BEST Noah's Ark PDF

Preview BEST Noah's Ark

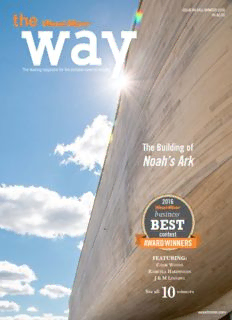

ISSUE 98 FALL/WINTER 2016 US $3.00 The leading magazine for the portable sawmill industry The Building of Noah’s Ark 2016 business BEST contest AWARD WINNERS FEATURING: Cook Woods kamuela HardWoods J & m logging 10 See all winners woodmizer.com FROM THE CEO Dear Fellow Sawyers, Welcome to the 98th edition of The Wood-Mizer Way EDITOR Deanna Bunten Magazine. This year, Wood-Mizer hosted our Business Best Contest to recognize hardworking business owners that are ASSOCIATE EDITOR profiting with their Wood-Mizer sawmills. The winning Chase Warner 317.808.0818 – [email protected] businesses from the contest are featured in this magazine edition. With my background in the commercial sawmilling ART DIRECTOR industry, this business-inspired edition is always my favorite, Janine Axsom Richard Vivers, CEO hearing from sawmillers throughout the world that are CONTRIBUTING WRITERS Wood-Mizer LLC making a living with their Wood-Mizer equipment. J ennifer Alger Jacob Mooney Tony Kryzanowski Jack Petree Paul MacDonald Chase Warner This year’s Business Best Contest received the most entries to date which is a testament to the growing number of Wood-Mizer sawmill operations that are successfully CONTRIBUTING producing quality wood products for the marketplace. From the family in Oregon PHOTOGRAPHER & DESIGNER Kim Tabor producing unique large slab material to the young team in Hawaii supplying their community with locally sourced lumber, these businesses and many others are LETTERS TO THE EDITOR prospering in different markets and locations with one common thread – a Wood- Wood-Mizer welcomes your tips, stories, and comments. Please understand, due to the high Mizer sawmill. I’d like to take a moment to personally congratulate every Wood-Mizer volume of mail received, we may not be able to respond personally to each letter. Submissions sawmilling business, not just this year’s winners, that have built their operations with become the property of Wood-Mizer and may be edited for publication. the hard work and dedication we recognize and admire. REPRINTS AND PERMISSIONS In addition to the award-winning businesses, we are pleased to share with you a To order reprints of the magazine or request permission to republish an article, call Colorado sawmilling company that supplied building materials for the world’s largest 317.271.1542 or email [email protected]. freestanding timber frame structure. The re-creation of Noah’s Ark in Kentucky CONTACT US was constructed with material sawn on one of our smallest units - an LT15 sawmill. 8180 W. 10th Street • Indianapolis, IN 46214 The Ark project involved many dedicated people and I applaud the individuals and www.woodmizer.com 317.271.1542 • 800.553.0182 companies involved in the design and construction of this remarkable timber frame structure. SUBSCRIPTION CHANGES Chase Warner – [email protected] My hope is that you will enjoy this issue and I encourage you to continue sharing your successful operations with us. In closing, I wish you and your family a happy holiday season filled with the joys and memories this season can bring. ON THE COVER: The Ark Encounter is the world’s largest Wishing you all happy “Wood-Mizering”! freestanding timber frame structure. God Bless, Story on page 6. Photo by Jake Mooney Richard Wood-Mizer supports environmentally-friendly business practices and sustainable forestry initiatives in the forest and in its printed communications. 2 The Wood-Mizer Way Fall/Winter 2016 CONTENTS HYDRAULIC SAWMILLS Departments 6 18 4 Wood-Mizer Newsbriefs First Place Kamuela Hardwoods 10 Blade Corner 20 16 Customer Service Corner Second Place Wenstob Timber and Xemex 17 Meet The Rep Industries 29 Board Foot Clubs 22 6 Third Place (TIE) 30 Upcoming Events The Building of Noah’s Ark The Wood Cycle of Wisconsin One of Wood-Mizer’s smallest 31 Wood-Mizer Locations sawmills was used to cut 50% 23 of the timber for the world’s Third Place (TIE) largest freestanding timber frame Knotthead Custom Sawing structure— a Biblically-sized and Fabworx reconstruction of Noah’s Ark. 12 11 2016 Business Best Contest This year’s contest showcases ten Wood-Mizer sawmill owners and their award-winning businesses. INDUSTRIAL SAWMILLS 12 First Place Cook Woods 14 Second Place Coomer & Sons Sawmill 15 Third Place AA Farms, Inc. MANUAL SAWMILLS 14 24 First Place J & M Logging 26 Second Place 23 Montana Log Works 27 Third Place Branch River Portable Sawmill woodmizer.com 3 NEWSBRIEFS NEW! WOOD-MIZER LOG SPLITTERS NY BRANCH MANAGER DAVE SCOTT RETIRES Long-time Wood-Mizer NY Branch Manager Dave Scott has announced his retirement from Wood-Mizer at the end of 2016. We would like to recognize and thank Dave for his 28 years of service to not only Wood-Mizer but to everyone he has influenced throughout the years. The first and only branch manager in New York, Dave has grown and supported our Northeast customers by building an Wood-Mizer log splitters are engineered for performance to provide you with the best excellent service available wood splitting equipment on the market. Offering three portable, heavy- team from the duty models, the Wood-Mizer FS300, FS350, and FS500 log splitters provide many start of the unique features for firewood producers looking to maximize efficiency and productivity. branch in 1988. Portability, bi-directional splitting and an efficient and ergonomic operator It’s not unusual location make Wood-Mizer log splitters a profitable investment for farm operations, to hear about small businesses, and commercial wood splitting companies. Features on our line of log Dave spending splitting equipment include: his weekend • Solid and rugged construction sawing as he • Back-Saving working height and log lift has always lived • Smart and efficient operator location Dave Scott and breathed • Rectangular firewood for easy stacking Wood-Mizer orange. As he plans for • Material is automatically moved and sorted retirement we already know that part of • Quick and easy setup that next life chapter will include Wood- • Completely portable FS500 Mizer equipment, but Dave is most looking forward to spending more time Wood-Mizer log splitters are now available to order.Visit woodmizer.com/logsplitters or at home with his wife Linda, 9 children woodmizer.ca/logsplitters for more information or to download the FREE Catalog. and 7 grandchildren. From all of us at Wood-Mizer, thank you for your service and friendship and we wish you a happy NEW! TURBO 7 BI-METAL BLADE retirement! We welcome you to share your good memories and well wishes with Dave EXOTIC AND FROZEN HARDWOODS, YOU’VE MET YOUR MATCH. by phone, email, or on social media. The unique and aggressive Turbo 7 blade profile is NOW AVAILABLE in our Bi- Metal product line! Bi-Metal high-alloy material offers up to three times longer sawing Wood-Mizer has announced that Jack sharp life than carbon blades and is engineered for production sawing environments. Beckwith, Customer Service Representative When the Bi-Metal two-piece steel with a at the NY Branch, will become the new wire-welded, hardened tooth tip is paired Wood-Mizer NY Branch Manager. “The with a Turbo 7 degree profile, exotic and Wood-Mizer team frozen hardwood is no match. and I look forward Bi-Metal Turbo 7 blades are to continuing Dave’s available in .042" x 1.25" and legacy of providing .050" x 1.5" sizes at any length. excellent support Call 800.522.5750 to order and dedication (877.866.0667 in Canada). to the Northeast for many years to Jack Beckwith come," said Jack. said Jack. JOIN THE CONVERSATION! LAMES À BANDE INDUSTRIELLES Join more than 450,000 fans following Wood-Mizer on Social Media to stay in the loop on upcoming shows, amazing projects, and inspiring stories from owners just like you! Follow Wood-Mizer and join the conversation on any of these Social Media Networks: 4 The Wood-Mizer Way Fall/Winter 2016 LETTER TO THE EDITOR “Tom Pasternak, a well-respected man of faith and tree expert went to his sawmill to mill a large maple tree. Tom was excited to find sap spiel FROZEN LOGS? NO SWEAT. markings in the old maple tree for use in a new post and beam maple syrup building. The milling was going according to plan when suddenly NEW! WINTER SAWING BLADE BOX the blade hit metal. The eerie noise Tough winter weather is here, but that doesn’t mean you of metal hitting metal while sparks have to put a freeze on sawing. Maintain a high-level flickered and Tom instantly knew the of production and quality while sawing in cold weather with Wood-Mizer’s NEW Winter Sawing Blade Box! saw blade teeth were damaged. Ideal for sawing tough frozen logs, this WOOD-MIZER After appraising the situation the EXCLUSIVE blade box includes: mill appeared to be safe and it was time to shut the mill down, dim the lights • 2 x DoubleHard 4° • 2 x DoubleHard 7° and head for the shower and bed. • 2 x DoubleHard Turbo 7° In the night watch, the sparks that • 2 x DoubleHard 9° flew earlier had reared up and caught • 1 x RazorTip Stellite 10° the wind of the air. The sparks were THE WINTER SAWING BLADE BOX IS ONLY smoldering in the sawdust and Tom AVAILABLE IN .045" x 1 ¼" AT 158" LENGTH. Blade Box Available in US only. had no clue the building was 800.522.5760 | woodmizer.com/blades © 2016 Wood-Mizer LLC Smoldering sawdust. smoldering while he rested. God intervened. Jesus Christ is faithful according to His Word. He is our shield and buckler. Our very present help in times of trouble. His sawmill smoldered, but did not catch fire. The following morning Tom headed straight toward the sawmill to take another look at the damaged blade, but was shaken to discover the smoldering sawdust. God protected our sawmill, building and equipment from the fire! Being very grateful, Tom bowed his head to thank God for His Wood-Mizer’s VORTEX dust removal protection and faithfulness.” blade will CLEAR THE DUST from your VORTEXTM BLADE INDUSTRY TEST cut like no other blade on the market. – Leta Pasternak This EXTREMELY UNIQUE profile has generated EXTRAORDINARY results Dbouasrtd o/n 3g 2g in HIGH PRODUCTION PALLET grams 0g FACTORY TESTS. Patent pending & NO measurable amount! TdeRsAigDnE aMndA RreKsEulDts ,f othr iists b rlaedvoel’us taiobnilaitryy to 7SB/pla8ad"c eTinogo th I ndustry Favorite Blade #1 I ndustry Favorite Blade #2 WSAoWodD-UMSiTz eRrE NMEOWV AVLO RBTLEAXD E leave only a trace amount of sawdust will leave you spinning and FOREVER CHANGE YOUR EXPECTATIONS of what is an acceptable amount of sawdust from a dust removal blade.. 800.522.5760 | woodmizer.com/blades Canada: 877.866.0667 | woodmizer.ca © 2016 Wood-Mizer LLC Leta and Tom Pasternak woodmizer.com 5 Noah’s Ark The Building of One of Wood-Mizer’s smallest sawmills was used to cut 50% of the timber for the world’s largest freestanding timber frame structure – a Biblically-sized reconstruction of Noah’s Ark. T he Ark is one of the most considered the largest freestanding timber By Jacob Mooney iconic religious symbols in frame structure in the world with a total the world. Flood legends of 3.1 million board feet of timber used And God said to Noah, “Make exist everywhere people do, in its construction. A football field and with more than 200 cultures a half long, the volume of the Ark is the yourself an ark of gopher around the world preserving some kind of equivalent of 500 standard semi-truck wood - the length of the ark 300 flood or ark story. So when the founders of trailers and features three levels of exhibits cubits, its breadth 50 cubits, The Ark Encounter were considering their with a 600-seat restaurant being prepped and its height 30 cubits. Make next big project, the Ark was at the top of for the top deck. The Ark’s maximum the list. capacity is 10,000 people, however it with lower, second, and third The inspiration for the project began organizers plan to limit it to 3,000 inside decks. For behold, I will bring with the founder’s desire to create a at any one time. a flood of waters upon the family-friendly attraction that would encourage people to reconsider the Bible’s THE DESIGN earth... Noah did this; he did relevance in our day and age. The now The vision originated with Ken Ham, all that God commanded him.” completed reconstruction of Noah’s Ark president of Answers in Genesis, and Excerpts from Genesis 6, ESV in Williamstown, Kentucky took just Patrick Marsh - a world-renowned art over one year and a half to build and is director whose designs include the Jaws 6 The Wood-Mizer Way Fall/Winter 2016 Noah’s Ark The Building of Developed by missionary philanthropist John Enright, Bee Sweet Honey, a co-op style honey initiative, is taking off in Zambia, and improving lives for the 10,000 individuals already involved. and King Kong attractions at Universal on the distance from the elbow to the tip factory bursts with the latest technologies Studios in Florida, among other high of the longest finger, various cubit lengths in timber frame equipment that includes profile projects around the world. The existed in the past. For the Ark project, an extended Wood-Mizer LT15 sawmill. Ark project began on paper with the the Hebrew cubit length of 20.4 inches Keenan Tompkins, owner of combination of Patrick Marsh’s vision was used – making the overall size of the Colorado Timberframe, received a text and the building and architectural Ark itself 510 feet long, 50 feet tall, and message from one of his employees that expertise from the Indiana-based Troyer 85 feet wide. said, “If we have the largest timber frame Group that had built the American manufacturing facility in North America, Countryside Farmers Market in Elkhart, SUPPLYING THE TIMBER why aren’t we cutting the largest timber Indiana- the largest wood-pegged barn in One of the biggest challenges facing frame?” Keenan did some research and the country. LeRoy Troyer of the Troyer the project was the question of who was contacted The Troyer Group. The timing Group spearheaded the architectural plan going to be able to supply all the wood could not have been more perfect with for The Ark Encounter and recruited in the quantities and sizes required. Enter the Ark design nearing completion and Amish builders from previous projects to Colorado Timberframe, a company just the Troyer Group actively looking for a head up the heavy timber framing and outside of Denver that claims to have company to provide the required timber. carpentry work for the Ark. “the largest and most technologically “They were still trying to figure out if The very first design question was a advanced timber frame manufacturing one company could actually handle the simple one – how long is a cubit? Based facility in North America.” Their massive volume of the project,” said Keenan. “We woodmizer.com 7 told them we had the capability of doing the entire project. We’re the only company that can do the sizes of the timbers that they had, and actually fabricate all the timbers.” SAWING THE MATERIAL Colorado Timberframe was awarded the contract and immediately got to work. With 1.5 million board feet of heavy timbers required for the construction of the timber frame itself, each individual timber element needed to be sized precisely. WOOD-MIZER SAWMILLS AT THE ARK In addition to the LT15 sawmill from Highly accurate joints and holes needed to Colorado Timberframe, at least two other Wood-Mizer sawmills were involved in the Ark project. An LT70 was used to cut the first beams used in the inaugural “Peg and be cut into each timber so the whole frame Beam” ceremony for the project commencement. An LT40 was also used on-site during could be assembled on schedule. “We had the final months of the project to produce bench material and additional finishing to add staff, because we ended up running items that could be processed from leftover timber. three shifts and working 24 hours a day, 6 days a week for about a year,” Keenan recalls. “The crew consisted of 25 guys in of the timber had to be resized before it was essential part of the process,” said Keenan. the shop for about a year – hand cutters, milled on the CNC machine. So that’s where “It was both the resizing of the timbers machine operators, and yard guys. That we really worked the Wood-Mizer for a year. for the Ark, and since the timbers for this doesn’t count our install crew. We had About half of the Ark timber frame passed project were so huge, we had to custom- another 10 guys that worked alongside the through the LT15.” make our own pallets. So all the pallets Amish at the Ark site.” The LT15 is part of Wood-Mizer’s were made on the LT15 by ripping down All of the square-cut timbers used inside entry level range of sawmills, often all the offcuts and waste material. You can the Ark are douglas fir harvested and milled in purchased by woodworking hobbyists or imagine how many pallets were needed for Oregon, Washington, and British Columbia. first time sawyers. However, due to the 1.5 million board feet of timber!” “All in all, there were 120 semi-trailer loads ability to saw any length of timber with Standard Wood-Mizer DoubleHard of timber,” said Keenan. “We brought in unlimited bed extensions, the LT15 is 4 degree and 10 degree blades were used all this rough-sawn, squared timber and also used by companies like Colorado throughout the project, however, the the engineering plans had very specific size Timberframe for strictly commercial blades were customized to achieve the requirements for the final timber sizes. Half purposes. “The LT15 sawmill was an rustic surface finish the Ark planners were Massive reclaimed spruce and Douglas fir logs line the center of the Ark. 8 The Wood-Mizer Way Fall/Winter 2016 could not have done it without him,” said Keenan. “I personally believe that he’s the best timber framer in the country.” THE CONSTRUCTION 1,200 miles east of Colorado Timberframe’s facility, excavation at the Ark site began inAugust 2014 in Kentucky with 500,000 yards of dirt removed to clear the area for the Ark. Foundation work began in February 2015 and the “Ark raising” began in June 2015. The Ark plan called for the timber structure to be set 12 feet off the ground on 102 concrete pillars. As the timber arrived in Kentucky, construction began on the The Colorado Timberframe team responsible for delivering the largest freestanding massive timber frame structure itself. Like timber frame in the world. any other timber frame structure, the Ark frame was divided up into a series of 2D looking for on the beams. “They wanted schedule, working on the project for just sections called “bents”. As each “slice” the wood to have a rustic character to look over a year, in addition to continuing or bent is assembled and put into place, like rough-sawn timbers,” shared Keenan. to build custom timber frame homes then the 3D structure begins to grow. Bent “We had to modify the blade to get the and structures for other clients.” They assembly was done on the ground using same rough sawn finish that you would get did some pretty incredible things with raised wooden platforms to keep all the from a mill.” wood before the invention of steel and various timber elements aligned as they concrete,” Keenan reflects. “So it’s kind were joined like a giant puzzle. FURTHER PREPARATIONS of going back to incorporating and using The first bent weighed 25,000 pounds Once the beams were the correct that, but applying it in a modern context.” and took two weeks to assemble and put size, the machining process would begin – into place. Two smaller cranes lifted it notches, holes and more would be bored upright and then a large crane lifted the into each beam with maximum precision, CONSTRUCTION FACTS: bent into place on the concrete pillars. As thanks to Colorado Timberframe’s new • Ark weight – 31,600,000 pounds the Amish construction crew got faster CNC machine. “The timber would (15,600 tons) with each bent, by the end of the project, go through the K2I Hundegger CNC • The fire exits are rated to handle bents were being assembled and installed Massive reclaimed spruce and Douglas fir logs line the center of the Ark. machine. We have a four foot wide track, up to 10,000 people. at the rate of two per week. As the project so it can do beams four foot wide to up to neared completion, Orie Lehman, one • 5,000 sheets of drawings of every 20 inches tall, and 60 feet long. We got that aspect of the structure of the Amish carpenters that oversaw the machine for large commercial projects. timber framing set up his Wood-Mizer • Parking lot holds up to 4,000 cars It does all the traditional timber frame LT40 sawmill at the Ark site in order to cut connections - mortise and tenon joints, as • A 600-seat restaurant is under all the timber needed for the hundreds of construction on the roof deck well as drillings and slot cuts, and any kind benches placed inside and outside the Ark. of recesses or notches that the timbers need • 15,150 sheets of plywood to accommodate either wood connections • 290,000 board feet of bamboo VISITING THE ARK or steel plates.” flooring The Ark Encounter is now open to the But not all the timber needed to be general public and reports that more than • 67,467 drilled holes in beams squared-up. The Ark design plan called for 300,000 people have visited within the first • 95 tons of steel plates and 66 massive lodge pole logs running from two months. Next to the Ark Encounter is connectors the bottom floor to the top of the Ark – a petting zoo and a massive zipline course, 55 feet long. A significant number of the • 3.1 million board feet of timber but these attractions are just the beginning used for the structure logs used for the columns were standing for what they have planned for the future. dead engelmann spruce from Utah. “We • 5,435 heavy timber beams The Ark Encounter has been referred to made a deliberate and concentrated effort • 300,000 screws as the 8th wonder of the world and required to incorporate as many reclaimed logs as hundreds of people directly working • 50,000 pegs and bolts possible,” shared Keenan. “The spruce together towards a common goal – crafting logs were standing dead, and responsibly the largest freestanding timber frame harvested.” Colorado Timberframe built Keenan shared that even though structure in the world. With the necessary a special jig in order to rotate the massive The Ark Encounter was a huge project, skillset, equipment, and dedication from lodge pole logs and cut all the needed the key to being successful was project companies such as Colorado Timberframe joinery, which was done by hand and took management, organization and scheduling and the Troyer Group, the breath-taking their team of six men two full days to to ensure the company didn’t get Ark Encounter project can now be enjoyed complete one log. overwhelmed with the magnitude of the by visitors coming from around the world. Miraculously, Colorado Timberframe project. “Henning Mund, our German For more information visit www.arkencounter.com delivered the timber requirements on master timber framer and my partner –we and www.coloradotimberframe.com woodmizer.com 9 BLADE CORNER HOW TO FOLD AND UNFOLD BLADES Coiling and uncoiling bandsaw blades needs to be done correctly. Here is a quick, step-by-step guide to proper blade folding. ALWAYS REMEMBER to wear gloves and eye protection when BBLBALLADADEDE FE FO FOLODLLDIDNIINGNG GG G UGUIUDIIDEDEE handling blades in addition to keeping others at a safe distance when coiling or moving blades. UNUCNUOCNILOCIINOLGIILN ITGNH GET H TBEHL EAB DLBAELDAEDE INVINEIRVNETVIRENTRGITN ITGNH GET H TBEHL EAB DLBAELDAEDE 1. 1 .1. 2. 2 .2. 3a .3 a3.a. 1. 1 .1. 2. 2 .2. 3. 3 .3. TakeTa tkThaeek ttehh etrh eteeh -rtlehoeroe-pleo -coloopio lc pion ci lyo ioinlu iyrn or yuigorh urtri g hrhaigtn hhdta. hnadn.d. FindF itnhFdein tldho eoth pleo t ohlopao ttp hc atrhte aacttr eecsar etaea sfit e gasu fira eg fi u egrieug rheeti, g eahingt,dh a t,n adn d TheT thoTeph tteow ptoo t plwo toow ploos o lwopiosllp wfsoi lwrl miflol arfmo cr rmao scasr .ocsros.ss. HoldH otHhldeo ltbdhl eath dbeel a b(dtlaeede (etthe ( etteothew ttahor wdtosaw rydaosrud y)s oo yuuo)t u oi)nu otf urinot nifntr ofnrot nPt usPhu wPsiuhts hwh yi twohui tyrh ot yuhoru umtrhb utshm,u bcmsab,u scs,ai ncugas uitnhsgein tmgh eitdh mdel iemd doidlfe d loef ofR otaRtoeRt aothtteae t tcehu etrh vceeu dcrv userevdce stdieo scnet iocoftn ito honef o tbhfl eath dbeel a budlpae d uep u p pullp duopllwu dlnlo dwwointw hwn yi twohui tyrh ol eyuofrt u lher aflten hfdta. hnadn.d. of yoofu oy, fol eyuto,t uilne, gtlte iontntgien o gsn ioedn ese ir deseisd tre eo srnet tsohtne o tgnhr etoh ugenr ogdur.onudn.d. the tbhleath dbeel a btdolae cd tueor tvcoeu crdvuoerwv deno wdwaonrwwdn.awrda.rd. towtaorwdtosaw rydaosrud y,s ot hyueo, nuth ,a etwhnea anyw faarwoya mfyr oyfmorou my.o yuo.u. 3b .3 b3.b. 4. 4 .4. 5. 5 .5. 4. 4 .4. 5. 5 .5. PLPEPLAELSEAEAS SEBE EB BEAE DA VADIDVSVIESIDSE!ED D! ! For FthoerF otphru etr hppeou srpepusor spoeof ssv eiossfu ovafils vduieasmlu adolen mdsetormnasotitnorsnat,tr iatohtnie,o nth, et he bladbel awbdlaeas d weina vwse airnstv eiendrv toeenrd tc eoodnn occnro enctcoern. ecHtreoe.wt Hee.ov Hewroe,w vteheriv,se trh, itsh is coulcdo ducalodmu ldadag mdea aymgoeau grye ob uylarod uberl. a bIdltea i.ds eI tr. eiIsct orisme crmoeemcnomdmeemdn deendd ed thatt yhoatuth ayinot vuye oirnutv iyenorvute ryr otb ulyarod uberl a obdnlea s dooenf t oesnor fsstouefrrtf esaruc rsefusar.cfeasc.es. WhiWchhWeicvhheicer hvbeelavr edbrel a bldolaeod pleo i oslop oo inps tioosnp o ,t noh poto,l dph ,ow hlidot hlwd yi twohui tyrh o yuor urH oldH otHhldeo ltbdhl eath dbeel a bodluaetd oaeun otd ua atn wadna adyw faarwoya mfyr oyfmorou my .o Syulo o.u wS .ll yoS wlolyw lyY ouYr obYuloar udbrel a bidslae sd uiesc iscsue scsucfucelcslyefu sulflnuycl luoyni lucenodci.loeidle.d. TheT bhlTeah dbeel a bwdlaieldl webi elwl iibnlle ab inen oianvn aa oln vs oahvla asplhe sa, hpbaeup,t ebt,wu bti suttwte tidsw.t iesdte. dT.h eT bhlTeah dbeel a bhdlaaesd h esa uhsca scsue scsucscfeucsleslyfsu silnfluyvl eliynrt vienedvr.teerdte.d. righrti ghrhaigtn hhdta. hnHadon.l ddH .ot Hhldeo ltodht ethh eoert holoethor eplor w oloipto hwp yi twohui tyrh ol eyuofrt u.ler flte.ft.movmeo myvooeuv yre oh yuaorn uhdras hn aadpnsad arstp aawprhtai lrweth wriolheti alretoi ntraogtt iyanotgiun yrg o yuor ur SlowSllyoS wmlolyow vlmye o myvooeuv yre oh yuaorn uhdras hn aadpnsad arstp ,aa aprltal,or awt,l ilanolgwlo itnwhgein tgh eth e forefaorrfmeoarser mdaorsmw dnso dawonnwd a non uadtn wodua otrwdu.tawrda.rd. bladbela btdolae ud tneot twuoni suttwn, tiwswtiit,s hwt ,ti htwhei t tthhe eteh ttehe etfeathec tifnhag cf aiancwgina agyw. aawy.ay. COCILOCIINOLGIILN ITGNH GET H TBEHL EAB DLBAELDAEDE 1. 1 .1. 2. 2 .2. 3. 3 .3. STOSRTSOITNROGIRN ITGNH GET H TBEHL EAB DLBAELDAEDE UseU csaUers ece a wcrheae rwenh wmehnoe vmnin omgv,oi nsvgtion, rgsi,tn osgrt,io norgrin ,h goa,r n ohdral ihnnadgnl ibdnllgain dbgel asbd.l aeWdshe. esWn. h Wbelhnae dbnel asbd laaerdsee asr ea re stacsktaescdtak ocerkd et ohdrr ootwrh rntoh twroongw etnot hgteoergt,he tethhre,e trth,i petsh t eicp atsinp c sba ecn a dbnue lb ldeeud dl louerldl et ohdre o tsrhe etth sceeh sta ecnthg caehndag.negde.d. StacSkta Stctwakoc t kbw ltoaw dboel asbd lbaeadsce bksa- btcoak-c-btkao-c-tboka- ubcsakic nukgs uidnsigvin iddgie vdrisidv ebidreset rwbsee btewente weeaence ehna seceahtc sohef stb eoltaf dobefl asbd laedse s to ptroe tvpoer enpvtr eethvneet n tthte eteh ttehe etferthoe mtfhr ocfmroon mctao ccntotiannctgat iecnatgicn ehga oectahhc eohrt .hoethr.er. If stIof rsIiftn osgrt iobnrlgain dbgel asbd lfaeodsre flsoo nrf oglor p nleogrn ipgoe dprsieo ordifos td iomsf oetif,m btieem, sebu,e rb ese ut srheue r tbehl eath dbeel asbd laaerdsee adsr reay r dtehr yde rntyh ethne n coact owcaiott haw tli utwhbi rtlhiuc blaurnibctr.aicnat.nt. RaisRea Ritshaeeis tbehl eath dbeel a bwdlaietd hwe ti etwhei ttthhe etpetohei ntphtoe pidno ttienodtwe tador wdto aywrodau ry.do yuo.uK.eeKpe yKeoepue yrp oa yurorm uasrr mlaorscm klsoe cdlok scewkdie nsdgw isinnwggi nitnhggein ttgho etph toeof pt to hopef o thf eth Oen tOhneO tdnho etwh deno wdwaonrwwdn abwredan rbdde, bnbedrni,n dbg,r ibynorgiun yrg oh yuaorn uhdras hn adnsd s StorSet oSinrteo a ri enc liaen a canl e caalnenda a ndn radyn dpdrl yad crpyel a.pclaec.e. SligShltilSgylh isgtqlhyut lseyqe suzqeeue tezheeez tbehl eath dbeel a bidnlaewd aienr wdin.awrda.rd. bladbela bddloaewd deno dswoon w istn ob s eiotn bdites bn uednnsdd uesnr .udnedr.er. togetothgteoergt hecetrhro escrsr iocnsrgos isonsvgien org ve oeavrc eehra oectahhc eohrt .hoethr.er. 4. 4 .4. 5. 5 .5. LEARN HOW TO COIL BLADES BWY WWAAWRATCNARHRININNNIGGNI N!TGHG!E! VIDEO AlwaAylwsA alwwyeasa ywrs e gwaleor avgerl osg vlaoenvsde a sen yaden e dy eey e protpercopttrieooctnet iwcothnioe wnnh wheahnne hdnal ihnnadgnl ibdnalginn bdgas bnaadwns daswa w SawSmaSwilalm wBimall niBldl a BBnadlan dBde laB dlaed e bladbelasbd.l aeKdsee.e sKp.e pKeeepoe pppel epo epaolwepa laeyw faarwoya mfyr owfmroor mwk o wrko rk CoilC/FoCoillo/dFilio/nFlgdo ilVndigidn eVgoi dVeidoeo areaa rweaharee wanh wceohnie lcinno gcil oionirlgi nm ogor ovmirn omgv oibnvlgain dbgel asbd.laedse.s. ONLOINNOELN IVNLIEIDN EVEOI DV:EIDOE:O: Go GtooG wtooo otwod omwoiodzomedri.mzceoizrm.ec/rou.cmso//Rmues/su/Roseu/Rsrceoesuosrc/uVericsde/eVsoi/dsVe itdooes o tso to watwcahwt caaht cv ihad evaio dv eoidone oohn oo wnh othowo fwtoo l dtfoo alfdno ldda n uadnn fduo nludfno ylfdoou ldyro yuoru r Scan this sawsmaswialmlw bmillla ibdll leab.d laIefd .y eIo.fu Iy foh yuao vuhe a havae sv mae saamr stpmahratoprnthpeoh nyooenu ye o yuo u TheT bhlTeah dbeel a bwdlaieldl wefoi lwrl miflol trfhmorr emteh rtlehoeroe pleos o.l opLoisfp.t sLt.ih fLet i tfbhto etth tbeoo mbtto otmto mYo uYr obYuloar udbrel a bidslae sd uiesc iscsue scsucscfeucsleslyfsu sclflouyil llceyod ci.loeidle.d. QR code with your bladbela budlpaewd ueap ruwdp awwridat hrwd yi twohui tyrh ol eyuofrt u lher aflten hfdta thnoad cn tadot tccoha ctacalhlt c ahl la ll Remember to secure the coiled blade with a smart phone. canc ahcnoa vnhe orhv ooevvree orrv toehvrie str hQ tishR iQ sc RQo dRceo cdooend oethn oe nt hr itegh hreit g rahignth dat n adn d threteh rtlehoeroe pleos o liopnos op insne io ncn ooein lc.eo cilo.il. wire tie to ensure it won’t uncoil. watwcahwt cathhtce ht hv itedh eveio dv eridioge hroit g rohignth oytno ou nyro ysuomru sarmr st madreat vrditc edeve.icveic.e. 10 The Wood-Mizer Way Fall/Winter 2016

Description: