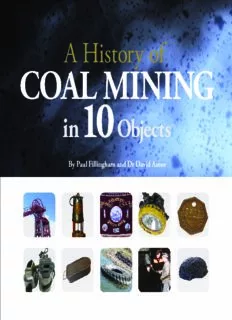

By Paul Fillingham and Dr David Amos PDF

Preview By Paul Fillingham and Dr David Amos

By Paul Fillingham and Dr David Amos Contents Headstocks 4 Flame Safety Lamp 10 Union Banners 12 Cap Lamp 18 Introduction Motties 19 workers, their families and the public. It explores the significance of ten Self-Rescuer 20 ‘The History of Coal Mining in 10 selected objects and how they have Snap Tin 21 Objects’ is part of an Arts and contributed to the development of the Pit Tips 23 Humanities Research Council, coal industry and coal mining culture. Pit Pony 25 Creative Economy Knowledge Coal 27 Exchange Project, led by the Univer- The study comes at a pivotal time in sities of Nottingham, Leicester and the history of the coal industry in Nottingham Trent: Archives, Assets Britain, with production capability and Audiences: new modes to engage reduced to three working collieries audiences with archival content and and many former mineworkers now heritage sites is funded by the AHRC entering their twilight years. and through match funding from the The project team enjoy close ties with Universities. these communities and have previous experience in academic research and ‘The History of Coal Mining in 10 the development of heritage projects Objects’ team consists of Dr David and cultural trails. Amos - Heritage Officer at Bestwood Winding-Engine House, Dr Sarah The project website incorporates Badcock Associate Professor, Depart- archive material and is supported by a ment of History, University of Not- range of social media channels, print www.miningheritage.co.uk tingham and Paul Fillingham Digital and exhibition material in order to Producer and Director of Thinkamigo. facilitate wider public engagement. It is hoped these assets will continue to The project pilots the use of digital develop and provide a focus for future technologies to engage former mine- activity. www.facebook.com/miningheritage Heritage Officer Dr David Amos Ex-miner from Bilsthorpe Heritage Society Digital Producer Paul Fillingham talks to presenting at the D. H. Lawrence Centre. explains mining memorabilia. former mineworkers. Heritage Events In September, a Steam Heritage Event The team also gave presentations at at Bestwood Winding-Engine House the 2013 D. H. Lawrence Festival In June, the Tin Hat Centre, in Selson captured the spirit of the traditional which included the debut of a hosted talks by the mining heritage Miners Gala with music from Best- ‘Headstocks’ video, featuring respect- project team. The event was supported wood Colliery Black Diamonds Brass ed local historan and retired mining by Bilsthorpe Heritage Society who Band. surveyor, Robert Bradley. displayed photographs and objects from their collection. The event provided a further oppor- Some members of the public brought The promise of a mining-themed tunity for public engagement, sharing in family photographs and evening combined with a pie-and- stories, displaying images and offer- documents for identification and peas supper proved so irresistible that ing hands-on contact with memora- scanning and in some instances, tickets for the event sold out in just bilia related to the former Notting- historic material was donated to the a matter of days. hamshire and Derbyshire coalfields. University of Nottingham archives. Steam Event at the Bestwood Winding-Engine House Photographic display in the Dynamo House. 3 Headstocks Bestwood Colliery headstocks. Headstocks have come to symbolise At first, people took coal from the Babbington, Selston, Pinxton, coal mining communities and coal surface (opencast mining) where extending into Derbyshire. production. Thirty-five years ago they found coal at the ‘Basset-edge’ there were some twenty-five pits where coal ‘outcropped’ to the in operation across seam. Shallow pits were dug to Nottinghamshire, each one (with extract the coal, which led onto the the exception of the fully-enclosed development of ‘bell-pits’. tower winders) clearly identified by These went a little deeper and when the sight of the headstock wheels working became too difficult the turning. The development of the miners simply dug another one headstock was born out of the nearby. Many bell pits were un- need to exploit deep coal seams covered during construction of the and is very much a product of the M1 Motorway which ran through industrial revolution. the outcrop area: Trowel Moor, M1 Motorway, 1968 4 Outcrop to the seam Bell-Pit & windlass Horse Gin As bell pits got deeper, hauling The windlass was replaced by the Steam-powered winding engines coal to the surface became more ‘horse gin’ a wooden structure brought huge gains in productiv- difficult. The situation was im- consisting of a large horizontal ity. Theses engines were usually proved by the introduction of a wheel powered by a horse, walking enclosed in brick-built winding ‘windlass’. This developed into in a circle underneath. houses which became a common putting a ratchet on the wheel The mechanism was attached to a sight around the country. which meant you could let go of smaller wheel with a rope extend- Winding engines were operated it without the load tumbling into ing down the shaft. The horse gin by boys and had ropes extending the shaft. As a result, women and increased production and facilitated to a vertical wheel located above a children could wind coal to the development of a more robust shaft single shaft that was used to trans- surface. This practice is illustrated system as heavy timber supports port men and materials in and out in the ‘Royal Commission on the could be transported into the mine. of the mine. In some collieries a Employment of Children in Mines diagonal ‘drift’ tunnel could be and Manufacturies’ (1842) which With the advent of the industri- dug to help transport coal to the documented the plight of children al revolution, horsepower was surface independently of the working underground. superceded by the steam engine, miners and materials. allowing even greater throughput and deeper, more extensive under- ground workings. Horses were still used in the production of coal but their role shifted from the surface ‘pit-top’ to the ‘pit-bottom’ where they were used to haul materials around the tunnels and transport coal-tubs Winding Engine from the coal-face to the shaft and out to the surface. 5 Single shaft coal mines were outlawed by Act of Parliament in 1862 as a direct result of the Hartley Colliery disaster in which two-hundred-and-four men and boys lost their lives. The accident was caused when the cast iron beam of the steam engine split in two, sending tons of debris down the pit shaft. Hartley Colliery Disaster, (Illustrated London news, 1864) The shaft at Hartley Colliery was divided by a wooden ‘brattice’ - the move towards twin shafts. Babbington, Cinderhill, High Park a fairly inefficient ventilation This configuration also brought (Eastwood), Watnall and Hucknall system designed to allow fresh air improved ventilation; with fresh collieries. to pass down one side, returning air passing down one shaft and ‘They found that over the years, the foul air up the other. The brattice contaminated air being expelled wood would tend to rot and become collapsed into the mine when the through the other. This meant unstable and unsafe. At Mansfield beam engine broke. that miners could dig deeper and Colliery, the Inspector of Mines said further underground. Tandem “this is unsafe” and he made them ‘There was no way these men could headstocks were also developed at stop winding coal. survive, until they could move all the debris from the shaft, which they tried. But by the time they got down there, they had all suffocated.’ (Bradley, 2013). The new legislation compelled colliery owners to sink two shafts instead of one, so that in the event of a similar accident, the miners would have a means of escape. Tandem headstocks made from pitched pine, like the ones pre- served at Brinsley are typical of the period and clearly illustrate Tandem headstocks at Brinsley. 6 David Amos and David Stewart filming at Bestwood Winding House. Mining Historian, Robert Bradley. But they were very clever, they built These new pits went straight to stopping, with often fatal a steel framework over the top of lattice frameworks which were consequences for the men inside. the wooden one and the Inspec- incredibly strong and commen- King devised a copper pin that tor let them keep winding with a surate with the depth of the shafts would break if it passed a certain small wheel under this framework’. which were going much deeper: point at the top of the headstock: (Bradley, 2013). Blidworth, Bilsthorpe, Ollerton Releasing a sprung claw to hold and Clipstone all went straight to the cage in-position. The device, Steel lattice frameworks began latticework. known as the ‘King’s Patent’ saved to replace the old pitched pine thousands of lives. headstocks. The changeover from ‘They weren’t allowed to do any wood to steel occured throughout other, the inspectorate wouldn’t A similar system was developed in the 1920’s: Pleasley and Hucknall allow it!’ (Bradley, 2013). Lancashire by Edward Ormerod were both converted but Brinsley and either of these two systems did not change as it was assumed Born out of the need to overcome have been employed in mines all that the mine would close. common problems , many techni- over the world. However, the shafts at Brinsley cal solutions were devised by the were retained as an escape route mineworkers themselves. View headstocks video (‘second means of egress’) for At Pinxton, John King who Selson Colliery. worked in the Blacksmiths work- shop on the engineering side of Throughout the twenties, the the colliery developed a Nottinghamshire coalfield mechanism to overcome rope expanded north-east of Mansfield ‘overwinds’ - where the cage would into the Dukeries. keep coming up the shaft without www.miningheritage.co.uk/headstocks 7 The colliery companies were sensitive to the welfare and education of their workforce. At Blidworth, plans drawn-up by the Newstead Colliery Company included 1,200 houses with gardens, sports grounds, shops and schools. They also commemorated the work of the writer James Prior whose novel ‘Forest Folk’ had recorded village life around the time of the Luddite uprisings (c 1811 - 1816). ‘The Forest Folk Hotel’ - a centre- piece of the village featured leaded Colliery Sinkers at Bilsthorpe, 1927. (Bilsthorpe Heritage Society). windows depicting themes from the novel. Initial development at Blidworth did not go to plan: After the First World War, Tunnel collapse and flooding were As the village lay between existing Nottinghamshire saw huge a constant threat but the work collieries at Newstead and expansion of its coalfields. proved highly lucrative. As local Rufford, it was not thought nec- The new mines were complimented labour became absorbed by work essary to sink exploratory bore by construction of ‘model villages’ at the new collieries, the county’s holes. Unfortunately, the strata improving living conditions for agriculture went into decline. proved different from that of its many working people. Private mining companies like the Stanton Iron Works and Newstead Colliery Company (responsible for Bilst- horpe and Blidworth respectively) effectively annexed the county’s existing rural settlements. When sinking began, many itinerant workers were Irish labourers. It was dangerous work extracting earth and rock and lining the shafts with brick and prefabricated ‘tubbing’. Colliery village, Blidworth, Notts. 1980. 8 neighbours and at one point the ‘Mechanisation developed strongly whole village was boarded-up in the nineteen fifties. And created amids fears that coal would never other problems in winding coal, be found in the area. because you couldn’t sort it out down the mine, you had to sort it Collieries established between the out on the pit top, which consisted war years employed steam winding of the screening and then a washery engines to drive the wheels that plant, which gave different grades were held aloft the lattice-steel that were put into trucks and taken frameworks. These towering away to different industries, for structures with their attendant pit power station or domestic use. Sutton Colliery, North Notts. chimneys and sprawling work- shops came to dominate the local All mining underground needs Steam winders were eventually landscape. There were huge social materials to be taken onsite: These replaced by electric winding changes too, the local population were things like; arches, timber, engines and modern collieries expanding with an influx of expe- steel props and ‘chocks’ (hydraulic such as Cotgrave, Ashfordby, rienced workers arriving from the supports) as we call them - ‘walking Selby and Harworth took on a declining coalfields of Scotland and chocks’ - all automated - Huge new form. These so-called ‘tower the North East. machines that had to be taken winders’ consisted of a vertical down the shaft to cut the coal. engine sitting directly above After World War Two as unskilled, The amount of stuff that went into a the shaft and were enclosed in a pre-mechanised working methods pit was unbelieveable, compared with concrete tower; its function now ‘stinting’ were phased out. Mine- the amount of coal that came out.’ hidden, because you could not see work became more skilled. (Bradley, 2013). any headstock wheels turning. The National Coal Board set up under the Coal Industry Nation- alisation Act (1946), sought to standardise working practices, conditions and pay. An important part of this new organisation was the NCB Film Unit which not only produced newsreels for public consumption but created a whole range of training films to improve safety and educate its workforce. Trepanner at Caphouse Colliery, Wakefield. Tower winders at Harworth, Notts. 9 Flame Safety Lamp In the early days, miners used candles, flaming torches and oil lanterns to light their way. As mines got deeper, this type of lighting presented enormous dangers due to the presence of methane gas which is potentially explosive in high concentrations when exposed to a naked flame. Underground explosions were common but the impetus to find a solution to the problem came from the Felling Pit Disaster of 1812, in which ninety-two men and boys were killed. The principle of the flame safety lamp was presented by Sir Hum- phrey Davy in 1815. Although ‘Davy Lamp’ is the common term used by most people to describe the device, the design was based on the pioneering work of George Stephenson and Dr William Reid Clanny. However, Davy, an estab- lished figure within the Royal Society was awarded a £2,000 prize for the invention. It was only later in 1816 that Stephenson’s con- tribution was officially acknowledged by the Royal Society. In 1816, Clanny published a paper ‘Practical Observations on Safety Statue at the summit of Teversal Pit-tip, Lamps’. He also made improve- the highest point in Nottinghamshire. 10

Description: