4-Achs K25 H SPE 4 4-axle K25 H SPE 4 PDF

Preview 4-Achs K25 H SPE 4 4-axle K25 H SPE 4

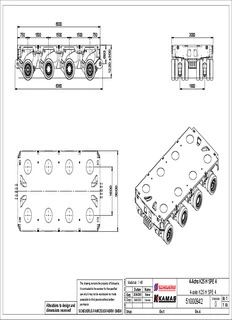

6000 750 1500 1500 1500 750 3000 3 0 9 0 6 3 – 0 2 2 1 6360 1800 0 0 0 0 8 0 1 3 Adilmteerantsioionnss t ore dseesrvigend !and SpauITCtecs hiHcesrisme Ee osdinnssUrtslaiyrbEiuwo.lIesntRi nt .metgLod a Er tyetho- minrF tdoahA tiep nbH esrere Rst chroeZeenpi Evspre oUrwrod iGpfutohecrFore ttuAdyht e nBow ofs rRrSpit temIceKchnaie fdiGueeedMrleB.H Copyright: DIN 34 / ISO 16016 UGGMreeszpap.r(cid:223)r..st(cid:1)(cid:1)aD(cid:2)(cid:5)b(cid:3)(cid:3)(cid:4)a(cid:4)(cid:7)(cid:5)(cid:5)(cid:7)t(cid:7)(cid:3)(cid:3)u(cid:7)(cid:1)(cid:1)(cid:1)(cid:4)(cid:4)m(cid:2)(cid:6)(cid:6)(cid:3)(cid:2)(cid:2)(cid:4) N(cid:13)(cid:8)(cid:14)(cid:9)a(cid:11)(cid:10)(cid:7)(cid:7)m(cid:11)(cid:7)(cid:11)(cid:7)(cid:12)(cid:12)e(cid:9)(cid:9) Ers.f. 51440--A0ac0xEhl9erss 4. KdK.222 5 5 HH SSPPEVEe 0r44sion B1l.B1l. Technical Data Sheet 4-axle K25 H SPE 4 (Type K2504HSP4E) Technical data Drawing no. 51000942 Travel speed 15 km/h **) 10 km/h **) 5 km/h **) 3 km/h **) 1 km/h **) Payload-max. [kg] *) 98.100 108.900 129.700 129.700 163.300 Deadweight-approx. [kg] 16.700 Total weight [kg] 114.800 125.600 146.400 146.400 180.000 Axle load - admissible [kg] 4x 28.700 31.400 36.600 36.600 45.000 Platform dimensions (L x W) 6000 mm x 3000 mm Coupling length 6.000 mm Platform height-driving pos. (loaded) 1.220 mm Axle compensation +/- 300 mm Platform height-lowered (loaded) 920 mm Type of steering/steering angle slewing ring - hydraulic motor / max. +/- 140(cid:176) No. of wheel bogies - total/braked 8 / 4 No. of wheel bogies - driven 4 Tractive force/braking force ***) 320 kN / 174 kN Brake system equipped with a dual circuit brake system Travel speed-driven up to 15 km/h ****) Tyres 32 x 215/75 R17,5 - 135/133J Operating temperature -20 (cid:176)C up to +40 (cid:176)C Oil volume - *) Payload without deadweight of PPU or other accessories **) Attention! Tyre pressure has to be increased up to 12,6 bar ***) Attention-if the traction force is bigger than the parking brake force, please consider the instructions! ****) Depending on PPU - design and combination Author : Kr(cid:228)mer, Axel Page 1 of 1 11.06.2013 Subject to technical changes 51000942-2 SCHEUERLE Fahrzeugfabrik GmbH - KAMAG Transporttechnik GmbH & Co. KG Technical specification K 25 H SP E (Type K 250x H SPy E) Vehicle design: • The K 25 H SP E self propelled platform trailer can be used as a single unit or in combination with other units. These combinations can consist of self propelled units of the same kind or of K 25 H platform trailers. • The K 25 H SP E platform trailer is a member of the K 25 H series. Adequate numbers of driven pendulum axles in the 3-, 4-, 6- and 8-axle platforms are installed to provide the propelling resp. drive function. • The load carrying capability of the standard pendulum axles and the hydrostatic power components are combined into the propelled resp. driven pendulum axles. Included in the vehicle: • Open frame design, produced as centre part in 2-, 3-, 4-, 6- or 8-axle platform trailer made from high-strength fine-grained steel. • Lamellar bolt coupling on both ends with a mechanical coupling pin on one end. • Swivel bolster securing point at distance of 1500 mm, above the axle lines. • Drill hole pattern integrated on both sides of the platform for mechanical connection of coupling blocks for 3- and 4-axle file combinations. • The platform trailers can be coupled behind each other or side-by-side. The SP E PPU can be coupled on the front or rear platform end or, with additional accessories, on top front or rear side. • Attachment points are situated on both longitudinal sides between each axle. They are able to take 200 kN horizontal or vertical lashing force. • The areas above the track rods are equipped with removable aluminium cover plates. • An electronically controlled hydraulic all-wheel steering system is implemented. Each wheel bogie is equipped with a hydraulically driven bevel wheel interfering with the tooth wheel of the table roller bearing which is fixed to the vehicle frame. An infinitely variable steering angle up to + / - 140(cid:176) is possible. Each wheel bogie is controlled individually. The nominal-actual angle comparison is based on values of a precision potentiometer interfering with the tooth wheel of the table roller bearing. The steering computer is adjusting the angle of the wheel bogies in accordance with pre defined steering programmes respective geometries. • Mechanical track indicators are fitted on all axles and steering plates. • Zero-maintenance swivel bearings for pendulum axles. • Swing arm bearings equipped with grease lubricated spherical bearings which are easy to maintain. • All lubrication points are equipped with lubrication nipples for manual lubrication. • All running gears can be lifted individually, the running gear can be mechanically locked (in the retracted position using axle pins, 2 pins per axle line included) and hydraulically shut-off. All driven pendulum axles have to be lifted in the towed mode. • The pendulum axles with brake are equipped with AGS (automatic brake adjuster). • Two circuit pneumatic brake system. Protection valve for actuated parking brake installed. • The connection of the brake system via fast-locking couplings installed at the front and rear left and right side. • Hydraulic axle compensation and platform lifting system. • Possibility for activating or disconnecting the hydraulic suspension system between each axle line. • Line break protection system (single-circuit version) in hydraulic suspension system. • Connection possibility for hydraulic steering by hydraulic couplings installed in all four corners of the vehicle. Autor: D. Zavcer Page 1 of 2 Edition: 23.07.2013 Variation: 0 Subject to technical modifications Scheuerle Fahrzeugfabrik GmbH - KAMAG Transporttechnik GmbH & Co KG Technical specification K 25 H SP E (Type K 250x H SPy E) • The connection of the hydraulic suspension system via fast-locking couplings installed in all four corners. • Side marking lamps installed in 3000 mm spacing. • 24 Volt lighting system. • Connection possibility for light and special functions by a 16-pin socket installed on all corners of the vehicle. • All control levers installed pointing towards the exterior of the vehicle. • Vehicle is equipped with operating and warning signs and markings required by law. • Contour marking of the vehicle in accordance with directive ECE R 104. • Corrosion protection in accordance with internal specification. • Platform inside and running gears are coated in RAL 7016 (grey) colour. • The coat of the frame top and frame side areas is coated in customer chosen colour out of the internal colour chart. • Rims and wheel hubs in silver colour. • Each platform trailer unit is equipped with a set end to end coupling elements consisting of: 1 PC 1 PC Hydraulically operated coupling pin with conn. To the P/T System P/T Hydraulic transition system with connections for the hydraulically operated coupling pin 2 PC‘s Track rod; each 1500 mm long 2 PC‘s Connection pin incl. bolts and washers 6 PC·s Bolt M30x150 incl. nuts and washers 1 Set Distance plates in different thickness for pre-bending 1 Set Hydraulic connection hoses for support, steering and transition system 1 Set Pneumatic connection hoses for the brake system 1 Set Connection cables for the power supply and ABS system • 1 set of complete documentation, on paper • 1 set of complete documentation, on CD OPTIONS: 12 Volt instead of 24 Volt lighting system) 1 Set Hydraulic lines for coupling with mechanically steered platform trailers 1 Set Contour marking Top surface anti-slip coated 1 PC Manual central lubrication system 1 PC Automatic central lubrication system 1 PC Distance indicator (Kilometre/Mileage counter) 1 Set Tools 1 Set Hydraulic connections drive system 1 Set Connection cables for drive and steering system Autor: D. Zavcer Page 2 of 2 Edition: 23.07.2013 Variation: 0 Subject to technical modifications Scheuerle Fahrzeugfabrik GmbH - KAMAG Transporttechnik GmbH & Co KG 0 0 9000 3 – 0 750 1500 1500 1500 1500 1500 750 2 3000 2 1 3 9 6 9360 1800 0 0 0 0 8 0 1 3 Adilmteerantsioionnss t ore dseesrvigend !and SpauITCtecs hiHcesrisme Ee osdinnssUrtslaiyrbEiuwo.lIesntRi nt .metgLod a Er tyetho- minrF tdoahA tiep nbH esrere Rst chroeZeenpi Evspre oUrwrod iGpfutohecrFore ttuAdyht e nBow ofs rRrSpit temIceKchnaie fdiGueeedMrleB.H Copyright: DIN 34 / ISO 16016 UGGMreeszpap.r(cid:223)r..st(cid:1)(cid:1)aD(cid:2)(cid:5)b(cid:3)(cid:3)(cid:4)a(cid:4)(cid:7)(cid:5)(cid:5)(cid:7)t(cid:7)(cid:3)(cid:3)u(cid:7)(cid:1)(cid:1)(cid:1)(cid:4)(cid:4)m(cid:2)(cid:6)(cid:6)(cid:3)(cid:2)(cid:2)(cid:4) N(cid:13)(cid:8)(cid:14)(cid:9)a(cid:11)(cid:10)(cid:7)(cid:7)m(cid:11)(cid:7)(cid:11)(cid:7)(cid:12)(cid:12)e(cid:9)(cid:9) Ers.f. 51660--A0ac0xEhl9erss 3. KdK.622 5 5 HH SSPPEVEe 0r44sion B1l.B1l. Technical Data Sheet 6-axle K25 H SPE 4 (Type K2506HSP4E) Technical data Drawing no. 51000936 Travel speed [km/h] 15 km/h **) 10 km/h **) 5 km/h **) 3 km/h **) 1 km/h **) Payload-max. [kg] *) 147.900 164.100 195.300 195.300 245.700 Deadweight-approx. [kg] 24.300 Total weight [kg] 172.200 188.400 219.600 219.600 270.000 Axle load - admissible [kg] 6x 28.700 31.400 36.600 36.600 45.000 Platform dimensions (L x W) 9000 mm x 3000 mm Coupling length 9.000 mm Platform height-driving pos. (loaded) 1.220 mm Axle compensation +/- 300 mm Platform height-lowered (loaded) 920 mm Type of steering/steering angle slewing ring - hydraulic motor / max. +/- 140(cid:176) No. of wheel bogies - total/braked 12 / 8 No. of wheel bogies - driven 4 Tractive force/braking force ***) 320 kN / 348 kN Brake system equipped with a dual circuit brake system Travel speed-driven up to 15 km/h ****) Tyres 48 x 215/75 R17,5 - 135/133J Operating temperature -20 (cid:176)C up to +40 (cid:176)C Oil volume - *) Payload without deadweight of PPU or other accessories **) Attention! Tyre pressure has to be increased up to 12,6 bar ***) Attention-if the traction force is bigger than the parking brake force, please consider the instructions! ****) Depending on PPU - design and combination Author : Kr(cid:228)mer, Axel Page 1 of 1 16.12.2013 Subject to technical changes 51000936-2 SCHEUERLE Fahrzeugfabrik GmbH - KAMAG Transporttechnik GmbH & Co. KG 4320 approx. 3122 85 0 5 6 3 3 8 8 4200 2880 0 8 8 2 3700 Adilmteerantsioionnss t ore dseesrvigend !and SpauITCtecs hiHcesrisme Ee osdinnssUrtslaiyrbEiuwo.lIesntRi nt .metgLod a Er tyetho- minrF tdoahA tiep nbH esrere Rst chroeZeenpi Evspre oUrwrod iGpfutohecrFore ttuAdyht e nBow ofs rRrSpit temIceKchnaie fdiGueeedMrleB.H Copyright: DIN 34 / ISO 16016 UGGMreeszpap.r(cid:223)r..st(cid:1)(cid:1)aD(cid:2)(cid:2)b(cid:3)(cid:3)(cid:4)(cid:4)a(cid:8)(cid:5)(cid:5)(cid:8)t(cid:8)(cid:3)(cid:3)u(cid:6)(cid:8)(cid:6)(cid:1)(cid:4)(cid:4)m(cid:2)(cid:1)(cid:1)(cid:3)(cid:7)(cid:7)(cid:4) N(cid:13)(cid:14)(cid:9)a(cid:15)(cid:8)(cid:10)(cid:8)(cid:11)m(cid:8)(cid:15)(cid:8)(cid:12)(cid:12)(cid:11)e(cid:16) FAHDR-7(cid:214)ZE4Eh6rrU2sinG9.gf F.ePArf eSB d tR re.I lKb16 aGcmhbH P5 o0w0e0r 2PE8rKas.1c d2k.85 Z S 3P40E MVAe 0rKsio0n3 B1l.B1l. Power Pack PPU Z 340 MA K03 for K25 H SPE 50002818-2 Technical Data Sheet Dimensions L x W x H approx. 4.320 x 2.850 x 830 mm Coupling length approx. 4.200 mm Dead weight approx. 7.300 kg Possible tilting angle of PPU upwards approx. 12(cid:176) Diesel engine (cid:150) Manufacturer / Type MAN (cid:150) D 2876 LUE 622 Exhaust emission category EUROMOT IIIA / EPA tier 3 Number of cylinders / Design / Capacity 6 / in-line horizontal / 12 816 cm‡ Performance 338 kW (460 PS) at 2.000 rpm Torque 2.000 Nm at 1.100 (cid:150) 1.500 rpm Cooling system Liquid cooling (cid:150) charge air cooling Admissible engine inclination (cid:150) along /across max. 15(cid:176) / 2(cid:176) Starter (cid:150) Voltage / Performance 24 V / 6,6 kW Generator (cid:150) Voltage / Performance 24 (28) V / 3.920 W (140 A) Air compressor (cid:150) flow rate / pressure approx. 830 l/min at 8.5 bar (12 bar at the tire filler) Fuel consumption approx. 10 to 83 l/h Batteries / Voltage 2 x 12 V, 225 Ah / 24 V Fuel tank approx. 400 l filling volume Hydraulic oil tank for driving system approx. 320 l filling volume, 240 l useable volume Hydraulic oil tank for steering / support system approx. 450 l filling volume, 340 l useable volume 1. Variable pump drive propulsion Qmax. = 345 l/min, pmax. = 400 bar 2. Variable pump drive propulsion Qmax. = 240 l/min, pmax. = 400 bar 1. Variable pump steering Qmax. = 360 l/min, pmax. = 345 bar Ambient temperature approx. (cid:150) 20 (cid:176)C up to + 40 (cid:176)C (- 4 (cid:176)F up to +104 (cid:176)F) max. 64 nos. of pendulum axles (32 axle lines) Suitable to operate a number of axles max. 20 nos. of driven pendulum axles Options Radio- / Cable Remote Control System Part No. 50000391 Cable Remote Control System Part No. 50000477 Date of issue: 2013.03.28 / DS Technical changes without notice/ Illustrations may contain optional equipment page 1 of 1 SCHEUERLE Fahrzeugfabrik GmbH (cid:214)hringer Strasse 16 D-74629 Pfedelbach Telephon 07941/691-0 www.scheuerle.com Radio / Cable Remote Control 50000391-2 Radio Remote Control / Cable bound Technical Data and Description Dimensions L x W x H approx. 470 x 250 x 520 mm (including breast plate) Weight approx. 7,3 kg (including rechargeable battery) Range up to 1.000 m (without obstacles), Cable length up to 10m Transmission Performance approx. < 10 mW Service Time up to 8 h (depending on battery condition) Ambient Temperature approx. (cid:150) 20 / + 70 (cid:176)C Protection Category IP 55 acc. to IEC 60529 The Radio Remote Control is optional equipment and consists of a radio transmitter and a radio receiver. The radio transmitter is arranged in a shock-resistant plastic housing with detachable standing brackets and contents displays, selector switches and joysticks. The radio receiver unit is pluggable either to the power pack unit, to the driver(cid:146)s cabin or to one of the platform trailers. The radio remote control is equipped with a protection bracket, thus preventing an undesired activation of the joysticks when falling to the ground. Hooked carrier straps allow comfortable and safe operating with the remote control. The unit is weatherproof (protection category IP 65 acc. To IEC 60529) and designed for rough operation conditions. It is in conformity with the EC-Directives 98/37/EC, 1999/5/EC, 73/23/EEC and 89/336/EEC. Following functions are available amongst others: • System On/Off / Diesel engine shut off • Control of steering / drive system / lift system / brake system • Selection of steering programs / deceleration / slow drive • Input of the values for variable distance steering • Indication of supporting pressure / steering angle • Supervision of major conditions • Emergency stop of complete system / diesel engine Issue date: 2013-01-28 / DS Technical changes without notice Page 1 of 1 Scheuerle Fahrzeugfabrik GmbH !!!P"!O"!Box!# !! !!!D-74629!Pfedelbach!! !!Phone!++49(0)7941/691-0! !!www.scheuerle.com Technical Data Sheet 50001180 Coupling Element Technical Data and Description Dimensions L x W x H approx. 300 x 400 x 290 mm Coupling Length approx. 300 mm Connecting screws 8 nos. M 42 x 120 DIN 931 - 8.8 Weight approx. 60 kg Inter Combi: S0, S1, IC SPE, IC PB Euro Combi: L0, L2, L6, L8, L9 Suitable for Flat Combi: M0. M1, M3, M4 Scheuerle – Kamag: K25 SPE The Coupling Element is an optional equipment and designed as the connection element of platform trailers when arranged parallel side-by-side. The mechanical connection of the platform trailers affords expanded loading areas with the appropriate payload. The lateral longitudinal beams of the platform trailers are provided with 4 each of bores (Ø 50 mm) arranged in an equivalent distance to each axle line for to flange-on the coupling elements. Both sides of the coupling element have to be connected to the platform trailer by means of four screws, nuts and washers. Coupling elements should be attached to all coupling positions of the platform trailers, due to the fact that the coupling elements can only transfer a limited bending moment. The scope of supply includes 8 connection screws, nuts and washers each. Issue date: 2011-09-28 Technical changes without notice Page 1 of 1 Scheuerle Fahrzeugfabrik GmbH (cid:1) P. O. Box 20 (cid:1) D-74629 Pfedelbach (cid:1) Phone ++49(0)7941/691-0 www.scheuerle.com

Description: