Calculating column relief loads PDF

Preview Calculating column relief loads

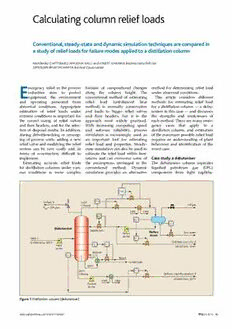

Calculating column relief loads Conventional, steady-state and dynamic simulation techniques are compared in a study of relief loads for failure modes applied to a distillation column Haribabu CHittibabu, amudHa Valli and VinEEt KHanna Bechtel india PVE Ltd dipanjan bHattaCHarya Bechtel Corporation E mergency relief in the process because of compositional changes method for determining relief load industries aims to protect along the column height. The under abnormal conditions. equipment, the environment conventional method of estimating This article considers different and operating personnel from relief load (unbalanced heat methods for estimating relief load abnormal conditions. Appropriate method) is normally conservative for a distillation column — a debu- estimation of relief loads under and leads to bigger relief valves taniser in this case — and discusses extreme conditions is important for and flare headers, but it is the the strengths and weaknesses of the correct sizing of relief valves approach most widely practised. each method. There are many emer- and flare headers, and for the selec- With increasing computing speed gency cases that apply to a tion of disposal media. In addition, and software reliability, process distillation column, and estimation during debottlenecking or revamp- simulation is increasingly used as of the maximum possible relief load ing of process units, adding a new an important tool for estimating requires an understanding of plant relief valve and modifying the relief relief load and properties. Steady- behaviour and identification of the system can be very costly and, in state simulation can also be used to worst case. terms of construction, difficult to estimate the relief load within limi- implement. tations and can overcome some of Case study: a debutaniser Estimating accurate relief loads the assumptions envisaged in the The debutaniser column separates for distillation columns under vari- conventional method. Dynamic liquified petroleum gas (LPG) ous conditions is more complex simulation provides an alternative components from light naphtha. PDC To flare, R 135°F PC 174 psia Off gas P = 214 psia set CWS CWR FC LC LC Debutaniser 196000 lb/hr Reflux Reflux Sour water drum pump Feed, F FC 673700 lb/hr, 301°F Distillate, sour LPG, D Feed TC FC 58120 lb/hr, 104°F pump Reboiler LC 412°F Steam Condensate 391°F 391°F FC 178 psia Bottom, naphtha product, B 615600 lb/hr, 391°F CWS CWR Product pump Figure 1 Distillation column (debutaniser) www.digitalrefining.com/article/1000487 PTQ Q2 2010 55 The overhead includes a reach and act upon the top tray cooling water total R liquid condenser, reflux drum • There is enough top tray liquid and off-gas valve, which available to generate vapour during Q C is normally closed. The upset conditions. debutaniser operates at To determine Q , the first unbalanced 174 psia and relief is set step is to develop a sketch around Reflux at 214 psia. The debutan- drum the affected system (see Figure 2) Top tray iser bottom is heated by and perform a mass and energy a thermosyphon reboiler balance in line with the upset Excess heat utilising medium-pressure condition: D, h F, h D steam. Figure 1 shows a F Debutaniser Q = F h - B h - D h + Q - Q - (F - B - D) h flow diagram of the debu- unbalanced F B D R C L R = Q / λ taniser under evaluation. unbalanced (excess) Major relief conditions or where plant situations identified Q F = Debutaniser or column feed R for the debutaniser are rate at relief loss of reflux, loss of feed h = Specific enthalpy of feed at F and site-wide power relief failure. B = Debutaniser or column B, h B bottom rate at relief Conventional method h = Specific enthalpy of bottom at B The conventional approach Figure 2 Distillation column: unbalanced heat envelope relief is also known as the D = Debutaniser distillate rate at unbalanced heat method, column is available in various liter- relief where a mass and energy balance is ature1 and hence is not covered in h = Specific enthalpy of distillate D developed under relief conditions, detail here. at relief based on the scenario under consid- There are several assumptions in Q = Reboiler heat input at relief R eration, to determine if there is any determining relief loads: Q = Condenser duty at relief C unbalanced or excess heat. The • Feed, products, reflux and top (generally, the design duty can be unbalanced heat is divided by the tray liquid compositions are unal- considered) latent heat of vapourisation of the tered during the relief condition h = Specific enthalpy of top tray L top tray liquid to give the relief • Feed, product, reflux and strip- liquid load: ping medium will continue at the λ = Latent heat of vapourisation normal rate unless the hydraulics at of top tray liquid Relief load = Q / λ the relieving condition determine R = Relief load unbalanced (excess) otherwise Credit may be taken for reboiler The conventional method for • Enthalpy is balanced on the top pinch. At relieving pressure, the determining the relief load of a tray and all unbalanced heat will column temperature rises and the reboiler temperature difference may fall, leading to lower heat input to (cid:25)(cid:16)(cid:16) the column. This is reboiler pinch.2 Assume that the volume of the (cid:24)(cid:16)(cid:16) sump is sufficient to maintain a (cid:23)(cid:16)(cid:16) constant reboiler circulation rate and to re-rate the reboiler to obtain (cid:72)(cid:82)(cid:22)(cid:16)(cid:16) duty at relief condition. If there was (cid:15)(cid:66)(cid:76)(cid:0)(cid:16)(cid:16)(cid:16)(cid:21)(cid:16)(cid:16) (cid:38)(cid:69)(cid:69)(cid:68) are bosiilgenr ifidcuatnyt atr erdeulicetfi,o nth e inli ghttheer (cid:65)(cid:12)(cid:17)(cid:0)(cid:12)(cid:69)(cid:84)(cid:20)(cid:16)(cid:16) Relief valve (cid:34)(cid:50)(cid:69)(cid:79)(cid:70)(cid:84)(cid:76)(cid:84)(cid:85)(cid:79)(cid:88)(cid:77)(cid:83) components would begin travelling (cid:82)(cid:0)(cid:87)(cid:79) Reflux stops opens (cid:36)(cid:73)(cid:83)(cid:84)(cid:73)(cid:76)(cid:76)(cid:65)(cid:84)(cid:69) towards the bottom, causing the (cid:76)(cid:38)(cid:19)(cid:16)(cid:16) (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70) duty to rise again. Many designers Reflux drum fills (cid:47)(cid:86)(cid:69)(cid:82)(cid:72)(cid:69)(cid:65)(cid:68) re-rate the reboiler with feed (cid:70)(cid:82)(cid:79)(cid:77)(cid:0)(cid:67)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78) (cid:18)(cid:16)(cid:16) composition instead of bottoms (cid:17)(cid:16)(cid:16) composition in these circumstances, to maintain a more conservative/ (cid:16) realistic reboiler duty at relief. (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) (cid:20)(cid:21) (cid:21)(cid:16) (cid:21)(cid:21) (cid:22)(cid:16) (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) loss of reflux Figure 3 Loss of reflux: flow vs time • Reflux stops immediately • The reflux drum and the 56 PTQ Q2 2010 www.digitalrefining.com/article/1000487 column sump level, and finally (cid:18)(cid:21)(cid:16) reaches zero • The column overhead vapour (cid:18)(cid:20)(cid:16) rate decreases, the reflux drum level Peak pressure (cid:18)(cid:19)(cid:16) drops, and the distillate rate (cid:18)(cid:18)(cid:16) decreases to maintain the condenser (cid:65)(cid:73)(cid:83)(cid:80) (cid:18)(cid:17)(cid:16) level and finally becomes zero. (cid:0)(cid:69)(cid:12)(cid:82)(cid:85) Therefore: (cid:83)(cid:83)(cid:69) (cid:18)(cid:16)(cid:16) O O O OO O (cid:80)(cid:82) (cid:70)(cid:73)(cid:0)(cid:69)(cid:76)(cid:69)(cid:50) (cid:17)(cid:25)(cid:16) Qunbalanced = F hF - B hB - D hD + QR - QC - (F - B - D) hL (cid:17)(cid:24)(cid:16) (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) (cid:17)(cid:23)(cid:16) Site-wide power failure (SWpF) (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69)(cid:0)(cid:83)(cid:69)(cid:84)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) (cid:17)(cid:22)(cid:16) (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69)(cid:0)(cid:65)(cid:67)(cid:67)(cid:85)(cid:77)(cid:85)(cid:76)(cid:65)(cid:84)(cid:69)(cid:68) • All electrical equipment fails, (cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) therefore the feed pump, the debu- (cid:17)(cid:21)(cid:16) (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) (cid:20)(cid:21) (cid:21)(cid:16) (cid:21)(cid:21) (cid:22)(cid:16) taniser bottom pumps and the (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) reflux pumps stop • Assuming all cooling water Figure 4 Loss of reflux: relief pressure vs time pumps are electrically driven, the condensing duty is also immedi- ately lost • Steam is assumed to flow contin- (cid:17)(cid:18)(cid:16) uously to the reboiler. Therefore: Reflux drum fills O O O O O O (cid:17)(cid:16)(cid:16) Q = F h - B h - D h + Q - Q - (F - B - D) h unbalanced F B D R C L (cid:24)(cid:16) (cid:5) (cid:12)(cid:76)(cid:0)(cid:69) dynamic simulation of relief (cid:69)(cid:0)(cid:86)(cid:76)(cid:80) (cid:22)(cid:16) conditions (cid:85) (cid:68)(cid:76)(cid:79) Chemical plants and refineries are (cid:40) never truly at a steady state and (cid:20)(cid:16) this is the case during relief. The transient behaviour of a column is (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) (cid:18)(cid:16) (cid:50)(cid:69)(cid:70)(cid:76)(cid:85)(cid:88)(cid:0)(cid:68)(cid:82)(cid:85)(cid:77) best studied by means of dynamic (cid:35)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) simulation, which has gained in (cid:16) importance since the 1990s and has (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) (cid:20)(cid:21) (cid:21)(cid:16) (cid:21)(cid:21) (cid:22)(cid:16) been used increasingly successfully (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) as the reliability of simulation soft- ware has increased. The equations Figure 5 Loss of reflux: holdup level vs time for material, energy and composi- tion balances include an additional condenser flood, restricting the O O O accumulation term, which is overhead vapour path and pressu- Q = F h - B h - D h + Q - Q - (F - B - D) h differentiated with respect to time. unbalanced F B D R C L rising the column The inclusion of an accumulation • The feed is pumped and suffi- term enables the dynamic model to cient head is available to maintain loss of feed rigorously calculate compositional the feed flow rate at relief • Feed stops immediately changes at each stage and to modify condition • After some time, when the vapour/liquid equilibrium over • Bottom product continues at the column level drops, the bottom time. same rate. Therefore: product decreases to maintain the Unlike steady-state simulation, dynamic simulation works within a relief load calculated by conventional method Pressure-Flow (P-F) network with two basic equations: resistance and volume balance. The resistance upset condition relief load, lb/hr temperature, °F molecular weight equation defines flow between pres- Loss of reflux 124 980 164 49.28 sure hold-ups, and the volume Loss of feed 43 650 164 49.28 Site-wide power failure 342 796 164 49.28 balance equation defines material balance at pressure hold-ups. For the case under consideration, table 1 the accuracy of dynamic simulation 58 PTQ Q2 2010 www.digitalrefining.com/article/1000487 provides extra inputs compared with steady-state simulation: (cid:23)(cid:16) (cid:17)(cid:18)(cid:16) • Dimensions, especially volumes, (cid:17)(cid:17)(cid:24) for all static equipment; column (cid:22)(cid:16) bottom and reflux drum levels are Pinched reboiler duty (cid:17)(cid:17)(cid:22) set to normal to simulate hold-ups (cid:21)(cid:16) (cid:17)(cid:17)(cid:20) •r•ve alASlavpt eiveoscen in(sfiChdcvio p rcvs o cafnuoludrrve ur)eco tftfaoaontrri c nppeg rr eefesosqssruuu irrcpeeom nflfletoornowwtl (cid:36)(cid:85)(cid:84)(cid:89)(cid:12)(cid:0)(cid:34)(cid:52)(cid:53)(cid:15)(cid:72)(cid:82) (cid:19)(cid:20)(cid:16)(cid:16) (cid:17)(cid:17)(cid:17)(cid:17)(cid:17)(cid:16)(cid:18)(cid:16)(cid:24) (cid:87)(cid:79)(cid:84)(cid:72)(cid:71)(cid:73)(cid:69)(cid:0)(cid:82)(cid:65)(cid:76)(cid:85)(cid:67)(cid:69)(cid:76) relationships, and an actuator mode (cid:45) and rate for valve actuator (cid:18)(cid:16) (cid:17)(cid:16)(cid:22) dynamics (cid:17)(cid:16)(cid:20) (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:68)(cid:85)(cid:84)(cid:89) • Detailed exchanger thermal (cid:17)(cid:16) (cid:35)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) (cid:77)(cid:79)(cid:76)(cid:69)(cid:67)(cid:85)(cid:76)(cid:65)(cid:82)(cid:0)(cid:87)(cid:69)(cid:73)(cid:71)(cid:72)(cid:84) (cid:17)(cid:16)(cid:18) design for calculation of pressure drop and heat transfer coefficient. If (cid:16) (cid:17)(cid:16)(cid:16) (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) (cid:20)(cid:21) (cid:21)(cid:16) (cid:21)(cid:21) (cid:22)(cid:16) detailed design is not available, a (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) resistance term for the pressure flow relationship and overall UA Figure 6 Loss of reflux: reboiler duty and molecular weight vs time can be specified • Actual tray information such as diameter, flow path, distributor (cid:24)(cid:16)(cid:16) details, weir length and height are (cid:38)(cid:69)(cid:69)(cid:68) required for column hydraulic (cid:23)(cid:16)(cid:16) (cid:34)(cid:79)(cid:84)(cid:84)(cid:79)(cid:77)(cid:83) performance (cid:50)(cid:69)(cid:70)(cid:76)(cid:85)(cid:88) (cid:22)(cid:16)(cid:16) (cid:36)(cid:73)(cid:83)(cid:84)(cid:73)(cid:76)(cid:76)(cid:65)(cid:84)(cid:69) • Controller for determining (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70) cCornetdriot l isa cntiootn tsa kdeunr ifnogr tthraen sciotniotnrosl. (cid:82)(cid:72)(cid:15)(cid:0)(cid:16)(cid:66)(cid:76)(cid:21)(cid:16)(cid:16) Feed stRoeplsief valve (cid:47)(cid:70)(cid:82)(cid:79)(cid:86)(cid:77)(cid:69)(cid:82)(cid:0)(cid:72)(cid:67)(cid:69)(cid:79)(cid:65)(cid:76)(cid:85)(cid:68)(cid:77)(cid:78) alocatido;n , fowr hiecxha mrepdleu, cesth et hec olruemlienf (cid:16)(cid:17)(cid:84)(cid:65)(cid:16)(cid:0)(cid:12)(cid:69)(cid:20)(cid:16)(cid:16) open Relcielof svealve bottom temperature controller (cid:38)(cid:82)(cid:0)(cid:87)(cid:79)(cid:76)(cid:19)(cid:16)(cid:16) Bottoflmow & zdeirsotillate reduces the steam flow rate when the column bottom temperature (cid:18)(cid:16)(cid:16) Relief flow rises at the relief condition. (cid:17)(cid:16)(cid:16) loss of reflux condition (cid:16) The reflux pump is stopped in five (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) minutes (see Figure 3). The level in (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) the reflux drum starts to increase (see Figure 5). The overhead vapour Figure 7 Loss of feed: flow vs time from the column continues to flow through the condenser and fill the reflux drum. After 17 minutes, the (cid:18)(cid:21)(cid:16) reflux drum floods and the flow to the condenser is blocked; the (cid:18)(cid:20)(cid:16) column pressure starts to increase (cid:18)(cid:19)(cid:16) Peak pressure (see Figure 4). When the column (cid:18)(cid:18)(cid:16) reaches the set pressure, after (cid:65) about 21 minutes, the relief valve (cid:73)(cid:83)(cid:80) (cid:18)(cid:17)(cid:16) (cid:12)(cid:0)(cid:69) starts to open. Note that the (cid:82)(cid:85) pressure did not reach the maxi- (cid:83)(cid:83)(cid:69)(cid:82)(cid:80) (cid:18)(cid:16)(cid:16) mum accumulated pressure for (cid:76)(cid:0)(cid:70)(cid:69)(cid:73)(cid:69) (cid:17)(cid:25)(cid:16) (cid:50) the given orifice area of the relief (cid:17)(cid:24)(cid:16) valve. (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69)(cid:0)(cid:83)(cid:69)(cid:84)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) (cid:17)(cid:23)(cid:16) Initially, the level in the column (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) (cid:50)(cid:69)(cid:76)(cid:73)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69) bottom sump decreases as the (cid:17)(cid:22)(cid:16) (cid:65)(cid:67)(cid:67)(cid:85)(cid:77)(cid:85)(cid:76)(cid:65)(cid:84)(cid:69)(cid:68)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) reflux is stopped, and the bottoms (cid:17)(cid:21)(cid:16) product level control valve closes to (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) maintain the column sump level. (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) The feed continues at a constant rate, since its pressure upstream of Figure 8 Loss of feed: relief pressure vs time www.digitalrefining.com/article/1000487 PTQ Q2 2010 59 the control valve is higher than the (cid:17)(cid:18)(cid:16) relief pressure. Reboiler sump level drops Figure 6 shows the reboiler duty and column sump molecular weight (cid:17)(cid:16)(cid:16) during this relief condition. As soon as the reflux is stopped, the molecu- (cid:24)(cid:16) lar weight in the column sump Column sump level drops (cid:5) (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) increases, leading to an increase in (cid:0)(cid:12)(cid:76)(cid:69)(cid:86) (cid:50)(cid:69)(cid:70)(cid:76)(cid:85)(cid:88)(cid:0)(cid:68)(cid:82)(cid:85)(cid:77) the boiling temperature of the (cid:69)(cid:76)(cid:0)(cid:80)(cid:85) (cid:22)(cid:16) (cid:35)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) column bottoms, finally resulting (cid:68) (cid:79)(cid:76)(cid:40) in reduced reboiler duty. (cid:20)(cid:16) After 17 minutes, when the path for the overhead vapour was blocked (condenser flooded), lighter (cid:18)(cid:16) components started to fill the column sump and reboiler duty (cid:16) again started to increase. After 21 (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) minutes, when the relief valve (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) started to open, reboiler duty Figure 9 Loss of feed: holdup level vs time settled, based on the column sump composition at relief condition. (cid:23)(cid:16) (cid:17)(cid:17)(cid:20) loss of feed condition (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:68)(cid:85)(cid:84)(cid:89) (cid:17)(cid:17)(cid:19) The feed pump stops after five (cid:22)(cid:16) (cid:35)(cid:79)(cid:78)(cid:68)(cid:69)(cid:78)(cid:83)(cid:69)(cid:82)(cid:0)(cid:68)(cid:85)(cid:84)(cid:89) minutes (see Figure 7). After 10 (cid:35)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) (cid:17)(cid:17)(cid:18) (cid:77)(cid:79)(cid:76)(cid:69)(cid:67)(cid:85)(cid:76)(cid:65)(cid:82)(cid:0)(cid:87)(cid:69)(cid:73)(cid:71)(cid:72)(cid:84) minutes, the column sump level (cid:21)(cid:16) (cid:17)(cid:17)(cid:17) drops (see Figure 9) and the bottom Pinched reboiler duty flow is reduced to maintain the (cid:15)(cid:82)(cid:72)(cid:53) (cid:20)(cid:16) (cid:17)(cid:17)(cid:16) column sump level. As the column (cid:52) (cid:12)(cid:34)(cid:0)(cid:89) (cid:17)(cid:16)(cid:25) overhead vapour starts to decrease (cid:84)(cid:36)(cid:85) (cid:19)(cid:16) Condenser (cid:17)(cid:16)(cid:24) (see Figure 7), the reflux drum level duty decreases and the distillate flow (cid:18)(cid:16) (cid:17)(cid:16)(cid:23) reduces to maintain the reflux drum (cid:17)(cid:16)(cid:22) level. After 20 minutes, when distil- (cid:17)(cid:16) (cid:17)(cid:16)(cid:21) late and bottoms stop completely, only the vapour generated by the (cid:16) (cid:17)(cid:16)(cid:20) (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) reboiler is condensed by the (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) condenser. Figure 10 shows the pinched reboiler duty, condenser Figure 10 Loss of feed: reboiler duty and molecular weight vs time duty and column sump molecular weight. During loss of feed, the column (cid:19)(cid:16)(cid:16) sump molecular weight increases, resulting in reduced reboiler duty. (cid:38)(cid:69)(cid:69)(cid:68) (cid:34)(cid:79)(cid:84)(cid:84)(cid:79)(cid:77)(cid:83) Since the top reflux is maintained (cid:18)(cid:21)(cid:16) (cid:50)(cid:69)(cid:70)(cid:76)(cid:85)(cid:88) at normal flow, the lighter compo- Site-wide power failure (cid:36)(cid:73)(cid:83)(cid:84)(cid:73)(cid:76)(cid:76)(cid:65)(cid:84)(cid:69) nents start migrating towards the (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70) (cid:82)(cid:72)(cid:15)(cid:0)(cid:16)(cid:66)(cid:76) (cid:18)(cid:16)(cid:16) (cid:47)(cid:70)(cid:82)(cid:79)(cid:86)(cid:77)(cid:69)(cid:82)(cid:0)(cid:72)(cid:67)(cid:69)(cid:79)(cid:65)(cid:76)(cid:85)(cid:68)(cid:77)(cid:78) bboecttoommi.n gT hlieg hctoelru amnnd pthreo fitleem sptearrats- (cid:16) (cid:16) ture profile starts lowering. This (cid:17) (cid:17)(cid:21)(cid:16) (cid:84)(cid:65)(cid:0)(cid:12)(cid:69) also results in the lower molecular (cid:82)(cid:0)(cid:87)(cid:79) Relief valve open weight of the column overhead (cid:38)(cid:76) (cid:17)(cid:16)(cid:16) vapour. After about 11 minutes, the condenser is not able to fully (cid:21)(cid:16) condense the overhead vapour due to its lower molecular weight, resulting in a rise in column pres- (cid:16) (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) sure (see Figure 8). When the (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) column reaches the set pressure, after about 23 minutes, the relief Figure 11 Site-wide power failure: flow vs time valve starts to open. Note that the 60 PTQ Q2 2010 www.digitalrefining.com/article/1000487 pinched reboiler duty at this time is higher because of the lower molec- (cid:18)(cid:21)(cid:16) ular weight in the column sump. (cid:18)(cid:20)(cid:16) After about 35 minutes, all non- condensable or lighter components (cid:18)(cid:19)(cid:16) Peak pressure exit the column, reboiler duty (cid:18)(cid:18)(cid:16) reduces again to about 42% of (cid:65) (cid:83)(cid:73)(cid:80) (cid:18)(cid:17)(cid:16) normal, and the column stabilises (cid:0)(cid:12)(cid:69) (cid:82)(cid:85) at total reflux mode. (cid:83)(cid:83)(cid:69) (cid:18)(cid:16)(cid:16) (cid:82)(cid:80) Site-wide power failure condition (cid:0)(cid:70)(cid:69)(cid:73)(cid:76)(cid:69) (cid:17)(cid:25)(cid:16) (cid:50) (cid:17)(cid:24)(cid:16) Assume that site-wide power fail- (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69)(cid:0)(cid:83)(cid:69)(cid:84)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) ure occurs after five minutes (see (cid:17)(cid:23)(cid:16) (cid:50)(cid:69)(cid:76)(cid:73)(cid:69)(cid:70)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) Figure 11). During the power fail- (cid:50)(cid:69)(cid:76)(cid:73)(cid:70)(cid:0)(cid:86)(cid:65)(cid:76)(cid:86)(cid:69) (cid:17)(cid:22)(cid:16) (cid:65)(cid:67)(cid:67)(cid:85)(cid:77)(cid:85)(cid:76)(cid:65)(cid:84)(cid:69)(cid:68)(cid:0)(cid:80)(cid:82)(cid:69)(cid:83)(cid:83)(cid:85)(cid:82)(cid:69) ure, the feed pump, column bottom (cid:17)(cid:21)(cid:16) pump, reflux pump and cooling (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) water pump stop, and their respec- (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) tive flows become zero immediately. The column sump level increases Figure 12 Site-wide power failure: relief pressure vs time immediately as the tray inventories are dumped to the bottom (see Figure 13). (cid:17)(cid:18)(cid:16) As the flows of feed, distillate, bottoms and cooling water are cut, (cid:17)(cid:16)(cid:16) the vapours generated by the reboiler cause the column pressure Column sump level increases to increase (see Figure 12). After 11 (cid:24)(cid:16) minutes, the relief valve opens. (cid:5) Initially, there is mass transfer (cid:0)(cid:12)(cid:76)(cid:69)(cid:86) between the vapours from the (cid:69)(cid:76)(cid:0)(cid:80) (cid:22)(cid:16) (cid:85) (cid:68) reboiler and the residual liquid on (cid:76)(cid:79) (cid:40) the trays; progressively, as the trays (cid:20)(cid:16) dry up, the temperature and molec- ular weight of the overhead (cid:18)(cid:16) (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) (relieving) vapour increase. The (cid:50)(cid:69)(cid:70)(cid:76)(cid:85)(cid:88)(cid:0)(cid:68)(cid:82)(cid:85)(cid:77) bottoms progressively become (cid:35)(cid:79)(cid:76)(cid:85)(cid:77)(cid:78)(cid:0)(cid:83)(cid:85)(cid:77)(cid:80) heavier, resulting in a continuous (cid:16) (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) decrease in the reboiler duty (see (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) Figure 14). As the pinched reboiler duty carries on decreasing, the relief valve will eventually close. Figure 13 Site-wide power failure: hold-up level vs time During power failure, the relief load is relatively low compared with the loss of feed condition (cid:23)(cid:16) (cid:17)(cid:18)(cid:16) because the pinched reboiler duty (cid:45)(cid:79)(cid:76)(cid:69)(cid:67)(cid:85)(cid:76)(cid:65)(cid:82)(cid:0)(cid:87)(cid:69)(cid:73)(cid:71)(cid:72)(cid:84) (cid:17)(cid:17)(cid:24) (cid:22)(cid:16) (cid:50)(cid:69)(cid:66)(cid:79)(cid:73)(cid:76)(cid:69)(cid:82)(cid:0)(cid:68)(cid:85)(cid:84)(cid:89) is much less due to the high molec- (cid:35)(cid:79)(cid:78)(cid:68)(cid:69)(cid:78)(cid:83)(cid:69)(cid:82)(cid:0)(cid:68)(cid:85)(cid:84)(cid:89) (cid:17)(cid:17)(cid:22) ular weight in the column. During loss of feed, continuing reflux (cid:21)(cid:16) Increasing column (cid:17)(cid:17)(cid:20) mTcohaleuk metsimn t heies tcamoklueuncmh t noh rigpelhraeetsrisv uienrlye t hluiegp h ltotehsres. (cid:82)(cid:72)(cid:15)(cid:34)(cid:52)(cid:53)(cid:0)(cid:12)(cid:89) (cid:20)(cid:16) sump molecular weight (cid:17)(cid:17)(cid:17)(cid:17)(cid:16)(cid:18) (cid:69)(cid:82)(cid:76)(cid:84)(cid:72)(cid:71)(cid:73)(cid:87)(cid:0)(cid:65)(cid:85) of feed scenario because the (cid:85)(cid:84)(cid:36) (cid:19)(cid:16) (cid:17)(cid:16)(cid:24) (cid:67)(cid:69)(cid:76)(cid:79) (cid:45) condenser is available, compared to (cid:18)(cid:16) (cid:17)(cid:16)(cid:22) the loss of power condition, Reboiler duty decreases (cid:17)(cid:16)(cid:20) where condensing duty was lost (cid:17)(cid:16) immediately. (cid:17)(cid:16)(cid:18) (cid:16) (cid:17)(cid:16)(cid:16) Summary (cid:16)(cid:14)(cid:16) (cid:21)(cid:14)(cid:16) (cid:17)(cid:16)(cid:14)(cid:16) (cid:17)(cid:21)(cid:14)(cid:16) (cid:18)(cid:16)(cid:14)(cid:16) (cid:18)(cid:21)(cid:14)(cid:16) (cid:19)(cid:16)(cid:14)(cid:16) (cid:19)(cid:21)(cid:14)(cid:16) (cid:20)(cid:16)(cid:14)(cid:16) loss of reflux condition (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) Figure 15 shows a comparison of relief load values obtained for loss Figure 14 Site-wide power failure: reboiler duty and molecular weight vs time www.digitalrefining.com/article/1000487 PTQ Q2 2010 61 for the top tray at bubble point and relief pressure when compared to (cid:17)(cid:20)(cid:16) dynamic simulation, which simu- Conventional method lates reflux failure, resulting in a (cid:17)(cid:18)(cid:16) higher temperature and molecular weight. (cid:17)(cid:16)(cid:16) In a dynamic simulation of loss of (cid:82)(cid:72) reflux, the column almost reaches a (cid:15)(cid:66) (cid:76)(cid:0)(cid:16)(cid:16) (cid:24)(cid:16) new steady-state condition after 25 (cid:16) (cid:17) minutes. The rectifying section of (cid:0)(cid:12)(cid:68) Steady-state simulation (cid:69)(cid:65)(cid:79)(cid:76)(cid:0)(cid:70) (cid:22)(cid:16) the column goes dry and only the (cid:73)(cid:76)(cid:69) stripping section is involved in (cid:50) mass transfer. This new steady state (cid:20)(cid:16) Dynamic simulation can also be reasonably simulated using a steady-state simulator (see (cid:18)(cid:16) Steady-state simulation to obtain relief load and properties). (cid:16) There is a marginal difference in (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) (cid:20)(cid:21) (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) the relief load obtained by steady- state simulation and dynamic simulation because, in steady-state Figure 15 Loss of reflux: relief load vs time simulation, the column pressure has been raised to an accumulation pressure (set pressure +10% or relief load calculated by dynamic simulation +16% based on the scenario), whereas in dynamic simulation the upset condition relief load, lb/hr temperature, °F molecular weight pressure safety valve starts opening Loss of reflux 90 800 310 62.5 at its set pressure and the pressure Loss of feed 93 500 117 44.2 does not reach the maximum accu- Site-wide power failure 29 250 290 76 mulated pressure for the selected orifice area. Note that the conven- table 2 tional method and steady-state simulation are not time dependent, of reflux. According to the conven- assumption is that all of the unbal- so the relief load appears constant tional method, the predicted relief anced heat will vapourise the top in comparison with the dynamic load is higher than the value tray liquid, which has a lower simulation relief load. obtained by dynamic simulation. In specific enthalpy. The molecular the conventional method, the weight and temperature are lower loss of feed Figure 16 shows a comparison of relief load obtained for loss of feed. The relief load calculated by the (cid:17)(cid:16)(cid:16) conventional method is lower than by dynamic simulation. In the (cid:25)(cid:16) conventional method, the condenser (cid:24)(cid:16) duty equals the design duty and the cooling effect is predominant. (cid:23)(cid:16) (cid:82)(cid:72) In dynamic simulation, the (cid:76)(cid:15)(cid:66)(cid:0)(cid:16) (cid:22)(cid:16) condenser duty is not fixed and the (cid:16) (cid:16) hold-up of the individual compo- (cid:17) (cid:0)(cid:12)(cid:68)(cid:65) (cid:21)(cid:16) Conventional method nents in the column determines the (cid:79) (cid:76)(cid:0)(cid:70)(cid:69) (cid:20)(cid:16) behaviour of the condenser. (cid:76)(cid:73)(cid:69) (cid:50) Initially, during loss of feed, the (cid:19)(cid:16) Dynamic reboiler duty decreases due to simulation (cid:18)(cid:16) pinch and the lighter components subsequently travel to the bottoms (cid:17)(cid:16) and the whole column profile (cid:16) becomes lighter. Eventually, the (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) reboiler duty again starts to raise (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) due to the decrease in molecular weight. This phenomenon cannot Figure 16 Loss of feed: relief load vs time be evaluated with the conventional 62 PTQ Q2 2010 www.digitalrefining.com/article/1000487 relief). This results in a conservative estimate. The effect of hold-up (cid:20)(cid:16)(cid:16) volumes and time taken to pressu- rise is normally ignored. (cid:19)(cid:21)(cid:16) The conventional method is the Conventional method most conservative and requires less (cid:19)(cid:16)(cid:16) effort during design. Steady-state (cid:82)(cid:72) simulation to determine the relief (cid:66)(cid:15) (cid:18)(cid:21)(cid:16) (cid:76)(cid:0)(cid:16) load has limited applicability. For (cid:16) (cid:16)(cid:17) grassroots designs, the conventional (cid:0)(cid:12)(cid:68) (cid:18)(cid:16)(cid:16) (cid:65)(cid:79) method may be the most appropri- (cid:0)(cid:69)(cid:73)(cid:76)(cid:69)(cid:76)(cid:70) (cid:17)(cid:21)(cid:16) ate, as detailed design and/or (cid:50) complete vendor information may (cid:17)(cid:16)(cid:16) not be available at the time of the relief system’s design. It also helps (cid:21)(cid:16) Dynamic simulation to build in inherent design margins for any possible future expansion/ (cid:16) debottlenecking operation, and to (cid:16) (cid:21) (cid:17)(cid:16) (cid:17)(cid:21) (cid:18)(cid:16) (cid:18)(cid:21) (cid:19)(cid:16) (cid:19)(cid:21) (cid:20)(cid:16) minimise changes during the late (cid:52)(cid:73)(cid:77)(cid:69)(cid:12)(cid:0)(cid:77)(cid:73)(cid:78) stages of the project due to any unforeseen design development. Figure 17 Site-wide power failure: relief load vs time Dynamic simulation models the system rigorously and tends to method, but validates the hypothe- much lower than by the conven- provide more accurate results, sis that, if the pinched duty is too tional method. In reality, during taking into account actual system low, the designer should re-evalu- this condition, after the trays dry dynamics and configuration. It tries ate the reboiler duty, assuming up the column simply acts as a boil- to emulate plant behaviour, which lighter composition in the column ing pot without mass transfer. usually results in lower relief loads. bottoms. The reboiler duty continuously Dynamic simulation also provides decreases as the contents become relief loads based on time, which Site-wide power failure heavier with time. According to the can be further analysed for optimis- Figure 17 shows a comparison of conventional approach, reboiler ing the relief system’s design. relief load obtained for site-wide duty and relief rate are calculated Dynamic simulation can be particu- power failure. In dynamic simula- at one instant, which is at the start larly useful in unit revamps, to tion, the relief load obtained is of the emergency (not at the start of limit the capital cost involved in relief system modifications. Steady-state simulation to obtain relief load and properties To relief Debutaniser • Simulate the distillation column To condenser Off gas into three sections: column, column overhead system and reboiler CWS CWR Reflux system drum Recycle • The column can also be simulated Reflux Sour water as a reboiled column (column with a reboiler) with theoretical stages Reflux Feed Total liquid from pump and normal operating pressure column bottom stage Distillate (internal stream) ■ Define a reflux stream and Internal Bottom feed it to the top tray energy stream ■ Define the feed stream and assign an appropriate feed location. Set Twinned Give a normal pressure drop across column bottom the column ■ Fix the normal reboiler duty to External To external reboiler the energy stream and normal boil- reboiler up ratio (as a specification) Internal energy duty = external reboiler duty ■ Converge the column Steam Condensate • The column overhead system includes a pressure safety valve (PSV), cooling water condenser and Figure 18 Distillation column – steady-state simulation – relief condition reflux drum 64 PTQ Q2 2010 www.digitalrefining.com/article/1000487 ■ Split the overhead vapour pressure + normal ∆P), the bubble where it is expected that the reliev- from the column “to relief” and “to point of the column bottom ing scenario could approach the condenser”, and set the “relief increases. The temperature differ- steady-state condition. flow” rate to zero ence across the external reboiler ■ Simulate the condenser as a reduces, leading to lower external references 1 Sengupta M, Staats F Y, A new approach to shell and tube exchanger with cool- reboiler duty (pinch). The calcu- relief valve load calculations, May 1978. ing water on the tube side and lated duty of the external reboiler 2 Rahimi Mofrad S, Tower pressure relief overhead vapour totally condensed. should be equal to the energy calculation, Hydrocarbon Processing, Sep 2008. Simulate the reflux drum, reflux stream attached to the column pump, distillate product and reflux (internal energy stream). Iterate the Haribabu Chittibabu is an Engineering ■ The reflux from the reflux column internal energy stream so Specialist in the Advanced Simulation and pump should be same as the that it matches the external reboiler Analysis group at Bechtel India. He has a defined reflux stream to the top duty. Even though the LMTD tends bachelor’s degree in chemical engineering tray, so connect them through a to increase in the condenser, many from University of Madras and a master’s in recycle block designers tend to restrict the maxi- petroleum refining and petrochemicals from • The reboiler system should be mum condenser duty to design Anna University, India. Email: [email protected] simulated as a separate shell and duty due to uncertainties in the amudha Valli is an Engineering Specialist in tube heat exchanger (external calculation. For this exercise, the the Advanced Simulation and Analysis group reboiler) in order to study reboiler condenser duty is limited to the at Bechtel, India. She has a bachelor’s degree pinch at relieving conditions design duty only. in chemical engineering from Coimbatore ■ Create an internal stream of Now the column is at relieving Institute of Technology, India, and a master’s the total liquid from the bottom pressure, giving an idea of the in chemical engineering from Anna University, stage in the column. The internal reduced reboiler duty and the India. Email: [email protected] stream minus the column bottoms amount of overhead vapour. The Vineet Khanna is Project Engineering Manager is the feed to the external reboiler, next step is to simulate the cause of with Bechtel India. He has a bachelor’s degree in so split the internal stream to the overpressure to the maximum chemical engineering from the Indian Institute external reboiler and twinned convergence of the column. For loss of Technology, Delhi, India. Email: [email protected] column bottoms. Set the column of reflux, increase the flow “to dipanjan bhattacharya is an Engineering bottoms flow rate to the twinned relief”, so that flow to the condenser Specialist in the Advanced Simulation and column bottoms stream is reduced and, ultimately, the flow Analysis group at Bechtel, Houston. He has ■ Specify the normal UA to the to the reflux is reduced. a bachelor’s degree in chemical engineering external reboiler Simultaneously reduce the distillate from Jadavpur University, India, and master’s ■ Specify the hot side of the flow step-wise as the reflux pump in chemical engineering from University of external reboiler. For the case under is stopped. At the same time, keep Oklahoma. Email: [email protected] consideration, the hot-side inlet is iterating the column internal energy steam at its saturation condition stream so that it matches the exter- and the hot-side outlet is total nal reboiler duty. Ultimately, when linKS condensate the reflux and distillate are zero, all • Increase the column pressure to the overhead vapour from the more articles from the following relief pressure (PSV set pressure + column is the relieving flow. category: allowable accumulation). Since the The above methodology can also process modelling & Simulation bottom pressure is higher (relief be extended to other emergencies, www.digitalrefining.com/article/1000487 PTQ Q2 2010 65