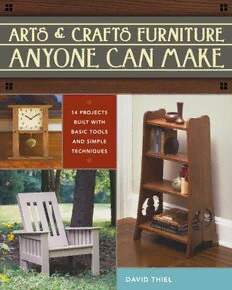

Arts & Crafts Furniture Anyone Can Make PDF

Preview Arts & Crafts Furniture Anyone Can Make

WOODWORKING AA RR GG OO OO DD LL OO OO KK II NN GG AA NN DD SS II MM PP LL EE TT AA RRTTSS && CC RR AA FF TTSS FF UU RR NN II TT UU RR EE SS && CC AA NN YYOONN EE CC AA NN MM AA KK EE RR AA Furniture doesn’t have to be complicated to be good adjusted for size to accomodate the standard poplar, red FF looking. By reducing classic Arts & Crafts furniture designs oak or pine boards readily available at your local home TT SS to their basics, then adding simple, screw-together joinery, center. The boards are sold cut to thickness and width, so anyone can build great-looking furniture. Using basic tools with most of the projects all you need do is cut the pieces to FF UU (jigsaw, miter saw or circular saw and a cordless drill) even length and put them together. RR as a first-time woodworker you can successfully create a Even the finishes used are “off-the-shelf,” relying on NN piece of furniture in a weekend that you’ll proudly display stains, paints and finish coats that are sold in any home II TT for years. center, and are easy to apply. UU 14 PROJECTS Each of the traditional (and some original) designs Pick up some supplies today and build one of these RR in Arts & Crafts Furniture Anyone Can Make have been classic projects. EE BUILT WITH AA BASIC TOOLS NN YY AND SIMPLE OO NN TECHNIQUES EE CC AA NN MM AA KK EE T H I E L Z7617 US $24.99 (CAN $28.99) ISBN-13: 978-1-4403-0673-0 IISSBBNN-1 09: 17-844-013--0464730-37-0673-0 52499 N A E C P U 9 781440 306730 POPULAR WOOD WORKING BOOKS DAVID THIEL ZZ77661177 CCMM AARRTTSS && CCRRAAFFTTSS..iinndddd 11 99//2222//1100 88::4422::1100 AAMM ARTS & CRAFTS FURNITURE ANYONE CAN MAKE DAVID THIEL POPULARR WOODWORKING BOOKS CINCINNATI, OHIO www.popularwoodworking.com ZZ77661177ii__ppgg000011--000077..iinndddd 11 99//2233//1100 44::2222::3366 PPMM READ THIS IMPORTANT SAFETY NOTICE ARTS & CRAFTS FURNITURE ANYONE CAN MAKE. Copyright © 2010 by To prevent accidents, keep safety in David Thiel. Printed and bound in China. All rights reserved. No part mind while you work. Use the safety of this book may be reproduced in any form or by any electronic or guards installed on power equipment; mechanical means including information storage and retrieval systems without permission in writing from the publisher, except by a reviewer, they are for your protection. who may quote brief passages in a review. Published by Popular When working on power equip- Woodworking Books, an imprint of F+W Media, Inc., 4700 East Gal- ment, keep fingers away from saw braith Road, Cincinnati, Ohio, 45236. (800) 289-0963 First edition. blades, wear safety goggles to prevent injuries from flying wood chips and Distributed in Canada by Fraser Direct sawdust, wear hearing protection and 100 Armstrong Avenue consider installing a dust vacuum to Georgetown, Ontario L7G 5S4 reduce the amount of airborne sawdust Canada in your woodshop. Don’t wear loose clothing, such as Distributed in the U.K and Europe by F+W Media International Brunel House neckties or shirts with loose sleeves, Newton Abbot or jewelry, such as rings, necklaces Devon TQ12 4PU or bracelets, when working on power England equipment. Tie back long hair to pre- Tel: (+44) 1626 323200 vent it from getting caught in your Fax: (+44) 1626 323319 equipment. E-mail: [email protected] People who are sensitive to certain chemicals should check the chemical Distributed in Australia by Capricorn Link content of any product before using it. P.O. Box 704 Due to the variability of local condi- Windsor, NSW 2756 Australia tions, construction materials, skill levels, etc., neither the author nor Popular Visit our Web site at www.popularwoodworking.com. Woodworking Books assumes any responsibility for any accidents, inju- Other fine Popular Woodworking Books are available ries, damages or other losses incurred from your local bookstore or direct from the publisher. resulting from the material presented in this book. 14 13 12 11 10 5 4 3 2 1 The authors and editors who com- piled this book have tried to make Library of Congress Cataloging-in-Publication Data the contents as accurate and correct Thiel, David, 1962- as possible. Plans, illustrations, pho- Arts & crafts furniture anyne can make / by David Thiel -- 1st ed. tographs and text have been carefully p. cm. checked. All instructions, plans and ISBN 978-1-4403-0673-0 (pbk : alk. paper) projects should be carefully read, stud- 1. Furniture making--Amateurs’ manuals. 2. Woodwork--Ama- ied and understood before beginning teurs’ manuals. I. Title. II. Title: Arts and crafts anyone can make construction. TT195.T55 2010 Prices listed for supplies and equip- 684’.08--dc22 ment were current at the time of publi- 2010034810 cation and are subject to change. SENIOR EDITOR: Jim Stack DESIGNER: Brian Roeth PRODUCTION COORDINATOR: Mark Griffin METRIC CONVERSION CHART PHOTOGRAPHER: David Thiel, Al Parrish (project openers) TO CONVERT TO MULTIPLY BY ILLUSTRATOR: Jim Stack Inches . . . . . . Centimeters . . . . . 2.54 Centimeters . . . . .Inches . . . . . . . . . 0.4 Feet . . . . . . . . Centimeters . . . . . 30.5 Centimeters . . . . . Feet . . . . . . . . 0.03 Yards . . . . . . . . . .Meters . . . . . . . . 0.9 Meters . . . . . . . . . Yards . . . . . . . . . 1.1 ZZ77661177ii__ppgg000011--000077..iinndddd 22 99//2233//1100 44::2222::4433 PPMM ABOUT THE AUTHOR ACKNOWLEDGEMENTS David started woodworking at an early age by As an author, whenever I refer to “my” book I using the drill press in his father’s woodwork- always feel uncomfortable. While it certainly is ing buisness to drill holes in blocks of scrap my book, there are always others who deserve wood on Saturdays. He eventually started recognition for its creation. actually building recognizable items as he First is to my family. My wife, Patti and all worked with and for his father through high five kids, Dillon, Danielle, Shannon, Ben and school and college. Zach, who put up with my disappearing into A degree in English Literature shifted his the garage to build something. There were too sights to journalism, but he was never far away many weekends lost to “the book” that could from woodworking, eventually opening his have been family time. own custom woodworking shop for a few years. I’ll again thank Patti, first for her love In the mid-90’s he found a blending of — then for her design direction and input on both worlds, going to work for Popular all the projects. Even if it was just a comforting Woodworking magazine as an editor, builder “that looks great” (and there were many more and tool reviewer. in-depth discussions), her support through the He took on a side job as host of the DIY project was extremely important; so I dedicate Network’s Tools & Techniques (still playing this book to her. Thank you, babe. somewhere out in space), and in the begin- Thanks to Jim Stack, my editor, who I’ve ning of the new millenia he started working at known for over thirty years, in a few differ- his current position as Executive Editor with ent roles. His patience and quiet support (and Popular Woodworking Books. excellent illustration work) kept me from chew- David lives in Cincinnati, Ohio and still ing my nails too far. enjoys checking out a new tool, whenever And to my designer Brian Roeth, again for possible. You can visit his web site at www. patience and for allowing me to gently nudge the theshopofthecrafters.com. design, even though he knew where he was going. Thanks also to my e-mail critic, Jeff Korbman, for his instightful read of the nearly- finished manuscript. A big thank you to Steve and Kit for letting us use “the house of many rooms” as back- ground for the opening photos. And lastly, to my readers over the years, both with Popular Woodworking Magazine, and in ear- lier books. Your feedback, both positive and “cor- rective” gave me the recognition of the need for a book that offered time- and material-consious woodworking projects that still looked good. I hope this book serves as a thank you. ZZ77661177ii__ppgg000011--000077..iinndddd 33 99//2233//1100 44::2222::4455 PPMM CONTENTS INTRODUCTION 6 1 THE SECRET TO EASY FURNITURE MAKING 8 2 USING THE TOOLS 12 3 HORIZONTAL MIRROR 18 4 GAMBLE HOUSE MIRROR 26 5 OUTDOOR TABORET 34 6 PINE BOOKCASE 44 7 OUTDOOR TABLE 52 8 MANTEL CLOCK 62 9 LIMBERT CHAIR 74 10 ALL-WEATHER MORRIS CHAIR 86 11 STICKLEY SPLAYED TABORET 100 12 ENTRY HALL BENCH 108 13 HALL TREE 116 14 MACKINTOSH TABORET 130 15 LIMBERT BOOKCASE 142 16 HILL HOUSE TABLE 150 ZZ77661177ii__ppgg000011--000077..iinndddd 44 99//2233//1100 44::2222::4455 PPMM ZZ77661177ii__ppgg000011--000077..iinndddd 55 99//2233//1100 44::2222::5511 PPMM INTRODUCTION It was 1995 when I first started appreciating Arts & Crafts furniture for its simple lines and honest strength. One of the foremost pieces in this style was the Morris chair (in a dizzying array of designs from known and unknown designers). These chairs held features that I ap- preciated. Strong, comfortable (for reading or relaxing), ample seat area for one-and-a-half people and generally not all that complicated in design — but for the mortise-and-tenon construction. So I built a couple. They lived up to my expectations, looked good and made me proud. Then fall entered my little part of south- west Ohio and I wanted to spend more time on my deck enjoying the crisp air and the beautiful colors (along with a good cigar and a nice glass of wine). And I wanted to be comfortable — like in my Morris chair. While white oak is actually a pretty sturdy outdoor wood, I wasn’t in the mood to drag (let alone leave) my Morris chair outside. What to do? Adirondack chairs for outdoor use, (both in plan form and for sale, completed) were in abundance. But I preferred the Morris, and out- door plans were sorely missing for them. But hey, I’m a woodworker, so this was a challenge that sounded like fun. I started with the over- all dimensions from one of Gus Stickley’s slant-arm chairs (that I found particularly comfortable) and tried to figure out how to build one using 1x pine from the home center store. I’ve built a few variations of that outdoor Morris since then, (each better, I hope) but they all sit well, are easy to make (just a screw gun, miter saw and a jigsaw) and with a few cans of spray paint, I have to say they look pretty good! Why would I, as a woodworker, buy lumber from the home center stores? Couldn’t I find better quality wood at a better price, that only required a little preparation? That “preparation” (kiln dry, face, plane and dimension the lumber) means access to rough lumber, and a jointer, planer and table saw. Not all readers who would like to build 6 ZZ77661177ii__ppgg000011--000077..iinndddd 66 99//2233//1100 44::2222::5522 PPMM furniture have access to the materials or tools. But almost everyone has access to a home center store. Even with the added expense, my Morris chair cost less than $75 for lumber. And today I can build one in under three hours, because I don’t have to prepare the lumber. A fair trade in my book (which happens to be the one in your hands…). As a woodworking editor, I frequently need to remember that not everyone building a project has the same experience, space or tools that I have. Many readers don’t even want to be a woodworker. They just like to build an occasional project for around the house. They’re not worried about mortise-and-tenon joinery and they don’t own a thickness planer. These are the folks that I can help: The Weekend Woodworking Warrior. Each of the projects in this book have been designed to use a mini- mum of tools. I’ve made some allowances for using a benchtop table saw, but most could be built with a jigsaw, miter saw, screws and glue. I’ve re-designed some classic furniture pieces (and designed a couple from scratch) to use only joinery that can be mastered in a couple of hours: biscuit joints, dowels, pocket screws and just plain screws. The wood I’ve used for each project (dimensional lumber in red oak, birch, poplar or pine) is available at Lowe’s or Home Depot. I’ve also added some plywood to avoid having to glue up solid panels. Gus would have done it! With some judicious staining, and painting, I feel that the designs retain much of the charm of the originals, while making a finished piece of furniture accessible to even the most inexperienced woodworker. I hope you enjoy the convenience of these modified Arts & Crafts classics, and also enjoy many years of comfort and use of all that you build. — David Thiel 7 ZZ77661177ii__ppgg000011--000077..iinndddd 77 99//2233//1100 44::2222::5555 PPMM 8 ZZ77661177ii__ppgg000088--001177..iinndddd 88 99//2233//1100 44::2233::0066 PPMM T H E S E C R E T 1 T O E A S Y F U R N I T U R E M A K I N G When a woodworker looks at a completed piece of furniture, they almost automatically start decon- structing it in their head. Are the shelves of a book- case captured by a groove cut in the sides? Do the stretchers on a table have tenons that are mortised into the legs? These are the details of furniture mak- ing that make woodworking a “skill”. And there’s nothing wrong with that. But what if you drill a recessed hole in the leg, drive a screw into the stretcher and glue a wooden plug into the hole? The strength created by the screw joint is still good. The plug will be sanded flush and may show a little. But “expressed joinery” is part of the culture of Arts & Crafts furniture. This may be stretching a little, but what is gained is a serviceable replacement for hours of work, and possibly years of experience. Sound good? Follow me... 9 ZZ77661177ii__ppgg000088--001177..iinndddd 99 99//2233//1100 44::2233::1100 PPMM