AP1000 Pre-Construction Safety Report (UKP-GW-GL-732) PDF

Preview AP1000 Pre-Construction Safety Report (UKP-GW-GL-732)

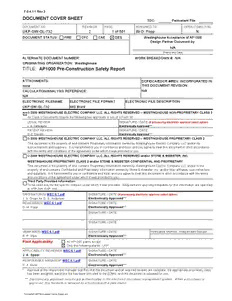

F-3.4.1-1 Rev 3 DOCUMENT COVER SHEET TDC: Permanent File: DOCUMENT NO. REVISION PAGE ASSIGNED TO OPEN ITEMS (Y/N) UKP-GW-GL-732 2 1 of 501 W-D. Popp N DOCUMENT STATUS: PRE CFC CAE DES Westinghouse Acceptance of AP1000 Design Partner Document by: N/A (Name and Date) ALTERNATE DOCUMENT NUMBER: WORK BREAKDOWN #: N/A ORIGINATING ORGANIZATION: Westinghouse TITLE: AP1000 Pre-Construction Safety Report ATTACHMENTS: DCP/DCA/EDCR #/REV. INCORPORATED IN none THIS DOCUMENT REVISION: CALCULATION/ANALYSIS REFERENCE: N/A N/A ELECTRONIC FILENAME ELECTRONIC FILE FORMAT ELECTRONIC FILE DESCRIPTION UKP-GW-GL-732 M/S Word © 2009 WESTINGHOUSE ELECTRIC COMPANY LLC, ALL RIGHTS RESERVED – WESTINGHOUSE NON-PROPRIETARY CLASS 3 All Class 3 Documents require the following two approvals in lieu of a Form 36. LEGAL REVIEW SIGNATURE / DATE (If processing electronic approval select option) L. A. Campagna Electronically Approved*** PATENT REVIEW SIGNATURE / DATE D. E. Ekeroth Electronically Approved*** © 2009 WESTINGHOUSE ELECTRIC COMPANY LLC, ALL RIGHTS RESERVED – WESTINGHOUSE PROPRIETARY CLASS 2 This document is the property of and contains Proprietary Information owned by Westinghouse Electric Company LLC and/or its subcontractors and suppliers. It is transmitted to you in confidence and trust, and you agree to treat this document in strict accordance with the terms and conditions of the agreement under which it was provided to you. © 2009 WESTINGHOUSE ELECTRIC COMPANY LLC, ALL RIGHTS RESERVED and/or STONE & WEBSTER, INC. WESTINGHOUSE PROPRIETARY CLASS 2 and/or STONE & WEBSTER CONFIDENTIAL AND PROPRIETARY This document is the property of and contains Proprietary Information owned by Westinghouse Electric Company LLC and/or is the property of and contains Confidential and Proprietary Information owned by Stone & Webster, Inc. and/or their affiliates, subcontractors and suppliers. It is transmitted to you in confidence and trust, and you agree to treat this document in strict accordance with the terms and conditions of the agreement under which it was provided to you. Third Party Provided Information To be used only for the specific contract under which it was provided. Requirements and responsibilities for this information are specified in APP-GW-GAP-104. ORIGINATOR(S) WEC 6.1.pdf SIGNATURE / DATE (If processing electronic approval select option) J. A. Green for G. S. Anderson Electronically Approved*** REVIEWER(S) WEC 6.1.pdf SIGNATURE / DATE D. M. Popp Electronically Approved*** SIGNATURE / DATE SIGNATURE / DATE VERIFIER(S) WEC 6.1.pdf SIGNATURE / DATE Verification Method: Independent Review R. P. Vijuk Electronically Approved*** Plant Applicability: All AP1000 plants except: Only the following plants: UKP APPLICABILITY REVIEWER WEC 6.1.pdf SIGNATURE / DATE J. A. Speer Electronically Approved*** RESPONSIBLE MANAGER* WEC 6.1.pdf SIGNATURE / DATE P. A. Russ Electronically Approved*** * Approval of the responsible manager signifies that the document and all required reviews are complete, the appropriate proprietary class has been assigned, electronic file has been provided to the EDMS, and the document is released for use. *** Electronically approved records are authenticated in the electronic document management system. When a document is approved, this footnote is replaced by a footnote with a date stamp. Forms/NS-NPP/Document Cover Sheet.doc UKP-GW-GL-732 Revision 2 AP1000 Pre-Construction Safety Report AP1000 Pre-Construction Safety Report REVISION HISTORY Report Description of Change Revision 1 This document contains numerous editorial improvements and referenced reports revision updates from Revision 0. Revision 2 The Pre-Construction Safety Report (PCSR), Revision 2 has been completely restructured to accommodate general NII comments on claims, arguments and evidence. The PCSR also includes a summary of new documents, External Hazards, a revised European DCD and a revised Environment Report. The PCSR also refers to the results of new evaluations, submitted in documents: AP1000 Equivalency / Maturity Study of the U.S. Codes and Standards, AP1000 UK Safety Categorization and Classification of Structures Systems and Components, and AP1000 UK Safety Categorization and Classification Methodology. UKP-GW-GL-732 i Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS Section Title Page REVISION HISTORY i TABLE OF CONTENTS ii ABBREVIATIONS ABB 1-1 1.0 INTRODUCTION 1-1 1.1 Purpose of the Safety Report 1-1 1.1.1 Background of the Generic Design Assessment Process 1-1 1.1.2 Structure of the Generic Design Assessment Process 1-2 1.1.3 Purpose of the Pre-Construction Safety Report in GDA 1-2 1.2 Development of the AP1000 Safety Report 1-2 1.2.1 AP1000 Design Basis 1-2 1.2.2 UK Regulatory Regime 1-4 1.2.3 AP1000 Safety Report 1-4 1.3 GDA Documentation Structure and Interfaces 1-6 1.3.1 AP1000 Generic PCSR 1-6 1.3.2 Topic Reports Supporting the AP1000 Safety Case 1-7 1.3.3 Supporting Technical Documentation to the AP1000 Safety Case 1-9 1.4 Generic PCSR: Structure and Content 1-10 1.5 Quality Assurance Process followed during the Production of the Generic Pre-Construction Safety Report 1-12 1.5.1 Stakeholders in the PCSR 1-12 1.5.2 Quality Assurance associated with Westinghouse Design and Technical Information 1-13 1.5.3 Safety Case Review Process 1-14 1.6 Conclusion 1-14 2.0 GENERAL PLANT DESCRIPTION 2-1 2.1 Introduction 2-1 2.2 Evolution of the AP1000 Design 2-1 2.3 Basic Design and Technical Characteristics 2-2 2.4 Layout of the Main Civil Structures 2-3 2.4.1 Site Characteristics 2-3 2.4.2 Site Plan 2-4 UKP-GW-GL-732 ii Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 2.4.3 Plant Arrangement 2-4 2.4.4 Containment/Shield Building 2-5 2.5 Plant Arrangement Considerations 2-8 2.6 Proven Components and Technology in the AP1000 Design 2-9 2.7 Conclusion 2-10 3.0 GENERIC SITE CHARACTERISTICS 3-1 3.1 Introduction 3-1 3.2 Site Design Parameters 3-1 3.2.1 Meteorology 3-2 3.2.2 Geology and Hydrogeology 3-3 3.2.3 Hydrology 3-3 3.3 Strategic Siting Assessment (SSA) 3-4 3.3.1 Exclusionary Criteria 3-4 3.3.2 Discretionary Criteria 3-5 3.3.3 Proximity to Hazardous Industrial Facilities and Operations (D3) 3-7 3.3.4 Proximity Access to Suitable Sources of Cooling (D10) 3-7 3.4 Other Site Specific Criteria 3-8 3.5 Monitoring of Site Specific Parameters 3-9 3.6 Conclusion 3-9 4.0 SAFETY ASPECTS OF DESIGN 4-1 4.1 Introduction 4-1 4.2 Use of Safety Functions 4-3 4.2.1 Key Safety Functions 4-3 4.2.2 Categorisation of Safety Functions 4-5 4.3 Identification of Design Requirements for Safety 4-7 4.3.1 Identification of Design Requirements associated with Normal Operation 4-7 4.3.2 Identification of Design Requirements associated with Fault Conditions 4-7 4.4 Approach to Hazards 4-8 4.4.1 Assessment of Internal Hazards 4-8 4.4.2 Assessment of External Hazards 4-24 UKP-GW-GL-732 iii Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 4.5 Engineering Substantiation 4-38 4.5.1 Safety Classification of Systems, Structures and Components 4-38 4.5.2 Seismic Categorisation of Systems, Structures and Components 4-41 4.5.3 Incredibility of Failure Issues 4-42 4.5.4 Application of Codes and Standards 4-43 4.5.5 Environmental Qualification of Systems, Structures and Components 4-43 4.6 Conclusion 4-44 5.0 SAFETY ASSESSMENT APPROACH 5-1 5.1 Introduction 5-1 5.2 Fault Schedule 5-1 5.2.1 Introduction 5-1 5.2.2 Identification of Initiating Events 5-2 5.2.3 Initiating Event Frequencies 5-3 5.2.4 Provision of Safety Measures 5-3 5.3 Design Basis Analysis 5-5 5.3.1 Introduction 5-5 5.3.2 Selection of Representative Sequences 5-5 5.3.3 Thermal-Hydraulic Analysis Approach 5-5 5.3.4 Radiological Analysis Approach 5-14 5.3.5 Results 5-15 5.3.6 DBA Conclusions 5-30 5.4 Probabilistic Risk Analysis 5-31 5.4.1 Introduction 5-31 5.4.2 Selection of Initiating Events 5-31 5.4.3 Analysis Approach 5-32 5.4.4 Results 5-34 5.4.4.7 Important Common Causes/Modes 5-41 5.4.4.8 Dependence on Operator Action 5-42 5.4.4.9 Treatment of Equipment Reliability 5-42 5.4.4.10 Shutdown PRA 5-43 UKP-GW-GL-732 iv Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 5.4.5 Sensitivity Analysis 5-43 5.4.6 PRA Conclusions 5-44 5.5 Severe Accident Analysis 5-45 5.5.1 Introduction 5-45 5.5.2 Identification of Plant Damage States 5-46 5.5.3 Construction of the Containment Event Tree 5-47 5.5.4 Quantification of Release Frequencies 5-50 5.5.5 Results 5-51 5.5.6 Severe Accident Analysis Conclusions 5-51 5.6 Safety Analysis Conclusions 5-52 6.0 DESCRIPTION OF PLANT SYSTEMS AND THEIR CONFORMANCE WITH DESIGN REQUIREMENTS 6-1 6.1 Introduction 6-1 6.2 Primary Systems General Operation 6-1 6.3 Reactor 6-3 6.3.1 Reactor System 6-3 6.3.2 Reactor Coolant System 6-18 6.4 Engineered Safety Features 6-25 6.4.1 Containment System 6-27 6.4.2 Containment Isolation System 6-27 6.4.3 Passive Containment Cooling System 6-29 6.4.4 Main Control Room Emergency Habitability System 6-32 6.4.5 Passive Core Cooling System 6-33 6.5 Auxiliary Systems 6-42 6.5.1 Chemical and Volume Control System 6-43 6.5.2 Containment Hydrogen Control System 6-50 6.5.3 Normal Residual Heat Removal System 6-52 6.5.4 Communication System 6-55 6.5.5 Component Cooling Water System 6-55 6.5.6 Compressed and Instrument Air System 6-57 6.5.7 Containment Leak Rate Test System 6-57 UKP-GW-GL-732 v Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 6.5.8 Demineralised Water Transfer and Storage System 6-58 6.5.9 Demineralised Water Treatment System 6-58 6.5.10 Fire Protection System 6-58 6.5.11 Gaseous Radwaste System 6-59 6.5.12 Liquid Radwaste System 6-61 6.5.13 Mechanical Handling System 6-63 6.5.14 Plant Gas System 6-66 6.5.15 Potable Water System 6-66 6.5.16 Primary Sampling System 6-67 6.5.17 Radiation Monitoring System 6-69 6.5.18 Radioactive Waste Drain System 6-70 6.5.19 Sanitary Drainage System 6-71 6.5.20 Secondary Sampling System 6-71 6.5.21 Service Water System 6-71 6.5.22 Solid Radwaste System 6-72 6.5.23 Spent Fuel Pool Cooling System 6-73 6.5.24 Standby Diesel Fuel Oil System 6-75 6.5.25 Turbine Building Closed Cooling Water System 6-76 6.5.26 Turbine Island Vents, Drains and Relief System 6-76 6.5.27 Waste Water System 6-77 6.6 Steam and Power Conversion Systems 6-77 6.6.1 Feed and Condensate System 6-77 6.6.2 Main Steam System 6-81 6.6.3 Turbine Bypass System 6-83 6.6.4 Main Turbine-Generator 6-84 6.6.5 Moisture Separator Reheaters 6-85 6.6.6 Condenser Air Removal System 6-86 6.6.7 Gland Seal System 6-87 6.6.8 Main Condenser 6-88 6.6.9 Steam Generator Blowdown System 6-89 UKP-GW-GL-732 vi Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 6.6.10 Circulating Water System 6-91 6.6.11 Auxiliary Steam Supply System 6-92 6.6.12 Turbine Island Chemical Feed System 6-93 6.6.13 Condensate Polishing System 6-93 6.7 Instrumentation and Control 6-93 6.7.1 Description 6-93 6.7.2 Design Requirements 6-94 6.7.3 Substantiation 6-94 6.8 Electrical Power Systems 6-102 6.8.1 Class 1E dc and Uninterruptible Power Supply System 6-103 6.8.2 Non-Class 1E dc and Uninterruptible Power Supply System 6-105 6.8.3 Main ac Power System 6-106 6.8.4 Onsite Standby Power System 6-107 6.8.5 Cathodic Protection System 6-108 6.8.6 Excitation and Voltage Regulation System 6-108 6.8.7 Grounding and Lightning Protection System 6-109 6.8.8 Lighting System 6-109 6.8.9 Plant Security System 6-109 6.8.10 Special Process Heat Tracing System 6-109 6.9 HVAC Systems 6-109 6.9.1 Annex/Auxiliary Building Nonradioactive Ventilation System 6-110 6.9.2 Central Chilled Water System 6-110 6.9.3 Containment Air Filtration System 6-111 6.9.4 Containment Recirculation Cooling System 6-112 6.9.5 Diesel Generator Building Ventilation System 6-112 6.9.6 Health Physics and Hot Machine Shop HVAC System 6-113 6.9.7 Hot Water Heating System 6-114 6.9.8 Nuclear Island Nonradioactive Ventilation System 6-114 6.9.9 Radiologically Controlled Area Ventilation System 6-120 6.9.10 Radwaste Building HVAC System 6-120 UKP-GW-GL-732 vii Revision 2 AP1000 Pre-Construction Safety Report TABLE OF CONTENTS (cont.) Section Title Page 6.9.11 Turbine Island Building Ventilation System 6-121 6.10 Conclusion 6-122 6.11 References 6-123 7.0 DESCRIPTION OF THE CIVIL WORKS AND STRUCTURES AND THEIR DESIGN REQUIREMENTS FOR SAFETY 7-1 7.1 Introduction 7-1 7.2 Nuclear Island Structures 7-1 7.2.1 Design Requirements for Safety during Normal Operations 7-5 7.2.2 Design Requirements for Safety during Fault Conditions 7-5 7.2.3 Internal Hazards 7-6 7.2.4 External Hazards 7-6 7.3 Non-Nuclear Island Structures 7-6 7.4 Conclusion 7-7 8.0 ALARP ASSESSMENT OF THE DESIGN OF THE AP1000 8-1 8.1 Introduction 8-1 8.1.1 Purpose 8-1 8.1.2 Scope 8-1 8.1.3 Content 8-2 8.2 Use of Relevant Good Practice 8-3 8.2.1 Application of Standards Defining Good Practice 8-3 8.2.2 Relevant Good Practice in Design 8-10 8.3 Use of the PRA Risk Model to Inform Design 8-16 8.3.1 Background to the PRA Work 8-16 8.3.2 System and Function Reliability 8-17 8.3.3 Human Reliability 8-17 8.3.4 Core Damage Frequency for Internal Initiating Events at Power 8-18 8.3.5 Large Release Frequency for Internal Initiating Events at Power 8-19 8.3.6 Core Damage Frequency and Large Release Frequency for Plant Initiating Events while Shutdown 8-20 8.3.7 Review of Defence in Depth Systems 8-21 UKP-GW-GL-732 viii Revision 2