3D Printing for Artists, Designers and Makers, 2nd Edition PDF

Preview 3D Printing for Artists, Designers and Makers, 2nd Edition

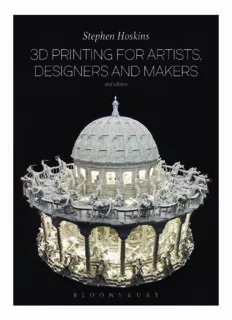

9781474248679_txt_app.indb 1 9/26/17 3:39 PM Acknowledgements: I would like to thank the following people for help with putting For kind permission for the use of images, Unfold, Heather and Ivan this book together. First and foremost, without the help of Jesse Morison, Karin Sander, Peter Terezakis, Masaki Fujihata, Freedom Heckstall-Smith the book would never have reached the publication of Creation, Professor Neri Oxman from MI, Jessica Rosencrantz stage. I would also like to thank Joanna Montgomery for editing from Nervous System, Charles Czurri, Aardman Animations Bristol down the final document and Dr Peter Walters for checking for and LIAKA from Portland Oregon, Peter Ting, Counter Editions The accuracy. Spira Collection, 3DRTP, Envisiontec, Stratasys, 3D Systems, EOS, Mcor, Renishaw, Viridis, Daniel Collin, Mary Vasseur and Christian My thanks go to all of the case study artists, and I hope that I Lavigne, EADS Bristol and Evil Mad Scientists Company and Markus have done them justice: Assa Ashuach, Laura Alvarado and Vivian Keyser. I would also like to thank all of those people I spoke to in Meller, Sebastian Burdon, Mat Collishaw, Dr Lionel Dean, Marianne the course of writing this Second Edition. Forrest, Sophie Kahn, Jack Row, Michael Schmidt, Jonathan Monaghan and Don Undeen. I would like to thank the UK Arts and Humanities Research Council for the research funding from which this book is an outcome. I particularly want to thank those artists from the previous volume, Tom Lomax, Professor Keith Brown and Jonathan Keep. In addition, Finally, I would like to thank my wife, Dr Sandy Hoskins, for her thanks go to Rick Becker for his help and images of his sculpture, patience and support. to Rita Donagh for her kind permission to use the Richard Hamilton images and to Gary Hawley from Denby Pottery for his help and assistance. Bloomsbury Visual Arts No responsibility for loss caused to any individual or organization An imprint of Bloomsbury Publishing Plc acting on or refraining from action as a result of the material in this publication can be accepted by Bloomsbury or the author. 50 Bedford Square 1385 Broadway London New York British Library Cataloguing-in-Publication Data WC1B 3DP NY 10018 A catalogue record for this book is available from the British Library. UK USA ISBN: PB: 978-1-4742-4867-9 www.bloomsbury.com ePDF: 978-1-4742-4872-3 ePub: 978-1-4742-4874-7 Bloomsbury and the Diana logo are registered trademarks of Bloomsbury Publishing Plc Library of Congress Cataloging-in-Publication Data A catalogue record for this book is available from the Library of © Stephen Hoskins, 2018 Congress. Stephen Hoskins has asserted his right under the Copyright, Cover design: Irene Martinez Costa Designs and Patents Act, 1988, to be identified as Author of this Cover image: Zoetrope 0739 by Mat Collishaw, photograph © Andrea work. Simi All rights reserved. No part of this publication may be reproduced or Typeset by Lachina transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage or retrieval system, without prior permission in writing from the To find out more about our authors and books visit www.bloomsbury. publishers. com. Here you will find extracts, author interviews, details of forthcoming events and the option to sign up for our newsletters. 9781474248679_txt_app.indb 2 9/26/17 3:39 PM 3D Printing for artists, designers and makers STePHeN HoSKINS Marianne Forrest. 'Silver Sliver' in electroformed silver over resin 3D print. Bloomsbury Visual Arts An imprint of Bloomsbury Publishing Plc LONDON • OXFORD • NEW YORK • NEW DELHI • SYDNEY 9781474248679_txt_app.indb 3 9/26/17 3:39 PM 9781474248679_txt_app.indb 4 9/26/17 3:39 PM Contents 6 Preface 8 Introduction 1 2 3 14 The history of 37 An overview of current 58 Crafts and craftspeople 3D printing in relation 3D printing technologies, to the visual arts what each offers and 64 Case study: Jack Row how they might develop 68 Case study: Marianne Forrest in the future 72 Case study: Michael eden 4 5 6 78 The fine arts 102 Design and designers: 130 Hackspaces, fablabs, case studies from makerspaces, arts research: 87 Case study: Mat Collishaw contemporary designers the collaborative and more 91 Case study: Sophie Kahn public face of 3D printing 95 Case study: 110 Case study: Assa Ashuach and its future in the arts Jonathan Monaghan 114 Case study: Laura Alvarado 99 Case study: and Vivian Meller 136 Case study: Don Undeen Sebastian Burdon 119 Case study: Dr Lionel T. Dean 144 Case study: The Centre 126 Case study: Dr Peter Walters for Digital Design and Manufacturing (DDM) 7 157 Conclusion 146 Fashion and animation 160 Glossary 165 Index 147 Case study: Michael Schmidt Sophie Kahn, Période des attitudes passionelles, part of Prodromes series, 3D printed nylon (from 3D laser scan), aluminum base © Sophie Kahn 2016 5 9781474248679_txt_app.indb 5 9/26/17 3:39 PM Preface 3D printing has received a great deal of publicity recently, much of which tends to skirt over the practical information of how the process actually works and ignore the fact that it is actually a number of 3D processes that contribute to the field of 3D printing. This preface is for those people who have little experience of 3D printing and need a clear description of what the basic processes are and how they work. It will also define what I understand is meant by 3D printing. Before we delve into the history and development of 3D printing, we need a description of what the process actually entails. First and foremost all 3D printing processes are additive by nature – in other words, you build up an object by adding material. 3D printing is a relatively recent innovation that allows physical objects to be fabricated directly from a 3D virtual model created in computer design software or by scanning the shape of an existing object. In 3D printing, objects are fabricated by computer-controlled machinery, which deposits or solidifies material, one layer on top of another, in a way that could be described as analogous to the building of a traditional coil pot. objects can be built in a range of materials, including plastics, ceramics and metals. The layer-by- layer fabrication process of 3D printing frees the artist, designer or engineer from many of the constraints of traditional fabrication methods – hence the process is sometimes referred to as ‘solid free-form fabrication’. Visually oriented artists and designers are beginning to explore the exciting aesthetic possibilities and implications of 3D printing as a medium for creative practice, and the purpose of this book is to provide an introduction to 3D printing from a visual arts perspective. This book introduces the historical and technological context of 3D printing and provides state-of-the-art case studies from creative practice in the fine and applied arts, crafts and design. Chapter 1 will begin by introducing the history of 3D printing, paying particular attention to how that history relates to a visual arts context. It will trace a dual path of development, starting with James Watt and his sculpture copying machines, through developments in rendering maps in three dimensions to a 1950s method of copying sculpture in an analogue manner. The parallel track follows the development of light sensitive gelatine materials in 6 PReFACe Preface 9781474248679_txt_app.indb 6 9/26/17 3:39 PM Tom Lomax, Michael: Angels Series, 2011. early Victorian photography and printing processes, first made commercially available as a process. It through the development of Photosculpture, to the presents four case studies of fine art practitioners creation of bas-relief printing and into photo-polymeric whom I feel are representative of a generation of fine emulsions, which finally lead to the photo-initiated 3D artists for whom the digital is an integral part of their printing processes. The chapter then describes how practice and not something new. visual artists have interfaced with, and then adopted, Chapter 5 explores the implications of 3D the processes to the benefit of artists, designers and printing for designers and design practitioners. It craftspeople. describes the field and differentiates the types of Chapter 2 outlines the history of 3D printing practice between those designers working within as a process and details the various technical large companies and those who work independently. developments of the machinery involved. It then The chapter presents four case studies of skilled details a selection of 3D printing machines currently designers who each have very different approaches available and presents the wide range of different to 3D printing. processes that fall under the umbrella term ‘3D Chapter 6 examines the public perception of 3D printing’. Where possible it also details some of the printing through literature and mainstream press visual arts practitioners that have used each of the and how this in turn impacts upon the creative various processes. arts. This includes fashion designers and stop Chapter 3 covers crafts and how they interface motion animation, both of whom reach large public with 3D printing. This chapter details some of the audiences. This chapter also details the rise of the philosophical approaches to the discipline and how Hackspace and Dorkbot cultures, then describes those approaches interface with methodologies how the future might look, illustrated by examples of necessary to develop a practitioner approach to 3D current research. printing. Three case studies of crafts practitioners Chapter 7 describes how 3D printing has entered who use 3D printing as an integral part of their work the mainstream with examples from both the fashion are presented, including details of how they both deal industry and the animation industry. Both of these with the process technically and how they approach are beginning to use 3D printing as an everyday part the process philosophically from a practitioner of their production. perspective. The conclusion summarises the future potential of Chapter 4 describes the relationship between the 3D printing for the visual arts and draws a conclusion fine arts and 3D printing. It also details how artists upon how artists, designers and craftspeople are have worked with the technology almost since it was embracing the technology. PReFACe Preface 7 9781474248679_txt_app.indb 7 9/26/17 3:39 PM Introduction This volume is of interest to a broad range of academics and 3D print users from across the arts, industry and science disciplines. It is aimed at artists, designers and people from the creative industries, but it will also appeal to a more general audience of people who have an interest in the new developments in technology. I also have to qualify what I mean by the term ‘makers’; I am not referring to the home computer geeks but to craftspeople. I do cover a little of the geek maker community, but this volume is primarily about art and artists. Between writing the first edition of this book in 2012– the technology to the arena of rapid manufacture – 13 and revising it in 2016–17, there has been a media where it is possible to produce a fully working part. barrage around 3D printing. The early coverage was Already it has proven possible to 3D print a fully mainly about the cheap do-it-yourself extruded plastic working nylon bicycle, gold and silver jewellery and technology (known as fused deposition modelling, or titanium teeth. The authors’ research team (at the FDM). Latterly most of the publicity has been in the Centre for Fine Print Research (CFPR) at University of area of bio-medics and prosthetics. The American West england, Bristol) is leading the field in printing technology company Gartner, which produces analysis three-dimensional ceramics, producing cups, plates, of the market through their Hype Curve predictions, bowls and sculpture using the process. predicts that consumer low-cost 3D printing (FDM) In a broader context there is a rapidly growing is now in a five-to-ten-year slough of despondency, population of Fab Labs. As of August 2016, there are whereas commercial high-cost industrial 3D printing, 683 Fab Labs worldwide, with 119 in the USA and 28 particularly in the area of prototyping, is heading into in the UK. Fab Labs are a community spin-off of open the plateau of productivity. access high technology workshops, originally founded Globally many universities, research institutions by MIT, based around 3D printing. Another new and industry are working with and developing 3D phenomenon are the Tech shops, which are a more printing as an additive manufacturing process, and commercial alternative to Fab Labs. Hackspaces are most believe the technology is on the cusp of the physical places for the technologically aware where next big breakthrough. The goal has been to move people can meet to learn, socialize and collaborate 8 introduction iInnttrroodduuccttiioonn 9781474248679_txt_app.indb 8 9/26/17 3:39 PM on projects. All of these are rapidly spreading the one could argue that any new process is concept of this new technology to an ever-growing beginning to gain capital and acknowledged credibility audience of users, who are looking to situate this in the world when it starts to accumulate a variety technology in their everyday lives. of names. 3D printing is currently in this phase. In this book, I aim to demonstrate that 3D printing Alternative names include: free-form fabrication, is now becoming an integral part of the canon of rapid manufacture, additive layer manufacture (ALM), arts practice. I have two clear aims. The first is to selective laser sintering (SLS), stereo-lithography introduce to an arts-based audience the potential of (STL), rapid prototyping (RP) and fused deposition the process now commonly known as 3D printing. The modelling (FDM). second is to place the sequence of processes that often a change in the cultural acceptance of a make up the discipline into some sort of historical new process can be traced to a single event, which perspective and timeline in relation to the visual arts. in itself may not have been significant at the time, I intend to demonstrate objectively how these new but in retrospect serves as an indicator of changing processes have been accepted by using a number of perceptions. An issue of Wired magazine in 2010 with case studies of current practitioners and explaining a feature article by editor Chris Anderson1 entitled ‘In how their diverse practices are creating new methods the Next Industrial Revolution, Atoms Are the New of working for others to follow. Bits’ highlights this changing perception. When this Keith Brown, ‘Crest’, 2009. introduction iInnttrroodduuccttiioonn 9 9781474248679_txt_app.indb 9 9/26/17 3:39 PM article was published I began to understand that a your Mac or PC and then just pressing a button to fundamentally different approach to manufacturing print it out in real materials was very appealing and was beginning to take place. futuristic. The reality has been, in fact, very far from Perhaps the most perceptive comment within this – at least in the years 2010 through 2016. even the article is the following: ‘Here’s the history of now, at the time of writing, the only processes within two decades in one sentence. If the past ten years the field of additive layer manufacture that even have been about discovering post-institutional approach the reality/quality of a finished article in models on the web, then the next ten years will be real materials are laser-sintered titanium, steel and about applying them to the real world.’ Anderson nylon. In the field of the visual arts, two research was probably talking more about the influence of projects define new directions in real materials: The social media, how society approached problems collaboration between Cookson’s and Birmingham collectively, and how this collaborative approach UCe Jewellery Innovation Centre to print gold and would operate beyond the web. However, the article precious metals and the work of my own research went on to highlight a number of new ways of working team at the University of the West of england, Bristol, inspired by 3D printing, such as a crowd-sourced car in 3D-printed ceramics. All of these processes still and the phenomena of Fab Labs and Tech Shops. require a great deal of cleaning and finishing after It is that real-world application of digital technology printing; you cannot just take them as finished items that has evolved from that past excitement over 3D straight from the printer. I can quite safely say at this printing. The prospect of designing a virtual object on point that currently no process offers what the user requires, and I say that as a fan and advocate of 3D printing! There is no doubt that these processes, in the long term, do have the ability to create a disruptive technology, as articulated by Chris Anderson. 3D printing’s disruptive path may well happen in a similar way to the introduction of web-based communication, which superseded the traditional newspaper printing industry. This takes time; the revolution in printing and communication took nearly 30 years from the initial introduction of computer typesetting. This is exemplified by the Wapping dispute with the Murdoch press in the early 1980s. Here the catalyst for change was the advent of desktop publishing software, such as Aldus PageMaker for the Apple Macintosh, developed in the late 1980s. The print unions struggled with management over job cuts because the journalists could now type their copy directly into a computer and the printed page could be made up on screen, without the need for trained typesetters. There was no longer a requirement for the legions of typesetters, platemakers and reprographics departments. Sophie Kahn, Head of a Young Woman. 10 introduction introduction 9781474248679_txt_app.indb 10 9/26/17 3:39 PM

Description: