IS 8641: Implants for Surgery - Acrylic Resin Cements PDF

Preview IS 8641: Implants for Surgery - Acrylic Resin Cements

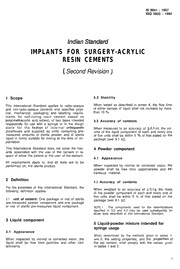

इंटरनेट मानक Disclosure to Promote the Right To Information Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public. “जान1 का अ+धकार, जी1 का अ+धकार” “प0रा1 को छोड न’ 5 तरफ” Mazdoor Kisan Shakti Sangathan Jawaharlal Nehru “The Right to Information, The Right to Live” “Step Out From the Old to the New” IS 8641 (1997): Implants for Surgery - Acrylic Resin Cements [MHD 2: Orthopaedic Instruments, Implants and Accessories] “!ान $ एक न’ भारत का +नम-ण” Satyanarayan Gangaram Pitroda ““IInnvveenntt aa NNeeww IInnddiiaa UUssiinngg KKnnoowwlleeddggee”” “!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता हहहहै””ै” Bhartṛhari—Nītiśatakam “Knowledge is such a treasure which cannot be stolen” IS 8641 : 1997 IS0 5833 : 1992 v7dwms Y Uii & f&q q%f?m TTmR * hTY@~J lndian Standard STNALPMI ROF CILYRCA-YREGRUS NISER STNEMEC ( Second Revision ) ICS 11.040.40 @ BIS 1997 BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELHI 110002 August 1997 Price Group 8 Orthopaedic Instruments and Accessories Sectional Committee, MHD 2 NATIONAL FOREWORD This Indian Standard (Second Revision) which is identical with IS0 5833 : 1992 ‘Implants for surgery - Acrylic resin cements’, issued by the International Organization for Standardization (ISO), was adopted by the Bureau of Indian Standards, on the recommendations of Orthopaedic Instruments and Accessories Sectional Committee and approval of the Medical Equipment andtfospital Planning Division Council. This standard IS 8641 was published in 1984 as dual number standard based on IS0 5833/i : 1979. Second revision has been issued to incorporate the modifications effected in the latest edition of IS0 5833 brought out in 1992. In this revised version a number of changes have taken place. Number of definitions have been reduced to one. Subclauses on liquid component, powder component have been elaborated and are covered as main clauses. Powder liquid mixture intended for syringe usage and for use in dough state has also been covered separately. Requirements and test methods for setting properties of liquid powder mixtures for both type of usage have been tabulated. Examples of graph showing working data for cement intended for dough usage and syringe usage have also been covered. Various method of tests, for example method of determination of stability, doughning time maximum temperature and setting time, intrusion, compressive strength, bending modulus and bending strength, etc, have been covered in detail in six separate annexures from A to F. The text of above mentioned IS0 standard hasbeen approved as suitable for publication as Indian Standard without deviations. Certain conventions are, however, not identical to those used in Indian Standards. Attention is particularly drawn to the following: a) Wherever the words ‘International Standard’ appear referring to this standard, they should be read as ‘Indian Sta n dard’. b) Comma (J has been used as a decimal marker while in Indian Standards, the current practice is to use a point (J as the decimal marker. For the purpose of deciding whether a particular requirement of this standard is complied with, the final value, observed or calculated, expressing the result of a test, shall be rounded off in accordance with IS 2 : 1960 ‘Rules for rounding off numerical values (revised)‘. The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard. IS 8841 : 1997 IS0 5833 : 1992 midn/ Standard IMPLANTS FOR SURGERY-ACRYLIC RESIN CEMENTS ( Second Revision ) 1 Scope 3.2 Stability This International Standard applies to radio-opaque nehW detset sa debircsed ni xenna ,A eht wolfemit and non-radio-opaque cements and specifies phys- of either sample of liquid shall not increase by more ical, mechanical, packaging and labelling require- than 10 .% ments for self-curing resin cement based on poly(methacrylic dica ,)sretse fo owt sepytdednetni 3.3 Accuracy of contents ylevitcepser rof esu htiw a egnirys ro ni ehthguod state for the fixation of internal orthopaedic When measured to an accuracy of f 0,l ml, the vol- prostheses and supplied as units containing -erp ume of the liquid component of each and every one measured amounts of sterile powder and of sterile fo evif stinu llahs eb nihtiw 5 % of that stated on the liquid in forms suitable for mixing at the time of im- package [see 9.1 a)]. .noitatnalp This International Standard does not cover the haz- 4 Powder component ards associated with the use of the cement in re- spect of either the patient or the user of the cement. 4.1 Appearance All requirements apply to, and all tests are to be performed on, the sterile product. When inspected by normal ;G detcerroc,noisiv the powder shall be free from agglomerates and -xe traneous material. 2 Definition 4.2 Accuracy of contents For the ses~oprup fo siht lanoitanretnI ,dradnatSeht When weighed to an accuracy of + 0,l ,g the mass gniwollof noitinifed .seilppa of the powder component of each and every one of evif stinu llahs eb nihtiw 5 % fo taht detats noeht 2.1 unit of cement: One package or vial of sterile package [see 9.1 a)]. pre-measured powder component and one package or vial of sterile pre-measured liquid component. NOTE 1 ehT stnenopmoc desu rof eht snoitanimreted deificeps ni 3.3 dna 2.4 yam eb desu yltneuqesbusrof ot;ler stset debircsed ni siht lanoitanretnI.dradnatS 3 Liquid component 5 Liquid-powder mixture intended for syringe usage 3.1 Appearance When determined by the methods given in tables 1 When inspected by normal or corrected vision, the and ,2 eht gnittes ,seitreporp dna eht seitreporp~ of liquid shall be free from particles and other con- the set cement, shall comply with the values given .stnanimat in tables 1 and 2. 1 Is 8641 : 1997 0SI 5833 : 1992 6 Liquid-powder mixture intended for use 9 Labelling In dough state 9.1 Unit package 6.1 Setting properties tA least the following information shall appear on When determined yb the sdohtem nevig ni selbat1 the unit package of each cement unit: dna ,2 eht gnittes ,seitreporp dna eht seitreporpfo the set cement, shall comply with the values given 4 a description of the contents, including the mass ni selbat ? and 2. of the powder component and the mass or vol- ume of the liquid component, and the generic 6.2 Intrusion names of the constituents; When determined as described ni xenna ,D eht-va )b the relative proportions of the powder and liquid erage intrusion of at least one sample shall be not components expressed as a mass or volume less than 2 mm. percent; c) the name and address of the manufacturer, and the supplier if different from the manufacturer; 7 Set and cured cement )d a statement that the contents are sterile, and a Table2 sets out the requirements and test methods warning against the use of an opened or dam- for set and cured cement. aged package; d a warning that the package contains flammable ;diuqil 6 Packaging an instruction to store the package in the dark Each component of the cement shall be packaged at below 25 ;C“ dna dezilirets in a double-layer sealed container and then packaged in an outer container which shall 9) the batch or lot numbers of the liquid and the contain the accompanying documentation. redwop~ component and the expiry date of the material; The materials of the package should not contam- inate or permit contamination of the contents. The )h the number and date of this International Stan- packaging should prevent damage to, or leakage of, drad .e.i( 0SI .)2991:3385 the contents during transit and storage and should eb dengised os taht ti si ysae ot nepo dnasetatilicaf ETON2 Legal requirements for labelling may apply in citpesa noitatneserp fo eht.stnetnoc some countries. Table 1 - Requirements and test methods for setting properties -of liquid-powder mixtures Doughing time Setting time Maximum temperature mumixaM mumixaM Mixture Average noitaivedmorf Test Average Test revAega noitaived morf Test dohtem dohtem dohtem egareva egareva nim min min C“ C“ egnirySegasu _ 6,5 ot51 xennAC 90 5* xennAC ees( esualc)5 hguoDetats .5xam 531 Annex 6 5o31t xennAC 90 f5 xennAC usage (see 6.1) 2 IS 8641 : 1997 IS0 5833 : 1992 Table 2 - Requirements and test methods for set and cured cement Average compressive Bending modulus Bending strength strength .nim .nim .nim tseTdohtem tseTdohtem tseTdohtem aPM I aPM I I aPM I 01 1 800 xennAF 05 xennAF handling and use of the components and the ce- 9.2 Accompanying documentation ment; d) a statement that high ambient or component At least the following information shall appear on temperatures will decrease, and low ambient or the accompanying documentation (see clause 8): component temperatures will increase, the doughing, working and setting times of the ce- 4 instructions for handling the components and ment; preparing the cement for use, including details of the equipment needed and an instruction to e) a graphical representation of effect of tempera- mix the entire contents of the package. The in- ture on the length of the phases in cement cur- structions shall emphasize the importance of ing, prepared from experimental data on the minimizing the entrapment of air; particular brand of cement; )b instructions and recommendations for using the NOTE 3 Examples of graphs are shown in figures 1 cement, including necessary precautions; and 2. c) a tnemetats gniward noitnetta ot eht ,cixot -zah )f whether the cement is intended for use with a suodra dna tnatirri seitreporp detaicossa htiweht egnirys ro ni eht hguod.etats 26 \ \ 4 \ 25 I \.\ \ \ \. \ \ 1, \, \ 24 \ \. \ ‘\ \ \ ‘\ 23 \ \ \ \ 22 - \\ ,\ .1 \ \ \, \ \ \,\ \ 2 1 \ ‘( \ \ \ \ I “\ m \ \ ‘\. pI \_ \ ‘\ 20 \ , .\\\ 1 \ \ \ 19 0 1 2 3 4 5 6 7 8 9 10 11 12 Time, mln Mixing time Sticky phase III Working time IV Hardening time A deviation of k 30 s on working and hardening times may occur. The optimum working temperature has been deter- mined to be 23 “C If: x “C. Figure 1 - Example of graph showing working data Tor cement intended for dough usage 3 IS 8841: 1997 IS0 5833 : 1992 Annex A (normative) Method for determination of stability of liquid component NOTE 4 Other methods of equivalent accuracy and A.4.2 Record the flow time taken for the meniscus precision may be used, but the method given in this annex to fall to the equilibrium level (time fJ. is the referee method in cases of dispute. A.4.3 Heat an aliquot of the liquid component at A.1 Principle 60 C“ +_ 2 C“ for 48 h + 2 hni the dark in a closed container; allow it to cool to 23 C“ + 1 C“ and to -er ehT wolf emit )ytisocsiv( fo eht diuqil tnenopmocsi main at this temperature for at least 16 h. determined before and after accelerated ageing by heating, and the increase in flow time after heating 4.4.A taepeR 1.4.A dna 2.4.A and record the flow is calculated. time (time .)al A.4.5 Repeat A.4.1 to A.4.4 on the liquid compo- A.2 Apparatus nent of a second unit of cement. 1.2.A Clean glass U-tube viscometer. A.5 Calculations and expression of results A.2.2 Timing device, of accuracy + 2!0 s Calculate the percentage change in flow time for hcae tinu fo tnemec gnisu eht:noisserpxe 3.2.A Means of heating test specimens. ta - percentage change = - x 1tb0 0 tb A.3 Test conditions A.6 Test report niatniaM eht retemocsiv dna eht tset snemicepsta The test report shall include at least the following 23 “C + 1 C“ for at least 16 h before gninnig&b the information: .tset Perform the viscosity measurements at 23 “C f 1 .C“ 4 the identity (including batch or-lot number) of the liquid component; A.4 Procedure )b the flow times before and afier heating; A.4.1 lliF eht retemocsiv ni eht lausu yaw htiweht c) the percentage change in flow time for each unit diuqil component. of cement. 5