DATANG Pakistan Karachi Power Generation, Coal Power Plant at Port Qasim, final report April 2016 PDF

Preview DATANG Pakistan Karachi Power Generation, Coal Power Plant at Port Qasim, final report April 2016

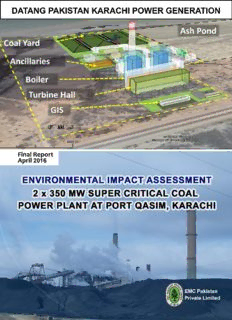

DATANG PAKISTAN KARACHI POWER GENERATION Environmental Impact Assessment (EIA) 2 x 350 MW Coal Power Project Final Report April 2016 Ref: EIA/05/04/16 Disclaimer: This report has Attorney – Client Privilege. EMC Pakistan Pvt. Ltd has prepared this report in accordance with the information provided by DATANG Pakistan Karachi Power Generation for their sole and specific use. Any other person(s) who use any information contained herein do so at their own risk. This report cannot be used in the court of law for any negotiation or standardization. © EMC Pakistan Pvt. Ltd. 2016 Environmental Impact Assessment for 2 x 350 MW Coal Power Project Executive Summary In order to contribute toward meeting Karachi’s growing electricity demand, Datang Pakistan Karachi Power Generation - DPKPG (Private) Limited proposes constructing a coal fired power station at 250 acres land available in the Eastern Industrial Zone (EIZ) of Port Qasim Authority – PQA (Figure 1). The project aims at installation of 2 x 350 MW Coal based supercritical thermal power plant to reduce the dependency on expensive high sulphur fuel oil and to introduce cheaper alternative fuel for power generation, increase the efficiency and provide reliable low cost power to the Karachi City. The project shall: Respond to the urgent need to close the yawning gap between power generation & demand, Provide an economically viable and environmentally acceptable power generation system to make the coal available for use in power production, in view of the wide gap between supplies of fossil fuel and demand, Ensure stable power production system for the Karachi City, and Respond to the need of improvement in quality of life through Sustainable Energy Resource development. The proposed 2x350 MW coal power plant shall adopt supercritical boiler technology. The major systems of the power project include: Coal Jetty Super-critical boiler Pulverised Coal (PC) generation plant An open coal storage area surrounded by wind shield Coal handling covered conveyors Water supply and waste water system Ash handling system Emission control system Flue Gas Desulfurization (FGD) system Dust prevention, and fire monitoring and prevention facilities. Datang Pakistan Karachi Power Generation - DPKPG (Private) Limited is an entity incorporated under the Companies Ordinance, 1984, to act as a special purpose vehicle (SPV) and develop a 2 x 350 MW imported Coal Power Project at Port Qasim Karachi, sponsored by China Datang Overseas Investment Co. Ltd. (CDTO), China Machinery Engineering Corporation (CMEC) and K-Electric Limited (KE). 51% of the equity stake in the Project is owned by CDTO, a wholly owned subsidiary of China Datang Corporation, a power generation giant based in China with assets of more than 120,000 MW under its ownership. 25% of the equity stake in the Project is owned by CMEC, an international conglomerate and the first Engineering and Trade Company in China, and was listed in the Hong Kong Stock Exchange in 2012. The remaining 24% of the equity stake in the Project is owned by KE. The co-sponsors have signed a Joint Development Agreement in September 2015 and a Shareholders Agreement on 20 May 2016 to jointly establish a 700 MW imported coal fired power plant using super critical technology with a dedicated Jetty at Port Qasim Karachi. EMC Pakistan Pvt. Ltd Page 1 of 7 Environmental Impact Assessment for 2 x 350 MW Coal Power Project Figure EX-1: Location of DPKPG 2 x 350 MW Coal Power Plant EMC Pakistan Pvt. Ltd Page 2 of 7 Environmental Impact Assessment for 2 x 350 MW Coal Power Project Figure EX-2: Power Island Layout DPKPG appointed EMC Pakistan Private Limited for conducting the Environmental Impact Assessment study of the Proposed Project to assess the likely environmental and social impacts that may result from Project activities and to identify measures to mitigate negative impacts, if any. EMC formulated the following team of officials and experts for conducting the EIA study and preparing the report: Table EX-1 - List of EIA Team S. # Name Position in Project 1 Syed Nadeem Arif Project Director 2 Saquib Ejaz Hussain Project Manager / Expert on Air Dispersion Modeling 3 Dr. Mirza Arshad Ali Beg Senior Environmentalist / Project Team Leader 4 Dr. Shahid Amjad Marine Biologist 5 Dr. Syed Ali Ghalib Expert on Fauna 6 Mr. Khurram Shams Khan Social Development Specialist 7 Ms. Zulekha Soorma Health & Safety Specialist 8 Ashar H. Lodi Transportation Specialist 9 Mr. S.M. Zaman Geologist The EIA study of proposed DPKPG – CPP Project responds to the Section 17 of Sindh Environmental Protection Act (SEPA) 2014 which requires that every new development project in Pakistan has to be preceded by an Initial Environmental Examination (IEE) or Environmental Impact Assessment (EIA) depending on the nature and severity of impacts anticipated on commissioning of the project. The plant design is based on imported coal with the capability to burn local coal in the future. To satisfy the fuel requirements of the proposed 2 × 350 MW coal-fired power plant, approximately, 2.5 million tons per annum coal will be imported from Indonesia, South Africa or Australia, with expected calorific value of 20.14 MJ/kg and brought to the plant via Panamax-type shipping vessels. These vessels will unload coal at a dedicated Coal Jetty at the southern edge of the proposed plant. The ash content is expected to be 8-14%. The expected sulfur content is <1%. Ash generated during Project operation will be ultimately sold to cement plants. Main parameters of the design coal and check coal determined based on the coal quality data are as follows: Table EX-2: Main Parameters of Coal Quality No. Item Symbol Unit Design coal Check coal 1 Total moisture Mt % 22.4 26 2 Air-dried moisture Mad % 14 18 3 Ash content on as-received basis Aar % 8.57 14.44 4 Volatile content on dry ash-free basis Vdaf % 51.63 48.48 5 Coal on as- received basis Car % 52.88 44.08 6 Hydrogen on as- received basis Har % 3.81 2.98 7 Nitrogen on as- received basis Nar % 0.79 1.07 8 Oxygen on as- received basis Oar % 11.04 10.84 9 Total sulphur St,ar % 0.5 0.6 10 Net calorific power on as- received basis Qnet,v,ar MJ/kg 20.14 16.25 EMC Pakistan Pvt. Ltd Page 3 of 8 Environmental Impact Assessment for 2 x 350 MW Coal Power Project Coal consumption of boilers in the whole plant is as follows: Design Coal Check Coal Table EX-3: Coal Consumption BRL BMCR BRL BMCR Hourly coal consumption (t/h) 293.72 308.82 363.0 389.08 Daily coal consumption (t/d) 5991.9 6299.9 7405.2 7937.2 Annual coal consumption (×104t/a) 218.70 229.95 270.29 289.71 Note: 1. BRL working condition corresponds to the steam turbine’s TMCR working condition; BMCR working condition corresponds to the steam turbine’s VWO working condition. 2. The annual utility hours is counted by 7446 hours. The equivalent hours for one day is 20.4 hours. Highest reliability & availability, convenience of operation and maintenance, neat and orderly arrangement, are of utmost importance. The functional requirements of the various systems and the pleasing physical appearance of the completed Plant shall also be taken into account. Due care shall be undertaken concerning the environmental impact due to plant operations and sufficient protective measures shall be incorporated in the design of the Plant for environmental protection especially on air pollution, water pollution and noise. The environment protection measures shall be undertaken in accordance with the Environment Protection Guidelines of World Bank / IFC and Environmental Protection and Emission Control Standards of SEPA. Coal will be transported through sea. 50,000 DWT capacity Ship will be unloaded at project site with single berthing, Double Unloader and 12.5 m Draft Jetty. For this 1.5 km strip of Channel with average draft of 8 m will be dredged to 12.5 meters corresponding to a dredged material quantity of 1.5 million meter3. The dredged material will be dumped to reclaim the land to the east of Plant site and submerged portion of Project site. Power Block Coal Jetty Figure EX-3: Layout of Coal Jetty Surface water resources in the macroenvironment of the ecosystem are limited to the catchment area of Ghaggar, Pipri and Badal Nalas, which run from the north and passing through the Bin Qasim Town fall in the Gharo Creek. On the west of the shoreline the Nalas are not prominent; while the Lyari which brings freshwater only during the monsoon season is grossly polluted with industrial as well as sewage effluent. The Pipri and Badal Nala remain dry during the dry season. During wet season there is flooding along the banks due to heavy rain. Pipri Nala and Badal Nala have an extensive catchment area starting from the far northern edge of Port Qasim industrial zone to the shoreline in the south at Arabian Sea. EMC Pakistan Pvt. Ltd Page 4 of 8 Environmental Impact Assessment for 2 x 350 MW Coal Power Project Both Nalas merge near the Engro Asahi plant. The physical examination indicates that municipal as well as industrial wastewater is being discharged into the stream and is polluting it. The marine ecology that exist in the mudflats and along the shoreline up to the tide lines in the neighborhood of the proposed DPKPG Power Plant site in Kadiro - Gharo Creek system consists of a unique and diverse ecosystem of birds, plants, fishes and benthic flora and fauna. The most notable aspects of marine fauna and flora are Mangroves and Aquatic birds. A survey was conducted in the microenvironment of project site to establish the baseline of the birds in the project area. 13 species of birds were recorded which include mostly the resident species such as Black Kite, Redwattled Lapwing, Blue Rock Pigeon, Little Brown Dove, Crested Lark, Black Drongo, Indian Myna, House Crow and House Sparrow. The migratory birds recorded include: Common Sandpiper, Collared Sand Martin, Variable Wheatear and Desert Wheatear. In the microenvironment of project area the most dominant species of flora is Avicenna marina that also grows on the northern and southern banks of the Phitti Creek. The Mangrove population of Avicenna marina is highly dense near project site. The density of mangrove trees is estimated at between 50‑60/100 m2. The height of the individual tree within the established Avicenna marina habitat is greater than ~3 m. The mangrove trees growing 200‑300 m away from the creek (seawater) in the landward direction show an overall decline in the height of the mangrove plantations. The Shannon Weiner Biodiversity Index was undertaken which shows that the species diversity and the species richness are relatively poor. The species diversity ranges from 0.69 to 0.90 (the normal range is 3.0) whereas the species richness i.e. number of species in each of the community measured between 0.07 at sample 3 to 0.188 at station 1 [species richness ranges from 0.01 (low) to (1.0) high]. The seismic risk factor of 0.2 is advisable and will need to be incorporated in the design for constructions and installations in the coastal zone, for operational basis earthquakes (OBE) pertaining to damage due to moderate level earthquakes (MM‑VI to VIII). Dredging along the terminal piled bridge structure will be accomplished utilizing a bucket dredge that allows transfer of excavated material to the spoil storage area in large clumps, minimizing soil dispersion and siltation. Guidance of the London Convention recommends that consideration should be given to the environmental characteristics of the marine disposal site. The site for disposal of dredged material will be as per the advice from Port Qasim Authority (PQA). The dredging activity will have impact on the benthic ecology. Most studies on the impact of dredging on marine benthos show that dredging can result in a 30 to 70% reduction in species variety; some 40 to 95% reduction in the number of individual species and a similar reduction in biomass in dredged areas (Newell et al., 1998). Re-colonization and recovery of species is a complex process involving initial colonization by fast growing animals (opportunistic) species. In stable environments these are replaced and supplemented by a wider species diversity of slow-growing (equilibrium) species after cessation of dredging. In more disturbed habitats the community is dominated by opportunistic species, which do not move towards an equilibrium community of repeated environmental disturbance. EMC Pakistan undertook a baseline air quality monitoring survey at the proposed power plant site. The survey helped characterize the existing air quality in the air shed of the proposed power plant site. The measured minimum, maximum and mean concentrations for CO, NOx, SO , O SPM, PM and PM 2 3 2.5 10 are summarized and compared to the Sindh Ambient Air Quality Standards in the table below. EMC Pakistan Pvt. Ltd Page 5 of 8 Environmental Impact Assessment for 2 x 350 MW Coal Power Project The level of all air pollutants were well within the prescribed limits of Sindh EQS. Table EX-4: Ambient Air Quality of the Project Area Particulate Matter Sulfur Nitrogen Nitrogen Suspended Less than Carbon Less Site Dioxide Dioxide Oxide Particulate 10 Monoxide Ozone than 2.5 ID (SO ) (NO ) (NO) Matter Microns (CO) (O ) 2 2 Microns 3 (µg/Nm3) (µg/Nm3) (µg/Nm3) (SPM) (PM ) (mg/Nm3) 10 (PM ) (µg/Nm3) (µg/Nm3) 2.5 A-1 16.0 12.9 8.9 183 80.4 18.6 - - A-2 11.8 10.1 6.1 216.2 88.9 20.8 - - A-3 13.4 9.3 6.4 199.6 81.1 18.6 - - A-4 11.8 10.1 6.1 216.9 88.9 20.8 - - A-5 13.6 13.3 9.1 - 87.6 23.5 0.9 14.8 A-6 9.5 11.1 5.8 - 79.8 18.7 0.6 8.7 A-7 26 9.7 9.6 - 83.7 32.2 2.8 - A-8 17.4 10.0 13.5 386 51 26.4 2.16 12.0 A-9 12.5 8.7 14.5 419 131 22.2 0.8 12.2 Avg. 14.7 10.6 8.9 270.1 85.8 22.4 1.5 11.9 SEQS 120 80 40 500 150 75 10 130 The worst incremental 24 hourly average GLC value of SO , NOx, PM10 and PM2.5 from the project at 2 full operating load with 200 m high stack will be 17.6μg/m3, 32.6μg/m3, 2.0μg/m3 and 1.3μg/m3 respectively in the downwind ENE direction at a distance of 2 km from the plant site. The worst incremental annual average GLC vale of SO , NOx, PM10 and PM2.5 from the project at full operating 2 load will be 3.9 μg/m3, 7.3 μg/m3, 0.6 μg/m3 and 0.3 μg/m3 respectively in the downwind ENE direction at a distance of 2 km from the plant site. The 24-Hr. maximum incremental GLC is superimposed over the maximum baseline ambient air level. Apparently all the emissions are getting dispersed at the designed height of 200 m. The 200 m tall stack heights with high momentum and buoyancy takes the plume above the highest mixing height. 99.98%. PM emissions are controlled using ESP, SO by FGD and NOx by 2 Low NOx burners. This results in lowest ground level concentration of air pollutants in the study area. The values of the emissions at the fallout distance are within the Sindh Environmental Quality Standards (SEQS). The value of PM10 & PM2.5 which is the parameter of concern in coal fired power plants is much within the limits suggested by SEQS. As such introduction of mitigation measures will entail emissions that will be within all standards and guidelines. The effluents from the plant include the boiler blow down, cooling water and waste water from the plant. A water treatment plant will be constructed at the plant site which will ensure the effluents meet the SEQS limits. While developing the water system for the project, utmost care has been taken to maximise the recycle/reuse of effluents and minimize effluent quantity. All major water systems of the plant (cooling water system, service water system, coal handling water system and bottom ash handling system) have re- circulatory systems. There are no designated protected areas in the vicinity of the project area. Similarly, this EIA study has not found any antiquity artifact in the microenvironment of area concerned. No sites of cultural heritage are known to exist at or in the immediate vicinity of the DPKPG -CPP project location. There are also no indications of any old settlement in the area, nor is there any site covered under the listing of cultural heritage sites. Therefore, there will be no impacts from the construction and operation of the facilities; as such, no mitigation will be required. The annual ash produced from the coal boilers could be several hundred thousand ton based on the ash content of the coal. ASTM C618 defines two types of ash: Class F fly ash and Class C fly ash. The chief difference between these classes is the amount of calcium, silica, alumina, and iron content in the ash. The EMC Pakistan Pvt. Ltd Page 6 of 8 Environmental Impact Assessment for 2 x 350 MW Coal Power Project chemical properties of the fly ash are largely influenced by the chemical content of the coal burned, anthracite, bituminous and lignite. The use of fly ash as building material allows energy savings and the reduction of CO emissions as one 2 tonne of fly ash replacing cement saves one tonne of CO . Coal fly ash can also be processed to give a 2 material used for landfill cover and isolating lining that has better technical and environmental characteristics than most natural clays. Coal fly ash has also been proven to improve the yield from agricultural land and can be used as a pollution control agent, particularly for soil decontamination, sludge and effluent treatment and in hazardous waste stabilisation. There are a number of potential users of ash produced by the project in the vicinity of DPKPG -CPP. These include cement plants are located at a distance of 100-150 km from the plant mostly on the main highway M-9 linking Hyderabad to Karachi. Production of cement concrete blocks where bottom ash can be used as an aggregate is also common and widespread in the Karachi area. EMP specifies various technological measures for pollution prevention, waste minimization, end-of-pipe treatment, attenuation etc. proposed to be undertaken to mitigate the environmental impacts on each sector of environment during each phase of the project, i.e. construction phase and operation phase. The responsibility for implementation for all mitigatory measures rests with DPKPG. The environmental management will require specific approach in order to handle the issues effectively. Manager HSE will assign the roles and responsibilities to be performed during the construction and operations stages of DPKPG – Coal Power Plant Project. It is expected that a certain degree of redundancy is inevitable across all management levels, but should be in the order to ensure that compliance with the environmental management plan can be cross-checked. Frequent round/surveillance of the area is to be conducted by the Independent Monitoring Consultant (IMC) for in-time detection of pollutants/polluter and remedial measures. IMC should also ensure compliance with procedures that are part of mitigating measures, such as low-speed, no engine-idling and no-horn disciplines on the access road. The objective of post project monitoring will be to determine the level of residual impacts of the project activities on physical, biological and socio-economic receptors in the project area. The monitoring will start one month after the termination of all project-related activities in the project area. As a part of the post-project monitoring, restoration of sites will also be checked. Table EX-5: Mode of Implementation & Allocation of Resources for Mitigation Measures for Operation Phase Allocation of Mitigation Measures Mode of Implementation Financial Resources Air Environment High Efficiency ESPs Integral Part of Main Plant Packaged Rs. 916.34 Million Stack Civil Construction Package Rs. 1118.69 Million Coal Dust Extraction and Integral Part of Main Plant Package Rs. 32.89 Million Suppression Systems Reclamation of ash pond Part of O&M System Rs. 449.95 Million Water Environment Cooling water discharge channel Part of Main Plant Package Rs. 2275.43 Million Main Plant Effluent Treatment Part of Main Plant Package Rs. 381.98 Million Plant – ETP Sewage Treatment Plant Separate package Rs. 22.87 Million Noise Environment Included in Technical Design of equipment Rs. 195.77 Million Specification EMC Pakistan Pvt. Ltd Page 7 of 8

Description: