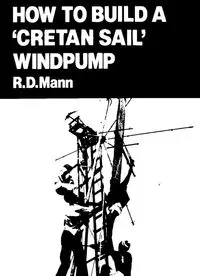

Table Of ContentHOW TO BUILD A

‘CRETAN SAIV

WINDPUMP

HOW TO BUILD A

“CRETAN SAIL’ WIND-PUMP

for use in

low-speed wind conditions

R.D. Mann, Al. Agr.

Agricultural

Gambia Christian Council

Wast Africa

INTERMEDIATE TECHNOLOGY PUBLICATIONS

The printing of this publication hes been made possible by

‘generous grants from three donors who wish to remain

anonymous.

Published hy intarmadiata Techno‘ogy Publications Ltd,

1108 ) 105 Southampton Row, Londen WC1B 4HH, UK

@ Intermediate Technology Publications Ltd +979,

Reprintad 1983

Roprinted March 1988

Aeprinced February 1992

§SBN 0.902031 66 3

fad by Artony Rowe Ltd, Chippenham

CONTENTS

PART 1

Introductian

Meteorological Considerations

Hydrologicat Considerations

Wind-Purnp Design

Wind Frequency Tables

G.C.C. Wind Pump Output, Table 2

Field Testing

G.C.C. Wind-Pump Fest Results, raph 1

Conclusions

Acknowledgements

PART 2

Construction details

Turniaate Frame

Furniable Bearings

Wind-Wheel Drive Shaft

Cranksvaft Bearings

Tower Head

Tower Upper Sectior

Toner Middle Section

Tower Lower Section

Tail Unit

The Wind-Wheel

The Sails

Pump and Connecting Rod

Drewing Sheets A-X

3

Sléanvesag

List of plares Page

Underneath wiew of turntable frame showing bearing

boxes if

Avview of the turntable 6

Turntable in operation on wwer 7

Making a turntable bearing track 18

Making upger tower section frame 2

Fitting bearing track or head frarie 22

Back view ot turrtable showing, on the fer le*t, the ball

hhofes to which the legs of the tail unit are attached = 26

Assembly of wind wheel 26

Fittirg the wind wheel 27

The sails in operation 28

The erected wind pume in action 32

List of iMustrations and tables

Map of the area 7

Table 1 Wind frequercies for site at Yundum 7

Table 2 G.C.C. Wind-pump outout on four selected days 8

Table 3 Wind frequencies for site 2 at Georgetown 8

Table 4 Wind frequencies for site 3 at Basse 8

Graph showing test results of the wind-pump 10

PART 1

Invoduetion

At the end of 1974, the Gambia Christian Council

stared a smatlscale villagelyvel agricultural

programme The rains in the Gambia occur from

mid-July ta mid October, and during the nine

month dry seaton there can be no fiekd crapping

without irrigation. The urowgh: conditions trom

1968 te 19/7, when werage rainfall decreased

from 31.6 inches to 3.8 inches per year, caused a

sho'tage ir domestic tood surly, and anv mathod

ff preducing food or cash craps in the dry season.

is of coneidarabe value to tie rura cammurity

The G.C.C. agricultural pragramme has consisted

of introducing vegetable production on # plane

basis, involving the use of lweslock-proof fercing

‘and ‘the sinking of 4 diameter concretelined

wells at the rate of twa wells per acre. The wells

ange ie depth from 15 in 35°, and. all water

extraction is by bucket and rope, the water keing

carried by hand to the vegetable plats. Each village

project Is planned far an area of oie ty sw ucres

under vegetables eacr season, one acre being

sufficient for 25 farnlies.

At their current stage of development, this

labourinteasive method of irigaticn hy hand ig

‘not limiting factor7o the succass of thase projacts

a the availablity of water from October to

May, together with improved «ethods of crow

husbandry, are he most important inputs.

However, when one considers future develop:

ment possiblities, and in particular the present

eed for troeptanting in all Sahelian aad near:

Sahelian countries, 2 emochanical meane of water

ting could have far-reaching results in making

such schemes feasible, and this has teen the

background thinking which prompted the devetop-

sent of the Gambia Christian Council Wind Puno.

Metearologicat Considerations

With reference to the wind trequencies given tor

three stations in The Gambia in Tables 1. 3 and 4,

will be seen that thera is 10 wind for 27% to

38% of the time, wind sponds of over 12 miles per

hour occur for only 38 0 3% of the year. and the

balance of 61% to 64% of the time has wind

speeds up to 12 miles per hour,

‘So for any practical use to be msde o* wind

power, a windmill dasion is required which can

start and operate in law wind sanads varying from

5 20 10 miles per hour

Hydralogicel considerations

“The river Samaia is lidal for a distance nf 150 miles

for imara fram the coast, and theraora water far

irrigation can o7y be taker trom the upper

reaches of the river. Tre graund water lever varies

‘ror 18! to BU, the dewier wells being mainly in

the eastern end of he county.

‘Mast dry-season vegetable growing areas are low

Iving with water tables varying fram 18° ta 25%,

but their location would require = high windmill

tower of 60" to 60" in order te reach the available

wind, However, there are sore areas, suitable for

dry-scason cropeing, with a water table af narmare

than 20° depth at the end of the dry season, and

it was decided to build a windrit 10 operate a

simple biston lift-pump,

Wind: pump design

Tre design was basse on the infrematian giver: in

the ITDC. publication, Food from Windmills, and

from practical advice given by Mr Pevar Fraenkel,

ITDG Power Project Engineer, In Septernber t876.

The design of the ‘Cmo’ windrril, devefoped by

the American Presbyterian Mission in Ethiopia,

‘as studied in detail, The ‘Omo" windmill worked

‘mainly ina wind regime of speeds from & ta

16 cites por hour, and it had oroblems asrociated

with turntable rotation ard directional stability of

the windheet into the wiad. Since our winds are

‘much lighter than those of the Ethiopian situation,

it was decided 10 make the wind-whee! 16° in

diameter and with six ams to permit the use af

‘wo, three, fou or six salle at required.

With referance =o drawings A and & (iven in

Part 2) the drive shaft tumns in three bearinas,

wo of oil-impregnated hardwood, the rear bearing

being a self-aligning ball-bearing which also takes

the axial thrust, The adjustable crank permits

uno strokes of 87%", 7” and St" to be used,

The pump is the same as used on the “Smo"

windmills: it ig a 3” diameter piston operating in a

16 pc. cylinder, ond it is connected to the

crankshaft via a universal join. The wurntaale is

fitted with four seated roller-bearing unit, which

run on a i" wide, 12° diameter bearing wack,

GAMBIA

sence 1,000,000

2 2e 30 muRe

Table + Wind frequencias for sire 1 at Yunctum

WIND SPEED JOR OM AM J J AS GO ON 0 Average

Gaim 2 17 % 1 12 20 30 39 di a8 48 28 20%

TA2eitesperhour = «707171727 «BD BB HO bs BAK.

1224 miecperhour «Bo 12:«16 «WB OB 14 8 8 kk BH

Qver 44 milesperhour 9 8 O CO 9 0 0 OO 0 Oo oO

‘The tai-fin has bean Lull hig! in relation to its

‘igth to obtain maximum leverage in the wind-

stream, The tall unit is of articulated design, with

ontrol rapes operated below the whee! to Dut the

wheel into of ot af the wind. The pesition of the

tail-in can be adjusted on tha teit boom to obain

tostance actos: the turntable bearings and 50

provide the best response te changes In wind

directien.

The tower is thiee-cormered and made in three

sections for ease of transport and erection. The

‘ower feat have platas welded on ta the battom of

the legs, end are sunk inta the graund to @ depth

cof 4". When erecting the tower, a spirit tevl is held

‘across the bearleg track at the top, the patition of

the Tags being adjusted in turn until the track ie

precisely feval in all directions. and the holes are

than filled in with tightly packed soit, The haight

of the tower is 23° fram ground level 19 the

bearing track,

‘Tha ‘main’ sails are made of heavy-duty marine

canvas, and the ‘starter’ sails are lightweight

The inner and outer sail comers. ore

fitted with aubber loops (details of which are given

In the construction deta in Part 2}, and it takes

io Table 2 6.C.C. Wind pump output on four selected days

sae Sins Bs 25rane Biber 1259 gi

Bos2%e Nexo Geoninae ofmns Shears Smet 1090 3a

S470 Nvwe ceso Tota mins Se fom Gaines ast

pene canis Une AMES Jee emi erh

J ries thins vequencies or ste 2 Georgetown

| OE ee

Calm 35 34 35 32024 73 «27 33 Be 46 A aD 35%

Tadimiscerhow SGT RS oo oh oe aS ee

ae

| rates ne rence torst 74 ese

| sinosreco SUF # ¥ 2 fA SOND mew

aim ee

1-12 miles per hour - 8 66 73 72 BO 70 64 49 52 43 41 B%

taza mies hour Ec ee

about six minutes to either fit or remove the salls,

‘The wind-whee is provided with struts and

Perimater-wire tension adjusters sn that the

wheel can be mada quite taut, and thus eny

tendency of the wheel arms to flex during gusting

winds is avoided.

‘As will be Seen in the construction drawings in

Part 2, the various windmill components Gen all be

unbolted to allow for easy maintanance and

modifications. After completing the workshop

construetion, all the mild steel perts are coated

with a murine anti-corrosive palnt to give tong

tetm rust protection,

‘The construction of this prototype machine

was carried out on a part-time basis, 2s and when

Cother field duties parmittad, in tha Ministry of

Agriculture engineering workshop . at “Yundum

Experimental Station, The constructioe com-

‘menced in Merch 1977 and was completed by the

end of September 1977.

Flos vesting

To feciltate testing, the wind-pump was sited

adjacent to a 74’ deep concrete water reservoir

tank at Abuko, 2% miles from Yundum. The top

of the tank was at grourd level, and the coxal lee

could he kept constant, the sutor lifted being

regsured ie rurs aud ter drained back int the

revervcur

There were a tery scavtered trees of up 0 38 1"

height, hot nane with n IDM yams af te wind

pune, and at 100 yarsk and heyore tre Tee

Foe was mainly cll-naim. The tstraction

wine-I'2W Cask by his wegatation asco TsIDEFe

ce fae'y typieal e rhae whien would be tourd

gt other su tabe Purping sites. nital tied tnas

ins aut im Nevcenaar and Dever ber 1977.

‘eet “ittod 47 8% large sails,

wish he outer

The veel was

a size, ait cons

feorer G shown in cvawing Ui tele by rigs:

ober nope 1a the cutee sail oes cm the peti

meter wins, (with ths arranmene”i there 286 0

diesticnal scarility ie wind snes nf 8 m.p h. anc

ove Ihe ea pattern sss shariged to Uhige [sige

ils, core’s titted as wefere, end this provides

etter winghwhee! staoiliny and less sail-lapping

During the frst srials, the aris af Ure with

‘heel were nat fitted with support steuls TL was

fennnt that thie ww edootiael was tne flexihle

in gusting winds, and struts ware tur fread to

teach arey weigh sulved this mechanical proble'n

and made the wheo compleraly rigia.

The taif boom design was also vvsiged. The

initia tail boom was mace af 17x 1” annle iran,

BO" total tength buat this allowed baisting nf the

booms and causad the 1ailfin to shake under

wind pressure. A new tubular tail boom was

designed (as shown in drawing QI, and to counter-

Lalance the extra weight of the struts on the wheel

it was then possible tc fit the tailsin @ further

away from the turntable

The result of these alte-ations ta the Wheel anc

teil, wagether ith hve use OF thine Farge sil, wees

improved sensttraty to changes in wind direction,

but the'e as still some sail lapping and the whee!

would tend to overrun at wind speeds above

9 mupsh. Durieg sudden high-speed gusle, dhe back

fof the sails would occasionally hit the Lower legs,

and there was still the (euuerey [er the wheel 10

move 19 the right-hand side around the tower as

the speed of the wind and the wheel incrensed,

‘The large sails provided avecuste saif area to

drive the wheal, but curing ligtt winds the starting

performance was. pacr. Ta provide more etarting

lorque, three sirallsi7e sails mare Uesigned with

4 na- oad ‘angle of attack’ to the vind cf approxi

mately 19°

During uniform wind conditions, in February

and March 1978, the sail arrangements of 3

‘rain’ ssik, 2 ‘Trait’ sails ane 2 ‘starter’ eile, and

‘main’ sails wth 3 ‘Harter’ sails were compared,

are ie war fae Oral for @ wind speed ranye of

§ te 10 mph. te test nwerall pertarmance was

tained with 3 ain’ sails and 2 starter’ sails,

ter frther teal, found that sail

flanpirg and any tondensy of the erain sail to hie

che tower "ags, could La: Cuirslelely eliminated by

ryire te Wad ug edges of te sas tightly against

the ware! a-ms, znd 4". sher considerable imarove=

net in whee! “oteon and ouIMa.ng OUSE.t was

ceslained fy “ting leregsha. nF rabhee From

Prucishing whee arins i the oucer sail curser,

full deta ls ef wach are givun int Curt 2 under

ie Sevvun aeated “Sal. This peavsion ol af

easceeated cormect an oft each sail Vailing edge

a0 730 the effec: cf gaverning the wheel specu

uring Tigh gusts, an Uns prevent

it war

he wheal

The final improwement inva val wuurteravting

she Tencency oF the wheel co swing to dhe right

hhand side around the teiaer a8 the wheel-rotation

snwed increagea. “0 do this, thy hoor ext Ie2e

Urawing P) was releasoa, and in the first instance

the la beo-n wise ted 11a positian 10" to the lett

Houking forvaas lo the wreel). The wenency was

ow for the vaizel to rrave progressively around

tha lower “0 the leftchand sice: a final nositien of

about 74” lo the left »as than fund te qive the

best diectinrs stability of the wlwel, and the

boom was fixod in this pasition for the remainder

of she trials,

For the pumping tosts, two ceums teach of

43.4 gallons capacity) with screwtype outless at

the hotiam were placed or the reservoir wall

The pump inlet was connestod viag 1!2" diameter

owe, pie to 2 1%” factory-matte brase toot

valve pieced in the wator :ank. The punip outlet

was taken by a 1%" ameter ov.c. pipe lo the

drums. ‘Nind-un wes measured by an integrating

cup anemameses mounted on a pole at a heignt

ot 8

‘ait we to Graph 1, tre windspred was

Calculated from the time taken to till a drum and

she wind run at shown by the nemometer at the

commencement anc cample:ian of each drum:

filling perind Qn some of the lest days, the total

Tift (measured from the water reservoit surface to

the purmp outlet, vertically) was 13''4", and on

others it was 14° 1”, so all output figures have

been suuated io footgallons for ease of com

parison, The work done in foot-gallons per hour

‘was calculated by noting the time required to fill

each drum. 45 ona drum was filled ta the top, tha

fen

WORK DONE: FOOT/GALLONS PER HOUR

13,000 GRAPH T

rac00 ’

‘TEST RESULTS OF THE

bc, WINDFUMP

11 090

12,080 @ ‘Gc! 1 PUMP

-oMo'— 1 PUVP

200 @ ‘omo"— 2 PUMPS

000

1080 :

’

6.000

,

,

4.000

seve

3,000

2.000

ave

z é 'o nm 26 18

c 6 ho eB