Diagnostics of mobile work machines PDF

Preview Diagnostics of mobile work machines

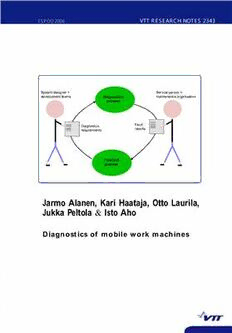

ESPOO 2006 VTT RESEARCH NOTES 2343 V T T R E S E A R C H N VTT Tiedotteita – Research Notes O T E S 2 3 System designer + Service person + 2332 Kutinlahti, Pirjo, Lähteenmäki Smith, Kaisa & Konttinen, Jari. Vaikuttavaa 4 3 development teams Diagnostics maintenance organisation tutkimusta. Arviointikäytäntöjä julkisissa tutkimusorganisaatioissa: Helia ja SAMK. process 2006. 131 s. + liitt. 6 s. D ia 2333 Hyytinen, Kirsi & Konttinen, Jari. Vaikuttavaa tutkimusta. Arviointikäytäntöjä gn o julkisissa tutkimusorganisaatioissa: Puolustusvoimien Teknillinen Tutkimuslaitos s t PVTT. 2006. 77 p. + app. 5 p. ics Diagnostics Fault 2334 Lähteenmäki Smith, Kaisa & Hyytinen, Kirsi. Vaikuttavaa tutkimusta. Arviointi o requirements reports f käytäntöjä julkisissa tutkimusorganisaatioissa: Maa ja elintarviketalouden tut m kimuskeskus MTT. 2006. 89 s. + liitt. 1 s. ob 2335 SHOPS – Smart Home Payment Services. Towards the liberalisation of Europe's ile w utilities industry. 2006. 35 p. o r 2336 Lähteenmäki Smith, Kaisa, Hyytinen, Kirsi, Kutinlahti, Pirjo & Konttinen, Jari. k FRACAS m process Research with an impact. Evaluation practises in public research organisations. a c 2006. 79 p. h in 2337 The Finnish Research Programme on Nuclear Waste Management (KYT) 2002 2005. e s Final Report. Kari Rasilainen (ed.). 2006. 246 p. + app. 45 p. 2338 Martikainen, Antti. Ilmastonmuutoksen vaikutus sähköverkkoliiketoimintaan. 2006. 74 s. + liitt. 5 s. Jarmo Alanen, Kari Haataja, Otto Laurila, 2339 Takasuo, Eveliina. Modeling of Pressurizer Using APROS and TRACE Thermal Hydraulic Codes. 2006. 99 p. + app. 4 p. Jukka Peltola & Isto Aho 2340 Modelling of multiphase chemical reactors (ModCheR). Final report. Manninen, Mikko (ed.). 2006. 181 p. 2341 Kara, Mikko. Electricity and emission allowance markets from Finnish viewpoint. Diagnostics of mobile work machines Stydy. 2006. 105 p. 2342 Häkkinen, Tarja&Wirtanen, Leif. Metlan Joensuun tutkimuskeskuksen ympäristö ja elinkaarinäkökohtien arviointi. 2006. 29 s. 2343 Alanen, Jarmo, Haataja, Kari, Laurila, Otto, Peltola, Jukka & Aho, Isto. Diagnostics of mobile work machines. 2006. 122 p. Tätä julkaisua myy Denna publikation säljs av This publication is available from VTT VTT VTT PL 1000 PB 1000 P.O. Box 1000 02044 VTT 02044 VTT FI 02044 VTT, Finland Puh. 020 722 4404 Tel. 020 722 4404 Phone internat.+35820 722 4404 Faksi 020 722 4374 Fax 020 722 4374 Fax +358 20 722 4374 ISBN 951–38–6798–6 (soft back ed.) ISBN 951–38–6799–4 (URL: http://www.vtt.fi/inf/pdf/) ISSN 1235–0605 (soft back ed.) ISSN 1455–0865 (URL: http://www.vtt.fi/inf/pdf/) VTT TIEDOTTEITA (cid:150) RESEARCH NOTES 2343 Diagnostics of mobile work machines Jarmo Alanen & Kari Haataja VTT Otto Laurila & Jukka Peltola Helsinki University of Technology Isto Aho Plenware Oy ISBN 951(cid:150)38(cid:150)6798(cid:150)6 (soft back ed.) ISSN 1235(cid:150)0605 (soft back ed.) ISBN 951(cid:150)38(cid:150)6799(cid:150)4 (URL: http://www.vtt.fi/publications/index.jsp) ISSN 1455(cid:150)0865 (URL: http://www.vtt.fi/publications/index.jsp) Copyright ' VTT Technical Research Centre of Finland 2006 JULKAISIJA (cid:150) UTGIVARE (cid:150) PUBLISHER VTT, Vuorimiehentie 3, PL 1000, 02044 VTT puh. vaihde 020 722 111, faksi 020 722 4374 VTT, Bergsmansv(cid:228)gen 3, PB 1000, 02044 VTT tel. v(cid:228)xel 020 722 111, fax 020 722 4374 VTT Technical Research Centre of Finland, Vuorimiehentie 3, P.O.Box 1000, FI-02044 VTT, Finland phone internat. +358 20 722 111, fax +358 20 722 4374 VTT, Tekniikankatu 1, PL 1300, 33101 TAMPERE puh. vaihde 020 722 111, faksi 020 722 3282 VTT, Tekniikankatu 1, PB 1300, 33101 TAMMERFORS tel. v(cid:228)xel 020 722 111, fax 020 722 3282 VTT Technical Research Centre of Finland, Tekniikankatu 1, P.O. Box 1300, FI-33101 TAMPERE, Finland phone internat. +358 20 722 111, fax +358 20 722 3282 Technical editing Maini Manninen Valopaino Oy, Helsinki 2006 Alanen, Jarmo, Haataja, Kari, Laurila, Otto, Peltola, Jukka & Aho, Isto. Diagnostics of mobile work machines. Espoo 2006. VTT Tiedotteita (cid:150) Research Notes 2343. 122 p. Keywords mobile work machines, diagnostics, automotive industry, cars, heavy-duty vehicles, diagnostics architecture, MIMOSA, data analysis, data mining, sensor fault modes Abstract In this research note, we take a look at the field of mobile work machine diagnostics. The perspective by the authors is limited by the research project (KODIE) behind this research. However, we have tried to provide generic guidelines for machine builders to set up their diagnostics strategy. Building blocks, like SAE J1939/73, ISO 15765 and ODX, from automotive industry are exhibited to prevent machine manufactures from reinventing diagnostics protocols and practices. Furthermore, examples of diagnostics architectures are presented, with OSA-CBM among others. To make the most of diagnostics data, an extensive set of data analysis methods are introduced. And in order to help engineers to design diagnostics feature for the sensor system, hints and examples are supplied as to how to establish the fault modes of sensors; a good knowledge about the (relevant) sensor and actuator fault modes is a prerequisite for comprehensive fault detection. 3 Preface This report is an outcome of the national KODIE project (Diagnostics and remote control of machines) carried out through 2003(cid:150)2005. The project belonged to the MASINA technology programme organised by Tekes (Finnish Funding Agency for Technology and Innovation). The project was financed by Tekes, VTT, Kalmar Industries Oy, Plustech Oy, and Plenware Oy. The research work was carried out by Helsinki University of Technology and VTT. We would like to thank all those who participated in this project. Tampere, April 2006 Authors 4 Contents Abstract.................................................................................................................3 Preface..................................................................................................................4 List of acronyms...................................................................................................5 1. Introduction.....................................................................................................5 2. Clarifying the diagnostics picture...................................................................5 2.1 Definition of the term diagnostics.........................................................5 2.2 Costs and benefits of diagnostics...........................................................5 2.3 Diagnostics and FRACAS.....................................................................5 2.4 What is diagnosed..................................................................................5 2.5 Where do the diagnostics procedures reside..........................................5 2.6 When is the diagnosis performed?.........................................................5 2.7 Who performs the diagnosis?................................................................5 2.8 How to partition diagnostics into more manageable chunks.................5 2.9 Application-specific or generic.............................................................5 2.10 Diagnostics strategy...............................................................................5 3. Automotive and heavy-duty vehicles diagnostics standards...........................5 3.1 ISO and SAE diagnostics standards......................................................5 3.1.1 J1939/73....................................................................................5 3.1.2 ISO 15765-3..............................................................................5 3.2 Open Diagnostic data eXchange (ODX)...............................................5 4. Diagnostics architectures................................................................................5 4.1 MIMOSA...............................................................................................5 4.2 Condition-based maintenance................................................................5 4.2.1 Prognostics................................................................................5 4.2.2 Other component-based CBM systems.....................................5 4.2.3 Interpretation of OSA-CBM in machine automation................5 4.3 IEEE 1451.............................................................................................5 4.4 ISO 13374..............................................................................................5 4.5 The OSGi Alliance................................................................................5 4.5.1 Vehicle Expert Group Charter...................................................5 5 4.6 Agent systems........................................................................................5 4.7 Client - Server........................................................................................5 4.8 Example applications.............................................................................5 4.8.1 Passenger cars...........................................................................5 4.8.2 Airbus (cid:150) Aircraft Maintenance Analysis...................................5 4.8.3 Boeing (cid:150) Aeroplane Health Management.................................5 4.8.4 The National AirSpace System-Wide Simulation.....................5 5. Methods for Data Analysis.............................................................................5 5.1 Model-based approach...........................................................................5 5.2 Data-driven methods.............................................................................5 5.2.1 Principal Component Analysis..................................................5 5.2.2 Fisher Discriminant Analysis....................................................5 5.2.3 Statistical Process Control.........................................................5 5.3 Analytical methods................................................................................5 5.3.1 Parameter estimation.................................................................5 5.3.2 Observer-based methods...........................................................5 5.3.3 Parity relations..........................................................................5 5.4 Knowledge-based methods....................................................................5 5.4.1 Causal Analysis.........................................................................5 5.4.2 Expert Systems..........................................................................5 5.4.3 Artificial Neural Networks........................................................5 5.4.4 Feed forward neural network....................................................5 5.4.5 Case-Based Reasoning..............................................................5 5.5 Data mining...........................................................................................5 5.5.1 What is data mining?.................................................................5 5.5.2 Why data mining?.....................................................................5 5.5.3 Data mining process..................................................................5 5.5.4 Methods used in data mining....................................................5 5.5.5 Data mining time series.............................................................5 5.5.6 Example: Anomaly detection....................................................5 5.6 Combinations of various methods and techniques................................5 5.6.1 Neurofuzzy networks................................................................5 5.6.2 Fuzzy logic and analytical methods..........................................5 5.6.3 Neural networks and expert systems.........................................5 6 6. Establishing sensor fault modes......................................................................5 6.1 General fault modes...............................................................................5 6.1.1 Potentiometer fault modes.........................................................5 6.1.2 Encoder fault modes..................................................................5 6.1.3 Proximity switch fault modes....................................................5 7. Conclusions.....................................................................................................5 References.............................................................................................................5 7 List of acronyms ABS Antilock Braking System AHM Airplane Health Management AI Artifical Intelligence ANN Artificial Neural Network API Application Programming Interface AREMA American Railway Engineering and Maintenance-of-way Association ASAM Association for Standardisation of Automation and Measuring Systems CAN Controller Area Network CBA Cost and Benefit Analysis CBM Condition Based Maintenance CBR Condition Based Reasoning CBS Condition Based Service CCP CAN Calibration Protocol CCW Counter clockwise CRIS Common Relational Information Schema CW Clockwise DTC Diagnostic Trouble Code EOBD Euro On-Board Diagnosis EPA Environmental protection agency ESP Electronic Stability Program FCM Fuzzy Cognitive Maps FDA Fisher Discriminant Analysis FDI Fault Detection and Identification FIPA Foundation for Intelligent Physical Agents FMI Failure Mode Identifier 8