... 4-23 4-7.4 Constructional Considerations ...................... 4-23 4-7.5 Testing ... ................................ 4-23 4-7.5.1 Folding Test ............................. ... 4-24 4-7.5.2 Roll Flexure lest .......................... ... 4-24 4-7.5.3 Straight Flexure Test ........................ 4-24 4-7.6 Installation .............................. ... 4-26 References ................................. 4-27 CHAPTER 5 COAXIAL CABLE 5-1 Introduction .... ............................ 5-1 5-2 Types of Coaxial Cable .... ..................... 5-1 5-2.1 Definitions .... ............................. 5-I 5-2.1.1 Coaxial ................................ 5-1 5-2.1.2 Twin Coaxial ............................ 5-1 5-2.1.3 Dual Coaxial ............................. 5-1 5-2.1.4 Double Shielded ............................... 5-1 5-2.1.5 Triaxial ..... ............................. 5-1 5-3 Materials ............................... 5-1 U -~_____ Downloaded from http://www.everyspec.com )f 706-125 -AMCP Paragraph Page 5-4 Electrical Properties of Coaxial Cable ................ 5-1 5-4.- Basic Parameters .... ......................... 5-1 5-4.1.1 Capacitance .... ............................ 5-2 5-4.1.2 Phase Angle .... ............................ 5-5 5-4.1.3 Power Factor .... ........................... 5-5 5-4.1A Dielectric Constant ........................... 5-5 5-4.1.5 Velocity of Propagation ... ..................... 5-5 5-4.1.6 Characteristic Impedance ..................... .... 5-5 5-4.1.7 Propagation Constant ........................ .... 5-8 5-4.1.8 Attenuation and Phase Shift ................... .... 5-8 5-4.1.9 Corona and Voltage Rating .................... ... 5-14 5-5 Air-spaced Cables .......................... .... 5-20 5-5.1 General Constructional Details ................. .... 5-20 5-5.2 Uses .................................. .... 5-20 5-6 Voltage Standing Wave Ratio (VSWR) .............. .. 5 -20 5-6.1 Reflection - Coaxial Cable System ................ .. 5-20 5-6.2 Reflection Causes - Coaxial Cable Systems ........... 5-22 5-7 Power Rating ... ............................ 5-22 5-7.1 Power Handling Capacity ... ..................... 5-22 5-7.2 Power Rating Due to VSWR ..................... 5-23 5-8 Shields ... ................................ 5-23 5-8.1 Picks ......... : ....................... 5-23 5-8.2 Carriers ... ................................ 5-23 5-8.3 Ends ... ................................. 5-23 5-9 Shielding Effectiveness .......................... 5-25 5-9.1 Surface Transfer Impedance ....................... 5-25 5-9.2 Reference ... .............................. 5-26 5-10 Transmission Unbalance ........................ 5-26 5-10.1 General ................................ .... 5-26 5-10.2 References for Test and Measurement .............. .. 5-27 5-11 Coverings and Sheaths ....................... ... 5-27 5-11.1 Uses .................................. .... 5-27 5-11.2 Fibrous or Textile ... ......................... 5-27 5-12 Special Purpose Coaxial Cables .................... 5-28 5-12.1 Pulse Cables ... ............................. 5-28 5-12.2 Delay Lines ... ............................. 5-28 5-12.3 Low Noise Cable ... .......................... 5-29 5-13 Practical Constructional Considerations ............... 5-29 5-13.1 Size ... .................................. 5-29 5-13.2 Concentricity and Eccentricity .................. ... 5-30 5-13.3 Abrasion ............................... .... 5-30 5-13.4 Contamination ............................ ... 5-30 5-14 Environmental Conditions ....................... 5-30 5-14.1 General Considerations ......................... 5--30 5-14.2 Insulation Guide ............................ 5-30 5-15 Dissussion of Application - Major Usage ............. 5-30 References ............................. . 5-31/5-32 viC Downloaded from http://www.everyspec.com r- 18 AMCP 706-125 Paragraph Page CHAPTER 6 CONTROL AND SIGNAL CABLES 6-1 Introduction ... ............................. 6-1 6-2 Ar-lications of Control and Signal Cables ............. 6-1 '0 6-3 Cor itructional Des.gn Factors .. .................. 6-1 6-3.1 Physical Considerations ... ...................... 6-1 6-3.2 Electrical Considerations ........................ 6-2 6-4 Cable Types ................................ 6-2 6-4.1 Portable ... ............................... 6-2 6-4.2 Nonportable ... ............................. 6.-2 6-5 Multiconductor Cable Design ..................... 6-2 6-5.1 General Considerations ......................... 6-2 6-5.2 Specific Coastruction Considerations ....... ........ 6--3 6-6 Multiconductor Construction ..................... 6-3 6-6.1 Conductors and Components ..................... 6-3 6-6.2 Component Strandings ......................... 6-6 6-6.3 Basic Insulated Wire ... ........................ 6-6 6-6.4 Component Shielding ........................... 6-6 6-6.5 Component Shield Covering and Component Jacket Dimensions 6-7 6-6.6 Cabling ... ................................ 6-7 6-6.6.1 Lay .. ................................... 6-8 IW 6-6.6.2 Pitch Diameter ... ......................... . 6-9 6-6.6.3 Lay Construction .. .......................... 6-9 6-6.7 Cable Fillers ... ............................. 6-9 6-6.8 Color Coding Control and Signal Cables .............. 6-10 i 6-6.8.1 Color Coding Methods ....................... .. 6-10 6-6.8.2 Color Code Application ...................... ... 6-10 6-6.8.3 Color Code and Related Numbers ................ .. 6-I1 6-6.8.4 Specifications .. ............................ 6-11 6-6.9 Cable Binders . ............................. 6-12 6-6.10 Cable Sheaths .. ............................ 6-13 6-6.11 Sheath Application ........................ 6-13 6-6.12 Armor ... ................................ 6-13 6-6.13 Cable Identification Marking .. ................... 6-15 6-7 Multiconductor Cable Testing .................... 6-16 6-7.1 Cable Cross-talk ........................... 6-16 6 7.2 Tests and Test Methods .. ...................... 6-16 6-7.3 Multiconductor Cable Tests ..................... 6-16 6-7.3.1 Cold Bend Test ........................... 6-17 6-7.3.2 Impact Test .. ............................. 6-17 6-7.3.3 Torque Test .. ............................. 6-17 6-7.3.4 Twist Te. . ............................... 6-17 i 6-7.3.5 Bend Test ... .............................. 6-18 6-7.3.6 Dielectric and Pulse Dielectric Tests ................ 6-19 6-7.3.7 Insulation Resistance Test ...................... 6-22 6-7.3.8 Measuring Capacitance in a Multiconductor Cable..........6-23 6-7.3.9 Abrasion Resistance .. ........................ 6-25 6-7.3.10 Tensile Strength of Multiconductor Cable ............. 6-27 References .............................. 6-29 i'- __vii_