Truck Model World PDF

Preview Truck Model World

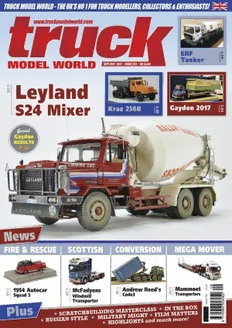

CONTENTS SEPTEMBER/OCTOBER 2017 | Issue 233 12 6 MODEL NEWS What’s new, what’s due 8 SCRATCHBUILDING MASTERCLASS ERF Tanker Pt 2 1:24 12 CODE 3’s Andrew Reed Model Highlights 1:50 14 RUSSIAN STYLE KrAZ 256B Dump Truck 1:35 18 HEAVY MOVERS Mammoet Model Reviews 1:50 21 HOLIDAY INSPIRATION 29 Leyland S24 Mixer 1:24 24 SCHONI MARKS DAF 105XF Tractor 1:24 26 FIRE REPLICAS Chicago Fire Department 1954 Autocar Squad 3 1:50 28 IN THE BOX IBG Scammell Pioneer 1:35 29 IN THE BOX Modellers Resource Site Dumper 1:24 30 MEGA MOVERS McFadyens Mega Windmill Transporter 1:50 34 32 A&N MODEL KIT Volvo FM Conversion 1:24 34 GOING CAMPING Bedford TK Caravan Transporter 1:24 38 FILM MATTERS “Duel” Tanker Truck 1:24 40 MILITARY MIGHT Accurate Armour Models 1:35 42 SHOWSTOPPER Gaydon Highlights 47 MEDIA HIGHLIGHTS Book Reviews 48 FLEET COLOURS Terex Branded Replicas 1:50 4 www.truckmodelworld.com SEPTEMBER/OCTOBER 2017 COMMENT Contact the editor either by post: TMW Editorial Office 3 Orchard Close, Saracens Head, Holbeach, Spalding, Lincolnshire, PE12 8AR, England or by email: [email protected] A fter going through the process of switching our main distributor and printer, we are now looking forward to our new relationship to bring you the best magazine we can. Unfortunately, the change has resulted in the MAIN CONTRIBUTORS last issue being out late and we are trying to ensure that the release schedule Andrew Bell, Andrew Reed, Cliff Read, Mick Russell, Rich Ellis, Damien Lision, becomes reliable and consistent, something I am hoping will be resolved when Dick Smith, Steve Lima, Kees Kamp we release the Nov/Dec issue in a couple of months. In the meantime, this issue EDITOR is packed with builds, conversions, model reviews and kit “In The Box” Steven Downes email: [email protected] highlights. We also take a look back at the Gaydon show with a gallery of images taken during the weekend, rounding out with a full listing of the winners. MANAGING DIRECTOR Andrew Ebbage email: [email protected] We would like to hear from anyone who is having trouble finding a copy of Truck Model World in their area, and for those in the UK, you can now go online to OPERATIONS DIRECTOR Sally Ebbage www.seymour.co.uk/storefinder where, by entering your postcode, you can see email: [email protected] local stockists of the title. DESIGN & PRODUCTION Greenland Design Limited Once again I would like to thank all the contributors who have submitted articles email: [email protected] recently, some of which are found on the pages of this issue. If you have any ADVERTISING COPY CONTROLLER suggestions or ideas for future articles, please don’t hesitate to get in touch. Sally Ebbage Tel: 01406 424681 email: [email protected] Until next time, Happy Reading PUBLISHED BY IGP LTD Limited, Steven Downes Editor 3 Orchard Close, Saracens Head, Holbeach, Spalding, Lincolnshire. England. PE12 8AR Tel: 01406 424681 Fax: 01406 426855 email: [email protected] PRINTER The Magazine Printing Company www.magprint.co.uk/ DISTRIBUTOR Select Publisher Services Ltd. www.selectps.com NEWSSTAND DISTRIBUTION Seymour Distribution Ltd. +44 (0) 20 7429 4000 SUBSCRIPTIONS 1 year subscription prices: UK £27.50 Europe £45.00 W/Wide £50.50 BACK ISSUES UK £3.99/US $7.99 Order Hotline: +44 (0)1406 424681 Online Ordering: www.themodelhobbyshop.com This magazine is sold subject to the following conditions: that it shall not without written consent of the publishers be lent, resold or otherwise disposed of by way of trade in excess of the recommended maximum retail price. All rights strictly reserved. No part of this publication may be reproduced in any way without the prior agreement of the publisher. All letters must be accompanied by the sender’s full name and address. The publisher cannot accept responsibility for unsolicited correspondence nor some of the opinions expressed. All material and artwork originated by IGP Ltd, photographs, drawings, plans used in this magazine become the publishers copyright under Copyright law. Some photographs may have been digitally re-mastered. The Company reserves the right to suspend or refuse any advertisements without giving reasons. Whilst every care is taken to avoid mistakes, IGP Ltd. cannot be liable in any way for errors or omissions. Nor can the Publisher accept any responsibility for the bona fides of advertisers. ISSN 0958-0530 © 2015 IGP Limited. All rights reserved. SEPTEMBER/OCTOBER 2017 www.truckmodelworld.com 5 TRUCK NEWS Drake Collectibles Several new Freighter Maxitrans models are now available from the drake online shop (www.thedrakeshop.com). These include B Double flat tops in several colours and company decorations including BBG, Burgundy, White and Red/White. Matching road train sets are also available consisting of a B trailer and 2-axle road train dolly. All new freighter models have working suspension, removable diecast gates, gate storage racks, adjustable landing legs, removable spare wheels and realistic hoses detail. More colour and company decorated versions are in production including National Heavy Haulage and NTS. 1:50th - Freighter Maxitrans B Double Set (Red/White). 1:50th - Freighter Road Train 1:50th - National Heavy Haulage Kenworth K200 Set (Red/White). with Freighter B Double set. 1:50th - National Heavy Haulage Kenworth C509 with Freighter B Double and Road train set. Fire Replicas New announcements in the Fire Replicas line of museum grade 1:50th scale fire and rescue models include three new models for the Chicago Fire Department, featuring the Spartan Engine which is available in three different engine numbers of 116, 117 and 123 along with a set of all three engines together. There is also a new image of the Milwaukee Fire Department Engine 26 which is expected to be available in September while the Ashburn Volunteer Fire Rescue Department Engine 606 is now available. For full details and to place an order, check out the Fire Replicas website (www.firereplicas.com) 1:50th - 1:50th - Milwaukee 1:50th scale Ashburn Volunteer Chicago Fire Fire Department Fire-Rescue Department Engine 606. Department Engine 26. Spartan Set (Engines 116, 117 & 123). 1:50th - Chicago Fire Department Spartan Engine 116. 1:50th - Chicago Fire Department Spartan Engine 117. 1:50th - Chicago Fire Department Spartan Engine 123. 6 www.truckmodelworld.com SEPTEMBER/OCTOBER 2017 Truck Model World is always happy to review new kits, products and accessories and welcomes information about new products and events. Manufacturers, distributors and retailers wishing to have items reviewed should send samples and information directly to the Editor, TMW Editorial Office, 3 Orchard Close, Saracens Head, Holbeach, Spalding, Lincolnshire, PE12 8AR, England. Tel +44 (0)1706 671822. Or email: [email protected] Start Scale Models SSM has announced some interesting 1:43rd scale MAZ, KAMAZ and Tatra Russian trucks including 2- axle and 3-axle chassis with different design cabins. Each features a tilting cab with plenty of detailing of the engine bay. Full details of the new releases can be found on SSM’s website www.startscalemodels.eu 1:43rd scale MAZ-5550 2-axle dump 1:43rd scale MAZ-5550 2-axle dump 1:43rd scale MAZ-5340 2-axle cargo 1:43rd scale MAZ 6430 3-axle tractor. truck (Blue/Orange). truck (Orange/Silver). truck. Weiss Brothers Heavy haulage fans may be interested in the latest announcement from Weiss Brothers, a 1:50th scale concrete bridge section 1:43rd scale KAMAZ 5320 3-axle 1:43rd scale Tatra 815S1 3-axle dump flatbed truck. truck (Emergency Service). produced from resin and highly detailed including tie-bars and fixing holes. It measures 13” x 2” x 4” and is expected to be available mid October. Pre-order now from the Weiss Brothers website (www.weissbrothers.us) 1:50th - Pre-cast Concrete Bridge section load. Conrad Models A new Liebherr HTM905 concrete mixer has been produced by Conrad, based on a 4-axle Mercedes Benz Arocs chassis featuring a brand new mixer body casting. It is avail- able now from the Liebherr online shop (https://liebherr-shop.liebherr.com) 1:50th - Liebherr HTM905 4-axle Concrete Mixer. SEPTEMBER/OCTOBER 2017 www.truckmodelworld.com 7 TMW 1:24 Author:Andrew Bell EEERRRFFF BBB---SSSEEERRRIIIEEESSS TTTAAANNNKKKEEERRR (((PPPAAARRRTTT 111))) In the last issue, Andrew detailed the process of building a chassis-cab for an 8-wheeler ERF fuel tanker and now he completes the model with its bodywork, paint and final assembly. P rior to me beginning the build, my customer Darren had managed to get into the most secretive of places, Rush Green salvage yard, and crawled all over a similar 8-wheeler tanker fitted with the same Thompson 6 compartment, 23,000 litre barrel the ERF had. These proved to be invaluable and I could not have built the model without them. I set to work designing the barrel in 3D using the modelling software I had used at university, and soon had a virtual 'solid lump' which had the correct shape and dimensions. This was split in CAD into 3 different 50mm sections (front middle and rear) and hollowed out to give a 3mm wall thickness. Internal lips were added to the two rear sections so that the barrel could be built up to any length in a modular fashion. I used the online 3D printing community 3DHubs to find someone who could print the sections for a reasonable price and at a decent quality. I opted for ABS, which cost about £20 per section. A few days later I had them in my possession, and they were promptly cleaned up and dispatched to Modellers Resource for replicating in resin. A slight oversight in the design stage meant I had made the internal lip exactly the same size as the section it had to fit into, which on a PC screen works absolutely beautifully. Introduce the vagaries of layer thickness in the 3D printing of ABS however, and this was more than just an interference fit! I spent several miserable hours attempting to sand, file and ultimately Dremel the excess material away. Turns out ABS is exceptionally difficult to work with! Once these had been completed, I worked on 3D CAD designs of the tanker manlids, foot valves, APIs (outlets) and fire extinguisher and spill kit boxes. These were printed at a much higher quality and in a higher quality material, because of their smaller size, which meant the cost was not prohibitive, again using 3DHubs, and again subsequently dispatched to MR for replicating in resin. With the 6 required tanker sections returned, a quick clean-up and a trial fit showed my efforts had not been in vain with the ABS sections, and the resin parts were a snug fit into each other. 8 www.truckmodelworld.com SEPTEMBER/OCTOBER 2017 1:24 SCALE I assembled the tank in about 5 minutes, literally stacking one section on top of another using superglue and a quick squirt of activator. An initial coating of filler in the joints, and a run round with a sanding mouse gave me a decent starting point. A perfectly smooth outer skin to the tank is not particularly necessary, as the joints between the sections resemble the baffles or compartments on a real tank. I considered adding photoetched weld lines to these, but decided I preferred the subtler effect I already had. Each end of the tank barrel was skinned with thin plasticard, so that the tank valance was encapsulated at each end. In the rear end, I cut out a section above where the ladder platform would sit. With these added, I gave the barrel a couple of rounds of priming, sanding and filling, particularly on the tank top where the moulding was not perfect. This would later be hidden underneath a set of photoetched walkway panels, so not a huge concern. I then turned my attention to the underside, first mounting the resin footvalves, each orientated so that the run-off pipework can get past the other valves in its path, and so that there is room for all the pipework behind the outlet manifold. My original plan here was to use ready-made elbows from EMA Models, but some 5mm solid round rod and a lighter proved to be far easier and I could rework any bend which was not quite correct almost instantly. These linked up to two individual manifold plates, and the outlets fitted to the other side. Small sections of tube were also added in the corners of the tank to replicate drain tubes, which run through from the tank top. The top of the tank required some careful thought. In my experience of the manufacture of tanker barrels, only two engineering drawings are required, one to build the actual aluminium barrel, and another just to detail the tank top, such is the complexity. Fixed quantities were the tank valance width, resin manlid diameter, and photoetched walkway sheeting width. Taking these into account, I worked out the best way of positioning the manlids so that I had to do the minimum amount of cutting the walkway panels down in width, whilst keeping them equidistant. Some planning here payed dividends and the measure- ments worked out nicely. With these all set in place, I added the dipstick stowage brackets, which in turn dictated the length SEPTEMBER/OCTOBER 2017 www.truckmodelworld.com 9 TMW 1:24 Author:Andrew Bell of the dipsticks. A quick check that these were roughly the height of the barrel confirmed that my guesstimates and measurements combined were pretty much correct! A rear ladder was added to the tank, using 2mm plastic rod and a small section of the photoetched walkway. These are usually set so that the slope of the ladder is parallel to the slope of the barrel. At this point the barrel was complete, except for the top halves of the mountings, which would normally be welded to the tank, which are in turn bolted to their corresponding brackets which are bolted to the chassis. Because of the difficulties I anticipated with masking and painting this arrangement, I decided once again to use some modeller’s licence and fit all the bracketry to the chassis. This would also serve the purpose of the tank being demountable yet firmly located, and therefore be safe to transport, but also able to reveal the chassis and barrel detail. The required brackets were simple fabrications fitted at 4 points on each side of the chassis. Next, I turned my attention to the pipework which is fitted to the chassis. Again, this was something which myself and Darren really struggled to find reference material for. Presumably, nobody ever felt the need to record the underside of a tanker! I gathered that there would be a pump driven from a short prop-shaft off the gearbox, a ‘loop’ of pipework, an outlet, and a connection to the manifold. What I ended up with is probably not correct, but nobody has proved otherwise thus far! With the barrel and chassis mated, I added guard bars around the 6 outlets, and hose trays on each side and at the rear. The delivery hoses are black elastic, with end caps made from 5mm resin spotlight backings from KFS, with two small lengths of round rod inserted on each side. One of these is permanently attached to the chassis pipework, and is known as a jumper hose. 10 www.truckmodelworld.com SEPTEMBER/OCTOBER 2017