Preview Belgian Laces 98

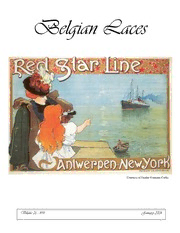

Belgian Laces Courtesy of Denise Fransaer-Corke Volume 26 - #98 January 2004 THE BELGIAN BELGIAN LACES: Official Quarterly Bulletin of RESEARCHERS THE BELGIAN RESEARCHERS Belgian American Belgian American Heritage Association Heritage Association Our principal objective is: Our organization was Keep the Belgian Heritage alive founded in 1976 and in our hearts and in the hearts of our posterity welcomes as members Any person of Belgian President/Newsletter editor: Régine Brindle descent interested in Treasurer/Secretary: Melanie Reynolds Genealogy, History, Past Presidents: Micheline Gaudette, Biography or Heraldry, Pierre Inghels either amateur or Co-Founders: Micheline Gaudette professional. You are invited to and Ardiena Stegen become a member and to participate actively in Send payments and articles to this office:THE BELGIAN RESEARCHERS Régine Brindle - 495 East 5th Street - Peru IN 46970 the work of the society. Tel/Fax:765-473-5667 OR e-mail [email protected] The annual membership *All subscriptions are for the calendar year* fee includes a *New subscribers receive the four issues of the current year, regardless when paid* subscription to the ** The content of the articles is the sole responsibility of those who wrote them** quarterly Deadline for submission of BELGIAN LACES Articles to Belgian Laces: November 30 – February 28 May 31 - August 31 I enclose my remittance for membership in The BELGIAN RESEARCHERS, Inc. NAME: Electronic ONLY : $10 Address: Anywhere City: Paper ONLY: $18 US/Canada State: Zip: Tel: BOTH: US/Canada: $25 Email: Overseas: $30 Make checks payable to The Belgian Researchers, Inc. And mail to 495 East 5th Street Peru IN 46970 Tel/Fax: 765-473-5667 Email: [email protected] Belgian Laces Vol#26-98 January 2004 - 1 - Dear Members, We hope your holiday season was a memorable one and send you all our best wishes for 2004. Guy Gallez and Kathleen Race are continuing their work on the 1870 census and shiplists. The result of their work is being loaded at http://web.wanadoo.be/gallez.nic/index.htm Ancestry.com is extracting the shiplists from 1851 to 1891 and publishing them online. Considering the human factor that makes extraction work less than perfect (illegible names on the shiplists added to the fact that these names were sometimes just written according to how the names sounded rather than the actual spelling), they are going to have to be double-checked against the originals. If you have a subscription to Ancestry.com we would appreciate hearing from you. If you are interested in helping but are not subscribed to Ancestry.com, you might be able to check with your local FHC and veify the extracted work there. I am including an example of this work here so that you will get an idea of how wonderful this new tool is. BUT as with every tool, remember to remain flexible in your use of the information you have and the one you find. For example, Guy asked me to do a look-up for a friend. His friend was looking for “Joseph Fournier, his wife and children, who arrived in New York on April 20, 1854, aboard the ship "Ann Washburn." The information was not quite correct, so I didn’t find the passengers right away. The “Ann Washburn” did not dock in New York on April 20th, 1854. It arrived on May 23rd, 1854. Then the entry found that ‘had to be’ the FOURNIER family was actually listed as FOURINA. A closer look at the original document on Ancestry.com images shows that it was easy to mistake FOURNIER into FOURINA and so there was the correct information. More about this further in this issue. This is the Gargantuan task laid before us. So your help would be most welcomed. If this is something you feel you can devote some time to, please contact us ASAP. Thank You!!! Régine TABLE OF CONTENTS Letter from the Editor/Belgian News p1 Books In Review p2 The Luck of a Belgian Horse Merchant p3 Flanders, a Self Portrait p4 Gas & Glass p6 Birth Records of Strepy-Bracquegnies p9 Pennsylvania & West Virginia Obituaries p11 Boneffe p13 Belgian Emigrants who arrived in 1865 p14 Obituaries Online p17 Researching Online: Ancestry.com Images and Databases p20 Internet Links of Interest p22 The King Baudouin Foundation p23 Issue’s Surname Index p24-25 Belgian Laces Vol#26-98 January 2004 Saints and Soldiers By Jeffrey Scott Hunker down with Captain Winley and the others in the snowy forests of Belgium during the winter of 1944. The Saints of War is an action packed story based on the horrifying historical event known as the "Malmedy Massacre." In mid-December 1944 Hitler's Army blitzkriegs through the Ardennes Forest into Belgium creating the colossal wintertime offensive known as the Battle of the Bulge. Sergeant Daniel Epstein and close friend, Nathan Greer, find themselves held captive with over seventy other American Soldiers in a snow- covered field. Without warning German soldiers open fire on the American Prisoners. Epstein, Greer and a handful of other soldiers are able to escape the massacre by hiding in the nearby woods. Without weapons or food they take on the unforgiving winter trying to find their way back to allied occupied territory. You will learn as much about the battles, historical events and the outcome of that great war as you will about human suffering, rebirth and spiritual growth. Based on the Ryan Little movie - The Film's Web Site: www.saintsandsoldiers.com softcover, 280 pages Rick Steves' Amsterdam, Bruges, and Brussels 2004 By Rick STEVE Check out the city on a seat of a bike; take a self-guided tour of Van Gogh's masterpieces at the Van Gogh Museum; sample the sweet leaf at one of the city's many "coffehouses," and more. With Rick Steves' Amsterdam 2004, travelers can delve into the culture, make friends with the locals, and experience everything Amsterdam has to offer — economically and hassle- free. Completely revised and updated, Rick Steves' Amsterdam 2004 includes color maps, selective coverage of both famous and lesser-known sights; friendly places to eat and sleep; suggested day plans; walking tours and trip itineraries; clear instructions for smooth travel anywhere by car, train, or foot; and Rick's newest "back door" discoveries. America's number one authority on travel to Europe, Rick's time-tested recommendations for safe and enjoyable travel in Europe have been used by millions of Americans in search of their own unique European travel experience. http://www.amazon.com/exec/obidos/tg/detail/-/1566915392/qid=1072993170//ref=sr_8_xs_ap_i1_xgl14/102-0895400-0923315?v=glance&s=books&n=507846 Paperback: 272 pages ; Dimensions (in inches): 0.76 x 8.01 x 4.50 Publisher: Avalon Travel Publishing; (October 2003) Belgian Laces Vol#26-98 January 2004 - 3 - THE LUCK OF A BELGIAN HORSE MERCHANT Submitted and translated by Micheline GAUDETTE Many thanks to the Societe Historique de la Saskatchewan and their coordinator, Mr. Rémy Lapointe for granting permission to use their internet publication “Titanic et chevaux belges” as a base for this story, and to further identify for us the Southeastern part of Saskatchewan and Bellegarde as places where numerous Belgians settled. http://www.societehisto.org/Musee/Recits/Titanic.html The Titanic The Mauretania http://www.skarr.com/titanic http://www.liv.ac.uk/~archives/cunard/ships/mauret1.htm - Cunard Archives It was around 1909, when a friend of Hector DELANOY, convinced him to abandon his life as a farmer in Belgium, and start a business exporting Belgian draft horses to the United States and Canada. Soon, Hector’s business activities brought him to Nebraska, to Deloraine, Brandon, Sainte Amelie in Manitoba and Estevan in Saskatchewan. He traveled back in forth between Belgium and Canada, using New York as a port of transit and is recorded in the 1910, 1912, 1913 New York passenger lists. In 1911, or is it at the beginning of 1912, Hector DELANOY went back to Belgium for unspecified business, but it must have been an urgent matter, since he had to leave before selling all his horses. The unsold horses were left with a businessman in Brandon, Manitoba. Well, the businessman sold Hector's horses and pocketed the money. It’s easy to imagine how upset Hector DELANOY must have been, he hired a lawyer in Brandon, who advised him to return immediately for an appearance in court. It was Hector DELANOY’s lucky day, but he didn’t know it at the time. Hector DELANOY had already made plans to travel back to Brandon, but the ship he had selected was leaving too late for him to make it on time for the court appearance. So, Hector cancelled his reservation on the TITANIC and instead boarded the Mauretania in Liverpool, England on March 23, 1912, arriving safely in NY on March 29, 1912! On the Mauretania passenger list of 29 March 1912, Hector DELANOY is described as 5’6, dark complexion, brown eyes, brown hair, he is 38 years old, his residence in Belgium is in Hooglede where his wife Mary lives, his place of birth is hard to read, but it might be Torhout – a place not far from Hooglede in West Flanders. Many Flemish emigrants from West Flanders to Manitoba can also be found listed on the Mauretania. Hector never recovered his horses or his money. He settled for a while with his family in Sainte-Amelie in Manitoba, but it’s only after the end of World War I that he was able to resume his business activities. In 1928, Hector and his family settled in Sainte Colette, Saskatchewan. We don’t know much about the composition of the Saskatchewan DELANOY family, but from the obituary of Germaine DELANOY, one of his children born in Belgium on April 6, 1909, who passed away in Winnipeg on April 6, 1999, we learned that the name of Hector’s wife was Marie VAN EXEM, that they had at least 7 children: George, Germaine (in religious life Sister Benedicte), Marie, Josephine, Marcel, Jules and Gerard. Sources: LAPOINTE, Richard, La Saskatchewan de A à Z, Régina, La Société historique de la Saskatchewan, 1987, pp. 294-296. New York Passenger Lists at: www.ellisisland.org Obituaries in the Weyburn Review. www.weyburnreview.com/obituaries/1999/9916.html Belgian Laces Vol#26-98 January 2004 " Flanders a Self Portrait " Extra "Knack" Magazine 3 July 2002 Reprinted with permission from Jos De Vuyst on behalf of the Magazine “Knack“editors and author Misjoe Verleyen Submitted by Ed Blomme, [email protected] p. 88-... "... The downtrend really began in 1830, when the new Belgium was created. In one blow the country lost the markets of The Netherlands and the Dutch colonies. And although the new constitution looked like the most liberal of its time, the liberal ideas in reality were an economic disaster. Belgium contracted business agreements whereby custom duties were reduced or eliminated. England, at that time the leading industrial nation, through far reaching mechanization produced much cheaper and took over the Flemish markets. That meant unemployment and of assistance other than charity, there was no discussion... The beginning mechanization eliminated many home workers. In 1833 the first rural flax spinning factories made a half million unemployed. Ten years later one small steam machine of 100 hp employed 750 workers. But they " The Houses were poor, unhealthy and over populated" spun as much thread as 200,000 home spinners... The life expectancy at birth was 35 years, or lower than today in Sierra Leone. Of a thousand children, twenty died before age five.... Eight out of a hundred women giving birth died delivering, that is higher than today in Tadzhikstan. Such numbers are indicative of bad nutrition, bad housing and bad medical care. And it could not be otherwise: almost half the work population- and they were counted from age 10 - were regularly unemployed. Those who did work, put in 70 hours. A workers family of six had to make do for a year with 780 francs. Equated on the basis of food prices that amounts to 464 modern euros of some 9 euros per week ($13.5 Can. or $10 US). That is for 6 people, in a family where the children worked. The figures for child labor are very incomplete, but from other statistics we know that not 45% of children under 10 ever went to school. For men 20 percent could read and write and for women that was 1o percent. Those figures are lower than Afghanistan after the Taliban were driven out. No wonder all medical reports speak of labor children who are " thin and shrunk, Show chlorosis, swollen glands and rickets. The muscles are hardly developed, the belly is swollen, digestion is difficult and is accompanied by sour regurgitations. The child complains about headaches, bellyaches and intestinal colic. It grows slowly and irregularly and the final height is below average."...Children and adults were short on calcium, eggwhite and vitamin D. Lung diseases were daily occurrences and epidemics like typhus and cholera regularly wiped out the weakest. ...Communities demanded police reinforcements to control the mass of beggars and vagrants, because the citizenry was scared, because the "scum" regularly revolted against the protectionist measures demanded by the factory owners. Working conditions demanded investigation. There were investigations that now give us a view of the terrible work conditions. Ironic detail: many of these reports were made by the owner himself "on his word of honor". Thus we read that " the workplace is warmed because cotton requires a temperature of eighteen degrees" and that" accidents only happen to drunk or inattentive workers". The reports and descriptions paint a picture of disturbing hard labor, noisy workplaces, many accidents, punishments and fines "having eaten a sandwich, was laughing, was looking". Workdays of 14 hours were not exceptional. Sunday rest only meant that for that day no pay was given. The unpaid midday break was short and many a time non-existent. Belgian Laces Vol#26-98 January 2004 - 5 - WET CONTINUS About one thing everyone agreed: the treatment of flax was especially unhealthy. Carding produced an enormous amount of dust so "many people got dustlung". Spinning occurred in a hellish temperature. The raw flaw was pulled through a bath of seventy degrees to remove the pectin to make the thread thinner. The new machines, the so-called "wet continus" had not stolen their name. Through ingenious techniques they were capable to do all work between raw cottonwick and thread continuously, as long as the thread remained springy and wet enough. The hot water produced clouds of steam and the female workers were sprayed by the condensed water, that leaked from the ceilings. After work they went home soaking wet. Women especially were chosen for work because they were handier and had to be paid less. That this increased the mortality of women and babies everyone knew. The song "The Continu Girl" of the Ghent singer Henri van Daele (1877-1957) describes it this way : " We spinners of the flax factory/ Are quickly cripple, pale and sick/We're only slaves/ By stinking water overrun/ Often cancer gets us/ A glowing child we don't expect/ More often just a little corpse." Everyone also knew that wages were reduced. Workers were played out against each other. Each spinner had three or four helpers. They had to retie broken thread, sweep up the dust from under the machines, remove the full spools and replace them with empty ones (see photo). The spinner had to pay them herself/himself and it was thus important to keep their wages as low as possible. Preferably a child that did not have to be paid much than an adult. Catholic and liberal politicians thus were right to claim that parents wanted their children to go to the factory. That was the only way to survive. The nineteenth century stayed a century of crises: between 1830 and 1900 one year in four was a year of crisis. Catholics and liberals supported one another to maintain the status quo and that meant that the labor force were surrendered to wage cuts, lock-outs, dirty and underpaid work and hunger. Only at the end of the century would there be slow change. The emergence of unions, co-operatives, credit unions... brought a beginning to a better life. Each famine produced a revolt, each revolt required social change. There came an end to the crudest abuses: wages were no longer permitted to be paid out in the pubs, workers could no longer be forced to shop (expensively) only in owners stores. And specially the "truck system" was prohibited. Under that system the worker was partially paid in useless goods, that he sold back immediately to the boss at reduced prices. Only to get them back the next week as part of his (her) wages.... The introduction of the general right to vote brought workers as representatives to parliament and they would introduce social legislation. That would take almost twenty years... The caption above the street picture reads and the one that interests you is from a popular singer Henri Van Daele: "Our pregnant good ones never hope for a rosy baby..." The whole song is worth quoting for you : "We spinners of the flax fabric Are quickly cripple, pale and sick. We are but slaves By stinking water always soaked And cancer often does us in. Our pregnant good ones never hope To see a rosy baby cope Most often one find a little corpse" There are few folk literatures that express themselves so tragically, I think. Belgian Laces Vol#26-98 January 2004 Gas and Glass: While Natural Fuel Lasted Indiana Industry Prospered (Excerpt) By Herbert R. Hill, Editor of Outdoor Indiana In 1880 Indiana had four glass factories, employing 862 men, women and boys. In 1890 there were 21 Hoosier glass plants, employing 3,010. The U.S. Census shows that the peak was around 1900, when 110 factories employed 13,454. By 1910, when the gas supply was rapidly failing, the factories were down to 44, employing 9,544. These statistics reflect also the absorption of many small plants by the two principal glass manufacturing combines which operated in Indiana, as well as the substitution of mechanized processes for manpower. The Ohio gas fields, having been worked longer, started failing even before 1900. The Indiana glass factories, farther away from Lake Erie white sand than the Buckeyes, were turning to the making of flint glass and container articles instead of concentrating on window and plate glass. There had been no strikes originally despite the use of child labor, the replacement of glass pots by continuous melting tanks, and individual piecework quotas. But in 1893, with “hard times” reducing the income of most families, a strike began against the United States Glass Company, which had units largely in Ohio and Pennsylvania. Of the 62 glass plants operating in Indiana in 1896, records show that 15 bottle-making factories and six fruit jar factories were unionized. The American Flint Glass Workers Union, organized in New York in 1862, had moved Westward to Pittsburgh by 1878. In 1881 it helped to form the American Federation of Labor. By 1899 the AFGWU had 14 Indiana locals—at Albany, Alexandria, Anderson, Elwood, Frankton, Gas City, Marion, Matthews, Muncie and Upland. Membership totaled 393 in Indiana. This union claimed jurisdiction over all pressed glass and bottle glass operators. The younger United Green Glass Workers Association was reorganized in 1896 as the Glass Bottle Blowers Association. It was a practice of the National Manufacturers Association, which included the largest operators in the glass industry, to attempt to play off one union against its rival. In Indiana the Ball Brothers Manufacturing Company negotiated contracts with both the AFGWU and the GBBA. The former held its 1897 national convention in Indianapolis. The latter held national conventions at Marion in 1893 and at Muncie in 1899. Indianapolis for a time was the national or international headquarters for such large unions as the Carpenters, Mine Workers, Teamsters and Typographers. In addition there were numerous smaller unions, many of them also joining the American Federation of Labor. Elwood (later to become widely known as the birthplace of Wendell Willkie) was a town of 400 when it was incorporated in Madison County in 1872. But the discovery of natural gas in 1887 more than doubled the population in one year, and in 1890 it was more than tripled. In 1893 it was 9,031 and in 1899 Elwood had grown to 15,289. The flexibility of gas as a fuel made Elwood a leading manufacturer of tinplate (sheet iron coated with tin), which was widely used in the food canning industry. But in 1898, in addition to the American Sheet and Tin Plate Company, Elwood also had five glass factories, and ~although the gas boom faded at the town after 1903 there is still some glass making there. The George A. Macbeth Glass Company started operations at Pittsburgh, Pennsylvania, in 1874. In 1891 it became a foremost manufacturer of optical glass, not only for individual wearers but for such advanced instruments as telescopes and microscopes. In 1898 Macbeth merged with the Thomas Evans Company. Subsequently Macbeth-Evans operated several plants around Pittsburgh and in Ohio, and also at Elwood and Marion in Indiana. Of Baden ancestry, John J. Klumpp began working for Macbeth just four years after it started Pittsburgh operations. He was only age 12, but child labor was common in numerous American factories at the time. The bright and ambitious lad became so skilled that he was one of the experts who presented a glass-blowing exhibition at the World Fair in Chicago in 1893. In 1898 Klumpp became a Macbeth-Evans plant superintendent in Pittsburgh. In July of 1902 he was transferred to Indiana as superintendent of his company’s operation at Elwood and Marion and also at Toledo, Ohio. The Elwood factory made lampshades, lamp chimneys and lantern globes that were sold throughout the World. In 1910 John Klumpp, Jr., became Elwood superintendent. Only the decline of the natural gas supply interrupted Elwood’s industrial progress. Napoleon Bonaparte had offered a prize of 12,000 francs (a considerable sum then) for a way by which food could be preserved and transported for his armies. In 1810 Nicholas Appert discovered food preserved by sterilization. Then on November 30, 1858, an American tinsmith named John Landis Mason patented a way to seal a glass jar hermetically by screwing a tin lid down on a rubber band around the threaded neck of the jar. Another form of sealing was to pour melted wax in the groove around a tin lid inserted at the top of a glass jar. In 1880 five brothers in upstate New York borrowed $200 from an uncle to organize the Ball Brothers Glass Manufacturing Company at Buffalo. They started making stamped tinware, and also glass containers fortified by wooden jackets for the marketing of oil, kerosene, varnish and other household liquids. In 1884 Mason’s patent expired, and the Balls adapted his threaded neck design to produce glass jars with lids made of zinc and lined with glass. But the enlarged Buffalo factory they had built in 1882 burned to the ground in 1886. At the time Muncie, Indiana, had a population of only 6,000. Then the series of gas well drillings inspired town officials to offer a six-acre tract, five years of free gas, and $7,500 for moving expense if the Ball Brothers Would come to Muncie. Accordingly George A., Lucius L., Frank C., Edmund B. and William C. Ball built a new factory in the Southeastern Belgian Laces Vol#26-98 January 2004 - 7 - part of Muncie. It started manufacturing glass on March 1, 1888, utilizing gas from a big well drilled the preceding September. This glass operation continued until 1962, and the far-reaching Ball operations are still headquartered at Muncie. Charles E. Blue had invented a hand-operated semi-automatic glass-blowing machine at Wheeling, West Virginia, in 1894. The Balls utilized this type of apparatus so extensively that by 1897 they were making 65% of all American glass fruit jars and also had developed foreign markets. They were sold at 5 cents each and shipped in one dozen lots in Michigan pine boxes beginning in 1894. The jars were packaged in corrugated paper cartons beginning in 1902. Ball Brothers absorbed the Fort Wayne Glass Works at Upland in 1898, and the Windfall Glass Company in 1901. Now a major manufacturer, Ball in 1904 bought glass companies at Marion, Fairmount, Converse, Loogootee and Swayzee in Indiana, and at Belleville in Illinois and Coffeyville in Kansas. The year before Michael J. Owens had come out with an improved glass blowing machine in 1903. This and every other manufacturing and fuel improvement was utilized by the Ball Brothers as they continued to expand. From 1902 to 1962 they shipped their fruit jars all over North America in their own freight cars. In 1909 they bought the fruit jar business of the Root Glass Company at Terre Haute. Root thereafter devoted its full time to making Coca Cola bottles. Also acquired by the Balls in 1909 was the Greenfield (Indiana) Fruit Jar and Bottle Company and another plant at Coffeyville. A third factory at Coffeyville was bought in 1912, and as the gas well drillings advanced Southwestward so did Ball, with a new factory at Wichita Falls, Texas. After World War I Ball glass factories were extended into Oklahoma, and then after World War II into Tennessee, North Carolina, Florida and California. These long years of continuous production made Ball glass fruit jars outstanding objects in millions of home canning operations. What might seem more unusual is the way the various versions of the Muncie glass have become “collectible”. Ball jars were made not only in flint (clear), but blue, green, aqua, amber and even pink. Exact color control could not be consistent, so there are varying shades of these colors, and also there have been various designs for the Ball trademark. To help promote the fruit jars the company began in 1909 to issue an annual edition of recipe books that were printed by the thousands. Frank C. Ball also began making regular weather and crop forecasts. As the company prospered, the closely- knit Ball family members were able to support numerous philanthropies throughout the Nation, including Ball State University at Muncie. A more detailed account of Ball family activities was published in the September 1973 issue of Outdoor Indiana. There were at least six other glass manufacturers in Muncie during the gas era. Nearby Albany, Dunkirk, In-galls, Yorktown and Redkey had factories, as did most of the other communities in the Indiana gas belt Counties. [An account of glass manufacturing at New Albany, which is a city on the Ohio River a considerable distance from the town of Albany in Delaware County, was published in the March 1975 issue of Outdoor Indiana.] Increasingly sought by collectors are examples of glass made by the Indiana Tumbler and Goblet Company at Greentown, to the East of Kokomo where Highway 22 forms a T with State Highway 213. The seemingly unexhausted supply of natural gas in Howard County prompted organization of the company on March 2, 1894. Promoters of the village offered not only free gas but also free water, as well as a free site and siding on the Cloverleaf Railroad (which later became the Nickle Plate and now is part of the Norfolk & Western. The proprietor—and also the pot room boss—was David C. Jenkins, Jr., an immigrant from the iron furnace country in Wales. He was an apprentice at the McKee & Brothers glass factory at Pittsburgh, Pennsylvania, and then a superintendent for the Columbia Glass Company at Findlay, Ohio. When that factory was sold to the newly organized United States Glass Company in 1891, Jenkins began scouting for a site for his own operation. He was joined at Greentown by several relatives from Jonesboro, in nearby Grant County. A freight car full of fruit glass cullet was obtained from Findlay. Machinery was moved to Greentown from Cincinnati early in April, and a big new gas well “came in on April 28. From 1894 to 1898 the Green-town factory made flint glass tumblers, jugs, stemmed glassware, bar goods, packer’s goods, jelly jars and tableware. The first product, a stemmed wine glass, was made on June 11, 1894. It resembled McKee’s “Champion” pattern. Soon the factory included five buildings, with eight new pots added to the 10 original pots in the Summer of 1896. It employed 250 men and boys. Charles Miller, Jr. and then Charles E. Beau had the important function of pattern designer at Green-town. Clear, bright blue, amber, canary, clear green, opaque nile green and a form of milk glass was produced from 1896 to 1900. These included cordial, wine, claret, and champagne glasses, ranging from one ounce capacity to 5½ ounces, as well as 8-inch and 9- inch goblets and 9-inch buttermilk goblets. The Spanish-American War brought introduction of patterns honoring Admiral Dewey and Admiral Sampson. When housewives showed they could prefer a food product packed in a decorative or unusual glass container, Greentown began making snuff, honey, mustard and pickle jars. This was expanded into a complete “novelty line” that included all sorts of unusual glass articles sold to food processors, to peddlers, and at County Fairs. Greentown glass attracted such attention at the famed Pittsburgh Exhibit in January of 1898 that in 1899 the Jenkins company was among the 1 8 flint glass factories merged to form the new National Glass Company. The National merger made it the principal rival of the United States Glass Company in the production of American pressed glass tableware. It was an era of corporate amalgamations and the smaller companies must either join or be ruined. Jenkins sold his stock in National in 1900 to organize the Kokomo Glass Manufacturing Company. Thus he continued to be a friend and neighbor of Elwood Haynes, the Hoosier-born automobile inventor who had come to Greentown in 1890 as Belgian Laces Vol#26-98 January 2004 an official of the Indiana Natural Gas Company and then moved to Kokomo in 1892. Two years later he made an historic test run with his gasoline-powered “horseless carriage” at the edge of Kokomo. (See Outdoor Indiana, May, 1976.) When the Kokomo glass factory burned in 1905, it was rebuilt the next year as the D. C. Jenkins Glass Company. A new building was erected to the west of the first Greentown factory in the middle of 1899, with six-ring continuous tanks and three leers (annealing ovens). When Jenkins departed in 1900 William Barns was transferred from Pittsburgh to be Greentown’s superintendent. Also transferred from Lancaster, Ohio, in September of 1900 was Jacob Rosenthal, an innovative research chemist who had learned the glass business in his native Pittsburgh. The Greentown line of transparent and opaque packers receptacles and novelties was again broadened. Rosenthal designed pattern glass, lamps, etc. in unusual colors ranging from deep chocolate to light caramel. Quickly imitators tried to match the new color. Then, in January of 1903, Rosenthal introduced the golden agate ware, which gave the little Indiana plant world-wide fame. “Greentown daisy”, “wild rose” and “Indiana Feather” were augmented by “holly amber”, an opaque layer making it a fine quality bi-textured sensation. Day and night shifts were kept busy around the clock six days each week, the payroll increasing to 300. The orders poured in but bad weather slowed shipments. Articles made during the Winter were stored in sawdust and excelsior at adjoining packing sheds. Greentown was booming! Then, at noon on Saturday, June 13, 1903, a bag of nitrate of soda exploded in the newer part of the factory. A high West wind quickly ignited the entire plant. The factory whistle brought the town’s new Oberchain chemical fire engine. But within minutes all was lost, only the furnace stacks standing above the charred rubble and iron junk. All molds were destroyed. The loss was put at $170,000 (and the U.S. dollar had a much higher real value then). The Indiana Natural gas fields were beginning to yield less. National’s factory at Marietta, Ohio, burned in 1904. The Greentown operation was ended, even though the dying community offered $5,000 to help rebuild the works along West Uncle Tom Street. Rosenthal went to Evansville, Indiana, and then to the Fenton Art Glass Company at Williamstown, West Virginia. But he did not make any of his golden agate glass there in his final years. His career began when he was an 11-year-old apprentice at the Pittsburgh plant of Campbell, Jones & Co., and which had brought him to Anderson, Indiana, in 1880, and then transferred him to Martin’s Ferry, Ohio, in 1890. It had reached its zenith in the three exciting years at Greentown. Some representative pieces of Greentown glass have survived, many in private collections. The biggest and most representative exhibit available to the public is at the Greentown Glass Museum, which was dedicated on June 13, 1970. More than 700 pieces are on display. The museum is open from 10 A.M. to Noon, and from 1 to 5 P.M. Tuesday through Sunday between Memorial Day and Labor Day. The remaining weeks it is open from 1 to 5 P.M. on Saturdays and Sundays. The Museum is small but outstanding.