Catalog: Connectors for Cold-Formed Steel Construction Catalog 2017-2019 PDF

Preview Catalog: Connectors for Cold-Formed Steel Construction Catalog 2017-2019

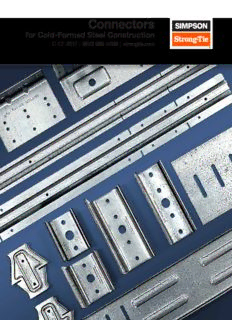

Cover Connectors for Cold-Formed Steel Construction C-CF-2017 | (800) 999-5099 | strongtie.com Innovation to make CFS jobs faster and easier At Simpson Strong-Tie, we are committed to being your valued partner and total solutions provider for cold-formed steel (CFS) commercial curtain-wall, mid-rise and residential construction. Our products are manufactured with quality that our customers can rely on — with precision engineering, thorough lab testing and design software that automates AISI design calculations. The result is, we deliver innovative and lower installed-cost solutions for CFS applications. Complete, Tested Solutions to Meet Specifier Needs We are committed to developing fully engineered products through extensive assembly testing — capturing the interaction of the connector with the framing member and the interaction of the connector with the anchorage. Assembly testing mitigates design risk by eliminating member behavior assumptions near the connector, and eccentricity and prying action assumptions for fasteners and anchors. We also provide our specifiers with state-of-the-art software, enabling powerful, efficient and accurate member/connector analysis and design in accordance with AISI specifications. Our Simpson Strong-Tie® CFS Designer™ software is an affordable, easy-to-use solution — helping you expedite most of your day-to-day CFS design needs. Visit strongtie.com/software to learn more. Lower Installed Costs to Meet Contractor Budgets Our commitment extends to reducing your installed costs — designing products to minimize screw count, eliminate predrilling the connector and minimize tool clearance issues without compromising strength or durability. We field-test our products to ensure they can be installed accurately and efficiently following your unique specifications. Connectors for Cold-Formed Steel Construction Alphabetical Index ABS Anchor Bolt Stabilizer ....................173 GCN-MEP Gas-Actuated MSCB Bypass Framing Concrete Nailer Magnetic Ring ..............228 Slide-Clip .....................................26–28, 63 AHEP Adjustable Hip-End Purlin ...........274 GDP Concrete Pins .......................225–227 MSSC-KW Kneewall Connector ...112–113 AnchorMate® Anchor Bolt Holder ........173 GDPS Concrete Pins .....................225–227 MST Strap Tie ...............................278–279 AT-XP® Anchoring Adhesive ..........186–188 GDPSK Spiral Knurl Gas Pins .......225–228 MSTA Strap Tie.............................278–279 BP/LPB Bearing Plates ........................175 H Hybrid Connectors .............................263 MSTC Strap Tie ............................278–279 CBSDQ Sheathing-to-CFS Screw ...150–151 H Seismic and Hurricane Ties ................262 MSTI Strap Tie ..............................278–279 CM/CMST Coiled Strap .......................280 H10S Seismic and Hurricane Tie ...........270 MSUBH Bridging Connector .........115–124 CNW Coupler Nuts ...............................176 HETA/HHETA Embedded MTS Twist Strap ....................................268 Code Listing Key Chart ........................11 Truss Anchors ................................266–267 MTSM Twist Strap ................................265 Conversion Charts ................................17 HPA Purlin Anchor .................................247 Nailon™ Pin Drive Anchors .....................212 Corrosion Resistance.....................18–21 HRS Strap Tie ...............................278–279 PA/HPA Purlin Anchors ........................247 Crimp Drive® Anchors ..................208–211 HSCNW High-Strength Coupler Nut .....176 PAB/PABH Anchor Bolts ..............240–241 CS Coiled Strap ............................136, 259 HTS Twist Strap ....................................268 PCSD Standing-Seam Custom Clips and Angles ....................56 Roofing Panel Clip Screw ......................154 HTSM Twist Strap .................................265 DBC Drywall Bridging Connector ...134–135 Powder-Actuated Fasteners HTT Tension Tie ....................................244 DBR/SBR Spacer Bracers ...........125–132 ................................................65, 230–235 HUC Hanger .........................................256 DIA Drop-In Internally PS Strap Tie ..................................278–279 Threaded Anchor ...........................218–224 ICFVL Ledger Connector ......................258 PSCA Panel Sheathing Clip ...................307 DIAB Drop-In Internally IDCB Drift-Clip Bypass PSCL Panel Sheathing Clip ...................307 Threaded Anchor ...........................215–217 Framing Connector ..................................43 DSP Stud Plate Tie ...............................261 L Skewable Angles ................................257 PSPN Protecting Shield Plate ................306 DSSCB Drift Strut Sliding LBP Bearing Plate .................................175 PT-27 General Purpose Fastening Tool ...229 Clip Bypass .......................................44–45 Quik Drive® Systems LCB Column Base ................................177 DTC Head-of-Wall Slide-Clip Application ...38 and Applications ............................159–171 DTC Roof Truss Clips ............................273 LCE Post Cap .......................................305 RCA Rigid Connector Angles ............92–98 NC. DTT1Z Tension Tie ................................244 LS Skewable Angles ..............................257 RCKW Kneewall Connectors ........100–111 PANY I M LSTA Strap Tie ..............................278–279 O DWF Drywall Screw ..............................155 RFB Retrofit Bolt ...................................239 C E DWFSD Drywall Screw .........................155 LSTHD/STHD Strap Tie S/B Hanger ...........................................254 G-TI Holdowns ......................................248–249 ON R FFiCxe Bdy-Cpalips sC Fornanmeicntgo r .........................57–60 LSTI Strap Tie ...............................278–279 S/BA Hanger .........................................254 ON ST S/DHUTF Drywall Hangers ...................255 S FFiCxeBd -BCylpipa .s..s. .F..r.a..m...i.n..g.. . ....35, 47–55, 65–67 LLTSAU2B MHa Bsoridngryin Cgo Cnonnencteocrt .o..r. .....................1..1..5..–.217204 S/DSC Drag Strut Connector ................277 017 SIMP 2 S/DTT Tension Tie ................................244 © FHA Strap Tie ...............................278–279 LTB/TB Bridging ...........................137, 259 17 S/H and H Seismic and 20 FSB Bypass Framing Fixed-Clip LTP5 Framing Anchor ............................281 Hurricane Ties .......................................262 CF- Strut Connector ...........................61–62, 64 C- LTS Twist Strap .....................................268 S/H1A Seismic and Hurricane Tie .........264 GCN-MEP Gas-Actuated Concrete Nailer ..............................225–226 MASA Mudsill Anchor ...................178–179 S/HDB Holdown ...........................245–246 GCN-MEP Gas-Actuated MASAP Mudsill Anchor .................178–179 S/HDS Holdown ...........................245–246 Concrete Nailer Fuel Cell .......................228 META Embedded Truss Anchors ...266–267 S/HDU Holdown ...................................243 GCN-MEPMAG Gas-Actuated Concrete Nailer Lathing Washer .............228 Metric Conversions ..............................17 S/HGAM Masonry Connector ...............270 VALUE ENGINEERED This icon indicates a product that is preferable to similar connectors because of a) easier installation, b) higher loads, c) lower installed cost, or a combination of these features. 4 Connectors for Cold-Formed Steel Construction Alphabetical Index S/HJCT Hanger ............................252–253 Steel Strong-Wall® Cold-Formed Steel on Concrete Foundations ..............286–288 S/HTC Heavy Truss Clip ........................272 General Steel Strong-Wall® Cold-Formed Steel 10–22 S/JCT Hanger ...............................252–253 Two-Story Stacked on Concrete Information Foundation ....................................292–295 S/LBV Hanger .......................................254 Steel Strong-Wall® Shearwall ......285–295 S/LS Skewable Angle ..............99, 257, 272 Deflection 24–41 Steel Strong-Wall® Uplift Equations .....289 Connectors S/LTT Tension Tie .................................244 STHD/LSTHD Strap Tie SB Anchor Bolts ....................................236 Holdowns ......................................248–249 Drift Clips 42–45 SBR/DBR Spacer Bracers ...........125–132 StrapMate® Strap Holder .....................174 SC Bypass Framing Strong Frame® Slide-Clip Connector .........................29–32 Special Moment Frame ..................283–284 SCB/MSCB Bypass Rigid Connectors 46–113 Strong-Bolt® 2 Wedge Anchor .....198–203 Framing Slide-Clip .................26–28, 35, 63 Strong-Drive® FPHSD SCHA Slide-Clip Connectors FRAMING-TO-CFS Screw ...........143–144 for Horizontal Anchorage ..................39–41 Bridging and 114–137 Strong-Drive® PPSD Bracing Connectors Screws Fastening to Metal ................140 SHEATHING-TO-CFS Screw .......152–153 SCW Head-of-Wall Slide-Clip ......36–37, 64 Strong-Drive® SELF-DRILLING X METAL Screw ...........................145–146 Fasteners and Self-Drilling E Metal Screw .................142 138–171 Quik Drive® Strong-Drive® TB Self-Drilling X Metal Screw .........145–146 WOOD-TO-STEEL Screw ............156–158 SET-XP® Anchoring Adhesive .......182–185 Strong-Drive® XE EXTERIOR Concrete 172–179 SFC Steel Framing Connector STRUCTURAL METAL Screw .............141 Connectors .............................68–69, 88–90, 132–133 Strong-Drive® XL LARGE-HEAD METAL Screw .........43, 140, 148–149, 165 SJC Steel-Joist Connector .........................61, 68–69, 82–87, 91, 251 Strong-Drive® XM MEDIUM-HEAD Anchors 180–241 METAL Screw ...................9, 140, 147, 165 SP Stud Plate Tie ..................................261 C. SUBH Bridging Connector ............115–124 N Special Order PANY I Custom Clips and Angles ....................56 TB and LTB Bridging ............................259 HTeonldsioownn Tsi easnd 242–249 M CO SSB Bypass Framing Slide-Clip Strut TBD22 Truss Brace Diagonal ................275 E ..........................................................33–35 TI ONG- SSC Steel-Stud Connector Tie-Wire Wedge Anchor ...............213–214 Joist Framing 250–259 TR ......................................69, 70–81, 90, 132 Titen HD® Heavy-Duty Connectors S N Screw Anchor ................................189–197 O S SSP Stud Plate Tie ................................261 P M Titen® 2 Concrete and Roof, Truss and 17 SI SSTB® Anchor Bolt .......................237–239 Masonry Screws ............................204–207 Rafter Connectors, 260–275 0 7 ©2 SSWAB Anchor Bolts ............................296 Titen® Hex-Head Screws Ties and Straps 01 .......................................29–28, 49, 66–67 F-2 SSWHSR Extension Kit .........................296 C Lateral Connectors, C- SSWT Anchor Bolt Template ........278–279 TJC Jack Truss and Rafter Connector ....271 Ties and Straps 276–281 TSBR Truss Spacer Restraint ................277 ST Strap Tie ..........................................303 TSP Stud Plate Tie ................................261 STC Roof Truss Clip ..............................273 Utility Clip Dimensions ...................90–91 Lateral Systems 282–303 STCT Roof Truss Clip ............................273 VGT and SVGT2.5 Variable-Pitch Steel Strong-Wall® Anchorage Details – Girder Tiedown ......................................269 Solutions – Templates ....................296–303 W/WP Hangers .....................................256 Miscellaneous 304–307 Steel Strong-Wall® Cold-Formed Steel 1st-Story Floor Systems ................290–291 Zinc Nailon™ Pin Drive Anchors ............212 5 Connectors for Cold-Formed Steel Construction Introduction For more than 60 years, Simpson Strong-Tie has focused on creating structural products that help people build safer and stronger homes and buildings. A leader in structural systems research and technology, Simpson Strong-Tie is one of the largest suppliers of structural building products in the world. The Simpson Strong-Tie commitment to product development, engineering, testing and training is evident in the consistent quality and delivery of its products and services. For more information, visit the company’s website at strongtie.com. The Simpson Strong-Tie Company Inc. No-Equal pledge includes: • Quality products value-engineered for the lowest installed cost at the highest-rated performance levels • The most thoroughly tested and evaluated products in the industry • Strategically located manufacturing and warehouse facilities • National code agency listings • The largest number of patented connectors in the industry Maple Ridge, BC Kent, WA • Global locations with an international sales team Eagan, MN Brampton, ON • In-house R&D and tool and die professionals W. Chicago, IL Enfield, CT • In-house product testing and quality PSlteoacskatnotno,n C, ACA AddisonC, IoLlumbus, OH Jessup, MD Kansas City, KS control engineers Riverside, CA Gallatin, TN High Point, NC Chandler, AZ • Support of industry groups including AISI, AITC, McKinney, TX Houston, TX Jacksonville, FL ASTM, ASCE, AWC, AWPA, ACI, AISC, CSI, CFSEI, ICFA, NBMDA, NLBMDA, SDI, SETMA, SFA, SFIA, STAFDA, SREA, NFBA, TPI, WDSC, WIJMA, WTCA and local engineering groups Canada Northwest Northeast Southwest Southeast The Simpson Strong -Tie Getting Fast Quality Policy Technical Support We help people build safer structures economically. When you call for engineering technical support, C. N We do this by designing, engineering and manufacturing having the following information on hand will help us Y I N A No-Equal structural connectors and other related to serve you promptly and efficiently: P M products that meet or exceed our customers’ needs • Which Simpson Strong-Tie® catalog are you using? E CO and expectations. Everyone is responsible for product (See the front cover for the catalog number.) G-TI quality and is committed to ensuring the effectiveness N O of the Quality Management System. • Which Simpson Strong-Tie product are you using? TR S • What are your application and load requirement? ON S P • What are the carried and/or supporting members’ M SI size, gauge and strength? 17 0 2 Karen Colonias © Chief Executive Officer 17 0 2 F- C C- We Are ISO 9001-2008 Registered Simpson Strong-Tie is an ISO 9001-2008 registered company. ISO 9001-2008 is an internationally-recognized quality assurance system that lets our domestic and international customers know that they can count on the consistent quality of Simpson Strong-Tie® products and services. (800) 999-5099 | strongtie.com All rights reserved. This catalog may not be reproduced in whole or in part without the prior written approval of Simpson Strong-Tie Company Inc. 6 Connectors for Cold-Formed Steel Construction New Products for 2017 Simpson Strong-Tie® CFS Designer™ Software Simpson Strong-Tie CFS Designer gives cold-formed steel (CFS) Designers the ability to design CFS beam-column members according to AISI specifications as well as analyze complex beam loading and span conditions. Intuitive design tools automate common CFS systems such as wall openings, compression posts for shearwalls and floor joists with unbalanced live-load combinations. Version V2.0 is now equipped with a powerful tool to automate the design of load-bearing wall systems up to eight stories in height. See p. 23 for more information. Version V2.0 RCKW Kneewall Connectors The Simpson Strong-Tie® RCKW rigid connectors have been developed to resist overturning moment at the base of exterior kneewalls and parapets as well as interior partial-height walls. These connectors offer a unique anchor-hole pattern that permits anchorage to both concrete and structural steel. See pp. 100–111 for more information. SCHA Slide-Clip Connectors for Horizontal Anchorage NC. The SCHA slide-clip connector is an ideal solution for panelized or stick-frame NY I construction where cold-formed steel bypass framing anchors to the top of a floor slab A P or the bottom flange of a steel beam. The connector features a wide anchorage leg M O that minimizes connection eccentricity and accommodates several different anchorage C TIE methods to concrete and steel. The included SCVS slider provides superior rotational G- support to the vertical leg of the SCHA connector, helping to improve the buckling N RO performance of the anchored leg. T S ON See pp. 39–41 for more information. S P M SI 7 1 0 2 © 7 1 0 2 F- C C- SBR and DBR Spacer Bracers Specify the only bridging connectors on the market with load ratings based on assembly testing. The new Simpson Strong-Tie® SBR and DBR spacer bracers come with load data based on assembly testing so you can mitigate risk and maximize design confidence. The tabulated design values and precision-engineered slots make it easier to provide a value-engineered solution to your customers. See pp. 125–132 for more information. DBR SBR 7 Connectors for Cold-Formed Steel Construction New Products for 2017 FC Bypass Framing Fixed-Clip Connectors Ideal for high-seismic areas, Simpson Strong-Tie® FC connectors are the optimal solution for fixed-clip bypass framing. FC clips are often welded to the structure in high-seismic zones, but they also feature anchorage holes so that concrete screws or powder-actuated fasteners can be used to attach the clip to the structure. In addition to its anchorage versatility, the FC clip features prepunched screw holes for the framing attachment, eliminating the need for predrilling holes or worrying that fastener placement doesn’t match the Designer specifications. FC connectors are manufactured using heavy-duty 10- and 12-gauge steel to provide exceptional resistance to in-plane seismic load. See pp. 57–60 for more information. SC Bypass Framing Slide-Clip Connectors Ideal for high-seismic areas, Simpson Strong-Tie® SC connectors are the optimal solution for slide-clip bypass framing. SC clips are often welded to the structure in high-seismic zones, but they also feature anchorage holes so that concrete screws or powder-actuated fasteners can be used to attach the clip to the structure. SC connectors are manufactured using heavy-duty 10- and 12-gauge steel to provide exceptional resistance to in-plane seismic load. See pp. 29–32 for more information. FSB Bypass Framing Fixed-Clip Strut Connector The FSB connector is the fixed-clip version of our popular SSB slide-clip strut connector. The FSB is commonly used at the bottom flange of a steel beam to accommodate large stand-off distances for bypass curtain-wall studs. The connector features anchor holes throughout the length of the part to enable use with a wide array of stand-offs. The FSB can also be field-trimmed for smaller stand-offs. See pp. 61–62 for more information. C. N Y I N A P M O C E TI G- N IDCB Drift-Clip Bypass Framing Connector RO T S The IDCB drift-clip connector is used to secure bypass stud framing to the edge ON S of a slab. The connector will accommodate 1" of lateral drift in each direction and P M 1" of upward and downward vertical deflection. Horizontal embossments and corner SI 7 gussets optimize performance for resisting out-of-plane loads. 01 2 © See p. 43 for more information. 17 0 2 F- C C- RCA Rigid Connector Angles The Simpson Strong-Tie® rigid connector angle is a general-purpose clip angle designed for a wide range of cold-formed steel construction applications. With prepunched holes for fastener attachment, these L-shaped clips save time and labor on the job. See pp. 92–98 for more information. 8 Connectors for Cold-Formed Steel Construction New Products for 2017 S/DHUTF Drywall Hangers The S/DHUTF top-mount hangers are designed to carry floor joist loads to a CFS stud wall through two layers of 5/8" gypsum board. These hangers install after the drywall is in place. The hangers come in sizes that accommodate 8", 10" and 12" joist depths. See p. 255 for more information. DTT1Z Tension Tie DTT1Z tension tie is suitable for lighter-duty hold-down applications on single or back-to-back studs, and installs easily with #10 self-drilling screws. See p. 244 for more information. Titen® 2 Concrete and Masonry Screw With patented undercutting threads that make installation easier and increase load capacity, the Titen 2 concrete and masonry screw is ideal for attaching all types of components to concrete and masonry. The improved thread design undercuts the base material more efficiently, reducing installation torque and making it easier to drive without binding, snapping or stripping, even during installation into hard base material. C. See pp. 204–207 for more information. N Y I N A P M O C E TI NG- DIAB Drop-In Internally Threaded Anchor O R T N S Simpson Strong-Tie introduces a new, redesigned Drop-In Anchor (DIAB) SO that provides easier installation into base materials. Improved geometry in the P M preassembled expansion plug allows the anchor to install with 40% fewer hammer SI 7 strikes than previous versions. These deformation-controlled expansion anchors 1 20 are easily set by driving the plug toward the bottom of the anchor using either © 7 the hand- or power-setting tools. 1 0 2 F- See pp. 215–217 for more information. C-C Drop-In Lipped Drop-In Strong-Drive® XM MEDIUM-HEAD METAL Screw Strong-Drive XM Medium-Head Metal screws have been engineered as a 1-for-1 replacement option for power-actuated pins in steel decking to structural members involving wide or narrow valley, nestable or interlocking steel decking. This means you can keep the same spacing and easily substitute screws for pins. This screw is also an ideal solution for CFS connectors that demand high pullover values. See p. 147 for more information. 9 o Connectors for Cold-Formed Steel Construction f n How To Use This Catalog I al r e n e New Products Value Engineered G This icon indicates a product that is preferable to similar connectors because of New products are shown a) easier installation, b) higher loads, c) lower installed cost, or a combination of these features. with the symbol. There are also many Extra Corrosion Protection new sizes within existing The teal arrow icon identifies products that are available with additional corrosion protection model series. (ZMAX®, hot-dip galvanized or double-barrier coating). The SS teal arrow icon identifies products also available in stainless steel. Other products may also be available with additional protection; contact Simpson Strong-Tie for options. The end of the product name will indicate what type of extra corrosion protection is provided (Z = ZMAX, HDG = hot-dip galvanized or SS = stainless steel). Stainless products may need to be manufactured upon ordering. See pp. 18–21 for information on corrosion, and visit our website strongtie.com/info for more technical information on this topic. How We Determine Allowable Loads Allowable loads in this catalog are determined using calculations and/or bolted section of the strap, which is calculated. Testing to determine one or more of the following methods: allowable loads in this catalog is not done on connection systems • a minimum of 3 static load tests in CFS assemblies; in buildings. Testing is conducted in an IAS accredited laboratory. • a minimum of 3 static load tests in structural steel jigs; Typically the allowable load is limited to an average test load • a minimum of 3 static load tests of products embedded at 1/8" deflection, an average or lowest test value (nominal load) in concrete or masonry. divided by a safety factor or the calculated value. The safety factor is prescribed by Section F of AISI-S100. For LRFD, the Where available, testing is performed to test criteria established by nominal connector strength is multiplied by a resistance factor, industry (ASTM, AISI or ICC-ES Acceptance Criteria). Where a test also prescribed by Section F of AISI-S100. standard is unavailable, testing is conducted per sound engineering principles. Some tests include only portions of a product such as purlin For detailed information regarding how Simpson Strong-Tie tests anchor tests — only the embedded hook is tested, not the screwed or specific products, contact Simpson Strong-Tie. Load Table Explanation Dimensions: This shows the Allowable Design Load: The maximum load imposed on a product dimensions (material connection during the life of a structure. There may be multiple design thickness, length and width loads acting in different directions (up, down, lateral, perpendicular, in this case.) The product etc.) imposed on a connection. When connectors are attached to drawing includes these two CFS members of different thicknesses, the Designer shall use C. callouts as a cross-reference. the thinner of the two members for selecting allowable loads. Y IN N A Model No.: Thickness: The thickness of Code Ref: See p. 11 MP This is the the CFS supporting member for the Code Reference CO Simpson Strong-Tie Fasteners: This shows to which the product is Key Chart, to determine TIE product name. the fastener quantity attached. Allowable load is which code reports NG- and type required to based on this CFS supporting include this product. RO achieve the table loads. member thickness. T S N O S P M Connector Dimensions (in.) Fasteners (Total) Allowable ASD Tension Load SI Model Material Code 17 No. Thickness Rafter/Stud/Joist Thickness 33 mil 43 mil 54 mil Ref. 20 W L © mil. (ga.) 33 mil (20 ga.) 43 mil (18 ga.) 54 mil (16 ga.) (20 ga.) (18 ga.) (16 ga.) 7 1 0 2 LSTA9 1 1/4 9 (8) #10 (8) #10 (8) #10 705 1,120 1,190 F- C LSTA12 1 1/4 12 (10) #10 (10) #10 (8) #10 885 1,190 1,190 C- 33 IP1, LSTA15 (20 ga.) 1 1/4 15 (12) #10 (12) #10 (10) #10 1,060 1,190 1,190 L2, FL LSTA18 1 1/4 18 (14) #10 (12) #10 (10) #10 1,190 1,190 1,190 Other Catalog Definitions: Deflection: The distance a point moves when a load is applied. Nominal Tension Load (Strength): The capacity of a structure or component to resist the effects of loads, as determined in accordance with AISI-S100 using specified material strengths and dimensions. Typically taken as the average value of at least three tests. The Nominal Tension Load should not be compared against design loads (ASD, LRFD), but used only where the AISI Lateral Design Standard requires the holdown to have nominal tension load (strength) to resist the lesser of the amplified seismic load or the maximum force the system can deliver. 10

Description: