DTIC ADA532486: Influence of Aluminum Passivation on the Reaction Mechanism: Flame Propagation Studies PDF

Preview DTIC ADA532486: Influence of Aluminum Passivation on the Reaction Mechanism: Flame Propagation Studies

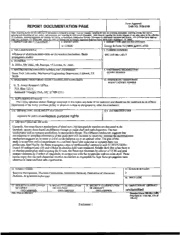

FDrm AppnM!d REPORT DOCUMENTATION PAGE OMS NO. 07GHH88 I'ublil: Ilc(IOrling burden for lhl, CQIJCtliOIl of infol'1lla,ioll is csllnulloo 10 avcragc I hour pcr rCSjllll15C. iDcIudillg !he time far ~ ~ ~ ""~ ..." "_ns. galllcring and Inalmalnlng thl! d~m "ccded. nnd colllpll'lins rulU ,.lviuwiDg Ihe collection of Infnnn.allOll. Scod CtlIIIIIII:'III ~ Illis btlAlnI <'liIiInIII:s ... a:!} ..... iIIIpIXIilf'." ~ "f Illrurmntion. Including ~ull8"S!lans for reduclnll ,bl~ burden. 10 Washin!ll0n HcalkluanclS Scr\-1<:es. Dlrrc10mll for hlformatloft ()pcr.o:irJM am Rq:>oIa. IllS Jcl'"_ IRri!. ~. Sulle 12.001. ArlllllllOn, VA 22202·4302. alld IU 11m OffiCI! of IMa na~clll"Rl ant! flIIIl'CI. I'llJlMWOl'k Rcductiolll'ml<!C1 (071)10188.) W~DII. DC Z05III. I. AGENCY USE ONLY ( Leave Blank) J. REPORT TYPE AND OATF.5 COVERED :/=~~OATE Energy & Fuels 23 (2009) pp4231-4235 4. TiTlE AND SU8TITLH S. FUNDING NUMBERS Influence of aluminum passivation on the reaction mechanism: flame W911NF...()4..l-0217 propagation studies 6. AUTHOR(S) B. Dikici. SW Denn, ML Pl'll1toya. VI Levitas, RJ. Jouet 8. 7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES) PERFORMING ORGA"IIZA TlON REPORT NUMBER Texas Tech University, Mechanical Engineering Department. lubboCK. TX 79409 9. SPONSORING 11',,10NITORING AGENCY NAME(S) AND ADDRESS(ES) 10. SPONSORING I MONlTORING AGENCY REPORT ""'UMBER U. S. Army Research Office P.O. Box 12211 Research Triangle Park, NC 27709-221 I II. SUPPLBMENTAItY NOTES The views, opinions and/or findings contained in this report nre those of the Iluthor(s) and should nUl be construed as an official Depl.lI'Lmenlllf'the Army position, policy or decision. unless so designated by other documentation. 12 a. DISTRIBUTION J AVAILABILITY STATEMENT 12 b. DISTRIBUTION CODE Approved ror public relcosefederal purpose rights 13. ABSTRACT (Ma1>il1lUm 200 lVords) Currently, two main known mechanisms of aluminum (AI) nanopartic1e reaction are discussed in the literature, namely those based on diffusion through an oxide shell and mell-dispersion. The two mechanisms lead to opposite predictions in nanoparticle design. The diffusion mechanism suggests that the reduction Dr complete elimination of the oxide shell will increase AI reactivity, whereas the meltdispersion mechanism suggests an increase in initial oxide thickness up to an optimal value. The goal of this study is to perform critical experiments in a confined flame tube apparatus to compare these two predictions. Specifically, the flame propagation rates ofperfluoroalkyl carboxylic acid (CI3F27COOH)- treated Al nanoparticles with and without an alumina shell were measured. Results show that when there is no alumina passivation shell encasing the Al core, the flame rate decreases by II factor of22-95 and peak pressure deceases by 3 orders of magnitude, in comparison with the AI particles with an oxide shell. These results imply that the melt-dispersion reaction mechanism is responsible For high flame propagation rates observed in these confined tube experiments. 14. SUBJECT TERMS 15. NUMBER OF PAGES Rt'Rclion Mechanisms, Thermite Combustion, Aluminum Particles, Passivation of Aluminum 5 Particles, AI synthesis techniques 16. PRICECODE 118. 17. SECURITY CLASSIFICATION SECURITY CLASSIFICATION 119. SECURITY ClASSIFICAllO!-1 20. UMITATIONOF ABSTRACT OR REPORT ON TI·HS PAGE OF ABSTRACT unclassified UNCLASSIFIED UNCLASSII'JED lll'lCLASSIFIED NSN 7540-01·280-5500 SUllu:llani Fonn 298 (Rtv..l..", I'I5:7ibed hv ANSI SId. 239.111 298-102 • Enclosure 1 : EnergyFuels2009,23,4231–4235 DOI:10.1021/ef801116x PublishedonWeb08/06/2009 Influence of Aluminum Passivation on the Reaction Mechanism: Flame Propagation Studies BirceDikici,†StevenW.Dean,†MichelleL.Pantoya,*,†ValeryI.Levitas,*,‡andR.JasonJouet§ †MechanicalEngineeringDepartment,TexasTechUniversity,Lubbock,Texas79409,USA,‡DepartmentofMechanical Engineering,DepartmentofAerospaceEngineering,andDepartmentofMaterialScienceandEngineering, 2025BlackEngineeringBuilding,IowaStateUniversity,Ames,Iowa50011-2161,USA,and§ResearchandTechnology Department,IndianHeadDivision-NavalSurfaceWarfareCenter,IndianHead,Maryland20640,USA ReceivedJanuary11,2009.RevisedManuscriptReceivedJune24,2009 Currently, two main known mechanisms of aluminum (Al) nanoparticle reaction are discussed in the literature, namely those based on diffusion through an oxide shell and melt-dispersion. The two g mechanismsleadtooppositepredictionsinnanoparticledesign.Thediffusionmechanismsuggeststhat or the reduction or complete elimination of the oxide shell will increase Al reactivity, whereas the melt- s. ac dispersionmechanismsuggestsanincreaseininitialoxidethicknessuptoanoptimalvalue.Thegoalofthis s. b study is to perform critical experiments in a confined flame tube apparatus to compare these two u 009 | http://pef801116x pptnrrroeeeaadstslieuucdtmrieAoidnnleasn.capeSnaapossesepcisavibfraitytciicao3llenloysrs,wdhtieehtrlehlseafonlnafcdmmawseainigptnghriootthpuueadtgaeA,anlitnaicolocunromerm,aitnptheaaesrsfihoslaefolmnplweewrerfiratluehteomtrhdeoeeaacAslrukelryapelsadecr.satRrbicbyeloesausxlyfwtalsiictcsthhoaoarcwniodfoth(2xCa2idt1-3ewF9sh52he7eaCnlnlOt.dhTOephrHeeeas)ikes- er 18, 20.1021/ roebssuelrtvseidmipnlyththesaetcthoenfmineeltd-dtuisbpeeresxiopnerrimeaecntitos.nmechanismisresponsibleforhighflamepropagationrates b1 BRARY on Septemugust 6, 2009 | doi: csoolnUidvseepnoatrifotnincaalnelomfmuiecelrtoarinmcdientogexrIri-endsdtiirzizoeeenddrtuspfcooatrirfomftneicurlsleamstiiaonnntysh.aeSdcivonamcnebtnaugasnetisooopnvaoerrf- ecmxooaFmlmoypbriondseneitantehnuseo.mpGeaftfrrreaitcoinctxileeoidrsf,eept(taMharetlori.ceOfloe3hu)sa.ni3zvdeesobinmeefillnaamrmreeassnpuyeltessdtfuotdhrireAosulgtahhnadat LIA mixture. One of the first investigations by Bockmon et al.4 NIV Web): tpioclienstshabveetwheigenherresapcetacniftiscscuormfapcaeraedretao,tmheicrreoamreetmero-rseizceodnptaacrt- examinedthecombustionbehaviorofnanocompositepowder U mixtures of Al and MoO as a function of Al particle size. by TEXAS TECH Publication Date ( tsrGaaipencsareldheeccaostiinfa.triencRtcrertsreesuhadtrsaouifmenmcasedcetodehsgicaepenarafncellrreeaateimit(acdyisl.eeeeecs.iss,rmpie1eztap0eehsrdeeaoμ.snvsTh)tdehhoscteemohrtdmeeohifgefpcofeoaurneerrsfere,ifeoidritscenyptiaeoodcnotnitcisfhodytaenitnnhsomgceofeiiccnmbrcrceuoeiraxtrmewctoatueeisvtoreeeeenndrr. Fcf1oro2bloan1smmeftironev7ee58sdd00pbeftnoueomdrr9nm.5aiCn0nixgdomtcnupo/srsrinedewsfseisgwhruaueirbtnreha3lettmphicoaeehnrapatssian.cuTrglrteeheiscsmelbieaneevsnloifetzlrswaeamwgw8eee0arsssnepprmeeaeeedn.d4duailcwnyeczedreredefarnosfeoomdrt d There are currently two main mechanisms of aluminum e particulatereactions(i.e.,10ms). d nanoparticle oxidation applicable to the high heating rate oa Aumann et al.1 examined the oxidation behavior of nl conditionsconsistentwithflamepropagationinatube.Each w ultrafine grain aluminum powder using Rutherford back- o mechanismissummarizedbelow. D scattering spectrometry, thermogravimetric analysis, and Diffusion Mechanism. Conventional metallic Al fuel na- high resolution transmission electron microscopy. They noparticlesarecoveredbyathin(1.7-6nm)aluminashell. suggestthatAlpowdermixtureswith20-50nmdiameters Duringcombustionthereactioniscontrolledbydiffusionof can react 1000 times faster than micrometer particle mix- theoxidizerand/orfuelthroughthegrowingoxideshell.5,6 tures because of the reduced diffusion distances between Thismechanismissimilartothatformicrometerparticles7,8 individualreactants.1Hunt etal.2studiedtheignitionand but also adds diffusion of aluminum toward oxygen. The combustionbehaviorsofnanometricnickelandaluminum diffusionmechanismwasjustifiedinref5experimentallyfor intermetallic mixtures. Laser ignition experiments on theheatingrateof103K/s.Thismechanismrequiresatleast pressedNi/Alpelletsshowthatnanometriccompositeshave 1 sfor complete oxidationto occur, whereas theestimated significantly reduced ignition times over micrometer-scale (4)Bockmon,B.S.;Pantoya,M.L.;Son,S.S.;Asay,B.W.;Mang,J. *Towhomcorrespondenceshouldbeaddressed.E-mail:michelle. T.J.Appl.Phys.2005,98(6),064903. [email protected]. (5)Park,K.;Lee,D.;Rai,A.;Mukherjee,D.;Zachariah,M.J.Phys. (1)Aumann,C.E.;Skofronic,G.L.;Martin,J.A.J.ofVac.Sci. Chem.B2005,109,7290. Technol.,B1995,13(3),1178–1183. (6)Rai, A.; Park, K.; Zhou, L.; Zachariah, M. Combust. Theory (2)Hunt,E.M.;Plantier,K.B.;Pantoya,M.L.ActaMater.2004,52 Model.2006,10,843. (11),3183–3191. (7)Rosenband,V.Combust.Flame2004,137,366. (3)Granier,J.J.;Pantoya,M.L.Combust.Flame2004,138(4),373– (8)Trunov,M.A.;Schoenitz,M.;Zhu,X.;Dreizin,E.L.Combust. 383. Flame2005,140,310. r2009AmericanChemicalSociety 4231 pubs.acs.org/EF : EnergyFuels2009,23,4231–4235 DOI:10.1021/ef801116x Dikicietal. Table1.MaterialPropertiesofReactantPowdersa material manufacturer particlesize(nm) oxidethickness acidcontent(basedonmass) activeAl(basedonmass) Al-80 NovaCentrix 80 2 71.6% 23.8% (Al-C F )cd IndianHead,NSW 100 noshell 75% 25% 13 27 (Al-C F )th IndianHead,NSW 100 noshell 75% 25% 13 27 MoO3 Mach-I 44 n/a n/a n/a aNotethatC F representsC F COOH. 13 27 13 27 reactiontimeinflamepropagationexperiments4is4orders forbothcompositesandbothmixtureswerepreparedwith ofmagnitudesmallerfornanoparticles.Theeffectofphase similarstoichiometry.Theexperiments wereperformedto transformations in the alumina shell from amorphous to measure the pressure output and flame speed of loose crystalline phases, which leads to fracture of a shell and powdersreactinginaconfinedconfiguration. acceleration of oxidation, was studied in refs 9 and 10. It is noted that there are conditions under which the Propagationratesforthediffusivemechanismofoxidation perfluorinatedcarboxylicacid-passivatedAlparticlesexhi- couldbeincreasedbyreducingorcompletelyeliminatingthe bit improved performance over the alumina passivated initialoxideshellthicknesses. Alparticles.Forexample,inrefs15and16acid-passivated Melt-DispersionMechanism.Levitasetal.11,12proposethe Alparticlescombinedwithplasticbondedexplosive(PBX) melt-dispersion mechanism for fast reaction of aluminum showedtwiceasgreatdentvolumecomparedtostandardAl nanoparticlesatfastheatingrate.ThemeltingoftheAlcore formulations in small-scale shock reactivity and internal g or causesa6%volumeincrease,whichleadstoapressurebuild- blaststests.Also,inrefs16and17theevolutionanddecay cs. upwithintheparticle(0.1-4GPa).Thishighpressurecauses ofaluminumandaluminummonoxideweremonitoredfrom a bs. the oxide shell to spallate, after which the melted Al core laser ablation studies. Both studies show that the reaction u http://p116x blaercgoemteensseixlepporseesdsuarnedaanndudnilsopaedrsinesgmproelstseunreAwlcalvuestperrosdinucaelsl rtiaotneooffathciedo-pxaidsseivcaotaetdinAg.lparticlesincreasedbytheelimina- 009 | ef801 dcliuresctetirosnasreanndotaltimhiigthedvbelyocdiitfyfu.Rsioeanctthiornouogfhsuacnhosxmidaellsbhaerlle, ExperimentalSection er 18, 20.1021/ wsehrvicehd.exTphlaeinmsetlht-edihspigehrsifolanmme escpheaendissmexpiserismcheenmtaalltyicaolbly- stuSdaiemdp:lweiPthreapnadrawtiitohno.uTtwaonadliuffmeriennatptayspseivsaotfioAnlsphaerltl.icTlehsewtyepree Septemb9 | doi: 1 iAllluTnshtarinasotmepdaercitnhicarlneefiss1cm2o.malblouwstsioonntehtaotcraensonlovtebveaerxiopulasinpeudzzblyesthine ouinfsfiAonrglmwtaiwtthiooonudtfifoafnreraeealnuctmhsisnyaanmtphpaelssesiisivsatlteiicsothnendsiqhinuelelTsw.aabPslhefuy1sr.itchTaelhrepprrfeiorppsaterrAetdyl ARY on st 6, 200 Adilffpuasriotinclemreacdhiuans,issmhe.llItthiisckfnoeusns,doirnalruemfsin1u1m-1c3onttheanttathree stoeafcm8h0pnlonelmgwie(aps)sroInpvcuid.r,ecAdhaubssyetidtnh,efTrmoXma,nwuNiftahocvataunCraeervnewtrrhaixgoeu(pfsoaedrrmtiBceElrelTyd)i.aNOmaxenitdoeer- BRugu notcontrollingparametersindividually.Instead,thereexists shell thickness was determined by the manufacturer. Detailed UNIV LIWeb): A saMpre,eelaadntsdiownflesarhmeipeobbspetatewiendeee.dnF,AowrlhcMeorre<easr1af9do,irumsMatxo>imsh1ue9mllrtahptioecssksnidbeelscesrferlaaatsmieode, adTnihaaemlsyeestepesraorotfifpcla8er0stiwnclmeerseifzrteohmednisNttrrieobavutaetCidoenwnstitrfhoixrtphisaerpCtricelseFesnwteCidtOhiOanvHreerafacg1ied0d.. CH ate ( with increasing M. In fact, an increase in shell thickness ThissamplewillbedesignatedasAl-80. 13 27 nloaded by TEXAS TE Publication D rsiMmfsleiaomdeImnwcun.hcemaLaestanesshetpciieMxshsermtea,e1dsnasn4tinudastoddhmerfedyeiA,nbcsfucarolbirmtrtoepii1acentaha-srrseltelu3siyltcpahμfleetlpemaixsoomardnwpmteisaifohtifrrnhfuiatpeiastcdaieblmosneefn,sdeut.iwlrntawt-ehndceieotdinshrnpfobtmleruayraemtsslsittoate-unntdsodpimsayeaplieeuneddcrmghisafaiitfonnhunndae-- ntCppwfrraaeieoertrTrmfettFelhhiducmeyloceal)aasartseotdhlhacute.(oalemAyustnAtrsildin-avincnduetoCgrydema1cpeta3gawceFlenouoto2ohmm7pfdie)cpaiicArnfrmodftaleas;iorsicctaeallsiiyednhnoms,tednisplstileClz,toeceh1fahbwe3nwnuFAadsita2qsle7HscuiCsisoye3sdOn*snei:NdntOtdthesh(eHrewtMesmesia.aifgzieisdnnre)TsPedapthpdtyrwseeaerudsupsaecsasashiinrvpanpedatsrgdahteerdapB(tdfteaAirEcsortilblehTgem-dyes-. Dow (Al2O3) shell. For this reason, two types of nano-Al/metal Th13ea2c7idcontentforallsampleswasdeterminedbasedonthe oxide composites are examined to determine the shell’s specificmassesofAlandacid. influence on flame speed. Thefirst Al sample is passivated SEMmicrographsofthecompositesofAl-80withMoO and 3 withAl O andtreatedwithperfluoroalkylcarboxylicacid (Al-C F )th with MoO are presented in Figures 1 and 2. 2 3 13 27 3 (C F COOH). The second Al sample is devoid of an Figure3isaschematicdiagramillustratingthetwotypesofAl 13 27 alumina shell and instead passivated with perfluoroalkyl surface passivation examined in this study. Each type of Al carboxylic acid (C13F27COOH). Elimination of alumina particlewascombinedwithnanoscaleMoO3,whichhasarod- likemorphologyandwaspurchasedfromMach-I.TheactiveAl shellshouldimprovediffusionbutmakethemelt-dispersion content for Al-80 in Table1 refersto Alin the zero oxidation mechanismimpossible.Thesameoxidizer(MoO )wasused 3 state. It is also noted that the alumina content for the Al-80 sampleis4.6%onamassbasis. (9)Trunov,M.A.;Schoenitz,M.;Dreizin,E.L.Combust.Theory Model.2006,10(4),603–623. (10)Trunov,M.A.;Umbrajkar,S.M.;Schoenitz,M.;Mang,J.T.; (15)Warren,A.D.;Lawrence,G.W.;Jouet,R.J.SockCompression Dreizin,E.L.J.Phys.Chem.B2006,110,13094–13099. ofCondensedMatterInAIPConferenceProceedings;Elert,M.,Furnish, (11)Levitas,V.I.;Asay,B.W.;Son,S.F.;Pantoya,M.L.Appl.Phys. M.D.,Chau,R.Holmes,N.C.,Nguyen,J.Eds.;2007;Vol955,pp1018- Lett.2006,89,071909. 1021. (12)Levitas,V.I.;Asay,B.W.;Son,S.F.;Pantoya,M.J.Appl.Phys. (16)Jouet,R.J.;Carney,J.R.;Granholm,R.H.;Sandusky,H.W.; 2007,101,083524. Warren,A.D.Mat.Sci.Technol.2006,22(4),422–429. (13)Levitas,V.I.;Pantoya,M.L.;Dikici,B.Appl.Phys.Lett.2008, (17)Jouet, R. J.; Carney, J. R.; Lightstone, J. M.; Warren, A. D. 92,011921. ShockCompressionofCondensedMatterInAIPConferenceProceed- (14)Levitas, V. I.; Pantoya, M.; Watson, K. W. Appl. Phys. Lett. ings;Elert,M.Furnish,M.D.,Chau,R.,Holmes,N.C.,Nguyen,J.Eds.; 2008,92,201917. 2007;Vol955,pp1247-1250. 4232 : EnergyFuels2009,23,4231–4235 DOI:10.1021/ef801116x Dikicietal. Figure4.SchematicdiagramillustratingtheAcrylictubeusedfor flamespeedmeasurements. Figure1.SEMmicrographsofthepostmixedcompositesofAl-80 withMoO3:(A)80000(cid:1)magnification;(B)40000(cid:1)magnification. Al as C13F27COOH on a per mole basis but is only approxi- mately33%Albymassduetothehighmolecularweightofthe acid. Adetaileddescriptionofthesynthesisandcharacterizationof Alnanoparticleswithoutanoxideshellispresentedinrefs15- g 18.Insummary,SEM,thermogravimetricanalysis(TGA)and or s. attenuatedtotalreflectanceFouriertransforminfraredspectro- c s.a metry indicate that the C13F27COOH molecule binds to the ub surfaceoftheAlparticle,protectingthesurfacefromoxidation p p://6x inambientair. htt11 For all Al particles reacting with MoO3, it was decided 009 | ef801 nboectatuosedetshceribcoemthpeetcionmgpooxsiidtaiotinoninatnerdmfsluoofrienqautiivoanlernecaectriaotnios ber 18, 210.1021/ wmThiatehteslAyamlthaperleesanAmol-et8mu0naadslessropstecoroconednt.atiaAngslelsaAnolfasAdalmdaiptnilodensaaccloid4n.t(6aseimneaTaspasbp%lreox1oi)-f. ARY on Septemst 6, 2009 | doi: mFCi1ag3guFnr2ei7f)i2tc.haStiwEoiMnt.hmMicorOog3r:a(pAh)so8f0t0h0e0(cid:1)posmtmagixneifdiccaotimonp;os(iBte)s4o0f0(A00l-(cid:1) AaFcoodxolr2dirdrOeeidza3s.pelalTrononAoddrelevacdacsoahrmimteoodbfpitl7nfher0aseo.,ts6mieothAnmaelatcshslmaesemarae%rxploiylmfe,sfMuu,thameolimOslefa3tlar.asansmRnpteseoelgrapcfatueerrneosdltplteoraosifgcsaMhaotfimofouOniewxl3thrurwaiirccatehhes. BRugu mixture. LIA Tocombinereactants,themixturesaresuspendedinhexane, UNIV Web): aspnededasMisiussoendixtoSiomnpicraotvoerm30ix0t0urperhoobme ovgibernaetiitnyg.Tahtisuldtreavsicoeniics H e ( programmedtoproducetheultrasonicwavesfor60swith10s ECDat on/off intervals.Thisintervalpreventsatemperatureincrease S Ton andpossiblethermaldamagetothesample.Itisnotedthatthe XAcati influenceofthehexaneonthereactantsisnotknown.However, y TEPubli itnhethseaemxepewriamyesnutcshdetshcartibtehdeheeffreec,tasllorfeathcteanmtsixwinegresporlueptiaornedairne b d maintainedasacontrolledparameter. e d ThemixturesarepouredintoaPyrexcontainerandplacedon a wnlo Figure3.SchematicdiagramillustratingAlsurfaceandpassivation ahotplateat50(cid:1)Cfor10mintoevaporatethehexane.Afterthe Do types. evaporation,thepowderisreclaimedforexperimentation. Roughly 450 mg of powder mixture prepared for each mix- ture composition and placed into an acrylic tube shown in the SurfacepassivationofAlnanoparticlesbyC13F27COOHis Figure 4. The tube is open at both ends, and acrylic is chosen based on a wet chemistry method. This method involves pre- because of its transparency and strength. Transparency allows paring and passivating the oxide-free Al.18,19 Oxide-free Al flamepropagationinsidethetubetobeseenduringcombustion. particlescanbepassivatedbyexposureofthemetalsurfaceto Moredetailsonthisapparatuscanbefoundinref6. C13F27COOH. This technique has been applied to several Thetubesarefilledwithpowder,thenplacedontoavibrating systems, but for the purposes of this paper the source of Al block and vibrated for approximately 5 s to reduce density wasthecatalyticdecompositionofH3Al3N(Me)Pyrorthermo- gradients, after which more powder is added. This process lyticdecompositionof(CH3CH2)3Al.Passivationoftheparti- results in a bulk density of 8% of the theoretical maximum clesoccursatroomtemperaturebyexposureoftheasformed density(TMD).TheTMDiscalculatedastheratiooftheactual Al0 particles to a solution of C13F27COOH in dry diethyl mass of reactants divided by sample volume to the weighted ether. The preparations are done under inert atmosphere and averageofpuresoliddensitiesofeachreactantinthematrix.In indrysolventtopreventcontaminationbyoxygen.Thehighest thisway,aTMDof10%describesasamplethatconsistsof10% Alcontentmaterialpreparedtodatecontains13timesasmuch solidparticlesand90%airvoids. Themassinthetubesvariedbecauseofthedensityrelatedwith different compositions and equivalence ratios. A bent piece of (18)Jouet,R.J.;Stern,A.G.;Rosenberg,D.M.USPatentNo.US Nichromewireisplacedononesideofthetubeandusedasthe 7,192,649B1;March20,2007. (19)Jouet,R.J.;Warren,A.D.;Rosenberg,D.M.;Bellitto,V.J.; ignition source. The tube is placed into the testing block with Park,K;Zachariah,M.R.Chem.Mater.2005,17(11),2987–2996. ports for 4 PCB piezo-crystal pressure sensors used to collect 4233 : EnergyFuels2009,23,4231–4235 DOI:10.1021/ef801116x Dikicietal. Figure5.Consecutiveframeimages(A)Al-80/MoO ;(B)(Al-C F )cd/MoO ;(C)(Al-C F )th/MoO . 3 13 27 3 13 27 3 pressuredata.Themixtureisignitedatoneendofthefilledtube viaresistanceheatingoftheNichromewire. The test block was placed in a stainless steel combustion chamber for safety purposes. The combustion chamber has an g acrylic window (139.7 (cid:1) 25.4 mm dimensions) that is used to or obtainhigh-speedvideoofthereaction.Thechamberisconnected s. c toavacuumpumptobringthechambertoadesiredpressure.A a bs. pressuregaugeonthetopofthechamberisusedtomeasurethe u p pressure. The product gases are evacuated from the chamber p://6x during and after the reaction. All experiments were performed er 18, 2009 | htt0.1021/ef80111 apaTtnohdA1seitawcitaoVammnsiseueiidnorsanepadcneaRrtapopeietrsruneeerdacneorivsccriuthdrhloafenPlravmhtmioaseiennbttthpl.oeermoedmpira7iegs.cs1atitoiiohnoningliohgrf-ahstftpelaaesmnewddeitthpcaairknomeptseharaegasateutwriboiaeenss. b1 Septem9 | doi: opTfrhopisphaofgrtaoamtgiroeanprahwtseearatelalrohewcigoehrddseaadm1ap6tliμn5sg1tf0er0em0qpuforearnamclye.rseIgsponelirutitsoieoncnoannbddetf(wlfapemes)ne. LIBRARY on August 6, 200 imwmiitPanhgereertseshs.seupPrfehlecaatwmntaoteosstmmpimeedeeada.stubaryeadtcrquaucsikinsiigntigofonthuseroPpfoCtwsBiatir1oe1n3wAoaf2st2huepseifedlazotmo-ecdrfyerstoetnart-l NIV Web): purseesdsutorecotrnavnesrdtutcheerst.raAnsdPuCcBer4s8ig2nAa2l2instiognaaclacloibnrdaitteidonoeurtpwuats. Figure6.Pressuremeasurementsfor(A)Al-80/MoO3reactionand H Ue ( ANationalInstrumentsdataacquisitionboardwasconnected (B)(Al-C13F27)th/MoO3. Cat to the signal conditioner and controlled by Labview Version ED by TEXAS T Publication 81.000skoHftzw.are. Pressure dataRweasusltcsollected at a sample rate of inTflhaemreesuplrtosptaabgautliaotnedriensDTuilastcbinulegss2ifoirnnodmicattweoexdtrifefmereednitffpearernticceles d assemblieseventhoughthechemistryofbothmixturesisthe e d Figure 5 show consecutive still frame images recorded at same (i.e., same fuel-rich mixture composition). Promotion a o wnl 51000 fps. Images for mixtures of Al-80 with MoO3 were ofdiffusionandeliminationofthemelt-dispersionmechanism o recordedat62500fpsaregiveninref4. byreplacingtheoxideshellwithaperfluoroorganicpassiva- D Pressure measurements for the Al-80 and (Al-C F )th tionlayerreducedflamerateandpressuregenerationdrama- 13 27 mixturesaregiveninpanelsAandBofFigure6,respectively. tically. This result implies that among the two alternatives, ForAl-80mixturesthedatafromthefourthpressuresensor the melt-dispersion mechanism is responsible for the high (farthest from ignition point) is used for characterizing the flame rate of Al nanoparticles. Despite the fact that the steady-state propagation behavior. For the (Al-C F )th aluminashellinhibitsdiffusion,doesnotparticipateinreac- 13 27 mixturesthedatafromonlythefirstpressuresensorisreported tion(i.e.,isadeadweight)andactsasaheatsink,thepresence becausetheflamepropagatedonlytothepointbetweenfirst of the alumina shell is a necessary condition for the melt- and second pressure channels. For (Al-C F )cd pressure, dispersionmechanismthatisproposedastheprinciplereason 13 27 thepressurehistorywasnotcapturedsincetheflamequenched for the high flame propagation rates observed in reactions beforereachingthefirstpressurechannel. involving nanometric Al particles. Although these experi- For the combustion of Al-80 with MoO , higher flame mentsdonotprovedirectlythemelt-dispersionmechanism, 3 speeds (95 times higher flame speeds compared to (Al- they are fully consistent with predictions based on this C F )cd, 38 times higher flame speeds compared to (Al- mechanism.Theseresultsarealsoconsistentwithexperiments 13 27 C F )th, and 2607 times higher peak pressures compared in ref 13 that show that a decrease in oxide shell thickness 13 27 with(Al-C F )th)aremeasured.Pressuredatacorrespond- reduces the flame rate in experiments similar to the one 13 27 ingtobothAl-C F sampleswithMoO showaninsigni- presentedhere. 13 27 3 ficant pressurerise compared toAl-80sampleswithMoO . In general, flame rate depends on various parameters, 3 Table2summarizestheseresults. includingmechanismofflamepropagation,Alparticlesize, 4234 : EnergyFuels2009,23,4231–4235 DOI:10.1021/ef801116x Dikicietal. Table2.SummaryofResultsfromHigh-SpeedCameraandPressureSensorsforOptimalMixtureCompositiona reactants Al-80 (Al-C F )cd (Al-C F )th 13 27 13 27 mass(mg) 480 420 420 flamespeed(m/s)(fromhighspeedcamera) 285.2(10 3(0.5 7.5(0.5 peakpressure(kPa) 1676.670 N/A 0.643 risetime(μs) 228.571 N/A 682 pressurizationrate(MPa/sec) 6601.89 N/A 0.10185 propagationrate(frompressuredata)(m/sec) 178.6 N/A 8.13 samplerate(pps) 100000 10000 10000 aN/A:notapplicablebasedonquenchingofthereaction. size distribution of fuel and oxidizer particles, oxide shell Conclusion thickness, the morphology of the mixture, and others. It is Flamepropagationinaconfinedtubeapparatuswasmea- impossible,atleastinthegivencase,tokeepallparametersthe sured for C F COOH-treated Al nanoparticles with and same, excluding oxide thickness. Thus, active Al content is 13 27 without an alumina shell. Removing the oxide shell should slightly smaller for the Al-80 sample with an oxide shell promote a diffusion reaction mechanism but make the melt (Table1), butthispresenceofaluminashouldreduceflame dispersionmechanisminoperative.Thealumina-passivatedAl speedforthemaccordingtothetraditionaldiffusionmechan- particlesexhibitedflamespeedsontheorderof285m/sandthe ism.ThediameterofAlnanoparticleswithashellisslightly acid-passivated Al particles propagated at roughly 7 m/s or g smallerthanthatwithoutashell.However,theflamespeedis bs.acs.or tohxeidseamsheeflol.r13boTthhepapratrictilcelesizseizseifdthisetyriabrueticoonvemreadybbyeaspirgonpifeir- wmisoaansgnwqiutiutehdnetchhfeoedrm.AixTlthuperaerpstiewcaliektshwpArietlhspsoauurrtteiacdlneesoctexhaidasetesilnabcyyleurd3ienotchrodemeorpxsiadore-f u cantlydifferentforsampleswithandwithoutanoxidelayer. http://p116x Hofomwiecvreorm,eevteern-sacnalaedpdaitritoicnletsodAidlnnaontocphaarntigceletshoeffulapmteov3e0l%o- smheecllh.aTnhisemseisrerseuslptsonimsibplleyftohrathitghhe fmlaemlte-dpisrpoeprsaigoantiorenacrtaitoens er 18, 2009 | 0.1021/ef801 cipAsirotloynpp.2awa0rgatFaisctolmierosantidhsreeas.stoeTedhearxenapdpsetorgiicienmnttheeinarsatttsthae,aldltthtpthehreeecssledseuiaifnrnfedeeresfettonerprcmtoehsbiesneitabtwwcleioeecestonycmpaflnepasnmaooretf- rsoeepxbdetsrueeedcrmvt,ieieondncaainicsnectoohorxefdiocdaouennrcsfpheinrewelelvidttihohtuuitcbhskeeenxemepxseesplreltie-rmddimietsnoeptneattrhlssef.iioTnrnedhdimenuygecrctsei,ho1pa3nrnweiisnshemenfnltaattmnhhdeee Septemb9 | doi: 1 udnradsetricmailnlyereoduurcecsopnacrlutisciloenreathcatitvitryeminotvhinegflatmheetouxbiedeexpshereil-l ictniovnec,dorinteidtorunacssttwiothnoeontfhttheheedmoifxefliutds-edioissnhpeerlrlessaihocotniuomlndelcmehaeadcnhtisoamntihsiemsin.nocFtreooarpseetrhaine- ARY on st 6, 200 amodfevtnahtne.tTmahgaiestserreoisafullwrteiimsthnooovutitninganctohonextridaoedxiiscdhteieollns,h1w6e-lilt1.h9Ipwnrhdeievceihodu,sshfosotwrudttihheees reactionrate,accordingtoexperimentsinrefs16-18. BRugu conditionswhenthemelt-dispersionmechanismisnotopera- Acknowledgment. The authors gratefully acknowledge sup- NIV LIWeb): A ttihvee,otxhideedsifhfeulsliwonillrpearoctmioontemreecahctainoins.mappliesandremoving p1-o0r2t17fro(mprotghreamArmdiyrecRtoerseaDrcrh. ROaflfpiche AconntthreancitenW),91O1fNficFe-0o4-f CH Uate ( (20)Moore,K.;Pantoya,M.L.;Son,S.F.J.Propul.Power2007,23, NDar.vCallifRfoersdeaBrcehdfocrodn)t,raacntdNN0a0ti0o1n4a0l8S1c0i1e0n4ce(Fproougnrdaamtiodnirgercatonrt S TEon D 181–187. CBET-0755236(programdirectorDr.PhillipWestmoreland). XAcati y TEPubli b d e d a o nl w o D 4235