Climate change and managed ecosystems PDF

Preview Climate change and managed ecosystems

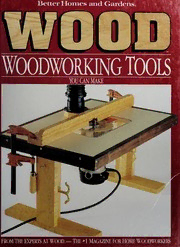

f r 1 *'1 >j— in JB. FROM THE EXPERTS AT WOOD — THE *1 MAGAZINE FOR HOME WOODWORKERS Digitized by the Internet Archive in 2019 https://archive.org/details/testcwfcircumvenOOOOiajy Better Homes and Gardens, I^CyiRE'— All of us at Meredith® Books are dedicated to giving you the information and ideas you need to create beautiful and useful woodworking projects. We guarantee your satisfaction with this book for as long as you own it. We also welcome your comments and suggestions. Please write us at Meredith® Books, LS-356WT, 1716 Locust St., Des Moines, IA 50336. ©Copyright 1991 by Meredith Corporation, Des Moines, Iowa. All Rights Reserved. Printed in the United States of America. First Edition. First Printing. Library of Congress Catalog Card Number: 90-64105. ISBN: 0-696-01947-7. A tm BOOK Published by Meredith. Books MEREDITH. BOOKS Vice President, Editorial Director: Elizabeth P. Rice Art Director: Ernest Shelton Managing Editor: David A. Kirchner Project Editors: James D. Blume, Marsha Jahns Project Managers: Liz Anderson, Jennifer Speer Ramundt, Angela K. Renkoski Associate Art Directors: Neoma Thomas, Linda Ford Vermie, Randall Yontz Assistant Art Directors: Lynda Haupert, Harijs Priekulis, Tom Wegner Graphic Designers: Mary Schlueter Bendgen, Michael Burns, Mick Schnepf Art Production: Director, John Berg; Associate, Joe Heuer; Office Manager, Michaela Lester President, Book Group: James F. Stack Vice President, Retail Marketing: Jamie L. Martin Vice President, Administrative Services: Rick Rundall WOOD. MAGAZINE President, Magazine Group: James A. Autry Editorial Director: Doris Eby Editor: I.arry Clayton MEREDITH CORPORATION OFFICERS Chairman of the Executive Committee: E. T. Meredith III Chairman of the Board: Robert A. Burnett President and Chief Executive Officer: Jack D. Rehm WOODWORKING TOOLS YOU CAN MAKE Project Editor: James D. Blume Contributing Project Editor: James A. Hufnagel Contributing How-To Editor: Marlen Kemmet Graphic Designers: Michael Burns, Tom Wegner Project Manager: Angela K. Renkoski Contributing Text Editors: Barbara L. Klein, Mary L. Price Publishing Systems Text Processor: Paula Forest Special thanks to Kathy Stevens On the front cover: Benchtop Router Table, pages 38-40 On the back cover (clockwise from top left): Handscrew Clamps, pages 5-7; Pocket-Size Try Square, pages 8-10; Strip Sander, pages 11-13 Meredith - Books also publishes Better Homes and Gardens® Books, Country Home™ Books, Meredith® Press Books, and Sedgewood® Press Books. HAND TOOLS 4-25 HANDSCREW CLAMPS 5-7 POCKET-SIZE TRY SQUARE 8-10 STRIP SANDER 11-13 FINE-FINISH SCRAPER 14-15 DEPTH GAUGE 16-17 SANDING BLOCK 18-19 MARKING GAUGE 20-21 HARD MAPLE WOODWORKER’S MALLETS 22-23 WALNUT-MAPLE MITER BOX 24-25 POWER TOOLS AND ACCESSORIES 26-73 EASY-TO-ADJUST RIP FENCE 27-31 DOUBLE-DUTY TABLESAW EXTENSIONS 32-35 BLADE-HEIGHT GAUGE 36-37 BENCHTOP ROUTER TABLE 38-40 HEAVY-DUTY ROUTER TABLE 41-47 DELTA-WING PIN-ROUTING ATTACHMENT 48-50 ACCURATE BOX-JOINT JIG 51-53 BACK-TO-BASICS SHOP LATHE 54-63 DRUM-SANDING TABLE 64-66 THICKNESS SANDER 67-73 SHOP ORGANIZERS 74-95 ONE-WEEKEND WORKBENCH 75-80 PLANE RACK 81 MODULAR WORKBENCH GROUP 82-89 TRIPLE-CROWN SAWHORSE 90-91 STORAGE FOR SANDING 92-94 DRUM-SANDER HOLDER 95 HAND TOOLS Clamping. . . squaring .. . sanding. . . scraping. . .marking. . .pounding. . . mitering — everyday woodworking tasks become even more satisfying when you accomplish them with hand tools you’ve crafted yourself. Here are nine handsome projects you’ll reach for again and again. 4 HANDSCREW CLAMPS I f you’re like most woodworkers we know, you could use a few more handscrew clamps around your shop. Now you can make your own. Our instructions tell how to huild 8" handscrew clamps (pictured opposite). Be sure to see the Buying Guide on page 7 for our source of the hardware for this and the other sizes of clamps available. And, don’t forget to order the brass “WOOD Collector’s Edition” emblem we’ve had computer- engraved for this project. It really sets these clamps apart from the rest. Note: You’ll need ‘//'-thick walnut and maple for the clamp jaws. Father resaw or plane thicker stock to size. ( We positioned the tahlesaw fence V/' from the hlade and resawed H"- thick stock to ‘//' thick.) Machine the jaw parts 1. Cut four pieces of ’/V'-thick maple and two pieces of '/V'-thick walnut to 1 Va" wide by 8" long. 2. Using double-faced tape, stick together two pieces of maple face-to-face, with the edges and ends flush. Repeat with the two remaining maple pieces and then w ith the two walnut pieces. 3. Using carbon paper or photocopies and spray adhesive, transfer the full-sized patterns (A, B, C, D) on page 6 to each lamination. Cut the walnut pieces (B, C, D) to shape. continued 5 HAND TOOLS HANDSCREW CLAMPS continued 4. Later, remove the pivot nuts Laminate the jaws and scrape off the excess glue. 1. With a lVi6" bit chucked in a Rout Vs" round-overs along the drill press, bore two holes edges of each jaw where shown through each pair of maple pieces on the Exploded View Drawing, where located on the patterns. page 5. Sand smooth. (For smooth operation of the 5. Drill a 1 Va" hole Vs" deep pivot nuts in the holes, we where shown on the full-sized recommend a brad-point bit.) pattern for the engraved “WOOD 2. Taper the fronts of each Collector's Edition” emblem. (We maple lamination on a bandsaw. used a Forstner bit, but a spade Pry apart all the taped-together bit also would work.) For better pieces, remove the tape, and adhesion, sand the back of the clean off the sticky residue with emblem, then epoxy it into the lacquer thinner. hole. 3. Using the pivot nuts for alignment and the walnut pieces Add our customized handles, spaced apart where shown on the if desired Full-Sized Clamp Body Pattern, Note: The kit comes with right, glue and clamp together turned handles. However, our each clamp jaw as shown in handles give you a firmer grip photo A, opposite, left. (For even and look better than the turned clamping pressure, and to prevent ones. denting the maple, we used 1. Start with a piece of walnut plywood scraps as clamp blocks. 11/4X11/4X12" long. (We We adhered the plywood to the maple pieces with double-faced laminated ¥4" stock, then jointed both faces to keep the joint line tape.) To keep the walnut pieces centered.) Crosscut two pieces from sliding around, let the glue get a bit tacky before clamping. 3¥4" long from the 12" length. 2. Mark diagonals on one end Check for slippage after clamping. of each 33/4"-Iong handle blank Remove any excess glue from the (E) to find the center. Drill a ¥%" openings with a chisel. hole 1" deep centered in the end of each. FULL-SIZED HANDLE PATTERN 13/4" FULL-SIZED CLAMP BODY 6 Use a temporary dowel handle for stability when bandsawing the walnut handle to shape. Brush glue onto the mating surfaces, and clamp the jaw parts together with the edges and ends flush. 3. Stick a 12" length of Vs" Apply the finish, and install the Buying Guide dowel into each of the walnut clamp hardware kit • Handscrew clamp kits. Each kit handles to act as a temporary' 1. Remove the dowel handles. contains two threaded rods, four grip. Apply an oil finish to each part pivot nuts, and two turned 4. Transfer the Full-Sized (we used Watco Natural Oil). handles. Catalog no. PI 10. Handle Pattern, opposite, to one 2. Thread the rods through the Contact Leichtung Workshops, face of each handle blank, and pivot nuts as described in steps 7, 4944 Commerce Parkway, bandsaw along the marked 8, and 9 of the instructions Cleveland, OH 44128, or call 800- handle lines, as shown in photo supplied with the clamp 321-6840 or 216/831-6191, for B, above right. Using double- hardware. Close the clamps until kit prices and shipping charges. faced tape, stick the waste pieces the jaws are flush against each We’ve provided Leichtung with back on the edges from which other. Grind or file the handle full-sized patterns for building 6", they were cut. Now transfer the end of each threaded rod to the 10", 12", and 14" handscrew handle outline to an adjacent shape shown on the Taper Detail, clamps. The patterns will be surface and cut it to shape. page 5. included with each clamp 5. Still using the dowel handles 3. Epoxy the handles onto the hardware kit. as grips, use a stationary belt tapered end of each threaded rod • Computer-engraved brass sander to remove the saw marks where shown on the Exploded emblems. To order, send $ 1.04 from the handles. With a palm View Drawing, page 5. (U.S.) per emblem along with a sander, sand Va" round-overs Immediately wipe off any excess self-addressed stamped envelope along the edges, then sand the epoxy on the rods. to Custom Awards, 1427 NW. handles smooth. 4. If the handles turn a bit 81st St., Des Moines, IA 50311. rough, put a drop or two of • 9/i6" brad-point bit. Carbon lubricant (we used WD-40) on steel with Vi" shank. Catalog no. each threaded rod. Then, open 200-Vi. For current price, contact and close each clamp a few times. Puckett Electric Tools, 841 Eleventh St., Des Moines, IA Supplies: double-faced tape, 50309, or call 800-544-4189 or epoxy, spray adhesive or carbon 515/244-4189. paper, finish. 7 HAND TOOLS POCKET-SIZE TRY SQUARE T here are few tools more measured to within .008" of 2. Chuck a Vs" core-box bit into indispensable in a perfect square—well within the a table-mounted router. Raise the workshop than an accurate requirements of home bit V32" above the table surface square. That’s why we’re so woodworkers. where shown on the End Section pleased to be able to share this Detail, opposite. Position the tried-and-true project design Begin with the walnut body fence exactly Vs" from the center with you. Are the squares 1. Cut a piece of Va" walnut to of the bit accurate? You bet they are. Va" wide by 7Va" long. ( We 3. Clamp two stops to your Several of us on the WOOD ,, searched through our walnut router table fence where shown magazine staff spent a few stock until we found a piece with in the Cove Routing Setup hours in the shop constructing highly figured grain. Also, we cut Drawing, opposite. With one end seven squares using the the piece extra long for safety of the walnut against Stop 1, drawings and instructions when routing the coves in the lower the face-grain edge onto shown here. Then we sent our next step.) If you rout coves on the bit and push the walnut to squares to the College of both ends before crosscutting, Stop 2 to rout the groove. Repeat Technology at Bowling Green you’ll have enough stock for two the procedure on the opposite State University in Ohio for handles. surface of the walnut. testing. All of the squares 4. Crosscut the routed end of the walnut to 3V4" long. 8