Table Of ContentUmt. e. d States P31161111 [19] [11] Patent Number: 4,960,734

Kauai et a1. [45] Date of Patent: Oct. 2, 1990

[54] CERAMIC COMPOSITE AND PROCESS FOR 61-31360 2/1986 Japan ................................... .. 501/98

PREPARATION IHEREOF - OTHER PUBLICATIONS

[75] Inventors: Takao Kauai; Kei Tanemoto; Hiroshi - ' -

Kubo; Toyohiko Sam, an of .IJ). lllllldlvgfgggvvley et al., Progress in Nltrogen Ceramics,

Kawasaki’ Japan R. W. Nurse et al., trans. Brit. Ceram. Soc., 64(9), 416

[73] Assignee: Nippon Steel Corporation, Tokyo, (1965).

Japan Electronic Ceramics, vol. 1, 17, No. 84, p. 68 (1986).

_ Toshikazu Sakai, Journal of the Ceramic Society of

[21] Af’pl' N°" 376909 Japan, NO. 86, (3) p. 125 (1978).

[22] Filed: Jul‘ 5’ 1989 Primary Examiner-Karl Group

Related Us. Application Data Attorney, Agent, or Fzrm—Wenderoth, Llnd & Ponack

[63] Continuation-impart of Ser. No. 247,263, Sep. 21, 1988, [57] ABSTRACT

abandoned. Disclosed is a ceramic composite consisting essentially

0 - - - - - D of hexagonal boron nitride (h-BN), aluminum nitride

[3 1 Foreign Apphcauon Pnonty am I and, if any, unavoidably formed aluminum oxynitride

Sep. 22, Japan .............................. n0 and a and/or a reaction product

1366- 28, 1987 [JP] Japan 62'329626 of the sintering aid with the above-mentioned compo

May 18, 1988 [JP] Japan 63419236 11611128 (h-BN, AlN and mom, in which the total

Jun. 3, 1988 [JP] Japan .............................. .. 63-135562 amount of the Sintering aid and the reaction product is

[51] Int. (:1.5 ............................................ .. 00413 35/58 0-01 t9 5 parts by weight per 100 parts by weight of the

[52] US. Cl. ...................................... .. 501/98; 501/96; sum of h—BN, MN and AION- This sintered body 99m

264/65; 264/66 prises AlN and AlON in a total amount of 45 to 5% by

[58] Field of Search .................... .. 501/96, 98; 264/65, weight with 55 to 95% by weight of h-BN- Alterna

264/66 tively, this sintered body comprises AlN and AlON in a

_ total amount of 80 to 5% by weight with 20 to 95% by

[56] References Cited weight of h-BN, the degree of anisotropy of the thermal

e U.S. PATENT DOCUMENTS conductivity of the sintered body (the ratio of the maxi~

3,254 967 12/1974 Reinmuth ............................ .. 501/98 mm thermal °°nductivity t° the minimum thermal

4,542:293 2/1937 Kummoto et aL _ “ conductivity, the direction of the maximum thermal

4,666,873 5/1987” Morris, Jr. et al. ................. .. 501/96 conductivity being perpendicular to the direction of the

minimum thermal conductivity) being at least 2.

FOREIGN PATENT DOCUMENTS

0154992 9/1985 European Pat. Off. ............ .. 501/98 24 Claims, 1 Drawing Sheet

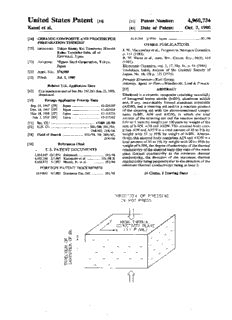

DIRECTION OF PRESSING

IN HOT PRESS

y HIGH THERMAL /

CODUCTIVITY PLANE ,

Z x (XY PLANE) ,

CD ’ /

LL 2 /

oLL g _ __ _ _ ’ /

69 - - - ~ - ’ / ’

|,_- /

S._. g< _ __ _ _ /

O —J __ _ _ _

US. Patent 4,960,734

Oct. 2, 1990

Fig.1

DIRECTION OF PRESSING

IN HOT PRESS

Y HIGH THERMAL

CODUCTIVITY PLANE

(XY PLANE)

ZTII

EZmOED0ME

4,960,734

1 2

assistant, and it is known that the sintered body obtained

CERAIVHC CONIPOSITE AND PROCESS FOR according to this method has a structural anisotropy

PREPARATION THEREOF attributable to the layered crystal structure of hexago

nal boron nitride [see, for example, Bulletin of the Ce

This application is a continuation-in-part of now ramic Society of Japan, Vol. 7, No. 4, page 243 (1972)].

abandoned application, Ser. No. 07/247,263 ?led on This anisotropy is also found in the physical properties

Sept. 21, 1988 now abandoned. such as thermal conductivity, but even in a sintered

body in which the anisotropy exists, the thermal con

BACKGROUND OF THE INVENTION

ductivity is not very high, e. g., it has been reported that

(1) Field of the Invention the thermal conductivity is only about 60 W/m.K at

The present invention relates to a ceramic composite highest [see, for example, Electronic Ceramics, Vol. 17,

and a process for the preparation thereof. More particu No. 84, page 68 (1986)]. The reason for this is consid

larly, the present invention relates to a ceramic compos ered to be that a large amount of the oxide type sinter

ite composed mainly of hexagonal boron nitride and ing aids or a reaction product of the sintering aids with

aluminum nitride, which is electrically insulating and another component is present in the sintered body.

has a high thermal conductivity, a relatively small ther A sintered body composed solely of boron nitride has

mal expansion coefficient, a low dielectric constant, and a relatively lower thermal conductivity than that of the

a good machinability. More speci?cally, the present aluminum nitride sintered body, but the thermal expan

invention relates to a ceramic composite which can be sion coefficient of boron nitride is too low, and a good

used as an IC package material, an IC substrate mate 20 match with silicon, which semiconductor is to be actu

rial, an electrically insulating radiating material with ally mounted on a substrate or package, cannot be ob

high thermal conductivity applicable at room tempera tained. Accordingly, boron nitride is rarely utilized as

ture to a high temperature, and a machinable ceramic an IC package material or an IC substrate material.

material. A sintered body formed by combining aluminum

(2) Description of the Related Art 25 nitride with hexagonal boron nitride, mainly in an at

Aluminum nitride has a high thermal conductivity of tempt to improve the machinability of the sintered body

about 110 to about 195 W/m.K at room temperature, while maintaining the high thermal conductivity of the

which is several times to ten times as high as the thermal aluminum nitride sintered body, and a process for the

conductivity of alumina. Accordingly, aluminum ni preparation of this composite have been proposed. For

tride has attracted attention as a substrate of a semicon example, Japanese Unexamined Patent Publication No.

ductor device or a package material, to replace alumina, 60-195058 discloses a process for preparation of an alu

and is in practical use in this ?eld (see, for example, minum nitride sintered body by adding at least one

Japanese Unexamined Patent Publication No. compound selected from the group of calcium nitrite,

61-275264, Japanese Unexamined Patent Publication barium nitrite and strontium nitrite as a sintering aid in

No. 62-36069 and Japanese Unexamined Patent Publica an amount of 0.01—5% by weight to an aluminum nitride

tion No. 62-41766). This is because, to satisfy recent powder or a mixed powder of aluminum nitride with

requirements for a reduction in the size of electronic boron nitride and/ or silicon nitride, and Japanese Unex

devices, and to improve the performances thereof, an amined Patent Publication No. 60-195059 discloses a

increase of the degree of integration, a multiplication of sintered body comprising aluminum nitride, boron ni

the functions, an increase of the operation speed, an 40 tride, and compounds of metals of the groups 11a and

increase of the output, and an enhancement of the reli IIIa, in which polygonal aluminum nitride particles are

ability are being rapidly developed, with the result that ?lled in fracture planes and a thin layer of boron nitride

the quantities of heat generated from semiconductors is interposed in a part of, or all of the grain boundary.

tend to increase correspondingly. It is stated that this sintered body is characterized in

Nevertheless, several problems are encountered 45 that it is a machinable ceramic composite which can be

when aluminum nitride is utilized as an IC package machined at a high speed by an ordinary tool. This

material, an IC substrate material or an electrically sintered body is homogeneous and isotropic, and a

insulating material. For example, although aluminum’ value of 55 to 122 W/m.K has been reported as an

nitride has a higher thermal conductivity than alumina, example of the thermal conductivity thereof.

and thus the problem of the heat radiating ef?ciency Nevertheless, although this sintered body has an ex

can be solved, the dielectric constant at room tempera cellent machinability, the thermal conductivity is 122

ture and 1 MHz is as large as 9 to 10, and therefore, the .W/m.K at highest, and in some applications this ther

delay of a signal in a wiring pattern formed thereon is mal conductivity is not sufficient for an IC substrate

prolonged, and accordingly, high-speed operation is material, an IC package material or an electrically insu

hindered. Moreover, since the thermal expansion coeffi lating material.

cient of aluminum nitride is larger than that of a single Japanese Unexamined Patent Publication No.

crystal of silicon, high-density packaging is dif?cult. 58-32073 discloses a process in which an electrically

The machining of an aluminum nitride sintered body, insulating sintered body having a high thermal conduc

as well as that of ordinary‘ structural ceramics, is diffi tivity is prepared by incorporating up to 30% by weight

cult, and the sintered body is defective in that a long 60 of cubic or hexagonal boron nitride in a aluminum ni

time is required to machine it into a desired shape, and tride, forming the mixture, and sintering the formed

thus the machining cost is increased. body in a vacuum or in a non-oxidizing atmosphere, or

A hexagonal boron nitride sintered body has an excel hot-press-sintering the formed body. This publication

lent machinability, corrosion resistance, thermal shock discloses that this sintered body has a thermal conduc

resistance, and electrically insulating property, and 65 tivity of about 85 to about 195 W/m.K, but does not

therefore, this sintered body is used in many ?elds. In disclose the anisotropy of the sintered body or the ma

general, the hexagonal boron nitride ceramics is pro chinability of the sintered body with an ordinary tool or

duced by the hot-press method using an oxide type the like.

4,960,734

3 4

Furthermore, since these aluminum nitride/ boron ' In accordance with the present invention, the follow

nitride ceramic composites have a composition close to ing processes are provided for preparing the above

aluminum nitride, these ceramics are defective in that, mentioned sintered body. First, a process is provided

like aluminum nitride, the dielectric constant is large for the preparation of a ceramic composite, which com

and the thermal expansion coefficient is large. prises adding a sintering aid in an amount of up to 10

Even in these aluminum nitride/boron nitride ce parts by weight to 100 parts by weight of a powder

ramic composites, in some certain preparation, as in the comprising 55 to 95 parts weight of a hexagonal boron

case of boron nitride which is sintered by hot-pressing, nitride powder and 5 to 45 parts by weight of an alumi

sometimes the structural anisotropy and the anisotropy num nitride powder, and heating under pressure the

of the physical properties attributed to the structural mixture in an inert gas flow under conditions of l500° to

anisotropy of boron nitride are present (see Japanese 2000" C. and 5 to 100 MPa. Second, a process is pro

Unexamined Patent Publication No. 62-56377), then the vided for the preparation of a ceramic composite, which

preparation process for eliminating this anisotropy and comprises further heat-treating the sintered body ob

the way of the utilization of a material having a very tained by the ?rst process at a temperature of 1300’ to

small anisotropy has been focused and subjected for 1500" C. or 1800° to 2000° C. in a reducing atmosphere

investigation. or an inert gas flow. Third, a process is provided for the

preparation of a ceramic composite, which comprises

SUMMARY OF THE INVENTION hot-pressing a mixed powder comprising 20 to 95 parts

In view of the foregoing conventional techniques, the by weight of a hexagonal boron nitride powder, 80 to 5

present invention is intended to provide a novel sintered 20 parts by weight of an aluminum nitride powder, and

body of a boron nitride/aluminum nitride ceramic com 0.01 to 10 parts by weight of a sintering aid in a vacuum

posites system satisfying all of the requirements for or in an inert gas flow under conditions of 1700“ to

thermal conductivity, thermal expansion coefficient, 2200° C. and 5 to 50 MPa. '

electrically insulating property, dielectric constant, and

machinability. 25 BRIEF DESCRIPTION OF THE DRAWING

Therefore, one object of the present invention is to FIG. 1 is a diagrammatic perspective view showing

provide ceramic composites having a relatively small the anisotropic h-BN/AlN ceramic composite accord

thermal expansion coefficient, a low dielectric constant, ing to the present invention.

and an excellent machinability, while maintaining a

30 DESCRIPTION OF THE PREFERRED

high thermal conductivity and a high electrically insu

EMBODIMENTS

lating property.

Another object of the present invention is to provide The h-BN/AlN ceramic composites of the present

a ceramic composite in which the thermal conductivity invention are commonly characterized in that the sin

is greatly improved, though only in a certain plane, tered body consists essentially of h-BN, AlN, unavoid

35

while maintaining an_excellent machinability. ably formed AlON, if any, and a sintering aid and/or a

In accordance with the present invention, these ob reaction product of the sintering aid with the above

jects can be realized by a ceramic composite consisting mentioned other components (h-BN, AlN and AlON),

essentially of hexagonal boron nitride (h-BN), alumi the total amount of the sintering aid and the reaction

num nitride (AIN), unavoidably formed aluminum oxy product thereof being 0.01 to 5 parts by weight, prefera

nitride (AlON), and a sintering aid and/or a reaction bly 0.2 to 0.5 parts by weight, per 100 parts by weight

product of the sintering aid with the other components of the sum of h-BN, AlN and AlON. Furthermore, the

(h-BN, MN and AlON), the total amount of the sinter (h-BN)/(A1N+A1ON) weight ratio is from 20/80 to

ing aid and the reaction product being 0.01 to 5 parts by 95/ 5.

weight per 100 parts by weight of the sum of h-BN, AlN Hexagonal boron nitride in the sintered body is ob

and AlON, wherein the sintered body meets one of the tained by using as the starting material a hexagonal

following conditions: (i) the sintered body comprises boron nitride powder having as high a purity as possi

AlN and AlON in a total amount of 40 to 5% by weight ble. Boron nitride includes hexagonal boron nitride and

with 55 to 95% by weight of h-BN; and (ii) the sintered cubic boron nitride. The hexagonal boron nitride is used

body comprises AlN and AlON in a total amount of 80 50 because the machinability is improved thereby.

to 5% by weight with 20 to 95% by weight of h-BN, a Aluminum nitride in the sintered body is obtained by

degree of anisotropy of the thermal conductivity of the using an aluminum nitride powder as the starting mate

sintered body (the ratio of the maximum thermal con rial.

ductivity to the minimum thermal conductivity, the Aluminum oxynitride is a compound formed during

direction of the maximum thermal conductivity being 55 the sintering by reaction between aluminum nitride and

perpendicular to the direction of the minimum thermal an oxide component, mainly aluminum oxide formed on

conductivity) being at least 2. the surface of the aluminum nitride powder [Toshikazu

This h-BN/AlN ceramic composite can provide two Sakai, Journal of the Ceramic Society of Japan, 86 (3),

types; a ?rst type of sintered body having a thermal 125 (1978), and J. W. Maccauley et al., Progress in

conductivity of at least 40 W/m.K at room temperature, 60 Nitrogen Ceramics, page 111 (1983)], and it is known

an average thermal expansion coefficient of 1.0 to‘ that several compound phases for aluminum oxynitride

4.0>< l0-6/K of from 0° to 400° C., a dielectric constant exist. Aluminum oxynitride is exactly represented by

smaller than 7.5 at room temperature and 1 MHz, a Al(g/3_l.,¢/3)O‘~,_,¢Nx but is referred to hereinafter as

porosity lower than 15%, and a ?exural strength of at AlON, for convenience. These compound phases de

least 40 MPa at room temperature, and a second type of 65 pend mainly on the temperature adopted for the pro

a sintered body having a degree of anisotropy of the ther duction of the sintered body. In the present invention,

mal conductivity of at least 2 and a thermal conductiv the compound phase of aluminum oxynitride is not

ity not lower than 150 W/m.K. particularly critical, and the aluminum oxynitride may

4,960,734

5 6

I be present in an amount of 0 to 7.5% by weight based on The ?rst type of the ceramic composite provided

the aluminum nitride content. according to the present invention is a sintered body

In the present invention, the aluminum oxynitride comprising 45 to 5% by weight of AlN and AlON (if

may be present in an amount of up to 7.5% by weight of present) with 55 to 95% by weight of h-BN, and further

the aluminum nitride, but is preferably in a less amount comprising 0.01 to 5 parts by weight, preferably 0.5 to

as possible to obtain high thermal conductivity. Particu 2 parts by wight of the sintering aid and/or the reaction

larly, the second type of the sintered body having the product thereof per 100 parts by weight of the sum of

anisotropy particularly preferably contains the alumi h-BN, AlN and AlON.

num oxynitride in an amount of not more than 1% by With the composition in which the amount of h-BN is

weight of the aluminum nitride. This reduction of the close to 55% by weight, a sintered body can be obtained

amount of aluminum oxynitride in the sintered body can in which the thermal conductivity is high, the mechani

be realized by appropriately selecting an amount of a cal strength is relatively high, and the thermal expan

calcium or yttrium compound added as a sintering aid sion coef?cient and dielectric constant are relatively

so that a complex compound of CaAl1zO19, CaAl4O7, large. In contrast, with the composition in which the

CaAl2O4 etc., when the calcium compound is added, amount of h-BN is 95% by weight, a sintered body can

and Y3Al5O12, YAlO3, Y4Al209, etc., when the yttrium be obtained that has a relatively small thermal expan

compound is added, is formed and the aluminum oxyni sion coefficient and a relatively low dielectric constant,

tride is disappeared in the sintered body. The appropri although the thermal conductivity and the mechanical

ate amount of the sintering aid to be added depends on strength are not high. If the amount of h~BN is outside

the amount of oxide formed on the surface of the start the above-mentioned range, a satisfactory sintered body

ing materials. Selection of the amount of the sintering cannot be obtained. For example, the thermal expansion

aid to be added should be carefully done since the ther coefficient and the dielectric constant are .too large in a

mal conductivity of the sintered body is sensitive to the sintered body having an h-BN content lower than 55%

amount of the added sintering aid, as described below. by weight, and in a sintered body having an h-BN con

As typical instances of the sintering aid used in the tent higher than 95% by weight, the thermal conductiv- _

present invention, there can be mentioned calcium com ity and the mechanical strength are low. With a compo

pounds such as calcium oxide, calcium carbide, calcium sition in which the amount of h-BN is 55% by weight or

carbonate, calcium nitrate, calcium ?uoride, calcium more, the dielectric constant becomes 7 or more and the

hydroxide, calcium cyanide, and calcium cyanamide, delay of the signal calculated by Tpd'ye/c (c: velocity of

and yttrium compounds such as yttrium oxide, yttrium light) becomes 9 ns/m or less. This speed is as high as

carbide, yttrium ?uoride, and yttrium nitrate. Boron the best of ceramics, and therefore, the above composi

oxide can be used in combination with these sintering tion allows a high speed signal transmission. By increas

aids. ing the proportion of h-BN, it was found that the ma

' The reaction product of the sintering aid with other chinability of the sintered body is distinctively in

components (h-BN, AlN and AlON) consists mainly of 35 creased in an amount of 55 to 60% by weight of h-BN.

calcium aluminate or'yttrium aluminate. Calcium alumi A sintered body having 55% by weight of h-BN was

nate and yttrium aluminate are a compound composed found to have twice as large a grinding ratio (amount

of calcium oxide and aluminum oxide and a compound of-removal-of-work/ amount-of-abrasion-of-diamond

composed of yttrium oxide and aluminum oxide, respec adhesive) as that of a sintered body having 40% by

tively, and it is known that several compounds can be weight of h-BN. A sintered body comprising 55 to 95%

formed by varying the mixing ratio of the two compo by weight, especially 60 to 90% by weight, of h-BN,

nents [R. W. Nurse et al., Trans. Brit. Ceram. Soc. 64(9), and 45 to 5% by weight, especially 40 to 10% by

416 (1965) and T. Noguchi et al.,,Kogyo Kagaku Zas weight, of AlN and AlON is preferred.

shi, 70(6), 839 (1967)]. In the present invention, the kind The sintering aid, especially the above-mentioned

of calcium aluminate or yttrium aluminate is not partic 45 calcium compound or yttrium compound, promotes

' ularly critical. As other compound, there can be men densi?cation because it forms a liquid phase, and to

tioned calcium boride, calcium borate, and yttrium reduce the amount of oxygen in aluminum nitride parti

borate, but substantially, there is no possibility of a cles and increase the thermal conductivity, the sintering

formation of calcium borate and yttrium borate. ' aid should be contained in an amount of at least 0.01

Where anhydrous boron oxide (B203) is used as the 50 part by weight, preferably at least 0.2 part by weight.

sintering aid, since this compound is substantially va Incorporation of the sintering aid in an amount exceed

poiized and most of the remaining B203 is converted to ing 5 parts by weight is not preferred because a decrease

boron nitride, duringthe sintering, boron oxide is not of the thermal conductivity occurs. ' _

substantially present in the sintered body. ‘ _ This ceramic composite is characterized in that the

In the sintered body of the present invention, th thermal conductivity at room temperature is at least 40

sintering aid and the reaction product thereof are pres‘ , W/m.K, the average- thermal expansion coef?cient of

ent in an amount of 0.01 to 5 parts by weight, preferably from 0° to 400° C. is controlled to ‘1.0 to 4.0>< l0"6/K,

0.2 to 5 parts by weight, per 100 parts by weight of the and the dielectric constant at room temperature and 1"

sum of h-BN, AlN, and AlON. If the amount of the MHz is smaller than 7.5.’ p’

sintering aid is smaller than 0.01 part by weight, a sin 60 This sintered body is also characterized in that the

tered body having the intended characteristics cannot porosity is lower than 15% and the flexural strength at

be obtained. Of the sintering aids, as mentioned above, room temperature is at least 40 MPa. _ ' -

B203 used in a particular case is not substantially pres In view of the utilization'thereof for an IC package

ent in the sintered body. Accordingly, the calcium com material, an IC substrate material, and an electrically

pound or yttrium compound and the reaction product 65 insulating material, preferably the thermal conductivity

thereof are mainly present in the sintered‘ body, butif at room temperature is at least 40 W/m.K. " This value

the amount exceeds 5 parts by weight, a decrease of the canbe attainedby a promotion of the densi?cation and

thermal conductivity occurs. a reduction of the amount of oxygen contained in ni-.v

4,960,734

7 8

tride particles by the sintering aid such as the calcium nitrogen gas ?ow, since if the heating is carried out in a.

compound or yttrium compound in the composite sin nitrogen gas ?ow, no crystal phase other than h-BN,

tered body. AlN, and aluminate phases substantially remains in the

The average thermal coefficient of from 0° to 400° C. sintered body.

is in?uenced by the kind, amount, and presence of the The reasons for the limitation of the temperature at

sintering aid and the reaction products of the sintering the heating under pressure step to 1500° to 2000° C. are

aid with the other components, but is mainly deter as follows: Where the temperature is lower than 1500°

mined by the content of h-BN. For example, this aver C., even if the above-mentioned calcium compound or

age thermal expansion coef?cient is about 4.0X 10*6/ K yttrium compound is added, a sintered body having a

in a sintered body containing 40 parts by weight of - 0 desired porosity and thermal conductivity cannot be

h-BN, and is about 1.0x lO-6/ K in a sintered body obtained, and if the temperature exceeds 2000° C., the

containing 95 parts by weight of h-BN. By controlling process becomes economically disadvantageous. The

the h-BN/AIN content ratio and the sintering condi reasons for the limitation of the pressure to 5 to 100

tions, the thermal expansion coefficient can be brought MPa are as follows: If the pressure is lower than 5 MPa,

close to that of Si, i.e., 3.6X10-6/K, and the thermal a sintered body having a desired porosity cannot be

expansion coefficient of the sintered body having the obtained, and if the pressure exceeds 100 MPa, the mold

above-mentioned composition (55 to 95% by weight of that can be used is restricted, for example, in the hot

h-BN) is in the range of 1.0 to 4.0X l0—6/K. A composi pressing method.

tion comprising 75 to 55% by weight of h-BN and 25 to As the compressing method, either a uniaxial com

45% by weight of MN and AlON is preferred, as it 20 pression such as hot-pressing or an isostatic compres

brings the thermal expansion coefficient close to that of sion such as HIP can be adopted. In the case of an

isostatic compression, many open pores are present in

Si. ‘

In view of the high-frequency characteristics, prefer the green body, and preliminary sintering to remove the

ably the dielectric constant at room temperature and 1 pores or a preliminary treatment such as encapsulation

MHz is smaller than 7.5. If the porosity exceeds 15% 25 is necessary.

and the mechanical strength is lower than 40 MPa, the Preferably, the heating under pressure is conducted

basic mechanical properties of the sintered body as the for 0.5 to 4 hours, especially 1 to 2 hours. If the heating

material are poor and it is dif?cult to utilize the sintered under pressure time is shorter than 0.5 hour, sometimes

body for electronic parts. the densi?cation of the sintered body is unsatisfactory,

The ceramic composite having the above-mentioned and thus satisfactory characteristic values cannot be

composition and characteristics is prepared, for exam obtained, and if the heating under pressure is conducted

ple, by a process described below. Note, this process is for more than 4 hours, the characteristic values are not

a preferred embodiment of the preparation process, and adversely in?uenced but the process becomes economi

the preparation process is not limited to this process. cally disadvantageous.

More speci?cally, up to 10 parts by weight of the To prevent oxidation of the nitride particles, prefera

sintering aid is added‘ to 100 parts by weight of a pow bly the heating under pressure is conducted in a flow of

der comprising 40 (not inclusive) to 95 parts by weight an inert gas such as nitrogen or argon.

of an h-BN powder and 5 to 60 parts by weight of an If the sintered body obtained by this heating under

AlN powder, and the mixture is heated under pressure pressure is further heat-treated in an inert gas ?ow at

at a temperature of 1500° to 2000° C. under a pressure of 40 1300‘ to 1500° C. or l800° to 2000° C., the thermal

5 to 100 MPa in an inert gas ?ow. conductivity in particular is improved.

At least one member selected from calcium com If the heat treatment is conducted at 1300" to 1500°

pounds and yttrium compounds is added as the sintering C., the solidi?cation product of the liquid phase present

aid in an amount of up to 5 parts by weight, preferably mainly in’ the grain boundary migrates to the triple

0.2 to 5 parts by weight. points of the grain boundary, and if the heat treatment is

The kind of the calcium compound is not particularly conducted at 1800“ to 2000° C., the content of the oxy

critical, for example, calcium oxide, calcium carbide, gen impurity contained in the nitride particles is re

calcium carbonate, calcium nitrate, calcium ?uoride, duced and the number of grain boundaries decreased by

calcium hydroxide, calcium cyanide, and calcium cyan the growth of the particles. The heat treatment temper

amide can be used, but calcium oxide and calcium car ature is limited to the above-mentioned range because, if

bide are especially preferred. the treatment temperature is lower than 1300“ C., no

The kind of the yttrium compound is not particularly effect is obtained because the temperature is too low,

critical, for example, yttrium oxide, yttrium carbide, and if the treatment temperature is higher than 1500° C.

yttrium ?uoride, and yttrium nitrate can be used, but and lower than 1800" C., the bulk density is reduced by

yttrium oxide and yttrium carbide are especially pre a volatilization of a part of the liquid phase and the

ferred. thermal conductivity is decreased because the reduction

If necessary, especially when the content of h-BN is of the oxygen impurity and decrease of the number of

80 to 95% by weight, preferably anhydrous boron oxide grain boundaries by the growth of the particles does not

is added in an amount of up to 5 parts by weight, since occur, since the temperature is too low. If the treatment

the densi?cation is conspicuously promoted by this 60 temperature exceeds 2000° C., the treatment becomes

addition of anhydrous boron oxide. Boron oxide forms economically disadvantageous due to this excessive

a liquid phase at a temperature as low as several hun heating, and since the treatment temperature exceeds

dred °C. and the majority of boron oxide volatilizes at a the sintering temperature, there is a risk of a change in

temperature of up to 1500° C., and moreover, the ma the sintered body per se.

jority of the residual boron oxide is converted to boron 65 Where the heat treatment is conducted at 1300“ to

nitride by heating in nitrogen gas ?ow. Accordingly, 1500° C., a treatment time of 0.5 to 2 hours is preferred.

where boron oxide is used in combination with the If the treatment time is shorter than 0.5 hour, a satisfac

sintering aid, preferably the heating is carried out in a tory effect cannot be obtained, and a treatment time

4,960,734

10

exceeding 2 hours is not preferred from the economical hand, in the x axis and y axis and the plane including

viewpoint. Where the heat treatment is conducted at both axes, the sintered body shows a high thermal con

l800° to 2000° C., since the intended effect cannot be ductivity. In the sintered body of the present invention,

obtained if the treatment time is short, the heat treat there exists an anisotropy of the values of physical prop

ment must be conducted for at least 2 hours. erties other than the thermal conductivity, such as the

To prevent oxidation during the heat treatment, pref thermal expansion coefficient and Vickers hardness, but

erably the heat treatment is conducted in a flow of an in the instant speci?cation and appended claims, refer

inert gas such as nitrogen or argon or in a reducing ence to the degree of anisotropy denotes only the an

atmosphere. An especially high effect can be obtained if isotropy of the thermal conductivity.

the heat treatment is carried out at 1800" to 2000° C. in 10 This sintered body has a degree of anisotropy of at

a reducing atmosphere. The reducing atmosphere can least 2, and the value of the higher thermal conductivity

be obtained, for example, by introducing a hydrogen (the thermal conductivity in an optional direction on

gas, ?lling with a graphite powder, or sealing in a the x-y plane including the x axis and y axis) is at least

graphite vessel. 100 W/m.K, preferably at least 150 W/m.K. The com

The second type of the ceramic composite provided position satisfying this requirement comprises 20 to

according to the present invention is a sintered body 95% by weight of h-BN, preferably 20 to 80% by

comprising 80 to 5% by weight of the total amount of weight of h-BN, of the sum of h-BN, AlN, and AlON.

AlN, and AlON if present, with 20 to 95% by weight of Although this anisotropy is observed in a sintered body

h-BN, and further comprising 0.01 to 5 parts by weight, composed solely of h-BN, the thermal conductivity is

preferably 0.2 to 5 parts by weight of a sintering aid 20 not very high, i.e., about 60 W/m.K, at highest. A ther

and/or a reaction product thereof with the other com mal conductivity of at least 100 W/m.K, preferably at

ponents per 100 parts by weight of the sum of h-BN, least 150 W/m.K, is obtained for the?rst time by an

AlN and AlON, wherein the degree of anisotropy of the incorporation of at least 5% by weight, preferably 20 to

thermal conductivity of the sintered body (the ratio of 80% by weight, of AlN (and AlON).

the maximum thermal conductivity to the minimum 25 The grain size constituting the sintered body, espe

thermal conductivity, the direction of the maximum cially the grain size of h-BN, has a great in?uence on

thermal conductivity being perpendicular to the direc the anisotropy of the sintered body. The average grain

tion of the minimum thermal conductivity) is at least 2. size of h-BN constituting this sintered body is at least 1

Where the composition has a content of h-BN close pm, preferably 5 um to 30 um. Changes of the thermal

to 20% by weight based on the sum of h-BN, AlN and 30 conductivity caused by changing the composition of the

AION, a sintered body can be obtained in which the sintered body composed of h-BN grains having an aver

?exural strength and Vickers hardness are relatively age grain size of at least 1 pm will be described in detail

high,=the thermal expansion coefficient is relatively in the examples given hereinafter. When the AlN con

large, and the anisotropy is relatively small. Con tent is increased, the thermal conductivity is highest at

versely, where the composition has an amount of h-BN 35 an h-BN content of about 75 to 50%. If the AlN content

close to 95% by weight, a sintered body can be obtained is further increased, the value of the high thermal con

in which the anisotropy is conspicuous, the thermal ductivity gradually decreases and becomes close to the

expansion is relatively small in a two-dimensional plane, value of the sintered body of AlN.

and the machinability is very good. If the composition is Changes of the lower thermal conductivity, i.e., the

outside this range and the content of h-BN is lower than thermal conductivity in the direction of the z axis in

20% by weight, the anisotropy of the sintered body is FIG. 1, are such that the thermal conductivity is almost

not conspicuous and the thermal conductivity is sub constant when the content of boron nitride is up to 50%

stantially equal to that of the AlN sintered body, and by weight, but if the AlN content exceeds 50% by

therefore, since the sintered body is composed substan weight, the value of the thermal conductivity gradually

tially solely of AlN, the machinability of the obtained 45 increases and becomes close to the value of the sintered

sintered body is reduced. In a sintered body having an body of AlN, and the anisotropy is usually lost.

h-BN content exceeding 95% by weight, the ?exural The change of the thermal conductivity will now be

strength and the thermal conductivity are low. Prefera examined with respect to the anisotropy. The degree of

bly, the content of h-BN is 20 to 80% by weight, espe anisotropy is largest in a composition comprising about

cially 25 to 75% by weight, based on the sum of h-BN,_ 50 75 to about 50% by weight of boron nitride, and the

AlN and AlON. . value is at least 10 in many cases and as large as about 15

This sintered body having an anisotropy has a struc in an extreme case. If the h-BN content is about 50% by

ture in which boron nitride particles are oriented and weight and higher, an increase of the content of AlN

laminated in the form of thin scales in the direction of and AlON results in a gradual decrease of the degree of

the z axis, as shown in the diagram of FIG. 1, and ac 55 anisotropy, and the degree of anisotropy is about 2

cordingly, the anisotropy of the physical property val when the h-BN content is about 20% by weight and the

ues such as the thermal conductivity is produced. By content of AlN and AlON is about 80% by weight.

the degree of anisotropy is meant the ratio of the ther The degree of anisotropy of the sintered body com

mal conductivity in an optional direction on the plane posed of h-BN grains having an average grain size

(x-y plane) including the x axis and y axis (the maximum 60 smaller than 1 pm will now be described. The degree of

thermal conductivity) and the thermal conductivity in anisotropy of the sintered body composed of h-BN

the direction of the z axis (the maximum thermal con grains having an average grain size of about 0.1 pm is

ductivity), i.e., the ratio of the thermal conductivity in small and about l/5 to about 1/ 10 of the degree of

an optional direction on the x-y plane/the thermal con anisotropy of the sintered body according to the present

ductivity in the direction of the z axis. If the hot-press 65 invention. Accordingly, in a speci?c composition, the

ing axis is set in the direction of the z axis, a lamination degree of anisotropy is at least 2 and the higher thermal

of BN occurs in the direction of the z axis and the ther conductivity is at least 100 W/m.K, preferably at least

mal conductivity is poor in this direction. On the other 150 W/m.K. In case of the sintered body composed of

4,960,734

11 12

h-BN grains having a grain size of about 0.01 pm, the determined. Furthermore, since the optimum amount of

degree of anisotropy is almost equal to 1, and the sintering aid added depends on the surface condition of

change of the thermal conductivity according to the the starting powder, especially the amount of the oxide

composition is such that the thermal conductivity tends formed on the surface, the optimum amount of sintering

to monotonously increase with an increase of the con aid added may differ according to the kind of starting

tent of AlN (and AlON). More speci?cally, in the aniso powder.

tropic sintered body according to the present invention, In this process for the preparation of the sintered

if the average grain size of h-BN grains constituting the body, if necessary, especially when 80 to 95 parts by

sintered body is at least 1 pm, a desired thermal conduc weight of the starting h-BN powder and 20 to 5 parts by

tivity and a desired degree of anisotropy can be easily 10 weight of the starting AlN powder are used, the densi?

obtained where a composition has an h-BN content of cation can be further increased by adding up to 5 parts

20 to 95% by weight, preferably 20 to 80% by weight. by weight of boron oxide in addition to 0.01 to 5 parts

By the grain size of h-BN grains referred to herein is by weight of the above-mentioned calcium compound

meant the size in the plane direction of thin scaly boron or yttrium compound.

nitride grains, and the size of the thickness direction is The starting material can be mixed with the sintering

excluded therefrom. aid by a known dry or wet mixing method using a ball

In this sintered body, preferably the sintering aid and mill or the like, but preferably the wet mixing method is

the reaction product of the sintering aid with other used. The kind of dispersing medium used for the wet

components are present in an amount of 0.01 to 5 parts mixing is not particularly critical, but preferably alco

by weight, preferably 0.2 to 5 parts by weight, per 100 20 hols, hydrocarbons and ketones are used. Water is not

parts by weight of the sum of h—BN, AlN and AlON. preferred, except in special cases, because water may

The thermal conductivity, especially the higher thermal cause a formation of ammonia gas by reaction with the

conductivity, of this sintered body is very sensitive to nitride powder.

the amount of sintering aid added, and the optimum The hot-press method, which is a uniaxial compres

amount of sintering aid added depends mainly on the 25 sion method, is adopted for the sintering when obtain

surface condition of the starting powder, especially the ing the sintered body of the present invention. If a pres

amount of the oxide formed on the surface. sureless sintering or isotropic sintering such as HIP is

The most preferred process for the preparation of this carried out after the forming, orientation or lamination

h-BN/AIN type sintered body will now be described. of h-BN particles does not occur or is unsatisfactory,

According to this process, a mixed powder comprising and accordingly, this sintering method is not preferable.

20 to 95 parts by weight of h-BN, 80 to 5 parts by In the hot-press sintering, the obtained powder mixture

weight of AlN and 0.01 to 10 parts by weight of the is directly charged in a graphite die, or the obtained

sintered aid is hot-pressed at 1700° to 2200° C. and 5 to powder is uniaxially molded under a pressure of up to

50 MPa in an inert gas flow. about 20 MPa and the green body is charged in a die so

A known AlN powder can be used as the starting 35 that the compression axis of the uniaxial molding is in

AlN powder, but to obtain a high thermal conductivity, agreement with the compression axis of the hot press. If

preferably an AlN powder having an average particle the mixed powder is formed under a hydrostatic pres

size smaller than 5 pm, preferably smaller than 2 pm sure by a high-pressure press (for example, 2 ton/cmz),

and an oxygen content lower than 3.0% by weight, the molded body is charged in a die, and the hot-press

especially lower than 1.5% by weight, is used. 40 sintering is carried out, whereby the anisotropy of the

A known h-BN powder can be used as the starting sintered body is reduced and a more isotropic sintered

h-BN powder, but if a powder having an average parti body is obtained (see, for example, Japanese Unexam

cle size larger than 1 pm, preferably larger than 5 pm, ined Patent Publication No. 62-56377).

is used, a desired sintered body is advantageously pre The hot-press sintering is carried out under a temper

pared and use of this powder is especially preferred. 45 ature of l700° to 2200° C. and a pressure of 5 to 50 MPa.

Nevertheless, even when a starting powder has an aver If the temperature is lower than 1700“ C., a sintered

age particle size smaller than 1 pm, an intended sintered body having the desired physical properties, especially

body can be prepared by adjusting and controlling the a high thermal conductivity, cannot be obtained, and a

sintering aid and the hot-press conditions. Preferably, sintering temperature higher than 2200° C. is not prefer

the purity of the used h-BN starting powder is as high as 50 able from the economical viewpoint. If the compression

possible. pressure is lower than 5 MPa, the densi?cation of the

As mentioned above, known sintering aids such as sintered body or the orientation of h-BN particles is

calcium oxide, calcium carbide, calcium cyanamide, often unsatisfactory, and if the compression pressure is

‘ yttrium oxide, and yttrium carbide can be used, and at higher than 50 MPa, the kind of the die that can be used

least one compound selected from these compounds is 55 for the hot-press sintering is restricted. To prevent oxi

added in an amount of 0.01 to 5% by weight, preferably dation of the nitride, an inert gas ?ow such as nitrogen

0.2 to 5% by weight, based on the sum of h-BN and gas is preferably used as the sintering atmosphere.

AlN. If the amount of the sintering aid is smaller than Where a speci?c sintering aid is used, if the sintering is

0.01% by weight, the function as a sintering aid is not carried out in a vacuum, the sintering aid or the reaction

satisfactory, and if the amount of the sintering aid ex product of the sintering aid with other components is

ceeds 5% by weight, the amount of the sintering aid left promptly vaporized from the sintering system and the

in the sintered body or the reaction product of the sin thermal conductivity is improved. Accordingly, the

tering aid with other components becomes excessive, sintering is preferably carried out in a vacuum.

resulting in a reduction of the thermal conductivity. As The anisotropy of the sintered body caused by orien

mentioned above, the thermal conductivity, especially 65 tation and lamination of h-BN particles and the high

the higher thermal conductivity, of the sintered body is thermal conductivity produced by this anisotropy can

sensitive to the amount of sintering aid added, and the be obtained by the above-mentioned process. More

amount of sintering aid to be added should be carefully specifically, calcium oxide, calcium carbide or calcium

4,960,734

13 14

cyanamide added as the sintering aid at the hot-press added, and wet mixing was carried out for 24 hours in a

sintering step reacts with aluminum oxide unavoidably ball mill using acetone as the solvent.

formed on the surface of aluminum nitride to form a The resultant powder was dried and hot-press sinter~

calcium-aluminum oxide, and this oxide begins to melt ing was carried out at 1800" C. under a pressure of 40

at about 14000 C. When yttrium oxide or yttrium car- 5 MPa for 2 hours in a nitrogen gas flow of 2 l/min, using

bide is added, this compound reacts with aluminum a graphite vessel having an inner diameter of 90 mm.

oxide to form an aluminum-yttrium oxide, which begins The crystal phase of the obtained sintered body was

to melt at a temperature higher than 1700° C. determined, and the thermal conductivity at room tem

This melt gradually surrounds h-BN and AlN or perature, the average thermal expansion coef?cient of

AlON and reacts substantially completely with the 10 from 0° to 400° C., the electric resistance at room tem

oxide layer on the surfaces of the nitride particles, to perature, the dielectric constant at room temperature

purify the surfaces of the particles and improve the and 1 MHz, the porosity, and the ?exural strength at

thermal conductivity of the sintered body. Also, due to room temperature thereof were measured. The results

the melt, the densi?cation of the particles is advanced are shown in Table l.

by liquid-phase sintering, through such processes as (1) 15 The crystal phase was determined by the X-ray dif

re-arrangement, (2) dissolution-deposition, and (3) grain fraction with internal standard using aluminum oxide

growth. This densi?cation mechanism participated in (corundum) as the reference material. The thermal con=

by the liquid phase promotes the orientation-lamination ductivity was measured by the laser ?ash method, and

of h-BN by the uniaxial compression, and causes the the thermal expansion coef?cient was measured by the

boron nitride particles to be laminated substantially 20 differential method using aluminum oxide as the stan

completely in the direction parallel to the compression dard with respect to the direction perpendicular to the

axis of the hot pressing, whereby a sintered body having compression axis of the hot press. The flexural strength

an anisotropy is obtained. was measured by the three-point bending strength

This h-BN/AlN sintered body having an anisotropy method of the J IS Standards, where the span was taken

can be easily machined and processed, regardless of the 25 in the direction perpendicular to the compression axis of

composition, so long as the boron nitride content is 20 the hot press.

to 95% by weight. From the results shown in Table 1, it can be seen that,

The present invention will now be described in detail in all of the compositions of from Sample 1 having a

with reference to the following examples, that by no highest boron nitride content to Sample 13 having a

means limit the scope of the invention. 30 lowest boron nitride content, a thermal conductivity at

room temperature of at least 40 W/m.K, an average

EXAMPLE thermal expansion coef?cient of 1.0 to 4.0x l0*6/K of

A hexagonal boron nitride powder (average particle 0° to 400° C., a dielectric constant smaller than 7.5 at

size of 0.2 pm) and an aluminum nitride powder (aver- room temperature and 1 MHz, and a ?exural strength at

age particle size of 1.8 pm) were weighed in amounts 35 room temperature of at least 40 MPa, were obtained.

shown in Table l, a sintering aid shown in Table l was

TABLE 1

Characteristics of Ceramic Composites

Crystal phase of Thermal Thermal

Sam- Mixing ratio Sintering sintered body conduc- Expansion Electric Dielectric Flextural

ple (parts by aid (parts (parts by tivity Coefficient resistance constant Porosity strength

No. weight) by weight) weight) (W/m - K) (X 10—6/K) (Q - cm) [1 MHz] (%) (MPa)

1 h-BN 95 B203 1.5 h-BN (hexagonal) 94.6 41 1.1 9.1 x 1013 4.49 7.4 51

MN 5 CaO 1.0 AlN 4.6

c3145] 08

2 h-BN 90 B203 1.0 h-BN (hexagonal) 90.3 47 1.8 7.4 x 10[3 4.79 5.1 63

MN 10 CaCz 1.0 AlN 8.8

c1421 0.9

3 h-BN 80 Yc2 0.8 h-BN (hexagonal) 79.1 75 2.7 7.7 X 1013 5.81 1.9 106

AlN 20 MN 18.5

YAG3 1.4

A10N4 1.0

4 h-BN 75 CaCZ 0.1 h-BN (hexagonal) 74.7 70 3.2 8.3 x 1013 6.37 1.6 144

MN 25 MN 20.8 '

AlON‘ 3.9

CA22 0.6

5 h-BN 75 CaCz 0.6 h-BN (hexagonal) 74.9 85 3.3 6.7 x 10‘3 6.48 1.5 1411

MN 25 AJN 21.1

A1oN4 3.0

CAZZ 1.0

6 h-BN 75 CaCz 1.0 h-BN (hexagonal) 75.4 143 3.3 9.6 x 1013 6.51 1.4 155

MN 25 MN 23.2

CA5 1.4

7 h-BN 75 CaCg 1.5 h-BN (hexagonal) 75.0 79 3.4 8.4 X 10‘3 6.44 1.4 153

AlN 25 MN 22.9

CA5 2.1

8 h-BN 75 CaCg 4.0 h-BN (hexagonal) 73.7 67 3.4 8.8 x 1013 6.45 1.5 161

MN 25 AIN 21.9

CA5 2.4

CaCNg 2.0

9 h-BN 75 CaCNZ 1.0 l1-BN(hexagonal) 75.0 122 3.2 >10" 6.50 1.3 159

MN 25 MN 23.6

CA5 1.4

10 h-BN 75 X203 1.0 h-BN (hexagonal) 74.2 85 3.2 6.6 X 10l3 6.33 1.2 163

4,960,734

15 16

TABLE l-continued

Characteristics of Ceramic Composites

Crystal phase of Thermal Thermal

Sam- Mixing ratio Sintering sintered body conduc- Expansion Electric Dielectric Flextural

ple (parts by aid (parts (parts by tivity Coefficient resistance constant Porosity strength

No. weight) by weight) weight) (W/m ‘ K) (X l0"6/K) (Q ' cm) [1 MHz] (%) (MPa)

AlN 25 AlN 23.9

YAG3 1.9

11 h-BN 60 no, 1.5 h-BN (hexagonal) 59.8 90 3.5 > 1014 7.01 1.3 183

AlN 40 AlN 37.8

YAG3 2.4

IC3A5 = 3CaO.5Al;O3

lCA; = CAO. 215.120,

3YAG = shots/n20;

4AIQN = AI(BIJ+X/J)O4—XNX

5CA = CaQAlgO;

EXAMPLE 2 (COMPARISON) strength, and Vickers hardness were determined with

The powders used in Example 1 were weighed so respect to either the directions perpendicular or parallel

that the amount of boron nitride was 99 parts by weight to the compression axis of the hot pressing. The bulk

and the amount of aluminum nitride was 1 part by 20 density was measured according to the Archimedes

weight, 1 part by weight of boron oxide and 1 part by method, using water, the thermal conductivity was

weight of calcium oxide were added as the sintering aid, measured by the laser ?ash method, the Vickers hard—

and the mixing and hot-press sintering were carried out ness was measured under a load of l to 5 kg, the average

under the same conditions as described in Example 1. thermal expansion coefficient was determined in the

The thermal conductivity of the obtained sintered body 25 range of from 0° to 400° C. according to the differential

was as low as 15 W/m.K, and the ?exural strength was method using an aluminum oxide (corundum) sintered

very low at 20 MPa. body as the reference material, and the strength was

determined according to the three-point bending

EXAMPLE 3 (COMPARISON) strength method of the JIS Standards.

To 100 parts by weight of the aluminum nitride pow- 30 The results are shown in Table 2. A degree of anisot

der described in Example 1 was added 5 parts by weight ropy as prominent as 2.1 to 13.6 was observed when the

of yttrium oxide, and hot-press sintering was carried out boron nitride content was 95 to 20% by weight, and in

at 1900' C. under a pressure of 40 MPa for 2 hours. The each composition, the higher thermal conductivity was

thermal conductivity of the obtained sintered body was at least 100 W/m.K. There was a tendency for the de

high and 150 W/m.K, but the thermal expansion coef?- 35 gree of anisotropy of the thermal expansion coefficient

cient was as large as'4.6><10-6/K and the dielectric to be decreased with a decrease of the boron nitride

constant was as large as 8.91. content. The ?exural strength tended to increase with a

decrease of the boron nitride content in both the direc

EXAMPLE 4 tions perpendicular and parallel to the compression axis

The sintered body (sample 5) formed by adding 0.5 40 of the hot press. The ratio of both values was substan

part by weight of calcium carbide to 75 parts by weight tially constant at about 2 in all of the compositions ex

of boron nitride and 25 parts by weight of aluminum cept an example of the composition of 90 parts of h-BN

nitride, as obtained in Example 1, was heat-treated at by weight and 10 parts of AlN by weight. The Vickers

1480° C. for 1 hour in a nitrogen gas flow. The crystal hardness increased with a decrease of the boron nitride

phase, dielectric constant, ' porosity, and ?exural 45 content, and the Vickers hardness abruptly increased

strength of the sintered body were substantially the when a boron nitride content reaches a boundary of

same as those of the starting sintered body, but the about 50%, and the anisotropy was gradually de

thermal conductivity was increased to 95 W/m.K and creased.

the thermal expansion coef?cient was smaller at As seen from the results obtained when the amount

3.2X l0—6/K. 50 added of CaCz was changed in the composition com

prising 50% by weight of boron nitride, the thermal

EXAMPLE 5 conductivity, especially the higher thermal conductiv

A hexagonal boron nitride powder having an average ity, was very sensitive to the amount added of CaCZ.

particle size of 6 pm, and aluminum nitride powder Note, the oxygen contents in the starting boron nitride

having an average particle size of 1.8 pm, and calcium 55 powder and aluminum nitride powder used in this ex

carbide were mixed at a ratio shown in Table 2, and wet ample were 0.13% by weight and 0.9% by weight,

mixing was carried out for 24 hours in a ball mill using respectively.

acetone as the solvent.

The resultant powder was dried and ?lled in a graph- EXAMPLE 6

ite die, and hot-press sintering was carried out at 1800° 60 The hot-press sintering was carried out in the same

C. under a pressure of 40 MPa for 2 hours in a nitrogen manner as described in Example 5, except that a powder

gas ?ow of 2 l/min. The cooling rate was adjusted to having an average particle size of 10 pm was used as the

10° C./min. starting h-BN powder and yttrium oxide was added as

The bulk density, thermal conductivity, thermal ex- the sintered aid. The physical properties of the obtained

pansion coefficient, ?exural strength, Vickers hardness, 65 sintered body are shown in Table 2. In each composi

speci?c dielectric constant and electric resistance of the tion, results similar to those shown in Example 5 were

obtained sintered body were measured, and since an obtained. The higher thermal conductivity was at least

anisotropy existed in the sintered body, the thermal 150 W/m.K and the anisotropy was 2.1 to 14.2 in each

conductivity, thermal expansion coef?cient, ?exural composition.

Description:sum of h—BN, MN and AION- This sintered body 99m . The machining of an aluminum nitride sintered body, as well as that of ordinary' structural ceramics, is diffi thus the machining cost is increased. promotes the orientation-lamination ductivity was measured by the laser ?ash method, and.